There are several types of drain systems, and they all tend to clog sooner or later. So that the blockage does not lead to unpleasant consequences, such useful fittings as a sewer check valve are mounted. Next, we will figure out why it is needed and how it works, and home craftsmen will learn how to install a check valve for the sewage system with their own hands and receive a rating of 5 TOP manufacturers.

The sewer check valve will help save the house from flooding with drains

What is a check valve

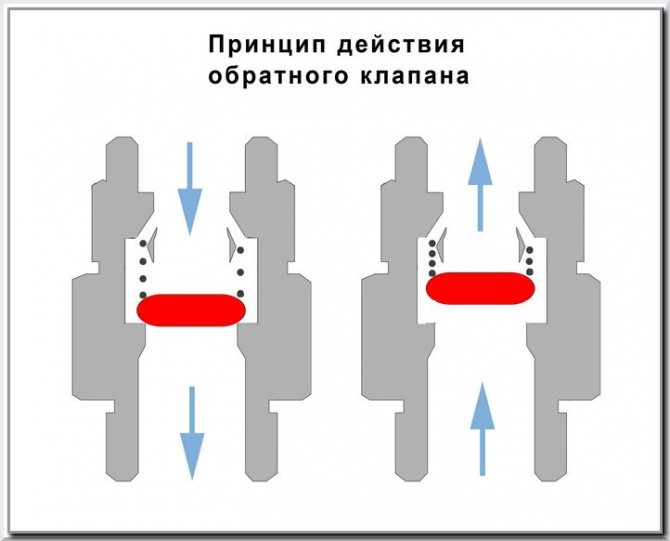

Based on the name, it is easy to guess that this device passes a certain substance in one direction and blocks its movement in the opposite direction. Sewer valve, this is only the most famous option. In addition to the sewage system, there is a similar shut-off valve that is installed on the water supply, heating, ventilation systems, etc.

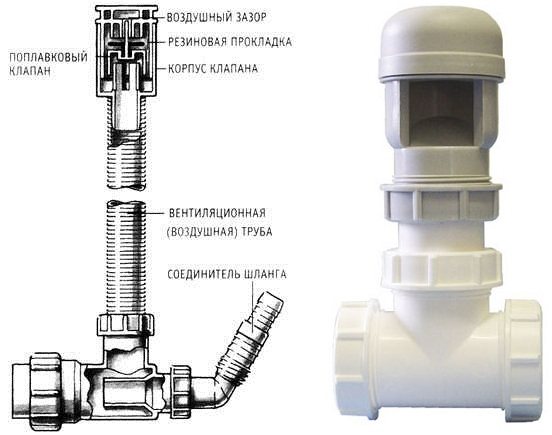

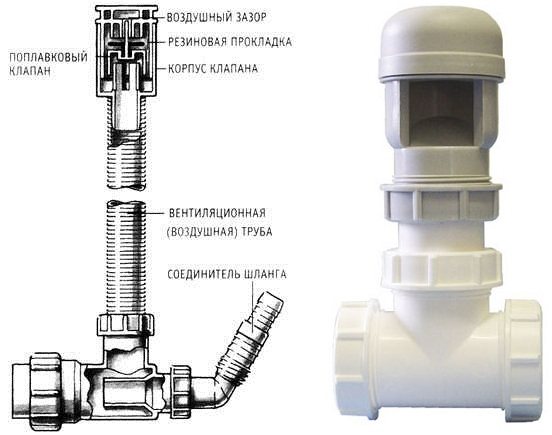

Important! A non-return air valve is also installed in the sewer system, it is designed to normalize the pressure in the pipes, the principle of operation is the same, but the device is slightly different.

Sewer liquid and air valve work on the same principle

Why do you need check valves

A liquid check valve is installed on the sewerage system to protect housing from drains. In multi-storey buildings, the sewer system is mostly gravity and if there is a blockage somewhere, all the drains that drain from above begin to fill the riser.

Further, according to the principle of communicating vessels, as soon as the drains reach the level of the nearest toilet bowl, a fountain of everything that has been drained from above begins to beat from it. To block the fetid liquid, a sewer check valve is placed on the outlet pipe.

- In old multi-storey buildings, where the system has already worn out and blockages are not uncommon, such fittings are installed by residents of the first floors.

The check valve in the sewer in the apartment is especially relevant for residents of the first floors.

