In order to stabilize the pressure in the pipes and prevent the spread of unpleasant odors, a sewer vacuum valve is installed. Actually, it is an alternative for a fan pipe, which is not always possible to install, for example, in such cases as:

- the tightness of the roof must not be violated;

- the outlet of the funnel pipes should not be located near the balcony or window.

The aerator (the so-called ventilation vacuum seal) can be installed in an apartment or house, for example, in a bathroom or toilet. Let's tell you more about this device.

The principle of operation of the vacuum valve and its design

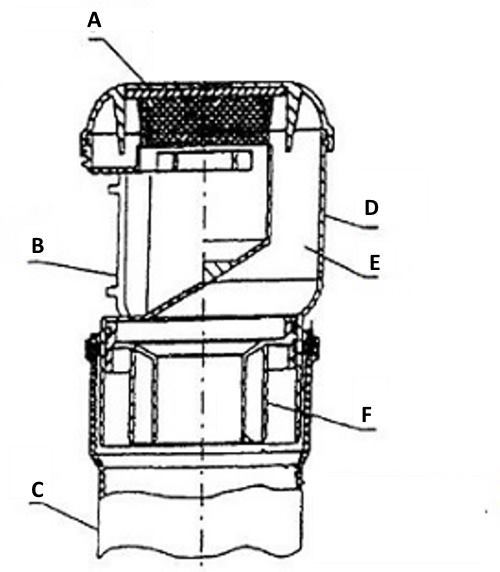

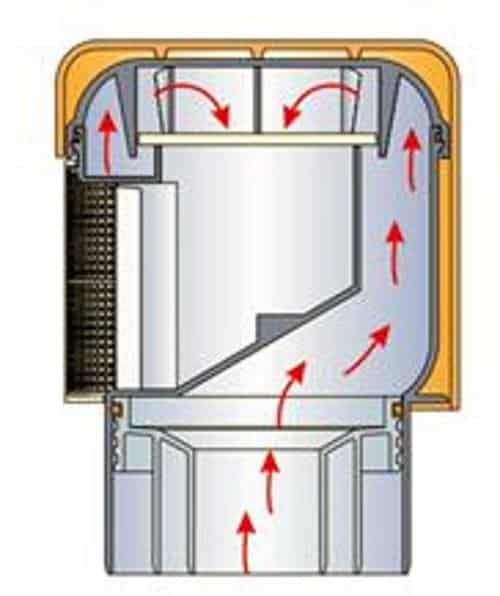

Before talking about how a vacuum type air check valve works, consider its device, it is shown in the figure.

Vacuum damper design (simplified diagram)

Designations of structural elements:

- A - damper;

- B - ventilation hole;

- C - the upper part of the riser;

- D - walls of the device case;

- E - air channel;

- F - insert.

