Swagelok offers a variety of needle shutoff and control valves to control flow in general and severe service systems.

Features:

- Provide reliable and constant flow control;

- They are made of various materials, have various sizes and types of end connections;

- Designed for use in aggressive environments and harsh conditions.

General Purpose Needle Valves (GU Series)

BUY catalog

General purpose GU series needle valves are designed to shut off or bleed media. The hardened stainless steel non-rotating needle ensures a seal and long system life. Low emission certification available in accordance with API 624.

Specifications:

| Operating pressure | up to 413 bar |

| Temperature | 0 to 650 ° F (343 ° C) |

| Flow rate | Up to 2.25 |

| Material | |

| Body material | 316 stainless steel, carbon steel |

| Seal material | Carbon / glass filled PTFE, graphite |

| End connections | |

| A type | NPT, socket weld connections |

| The size | 1/4 to 1 inch; from 6 to 25 mm |

History of invention

The device owes its name to the inventor Ch.B Maevsky, who developed it for radiators and other heating devices back in the 30s of the XX century.

In those days, ball valves were used to remove air, which made it possible to drain hot water for the personal needs of the consumer, which led to system failures.

However, the name, now known to everyone, has not been fixed in the standards and technical documentation, and even in special literature and textbooks, the term "radiator needle air valve" is still used.

For the attention of users!

In an automatic Mayevsky faucet, the outlet diameter is from 1.5 to 2 mm, which is sufficient for effective air removal.

It becomes problematic to drain large volumes of hot water for domestic and other needs.

Needle valve with integral bonnet (series 0,1, 18, 20 and 26)

BUYcatalogue

We offer injection-molded needle valves in various sizes, configurations, materials, and applications. Low emission certification available in accordance with API 624.

Specifications:

| Operating pressure | up to 413 bar |

| Temperature | -53 to 315 ° C |

| Flow rate | Up to 1.80 |

| Material | |

| Body material | 316 SST, Brass, Steel, Alloy 400 |

| Seal material | Polyurethane foam |

| End connections | |

| A type | Swagelok® Tube Fittings, ISO Female NPT |

| The size | 1/8 to 3/4 inches; from 3 to 18 mm |

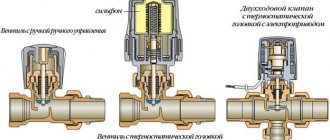

Types of automatic air dumpers

In total, there are three types of these devices - despite this, the operation of the automatic air vent, or rather its principle, remains unchanged. In all cases, the same needle valve and the same float that opens and closes it are used - the only difference is in the position of the body relative to the connecting pipe, i.e. threaded connection.

Direct automatic

air valve for heating. The most common automatic venting device.It is intended only for vertical installation - in the sense that if you suddenly decide to use it for a battery, then you will additionally need a corner at 90 degrees. The optimal area of their application is pipelines, or rather their upper points, where, according to all the laws of physics, the air formed in heating rushes. If it were not for such devices, then it would be very inconvenient to discharge air at the highest points of heating systems. In addition, some heating system equipment is equipped with automatic dumpers with straight connecting pipes. For example, the automatic air valve is an integral part of the boiler safety group, which also includes a pressure gauge and an explosion valve. Air vents are also equipped with indirect heating boilers and other equipment, at the top of which there is a possibility of air accumulation.

Screw Bonnet Stainless Steel Needle Valves (JB Series)

BUYcatalogue

Threaded bonnet needle valves can be supplied with a regulating stem or check-tip stem, straight and angle configuration, and adjustable packing.

Specifications:

| Operating pressure | up to 206 bar |

| Temperature | -40 to 315 ° C |

| Flow rate | Up to 0.58 |

| Material | |

| Body material | 316 stainless steel |

| Seal material | PTFE or Grafoil® |

| End connections | |

| A type | Swagelok Tube Fittings, NPT, ISO Male |

| The size | 1/8 to 3/8 inches; 6 and 8 mm |

How to get rid of air in pipes

example of installation of a spreader

If there is already air in the water supply system of a private house, but it is not equipped with bleed devices, it is necessary:

- Switch off the pumping station.

- Open all drain taps, drain water and air from the water supply system. Then the pipes are filled again.

You can remove air from the water supply system once and for all with the help of bleed or bleed devices:

- mechanical valves such as the Mayevsky valve;

- automatic air vents;

- ball valves;

- valves.