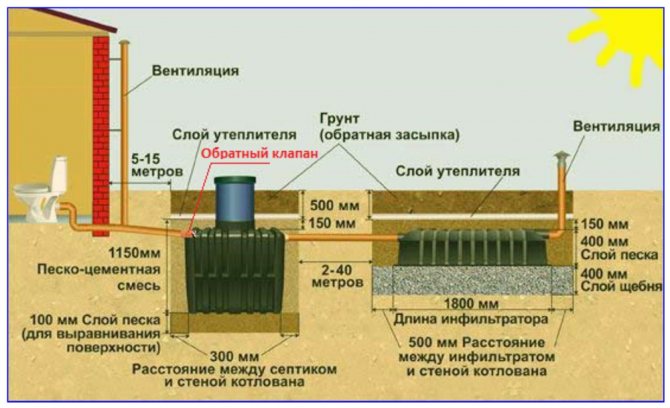

- In private houses equipped with septic tanks, sewer valves are installed at the exit from the basement, so that in case of flooding of the septic tank with groundwater, the drains do not go back.

- A sewage drain check valve must be installed in pressure systems, all these systems are equipped with fecal pumps, and in order to block the return flow of drains when the pump is turned off, a sewer valve is installed. You can find out about pressure systems for apartments, types of septic tanks and other nuances "HERE".

- The sewerage valve is also placed on the central drain pipe in the accumulation tank of the drainage system; without this fittings, water will go back, which can lead to flooding of the site or the foundation of the house. The intricacies of arranging drainage in a private house are shown and told in detail "HERE".

A 110 mm sewage check valve is installed in the storage tank of the drainage system

- Both in multi-storey and in private houses, the problem of rodents periodically arises. Hungry rats can climb quite high through the sewer pipes; the check valve will prevent animals from entering the apartment.

In older homes, rats can enter housing through drain pipes.

Important! Before buying a sewage check valve, pay attention to its color - the external fittings are orange, and the valves for internal installation are gray.

The check valve of the external sewage system is orange, and for the internal one, gray

How to choose a check valve for sewage 50 mm or more

When choosing the type of device, one should be guided by the features of the sewer system.Depending on this, the size of the check valve for the sewage system, the material of manufacture and the diameter of the socket are selected.

The size of the check valve is selected depending on the type of sewer system

When choosing a specific model, you need to make sure of the reliability of the device, which must be made of a durable material that is resistant to the negative effects of an aggressive environment. The check valve must be easy to install and easy to maintain. The best in this regard are models with a removable cover, which is necessary for cleaning the body elements.

The reliability of the automatic mechanism for shutting off the cross-section of the pipeline at the time of the reverse flow of the liquid is a guarantee of the durability of the device. Preference should be given to models with the possibility of manual adjustment in case of an accident.

The socket diameter is selected based on the size of the pipeline. You should not choose a larger or smaller size of the device section, since you will need to use adapters. This will disrupt the smooth functioning of the entire system, reducing the throughput of the pipeline. However, a 32 mm check valve for sewage is selected with a diameter of 50 mm, the necessary adapters are selected for it.