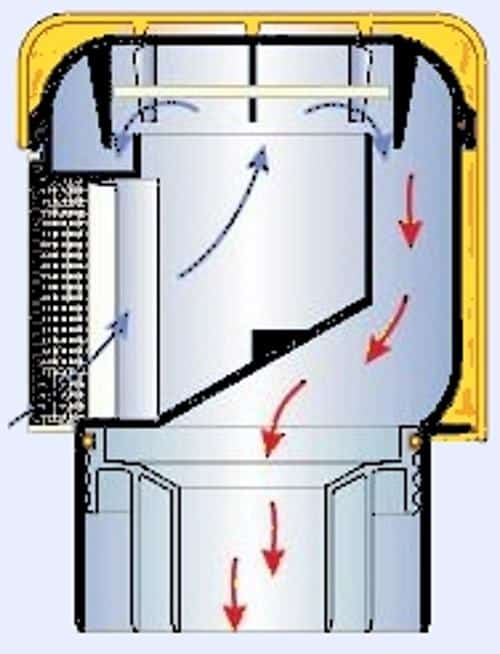

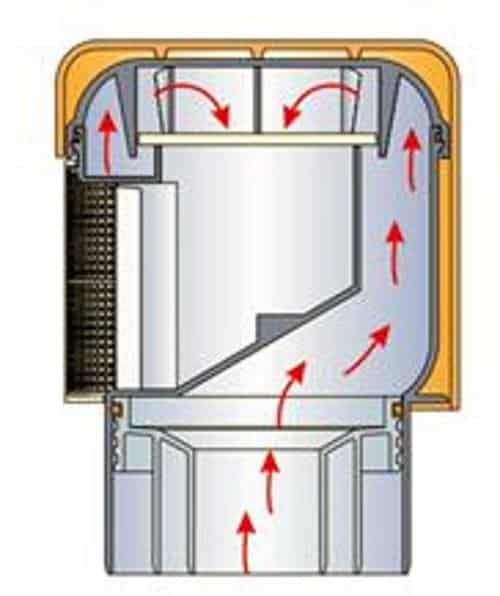

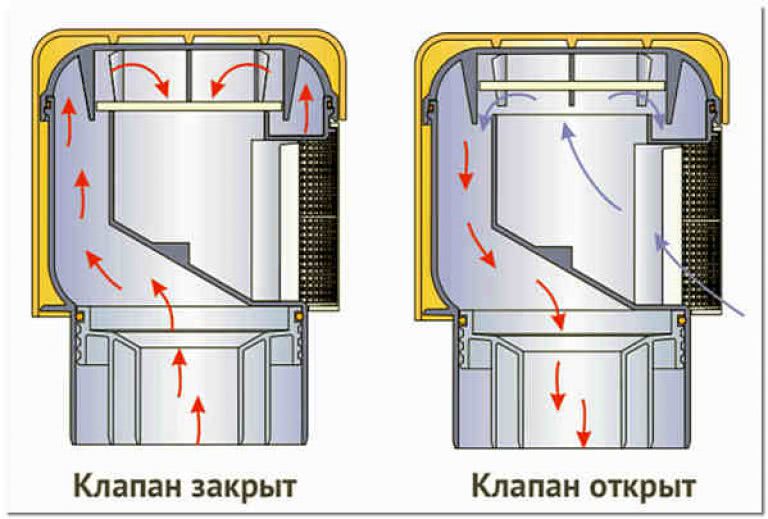

Now let's move on to the principle of the vacuum lock. When the water is drained into the system, a pressure change occurs. To stabilize it, a cover is opened in the valve through which air enters the system.

Open damper valve

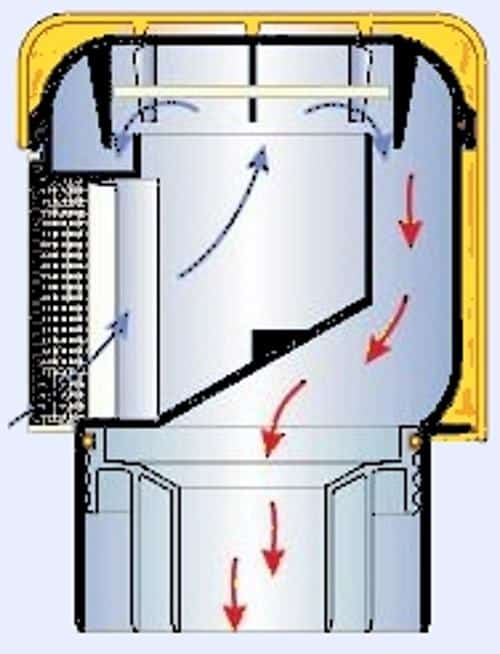

When the pressure in the system is equalized, the damper is in the locked position, so that unpleasant odors cannot enter the room.

The damper is closed, which prevents air recirculation

The aerator should be installed in the following cases:

- when the sewer systems are not equipped with drain pipes;

- if it is not possible to run the ventilation pipe through the roof.

The purpose of this type of shut-off valves is to provide the required level of ventilation inside the system. As a rule, vacuum valves are installed in low-rise buildings (no more than 5-6 floors), otherwise there is a high probability of failure of constipation.

When would a vacuum valve be useful?

It is advisable to install a vacuum valve for the sewage system in several cases. Firstly, it will be useful if the sewage system in the house does not have adequate ventilation. The second case when the vacuum valve will be simply irreplaceable is the inability to bring the sewer riser to the roof.

The valve allows you to once and for all solve the problem with accumulated gases in the riser. Moreover, such a device prevents the unpleasant smell of the riser from entering the house, since when installed in the system, this element acts as a ventilation. In addition to the riser itself, such an element can be installed for arranging ventilation in a septic tank.