Mechanical air relief valve device from the water supply system is as follows: a cylindrical box, the top is closed with a lid, from the bottom there is a thread for connecting to the water supply. There is a threaded plug in the middle of the cover. A plastic ball-shaped float is suspended inside the cylinder. If there is no air in the hot water supply system, the ball rises to the hole in the plug and closes it tightly under the pressure of the network. As soon as air enters the device, the ball leaves and the air is discharged. Air can enter the system through the bleed valves, which is useful when repairing or inspecting networks and accelerates the drainage of water.

Air extractors are installed at specific points in the water supply system: at the topmost ends, at bends or bends. That is, where there is an increased likelihood of air accumulation.

Homemade air accumulator

In rural water supply systems, air often flows interspersed with water. It is difficult and inconvenient to use such a water supply system, and automation does not always cope: if there is a lot of air, water overflows with a fountain directly from the valve. Therefore, instead of an automatic bleed device to release air in the water supply system, they install air accumulator... You can do it yourself, this is a tank with a drain pipe and a tap. The diameter of the accumulator must be 5 times the diameter of the water pipe, then it can work efficiently.

The air accumulator is installed at the highest point of the water supply system where it is convenient to manually bleed the air. Air storage tanks are widely used in multi-storey buildings in hot water systems.

Brass Screw Bonnet Needle Valves (JN Series)

BUYcatalogue

Specifications:

| Operating pressure | up to 41.3 bar |

| Temperature | -40 to 148 ° C |

| Flow rate | Up to 0.43 |

| Material | |

| Body material | Brass |

| Seal material | Primary PTFE |

| End connections | |

| A type | Swagelok Tube Fittings ISO NPT |

| The size | 1/8 to 3/8 inches; 6 mm |

Lever valves (OG, 1G, and 92 series)

BUYcatalogue

Easy and fast on / off regulation.

Specifications:

| Operating pressure | Up to 20.6 bar |

| Temperature | -28 to 93 ° C |

| Flow rate | Up to 0.70 |

| Material | |

| Body material | 316 stainless steel, brass |

| O-ring stem seal material | Fluorocarbon FKM |

| End connections | |

| A type | Normal pipe thread |

| The size | 1/2 inch |

| Configuration | Straight, oblique, oval |

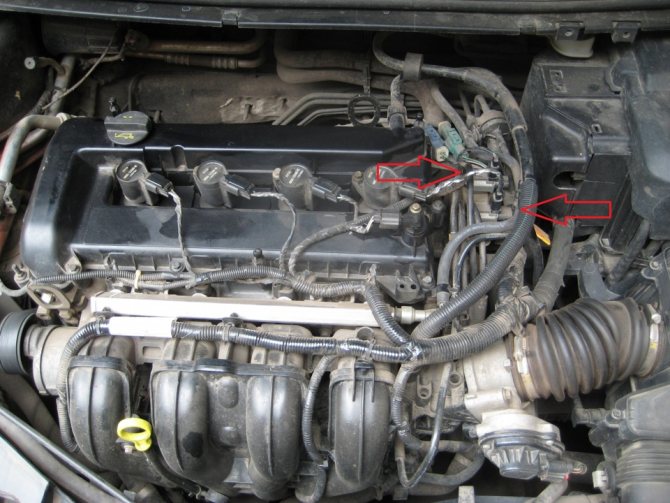

Device and principle of operation

In the device of this unit, a switching valve is of no small importance, practically decisive. Such a valve is only used in naturally aspirated engines, since there is no need to create additional pressure in this way during forced charging. With the intake valve already closed, the air fluctuates at a frequency proportional to the length of the manifold and the engine speed.

At the moment of resonance, resonant boosting begins to occur, due to which air enters the intake valves under increased pressure.

At different speeds of rotation of the crankshaft of the engine, air flows through the manifold at different speeds and the position of the valve of the system for changing the geometry of the intake manifold is also different. When the engine is not running, the valve stem is fully extended and the manifold is in a short position. When the start-up occurs, the valve opens and passes the rarefied air through the system into the pneumatic chamber, which retracts the stem, moving the manifold to a long position. Passing through the long manifold, air at a higher pressure enters the cylinders and at low revs the engine runs smoothly and confidently.