Types of sewer valves

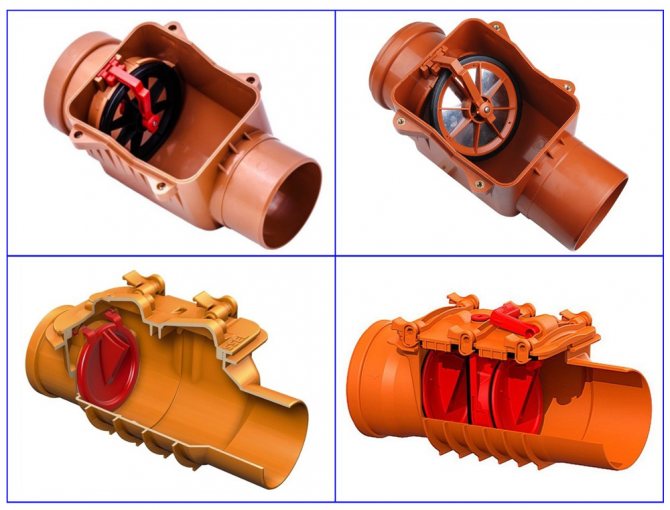

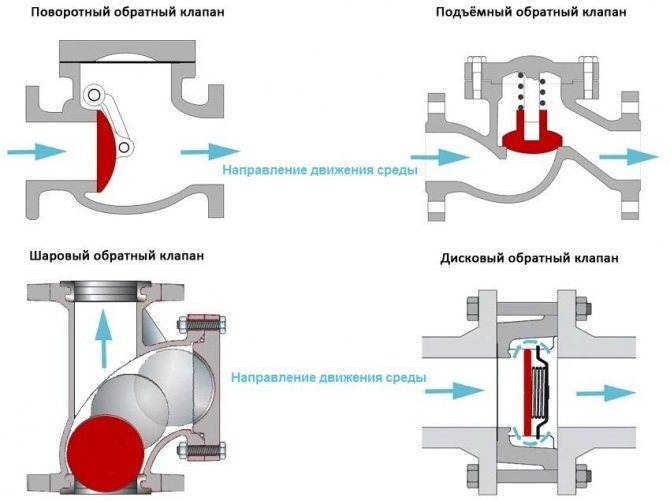

As already mentioned, the principle of operation of such fittings is the same everywhere, but the device can be very different, now 4 types of structures are actively used:

- wafer fittings;

- lifting fittings;

- rotary fittings;

- ball constipation.

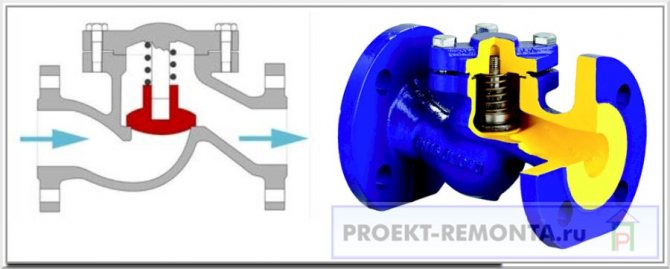

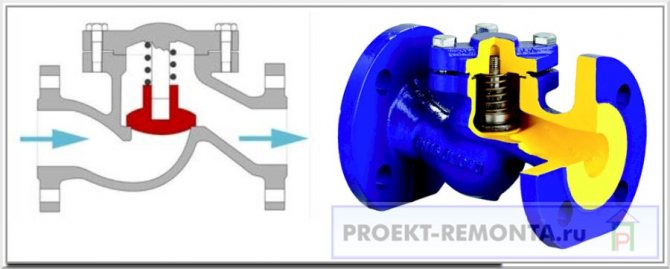

Wafer-type sewer locks

The wafer-type check valve is deservedly considered the most compact among all such constipations. The device is mounted inside the pipe between two flanges, therefore it does not require much space. But on the other hand, if such an armature is jammed, then you will have to untwist part of the system to get to the valve.

There are 2 types of wafer fittings.

- Disc constipation. In these models, the passage is blocked by a solid disc, fixed in the upper part. The disc often sinks under its own weight, without any springs, although there are exceptions. These models are considered to be among the most reliable, but they can only work in a gravity system.

Wafer check valves can be made from different materials, but the quality and price depend more on the brand than on the material.

- Bivalve center-stem wafer valves. In these models, an axis is installed in the center, on which the 2 petals are based. The leaves are pressed by a spring, the system is considered universal, the two-leaf horizontal and vertical valves are equally reliable.

Wafer check valve 100 and 110 mm are considered the most reliable

Lifting models

Here, the liquid moves in a curved path, when the drains go in the right direction, the plug is lifted and the liquid flows through. If the direction of movement changes, the spring will press the plug and the flow will be blocked.

Typically, such models are made of cast iron, they are quite powerful, the diameter of the lift check valves for the sewage system is 110 mm and higher, respectively, for private houses, and even more so for city apartments, this fittings are used extremely rarely.

Check valve cast iron - lifting type

Advice! For clean liquid, lifting structures are suitable, but it is better not to put them on the sewer, since blockages often occur due to the broken path of movement.