The valve is needed if the house does not have a ventilation system

So, taking into account all of the above, we can draw the following conclusions:

- using a vacuum valve, you can solve the problem associated with the ventilation of the sewage, regardless of the number of storeys and area of the house. But here it is important to take into account that one valve is designed for one toilet;

- it is forbidden to install vacuum valves in multi-storey buildings without prior agreement with the relevant authorities.

What to look for when choosing

There are three factors to consider before purchasing a vacuum type valve:

- diameter of the vacuum lock, valves can be Ø110 mm and Ø50 mm. The first is installed on the sewer riser, the second - on the corner outlet from it.Please note that the Ø50 mm aerator is designed to equalize the pressure when draining water from two devices (no more), for example, a toilet bowl and a sink;

Photo: vacuum valve with a diameter of 50 and 110 mm

- design features. Devices can be equipped with a diaphragm or stem, the latter being preferable since their service life is longer;

- equipment manufacturer. We recommend purchasing models of well-known brands, for example: Ostendorf, TDI, Ssangyong, EGR, KVE, KVM, KVR, etc.

Ostendorf air safety valve for internal sewerage systems

Related videos:

Installation instructions

Almost all vacuum aerators are manufactured for the common pipe connection DN110 with a diameter of 110 mm. If the diameter is not suitable for the connection, a profile adapter is used. There are also pipes DN50 and DN75, with the corresponding numerical designation of the diameter, for which valves with an outlet of 50 and 75 mm are used.

It is important to understand that a 110 mm sewer air valve, used for pipes with a diameter less than this size, is installed at a maximum of two points in the pipeline. To install the valve in a metal pipe, special adapters are also used, which guarantee a sealed plastic-to-metal joint.

Before installing a vacuum aerator, you need to decide on the installation site, taking into account the location rules and availability for future maintenance. After that, the water in the room is turned off by closing the taps on the pipes. If installation in a ready-made pipeline is required, the valve is tapped in and the corresponding adapter is installed.

Installation Algorithm

Installation of vacuum shut-off valves is carried out according to the following algorithm:

- choose a place to connect the valve;

- it is necessary to check the tightness of the device;

- install.

Recommendations for choosing a location

When choosing an installation site, the following tips should be taken into account:

- valves should be connected at a higher height than the connected hose from the plumbing fixture. In this case, the stable and reliable operation of the vacuum seal can be guaranteed;

- the premises where the installation is carried out must have good ventilation. That is, if it is the attic of a private house, it must be ventilated. When the place of inclusion is a bathroom or toilet, they must be equipped with an extractor hood;

- the vacuum shut-off valve does not tolerate cooling, therefore, in the room where it is installed, the temperature should not fall below the freezing point of water (0 ° C). If this rule is not followed, the device is likely to lose its functionality or may completely fail;

- the valve must be installed vertically. In the event that the pipe is laid horizontally in the selected place, an elbow must be cut into it. Below is a photo showing a similar solution.

Elbow embedded in the pipe for vertical installation of the vacuum seal

We consider it necessary to pay attention to the following point: the valve must be installed in such a place so that access to it is always provided in case it is necessary to make repairs or manual (forced) start of the device. It is also necessary for preventive maintenance (timely cleaning of the device).

How tightness is checked

There are several ways to check the anti-vacuum seal without using special equipment, that is, at home:

- it is necessary to fill the valve with air (you can use a bicycle pump for this), having previously treated the surface of the valve with soap. The bubbles that appear will show the place where the tightness is broken;

- a device filled with air is placed under water, the appearance of air bubbles will indicate a violation of the tightness;

- pour water into the valve, if it is sealed, then it will not flow out of the valve.

As a rule, valves are checked directly by the manufacturer, as evidenced by the entry in the device's passport. If a model of an unknown Chinese manufacturer is purchased, then it is better to carry out a tightness test using one of the methods described above.

Installation

After choosing a place and checking for leaks, proceed with installation. It depends on the design features of the shutter, it can be:

- flanged, in this case the connection is made using bolts;

- threaded, you will need to cut a thread on the pipe;

- flared, the connection is made using a special rubber cuff. This connection option, although the simplest, provides the required reliability.

For tightness at the connection point, it is recommended to use a silicone-based sealant.

The installation procedure is as follows:

- it is necessary to completely disconnect the house or apartment from the water supply;

- prepare the pipe for installation, cut threads if necessary, or install a special elbow (adapter);

- install in an appropriate way;

- check the joint for leaks.