Intake manifold valve in engine system

Until reaching 4.5 thousand rpm, the valve is still in the long manifold mode, but upon reaching the electronic control unit turns off the voltage supply to the valve and it goes into the closed position, the vacuum ceases to flow to the air chamber. In order for the system to return to its original state, it is necessary to lower the high pressure in the pneumatic chamber, for which there is an atmospheric union on the solenoid valve. When the voltage is turned off, the solenoid valve opens the connection of the pneumatic chamber with the atmospheric union and air is drawn into it, the stem extends.

The solenoid valve consists of three fittings and a solenoid coil. On different cars, it is located somewhat differently, however, you can always find it near the receiver. The atmospheric valve is closed with a cap, which must sometimes be removed to check for contamination and periodically check the voltage on the supply wire to diagnose possible problems with an uneven engine operation.

The solenoid valve is located near the receiver

Instrumentation Purge Valves (6DB Series)

BUYcatalogue

Specifications:

| Operating pressure | Up to 413 bar |

| Temperature | -53 to 648 ° C |

| Flow rate | Up to 0.86 |

| Material | |

| Body material | 316 stainless steel |

| Seal material | Grafoil |

| End connections | |

| A type | Swagelok tube fittings, NPT, socket weld ends, VCR male fittings, VCO male fittings |

| The size | 1/4, 3/8, and 1/2 inches; 10 and 12 mm |

Description

The intake manifold is the part of the engine that distributes the fuel mixture evenly between all cylinders. For each cylinder there is a separate branch pipe through which air or fuel-air mixture passes, moving due to the vacuum created by the downward pistons in the manifold.This system also neutralizes crankcase gases, which are drawn through the crankcase ventilation system into the intake manifold, mix with the fuel-air mixture and enter the cylinders.

To prevent the fuel from settling in the form of condensate on the walls of the collector, its inner surface is roughened, as a result of which turbulence is created in it and the smallest droplets of atomized fuel do not condense. The shape of the collector itself is always even, without angular bends, which is explained by the manufacturer's desire to eliminate unnecessary pressure drops during engine operation.

Intake manifold valve

Compact gauge valves

BUYcatalogue

Compact gauge valves with a purge function are easy to install and provide easy gauge maintenance: lighter and smaller than conventional gauge assemblies.

Specifications:

| Operating pressure | Up to 275 bar |

| Temperature | -53 to 315 ° C |

| Material | |

| Body material | 316 stainless steel |

| O-ring material | Polyurethane foam |

| End connections | |

| A type | Swagelok Tube Fittings |

| The size | 1/2 inch; 12 mm |

Inflatable pool valve repair. Inflatable pool repair

Of course, the inflatable structure is limited in many ways. But which pool is the easiest to install, the easiest to maintain, and the most affordable? Inflatable, of course. They are small and large, deep and not very deep. In general, a good inflatable pool in terms of its internal volume may not be inferior to, for example, a stationary one.

But its most important plus is that it can be easily transferred to a new place. After all, it is inflatable, which means that it is enough to drain the water from it, release the air, roll it up, and even the largest pool quietly moves to a new platform by one or two people. And there, if the platform is flat, it unfolds, inflates and refills with water in just one or two hours.

But everything would be simple if it were not for this "if the site is flat". The fact is that the inflatable pool does not have its own rigid frame. It, being inflatable, becomes sufficiently stable in terms of its geometry only when it is fully filled with water. When it is already installed and inflated, but not yet filled, it easily bends in all directions.

It is also optimal to cement the site or at least lay plywood, boards or just PVC film under the bottom of the pool. After all, an inflatable pool does not have its own hard bottom, its material is thin and fragile, which means that any knot forgotten on the site under the pool, and just a sharp pebble, can simply pierce it when filling the pool. This is the reason for most of the breakdowns of inflatable pools.

Most manufacturers sell a special kit, which consists of a complete set of certain vinyl patches, which are specially combined in texture, they are also carefully selected for the desired color of each individual pool and its bowl, vinyl glue and consistent detailed instructions.

We suggest that you familiarize yourself with How to eat feijoa with peel

When purchasing an artificial reservoir, ask about patches, also about a special tube of a specific glue, step-by-step detailed instructions for the correct use of these components. They can be useful to you not only for repairing the mattress, but also for repairing almost any vinyl product. Vinyl glue, when hardened, will replace the missing part or puncture, creating a new layer that will prevent air from escaping from the mattress.

High pressure needle valves

BUYcatalogue

Cold-machined 316 stainless steel body and high-pressure end connections allow these valves to be used in systems up to 45,000 psi. inch (3102 bar).