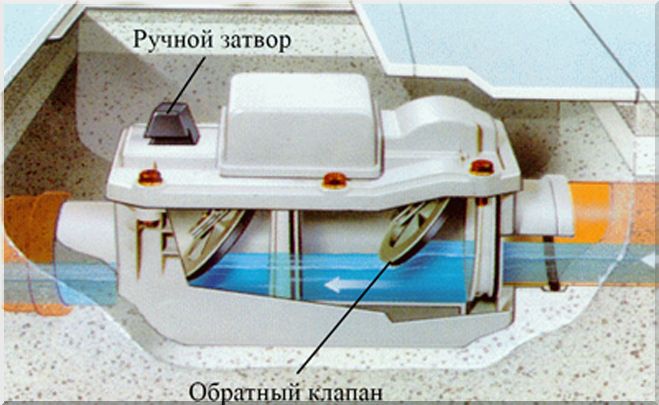

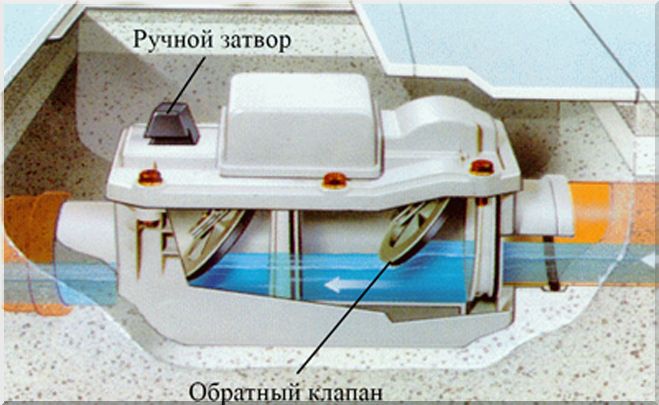

Butterfly valves

In essence, rotary or lobe systems are very similar to butterfly valves, the only difference is that there is a revision window through which the mechanism can be cleaned. There are 2 types of such fittings.

- Rigid systems. In them, the plate closes the passage under its own weight. They work flawlessly, but they are only suitable for gravity systems with a small volume of wastewater, if such fittings are placed under a pump or for large volumes, then when the petal collapses, a water hammer can occur, which is dangerous for pipes and gaskets.

- Soft valves. Without going into technical details, I will only say that the petal in them closes with a delay, as on a door closer, therefore, water hammer is excluded.

Flap check valve 50, 100 and 110 mm for domestic use is perfect

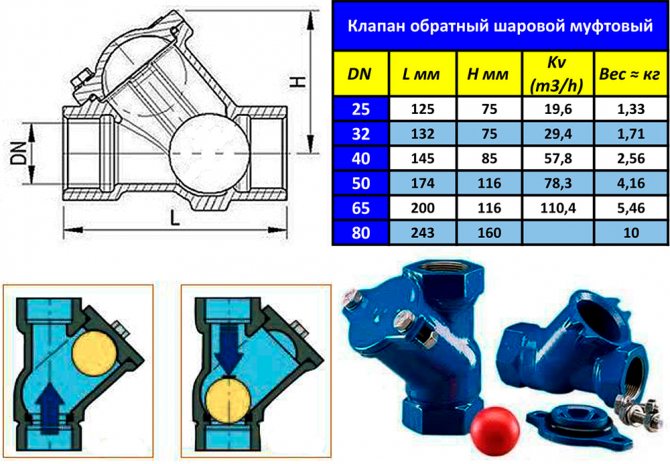

Ball valves

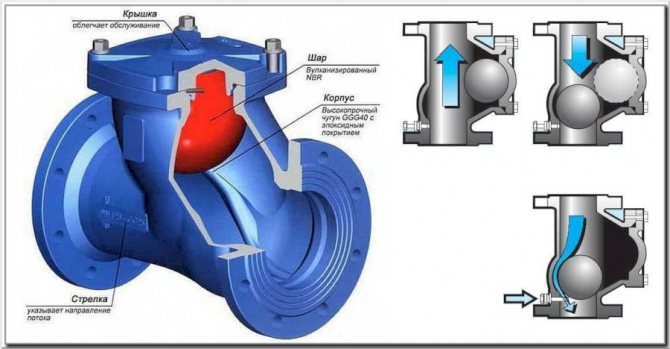

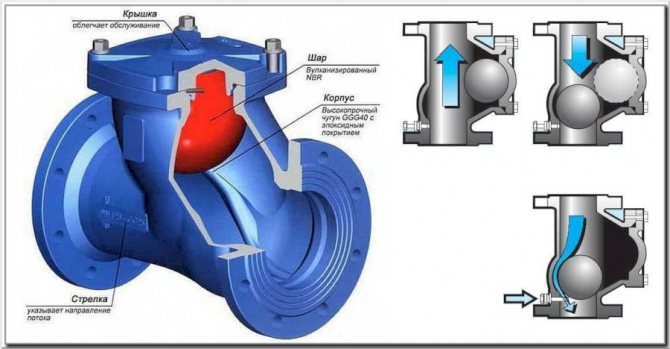

The ball check valve is considered one of the most reliable, the system is trouble-free, a ball is laid inside, which rolls back in the working position, and closes the main hole when the fluid returns.

Ball check valve is more suitable for industrial applications

Advice! When choosing a check valve for the sewerage of a house or apartment, it is better to give preference to fittings in which there is a manual blocking of the damper. A very convenient option, especially if you need to leave home for a long time, for example, to go on vacation.