We remind you that during operation, the vacuum valve for the sewage system must be periodically cleaned, this will significantly extend its service life.

Sewerage arrangement rules according to SNiP

The installation of one vacuum valve to adjust the operation of the entire sewer system will certainly not be enough. Moreover, any person should understand that in the process of arranging the sewage system, one must adhere to certain SNiP rules. The first thing to consider is that the sewer network for any purpose must be ventilated through risers, this is where a vacuum valve is needed.

An example of installing a valve in a sewer pipe

According to the SNiP requirements, the ventilation riser must necessarily be brought out of the roof, but in the case of a vacuum valve, this is not required. When organizing ventilation, it is very important to take into account that drains should never be connected to ventilation and chimney. Another requirement of SNiP concerns the diameter of the sewer drain and the ventilation drain system, the fact is that the diameter of these two parts of the drain must be the same.

It is the fact that most of the SNiP requirements relate to the withdrawal of the ventilation part of the riser outside the house, became the reason that the legislation does not provide for the installation of a vacuum valve in multi-storey buildings. Of course, if you make an effort and visit many authorities, residents can obtain permission to install a vacuum valve in their home. As for private houses, the owners can equip sewer ventilation in them at their discretion.

Previous articles Next articles

Similar posts

- 25.06.2016.

Sewer pipes from Politek: choose yourself

- 23.06.2016.

Sewer pipes Polytron: features, price, installation

- 14.05.2016.

Other types of vacuum valves

Vacuum seals are used not only in sewerage systems, for example, a bellows electromagnetic (electrovacuum) valve provides air release or supply in various equipment.

The throttle solenoid valve (electric) provides vacuum support in common systems.

In addition, vacuum valves are widely used in the automotive industry (brake booster, fuel pump, automatic transmission, in the hydraulic steering system of the front axle, for exhaust gas recirculation (thermal vacuum valve), vacuum turbine modulator, etc.).

The engine of a modern car cannot function without this equipment. Of course, such devices are much more complicated than vacuum valves for sewer systems, respectively, the price for a package of equipment is much higher.

Installation of a vacuum valve on the sewer

How to properly install a vacuum valve on the sewer?

The appearance of an unpleasant odor in the bathroom can be a sign of improper functioning of the sewer. A vacuum valve for the sewage system can correct the situation. The installation of this part does not require a complete dismantling of the system. The presence of an aerator (this is another name for a vacuum valve) can significantly improve the operation of the system, and in some cases, facilitate the installation of the sewage system.

When building the sewer system at home on their own, the owners often forget about the need for a ventilation device.

The consequence of this error will be the appearance of an unpleasant odor in the premises, since the gases in the pipes can "break through" into the house. The error can be corrected without carrying out a major overhaul of the system. It will be enough to install a vacuum valve.

Functions

Not all owners understand why it is necessary to install a ventilation riser at all (fan pipe

) or aerator. It would seem that it is enough to install a siphon with a water seal at each plumbing fixture in order to effectively solve the problem of the penetration of sewer gases into the premises. However, in practice, everything is not so simple:

- when draining a large volume of water, when the flow almost completely blocks the lumen of the sewer pipe, a vacuum occurs inside the sewer pipes. In this case, water plugs (water locks in the sewerage system

), located in the siphons of plumbing fixtures located nearby, break down. The siphon tubes remain empty, so gases with an unpleasant odor penetrate into the premises without encountering obstacles in the way; - odor can occur if sewage is often hot. Most often, the smell occurs when you pour hot water into the toilet.

If the sewage system in the house is working correctly, then draining the water does not lead to the appearance of odors. Sewerage ventilation quickly removes the vapors that occur when draining hot water and eliminates the vacuum that occurs in the system.

Device

The principle of operation of a vacuum valve for sewage is quite simple. When a vacuum occurs, the valve is triggered, opening the diaphragm. As a result, air enters the system and the pressure is equalized. When the situation normalizes, the membrane falls into place.

The standard aerator has a polypropylene housing that is standard dimensions for installation in polypropylene pipe

... The main element is the stem, the movement of which opens and closes the valve. The rubber gasket limits the movement of the stem, preventing it from rising higher than permissible. The second design option is the spring-loaded diaphragm valve, but this option is considered less durable.

