The need for arrangement of smoke and ventilation ducts

The laying of ventilation and chimney must be done at the stage of wall construction

Adequate ventilation is air circulation, in which enough fresh air enters the room and the waste masses are removed.

In modern dwellings, it becomes more and more complex. This is due to the equipment of apartments with plastic windows. The sealed structures reduce heat loss and protect against noise, but impede microcirculation. As a result, the natural hood cannot cope with air exchange. The dwelling has to be equipped with additional ventilation ducts or ventilated forcibly.

For stove or boiler heating, separate chimney ducts are needed, serving only the heating unit. Combustion of 1 cubic meter of natural gas requires 10 cubic meters of oxygen. It is impossible to take such a mass of air from the room. The supply of oxygen and the removal of combustion products are provided by chimneys.

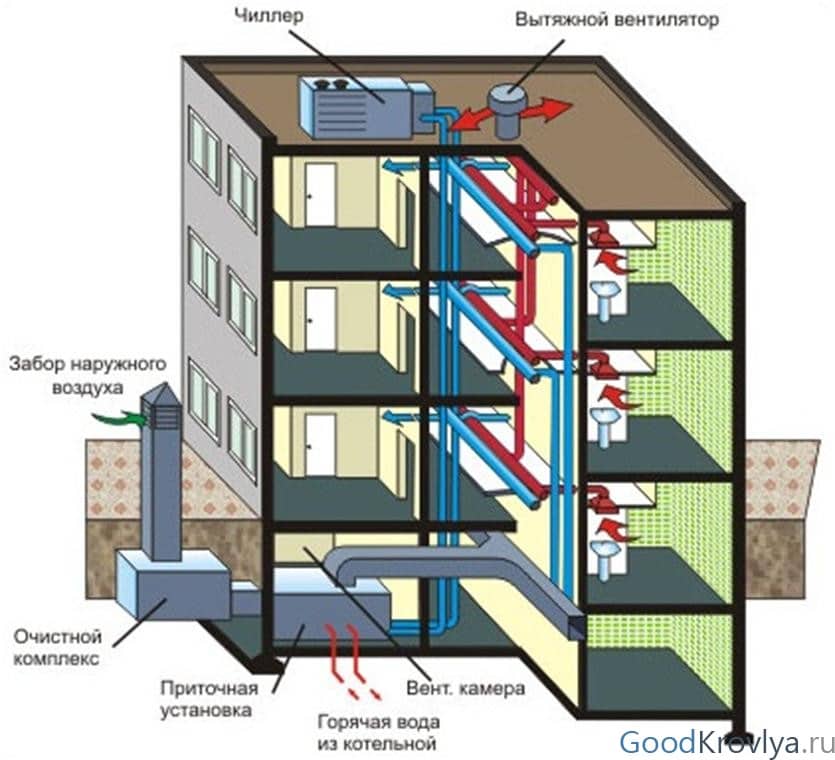

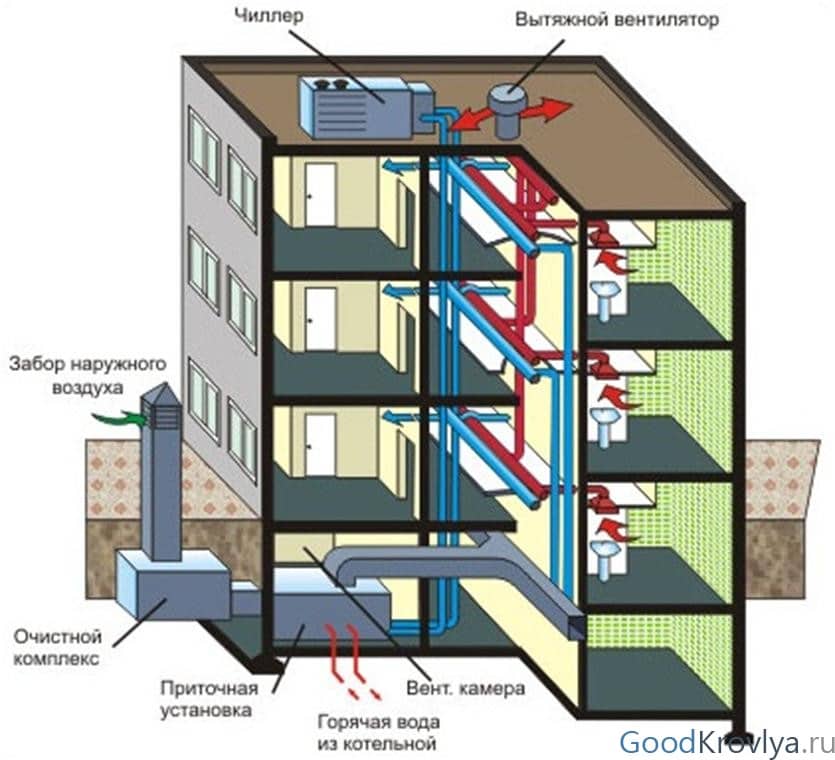

Ventilation and chimneys of apartment buildings ↑

Ventilation ducts and chimneys in apartment buildings are diverse in design, execution methods and, ultimately, comfort and safety for residents.

Types of ventilation and smoke exhaust systems ↑

The most common natural, supply and exhaust type of ventilation and chimneys. At the same time, through satellite channels, air or combustion products from the premises enter the common channel (or a collector in the attic), and then into the atmosphere. Air intake is carried out through natural gaps and leaks in windows and doors.

A more advanced and efficient solution is forced ventilation using exhaust and blower fans. There are hybrid projects combined with a supply and exhaust system, options with air recuperation (a recuperator is a device that transfers heat from the exhaust air to the supply air).