Correct and incorrect valve position

Although some engineers classify valves as horizontal and vertical, professionals do not recommend installing them on a vertical section of the pipeline, because this can lead to an emergency in an apartment located upstream of the riser.

A vertically mounted check valve accumulates debris much faster, reducing the flow rate of the pipe, leading to pressure build-up and rupture.

It is allowed to install a non-return valve:

- at the outlet into the well of the drainage system in the technical room (in the basement or on the basement floor);

- on the first floors of apartment buildings directly at the outlet of plumbing fixtures (toilet, bath, washbasin, sink);

- at the entrance to the living space after the transition element (tee or cross);

- in front of the well on the inside of the foundation.

Important! No matter where the check valve is installed, it must be installed only on horizontal sections of the pipeline (on the so-called loungers). This will prevent wastewater from climbing up the system and spilling through the toilet or bath in the event of a blockage.

Another important point: the valve must be easily accessible so that the plumber can open the lid of the device and clean / repair it.

We recommend that you familiarize yourself with: How to choose a brass water-folding ball valve

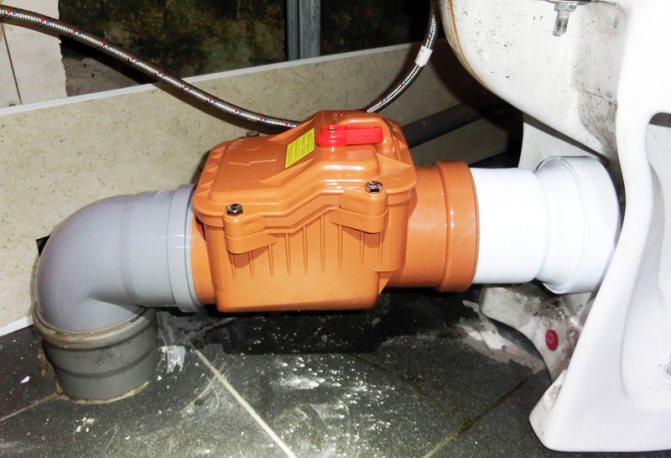

If for some reason it is not possible to install a standard valve in the apartment (the device itself is rather bulky and in a small bathroom it can take up a lot of space), you can install a compact cuff valve that is installed on the toilet outlet pipe.

Subtleties of installation

Installing a sewage check valve is not a tricky business, plus such work does not require an expensive tool, a home kit, a drill, a hacksaw, a level, a tape measure, etc. is enough. But first you need to decide where to put the check valve.

Seat selection

In this case, it all depends on where the system is most often clogged.

- If blockages usually occur in the first sewer from the house, then a 110 mm check valve is placed after the bend in the basement (before the pipe enters the wall).

Important! In multi-storey buildings, self-installation of such a valve can cause problems with the operating company. The fact is that, according to SNiP 2.04.01 - 85, a check valve with an electric drive and an emergency sensor must be installed in the basement so that in case of flooding, the signal goes to the dispatcher's console.Simple fittings are installed only in rooms with round-the-clock duty.

When installed in multi-apartment buildings, the electric check valve of the sewage system may require approval

- The sewer valve in the apartment is best placed on a tee or crosspiece near the central drain into the riser.

- If there is no place near the riser for centralized fittings, then you will have to install a separate check valve for the sewage system 50 mm to the outlet towards the bathroom, kitchen, etc. And a shutter with a diameter of 100 - 110 mm for the toilet.

Check valve PVC or polypropylene is considered the best solution for an apartment or a private house

Incorrect mounting points

There are 2 recommendations here

- Before installing a check valve on the sewer, think about how you will service it, because every six months such valves need to be revised.

- In a multi-storey building, it is unnecessary to install a vertical check valve on the riser.

About vertical fittings should be said separately, installing such a shutter, you can incur a lot of problems.

- If the riser is cast-iron, then you cannot touch it at all, especially with your own hands, not every master undertakes to repair or replace the cast-iron riser. This is due to the fact that there is a danger of collapse of the entire pillar.

- Whatever the vertical check valve, it will interfere with the movement of drains, respectively, sooner or later a blockage will appear at this point.

- If drains rise from below and the valve blocks them, then in a multi-storey building, they will continue to drain from above, which will make the installation of the shutter useless.

- A sewer riser in an apartment building belongs to public structures. If you, on your own initiative, install a valve on it, then if problems arise with this fittings, you will be obliged to dismantle everything and return it to its original position for your money, plus pay overhead costs, for example, cleaning the basement or repairing neighbors who were flooded after installation valve.