The diaphragm of the vacuum valve wears out relatively quickly, so this part needs to be replaced periodically.

There are two aerators available:

- for sinks, shower cabins and other plumbing devices, a valve with a diameter of 50 mm is used;

- for installation on a riser, a model with a diameter of 110 mm is used.

When does it make sense to install?

When is it advisable to install an aerator? Installation is recommended in the following cases:

- if there is no ventilation in the sewer riser, it may simply not have been done, or it works ineffectively;

- if it is not possible to bring the fan pipe through the roof.

It is recommended to install vacuum valves in a private house. If the owners decide to install this element in a multi-storey building, then they will need to obtain permission from the relevant authorities.

Advantages and disadvantages

Before deciding to install a vacuum valve on the sewer, it is worth learning about the advantages of this device and assessing its disadvantages.

Let's start with the pros:

- The main advantage of installing an aerator before installing a fan pipe is that you do not need to make a hole in the roof. And this can significantly reduce the risk of roof leaks;

- another positive point is that the presence of an additional pipe will not spoil the appearance of the building;

- the economic aspect should not be underestimated either. Installing a vacuum valve will cost significantly less than installing a fan pipe;

- another plus is the ability to install the part yourself, since the installation work is quite simple.

The disadvantages include the fact that the device will have to be periodically inspected and cleaned and repaired.

How to choose?

On sale you can see various options for vacuum valves, differing in price. But the principle of operation for all options is the same, so there is no need to purchase the most expensive option.

The most important criterion is the diameter of the device, it is available in two sizes. The fifty-millimeter model can be installed on sewer taps of the same size. As a rule, this variant of the valve is installed near the sink or shower stall. The 110 diameter model is designed for installation in a sewer riser.

Installation

Let's figure out how a vacuum sewage system is mounted, that is, a system equipped with an aerator. Here are general guidelines for work:

- before starting work, you need to make sure that the valve does not leak. To do this, it recommends opening the water supply and filling the aerator with water. If the model does not miss a drop, then this is a quality option;

- the valve can be mounted on both vertical and horizontal pipes, but the aerator itself must always be installed vertically. If you put a part with a slope, then the device will be much worse to cope with the functions assigned to it;

- If it is not possible to correctly install the aerator on the pipe, then it is recommended to use fittings - elbows and tees;

- it is necessary to position the device so that it can be accessed for maintenance and repair;

- it is recommended to connect the aerator higher in the level of the highest point of the network;

- the installation of the device must be carried out above the highest drain point;

- it is not recommended to install the valve close to the floor. The smallest valve height must be at least 20 cm.

Carrying out works

There are two valve sizes available on the market. If you need to install a part on a pipe of a different size, you must use special adapters. Work order:

- first outline the location of the aerator;

- then the water supply is turned off, this is necessary so that someone does not accidentally use the sewer during installation work;

- if the installation is carried out on an already functioning pipeline, then the model is embedded through special fittings;

- installation work is carried out taking into account the type of valve purchased;

- most models of aerators are installed in pipe socket

.

The connection of elements with sockets is carried out as follows:

- the parts to be connected are cleaned of dust;

- then you need to install a rubber seal in a special groove inside the pipe;

- a tube is inserted into the socket, after the part has advanced to the end, a mark is made from the outside with a pencil;

- then the temporary structure is disassembled and installation is performed;

- for this, the contacting surfaces are lubricated with silicone grease. Then the smooth pipe of the aerator is inserted into the socket up to the mark and slightly turned to distribute the lubricant evenly;

- if necessary, fix the pipe with the installed aerator, use metal clamps.

Immediately after completion of work, you need to check the tightness of all connections. After making sure that the connections are not leaking, you can safely use the sewage system.

If a hidden installation of a vacuum valve is planned, then you need to choose special models of aerators. If the riser is in a box made of plasterboard or other material, then you need to make sure that air can easily enter the box.

To do this, it is recommended to make a "window" in the box, which corresponds in size to the dimensions of the ventilation grill of the aerator. With this method of installation, only the grille remains in sight. Therefore, exhaust grilles are manufactured in different colors. This element can be white or black, but chrome grille options are especially popular.

So, there are situations when a vacuum valve for the sewage system is the only acceptable option for the normalization of the drainage system. These devices ensure equalization of pressure in the system and eliminate the smell of sewage in the apartment.