Specifications:

| Operating pressure | Up to 3102 bar |

| Temperature | -53 to 454 ° C |

| Flow rate | Up to 0.19 |

| Material | |

| Body material | 316 stainless steel |

| Seal material | Glass-filled PTFE |

| End connections | |

| A type | Straight male thread, high pressure, NPT female |

| The size | 9 / 16-18, 3 / 4-16, 1 1 / 8-12; 1/4 inch |

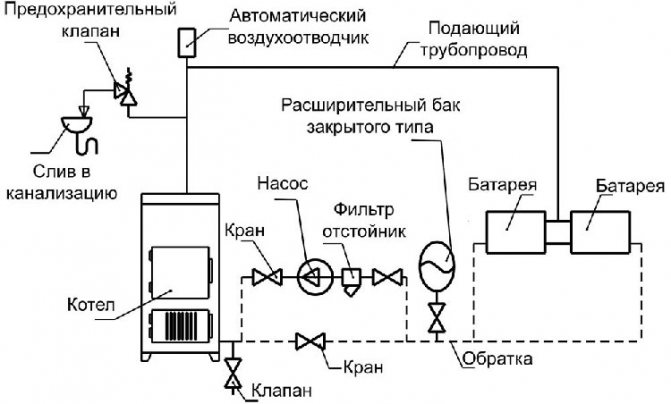

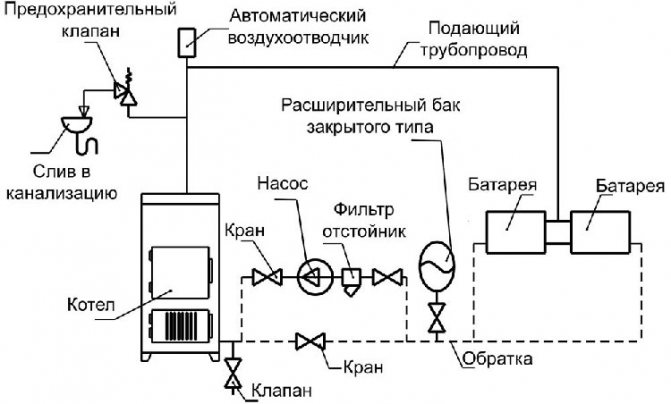

Causes and consequences of air locks in a closed forced circulation heating system

H2_2

The reasons are the same as for an open system, and also:

- Loose impeller of the circulation pump can "grab" air during operation;

- If hot water is supplied to the expansion tank from above, air can enter the system through cracks or ruptures in the tank membrane.

An air lock in the closed loop will increase the pressure in the system and activate the safety valve. The valve will bleed water over and over again until the boiler burns out or the heating pipes burst. Therefore, the security requirements for closed systems are much stricter. In particular, for the release of air, a closed circuit is equipped not only with Mayevsky's manual taps, but also with automatic air vents. One of these automatic valves is included in the safety group. The group is placed on the water supply, immediately after the boiler.

Important! A leaky pipeline or radiator cannot cause an airlock. The working system, whether closed or open, is under pressure. The air will never go towards a higher pressure - this is contrary to all laws of physics.

Non-Rotating Stem Needle Valves (D Series)

BUYcatalogue

Specifications:

| Operating pressure | Up to 206 bar |

| Temperature | -28 to 232 ° C |

| Flow rate | Up to 0.53 |

| Material | |

| Body material | 316 SST, Brass, Alloy 400 |

| O-ring material | Fluorocarbon FKM |

| End connections | |

| A type | Swagelok Tube Fittings NPT |

| The size | 1/8 to 3/8 inches; 6 mm |

Gauge Valves (6P Series)

BUYcatalogue

These gauge valves have an easily accessible through hole and gauge connection ports. They are made of various materials and provide system versatility.

Specifications:

| Operating pressure | Up to 413 bar |

| Temperature | -28 to 204 ° C |

| Flow rate | Up to 1.80 |

| Material | |

| Body material | 316 SST, Alloy 400 |

| Saddle material | Acetal |

| End connections | |

| A type | Normal pipe thread |

| The size | 1/4 to 3/4 inch |

Design and operation of the manual air valve

A needle manual air valve is also called a Mayevsky valve. Its device:

- Brass body (plug) with 1/2 // or 3/4 // male thread for connection to the radiator. There are two Ø 2 mm air outlet holes in the casing - one at the end of the casing, the other on the side wall;

- Brass locking screw. On one side of the screw there is a slot for a slotted screwdriver; on the other side, the screw is machined for a cone that closes the air hole (position "closed");

- Plastic cover.