A vertical check valve in apartment buildings should not be installed

Valve installation procedure

Installing a check valve for sewage with your own hands is not difficult. The instruction consists of several simple steps, which I tried to reflect below in the photo and video in this article.

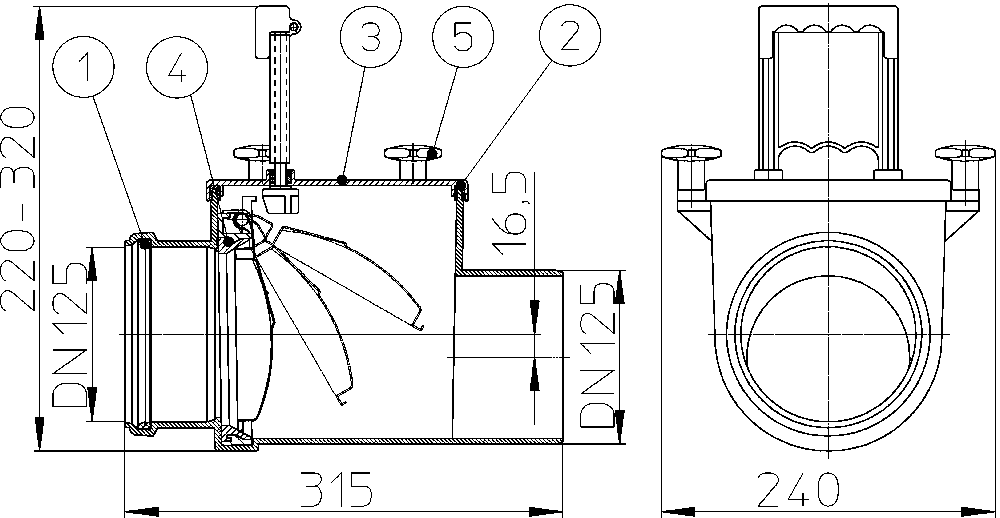

So, it is better for a simple home craftsman to buy a horizontal check valve with a manual interlock function, made of PVC or polypropylene. The pipe diameter does not affect the installation instructions, the check valve 50, 100 and 110 mm is installed the same

- The first step is to simply collect everything as it should be.

- Then measure the distance from the valve to the outlet into the riser.

- Take a connecting adapter pipe of a suitable diameter and set aside the desired length on it, cut off the excess.

- After cutting, the edges of the pipe must be cleaned with a knife from the burrs.

Advice! You should not put a corrugation here, a lot of debris accumulates in it.

Reducer Fitting Diagram

- Now find the central axis of the drain pipe and mark 2 points on it on which the shut-off valves will be fixed.

- Drill 2 holes with a puncher and insert plastic dowels into them under the pins of the clamps.

- Pick up the studs in height and screw in the supporting clamps.

- Then insert rubber gaskets into all grooves and thickly coat all joints with sealants, after which the stop valves are finally assembled.

Installation of supporting metal clamps

- Now you just have to connect the system to the sewer and fix it firmly on metal clamps.

Fixation of shut-off valves on clamps

- Depending on the type of walls and the size of the reinforcement, the system can be fixed in three ways, the photo below shows the principle of fixation.