On sale you can find the so-called "arm crane". To use it, neither a key nor a screwdriver is needed - the plug can be easily unscrewed by hand.

Unscrew the screw to vent air from the housing. To do this, you can, of course, use a screwdriver, but there are special keys that most often come with the kit. After several turns, the screw cone comes out of the end hole and air enters the body cavity, which is immediately released through the second side hole. The main thing is not to rush to turn off the tap. About 30 - 40% of the air should come out with water, so you need to stock up on time, a basin and rags. After the air is released, you need to add the lost water to the system.

Installation

In modern aluminum or bimetallic heating radiators, a hole is already provided for the installation of a Mayevsky crane. It can be found on the side opposite to the coolant supply, from above.Most likely, there is already a nut for installation. A plastic plug is screwed into it. After removing it, an air valve is mounted in this place. Before this, the tap threads must be sealed with a rubber or silicone gasket.

Installing a Mayevsky crane on a cast iron battery is much more difficult. Let's start with the fact that these valves are much more powerful than those on aluminum radiators - they can withstand pressures up to 16 atmospheres and temperatures of 150 ° C. Sequencing:

- Drain the radiator;

- Cut a hole in the upper plug of the cast-iron battery and cut a thread corresponding to the external thread of the air vent;

- Screw in the Mayevsky tap;

- Add water to the system.

Malfunctions and remedies

In the event of a valve malfunction, a leak appears. There may be several reasons for this:

- Manufacturing defects. One in fifty taps does not hold pressure at all. The only way out is replacement;

- Screw too short. In this case, its conical part cannot completely cover the hole, so a certain effort must be applied to screw in the screw all the way;

- Hard particles of debris getting between the screw and the housing can damage the internal threads. One-time fum tape can help here, but later you still have to change the tap.

The article shows the types of automatic air dumpers, types of valves for the heating system and disassembled the principle of operation of the dump valve.

Polyurethane foam needle valves

BUYcatalogue

These needle valves are made of high purity polyurethane foam for chemical resistance, with polyurethane foam tube fittings end connections for system reliability, full flow through bore, and a plug-on stem for flow control.

Specifications:

| Operating pressure | Up to 12.4 bar |

| Temperature | -17 to 148 ° C |

| Flow rate | Up to 1.39 |

| Body material | Primary PTFE |

| End connections | |

| A type | Swagelok Polyurethane Foam Tube Fittings |

| The size | 1/4, 3/8, and 1/2 inches |

| Safety-related product selection: In order for the system designer and user to be assured of safety-related product selection, the system design and the complete product catalog must be taken into account. When choosing products, the entire system should be taken into account in order to ensure safe and trouble-free operation. Compliance with the intended use of the devices, material compatibility, proper operating parameters, correct installation, operation and maintenance are the responsibility of the system designer and user. Caution: Do not replace or mix Swagelok two-ring tube fitting components (or other non-industry standard products) with components from other manufacturers. |

Valve installation location

There are points in the heating system where air is necessarily collected. So, Mayevsky's taps in the apartment should be installed on each radiator. In many modern radiator models, air bleed devices are installed at the manufacturing stage by the manufacturers themselves.

We recommend that you familiarize yourself with: How to make a bed frame from a profile pipe with your own hands

Note! If you have classic radiators, then the air valve should be installed in the upper part of it, which is located opposite the connection.

So you can always independently control the normal operation of your heating batteries and not depend on the desire of the housing office employees or the mood of the neighbors from above.

Points for installing air relief valves:

- radiators, bathroom coil, upper part;

- the top point of the pipeline;

- heating boiler safety system in individual communications;

- for hydraulic branching;

- on the collectors of the common manifold;

- on any U-shaped loops in communications, at the top point;

- for expansion joints in plastic heating systems.

It should be understood that air always accumulates in the upper part of the communications. An air lock can arise in the bend of a plastic pipe if the installation was carried out incorrectly and there was a temperature deformation.

The easiest way to get rid of the plug in the pipeline permanently is to cut a tee into the pipe. A valve is installed on the free vertical branch of the tee (the diameter of which is selected accordingly) to release air.