Three types of reinforcement fixation

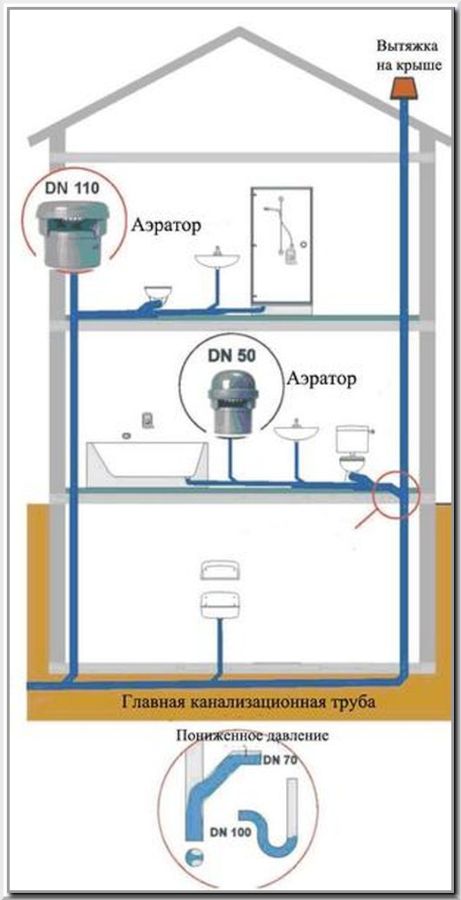

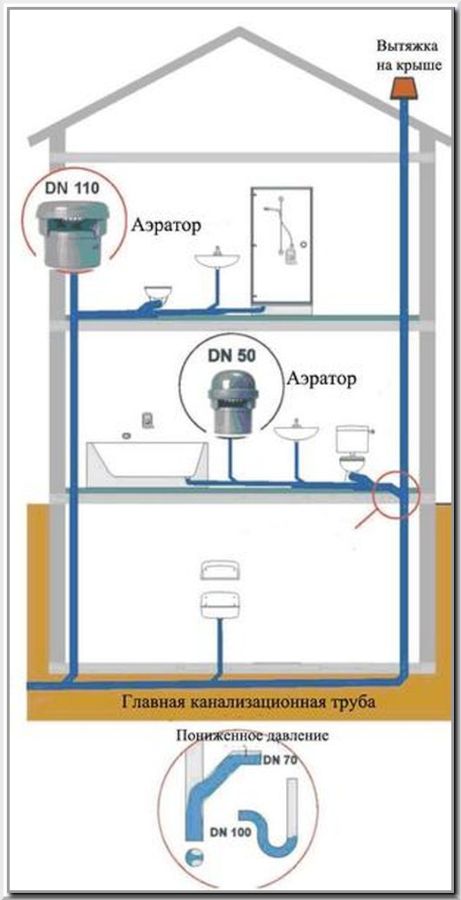

Ventilation valve installation

The riser ventilation locking mechanism is extremely easy to install. You just need to install it on the free end of the sewer pipe.

Installation of an air valve for sewerage

The step-by-step installation process is as follows:

- Choosing the location of the aerator. The mechanism can be located for ventilation of a separate plumbing fixture or the entire system as a whole.

- Fixing the device to the pipe in the prescribed way.

- Checking the tightness of all joints.

- Putting the aeration mechanism into operation.

The ventilation valve is mounted at a distance of 20 cm from the nearest siphon and 30 cm from the gravity pipe.

Fastening with a sewer pipe can be made by means of fittings, threads or other method provided by the manufacturer of the aerator.

Aerators are installed indoors, since for their operation the air temperature must not fall below 0 ° C. The cost of purchasing the mechanism quickly pays off due to the protection of the sewer system from breakdowns, and the living quarters from the spread of harmful odors. An important advantage is also a significant reduction in the noise level in the drain system, which contributes to the creation of a comfortable microclimate in an apartment or a private house.

Sewer aerator

If the house has more than 2 floors and there is plumbing on each floor, then the system must be equipped with ventilation. Usually, a free air exchange is provided by a fan pipe, but there are times when it is not possible to install it and then an aeration or ventilation valve is installed.

Important! If the sewer system is sealed and left without ventilation, then when a large amount of water is drained, a pressure drop will occur, as a result of which water will be regularly sucked out of siphons and other hydraulic seals, which will lead to the penetration of sewer gases into the room.

An air check valve is easier to install than a liquid check valve. According to the rules of a valve with a diameter of 100 mm or more, it cuts into the system 30 cm higher, the upper outlet, for example, on the sink, but now there are a lot of small models that are installed next to the toilet or siphon.

How to install the aerator

How does the air sewer valve HL 900NECO and the like work

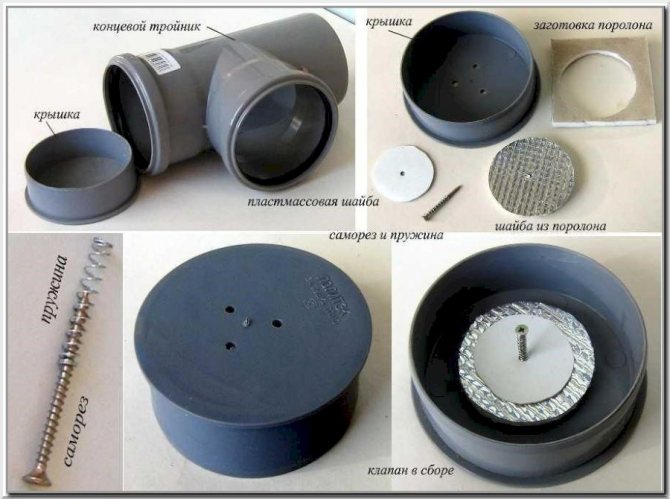

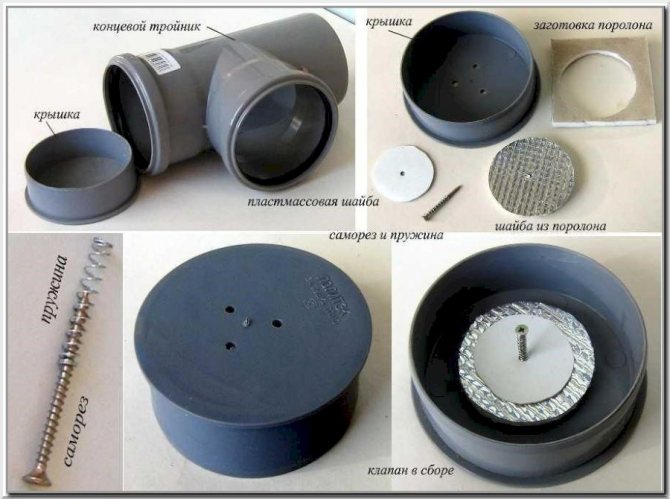

The aeration valve can be made by hand, the photo below gives instructions for making such fittings.

How to make a ventilation valve with your own hands

Why is it needed, what happens?

When there is a problem of clogging of sewer pipes and networks, residents of apartment buildings promptly contact a specialized service. But no matter how quickly they arrived, it is necessary to shut off the source and water as soon as possible, so that all this "good" does not rush into the apartment, and the property is not hopelessly damaged. It is in such cases that the sewer valve helps.

Installation of a non-return valve in the sewer is recommended for residents of the first floors. Mostly above the 1st or 2nd floors, sewage sewage does not rise.

The valve operation scheme is akin to a nipple. That is, the drains go in one direction, but they cannot return back. And it is this pattern that helps to stop them on their way to the apartment. The diameter of the valve depends on which pipes are installed in the house. This is predominantly the standard 110 mm for the riser; elsewhere a smaller size may be needed.

place for installing a sewage check valve

The valve is made of different materials: metal, polyvinyl chloride, polypropylene. Today, metal valves, like pipes, are rarely used. In addition, metal valves are short-lived and expensive. For indoor installation, polypropylene pipes are used, outside - polyvinyl chloride pipes.

Installation locations

Valves can be installed in one or more locations, depending on the tasks they are to perform.One valve can be mounted on a common sewer pipe, but it must have a large flow capacity. Many small ones are worth installing on every plumbing fixture.

Installation of the first type is possible only in private or small houses. In multi-apartment, such valves will not have the desired effect. Since the installation of a common valve is possible only in the basement, the residents of the first floors remain defenseless in the event of problems with the sewage system. In such cases, it is better to provide a valve for each device or in front of the riser.

You also need to install such a device in sewers with a reverse slope, since such an incorrectness of the system can be eliminated only by its complete alteration.

Valve types

According to the device of the check valve for sewage, the wafer, rotary, ball and lift valves are distinguished.

The wafer has small dimensions and weight. Its design does not include flanges that connect the valve to the pipeline. When a breakdown occurs, it will be necessary to replace not only the shut-off valves in the valve, but also the section of the pipe on which it is located. Such valves can be:

- Spring-disc - in them, the permeable membrane looks like a disc, and instead of a lever there is a spring.

- Bivalve - their principle of operation is based on the presence of a bivalve membrane in the structure. The rotary valve is also called a petal valve. The role of the membrane is played by the spool / slammer, they are actuated by a lever. Such valves can be:

- Simple. They are used in systems with low pressure and the same passage of liquids. When the spool returns to its place, a water hammer occurs - this can damage not only the valve, but also the entire sewer system.

- Unstressed. This type makes it possible to smoothly return the spool to its original position after it has passed the water.

Ball valves are predominantly used in systems with small pipe diameters. The role of the membrane is played by a metal ball, the lever is a spring. This type is the most commonly used and most reliable. Its installation is carried out by cutting into the system, it is fastened with two bolts, in case of failure, you can simply replace the unit.

installation of a check valve on the sewer pipe

The lift valve has a slightly different design. Its membrane is placed vertically, and a special device is responsible for its lifting, which is also located in a vertical position. This type has an important advantage - the valve can be repaired without disconnecting from the mains. But at the same time, the lack of susceptibility to frequent clogging calls into question the rationality of its use. Lift valves are classified into:

- Valves that are welded into the sewer.

- Those that are attached to pipes using flanges.

- Threaded connection.

- Wafer, they are clamped between pipes.