Modern ventilation of an apartment building

The most productive and stably working design is in which ventilation ducts are removed from each apartment separately. This increases the stability of the system and prevents odors and gases from flowing to other apartments (for example, when one of the residents installs a high-power exhaust fan).

Ventilation system design diagrams

Features and nuances of service ↑

Maintenance of smoke and ventilation ducts in apartment buildings is practically not required due to the thoughtfulness of the systems and the characteristics laid down with a margin. According to Soviet SNiPs, up to 80% of air exchange was carried out through window and door blocks. Therefore, the main problem for old high-rise buildings is the replacement of such elements by residents with modern, practically sealed, metal-plastic and steel structures. At the same time, air exchange sharply deteriorates, dampness and fungus appear.

This problem is solved either by constant ventilation or by installing special supply valves.

They are mounted under the window above the heating devices to heat the air coming from the street. It is also recommended to leave gaps at the bottom of the interior doors or equip them with breathable grilles.

Supply valve in the apartment

Checking, repairing and cleaning ventilation ducts and chimneys is a troublesome and responsible business. Therefore, it is better not to risk the health and life of loved ones and neighbors. Leave such work to professionals and just enjoy life in a cozy, warm house filled with fresh air.

Requirements and norms

Mainly vertical ducts are used for ventilation.

A number of documents regulate the construction of ventilation and chimney ducts: SNiP "Heating, Ventilation and Air Conditioning", SNiP "Gas Supply", "Safety Rules in the Gas Industry" and many others.

On the basis of these documents, a building ventilation project is developed. Calculations are made taking into account the amount of required air exchange. For a living room, 3 cubic meters of air is enough for 1 hour per 1 square meter. m area. For bathrooms, this value is much higher - up to 25 cubic meters. For a kitchen, at least 60 cubic meters are required. m. per hour, and if the gas stove is working - 100. Cooking in the kitchen with metal-plastic windows is possible only if there is a hood, since it is very difficult to arrange such powerful natural ventilation.

Requirements for ventilation ducts:

- The fewer the horizontal parts, the more efficient the ventilation. If forced, the horizontal fragments can be quite long, turns are allowed.

- A circular section is more efficient than a rectangular one. It is preferable to use pipes, the minimum diameter is 120 mm.

- Ventilation openings must be placed at a distance of no more than 10 cm from the ceiling.

- The minimum length of ventilation ducts made of heat-resistant bricks is 12.5 cm - half of an ordinary brick.

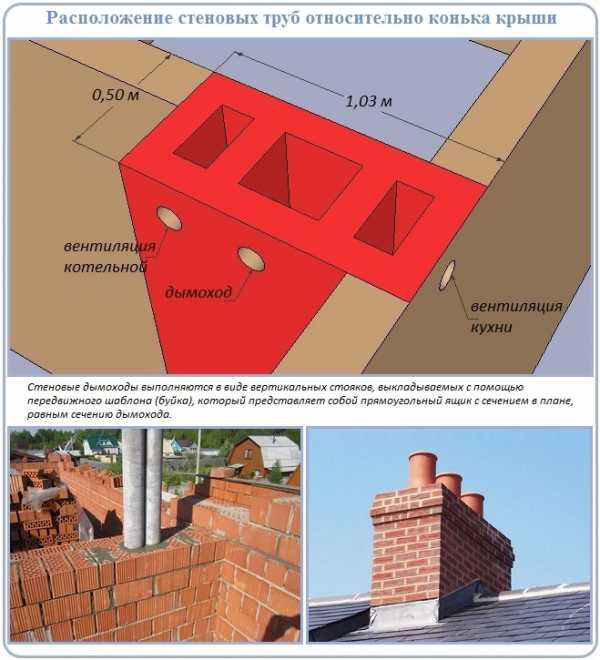

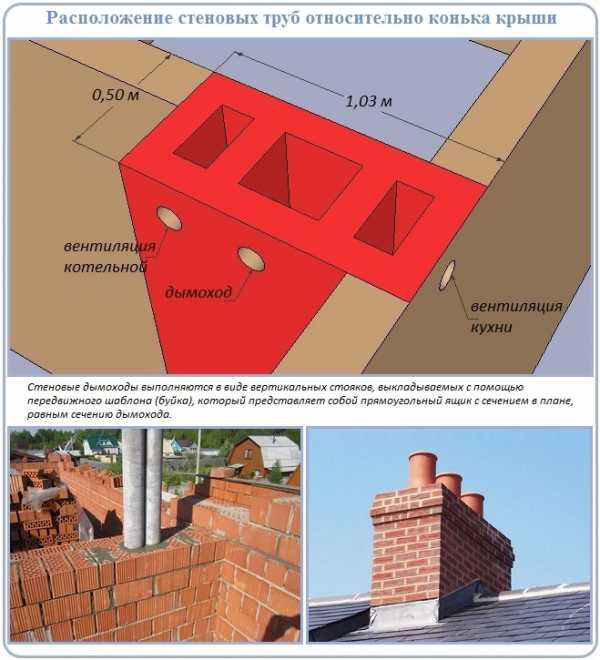

- The height of the shaft head depends on the distance to the ridge.

The chimney must be airtight and withstand high temperatures

Additional requirements are imposed on the chimney ducts. The combustion temperature of the fuel is very different. In addition, firewood, coal, even gas often do not burn completely, with the release of aggressive acid residues. This is taken into account when choosing.

- The flue duct must be absolutely sealed and not in contact with the air of the room through which it passes.

- The structure must be strictly vertical.

- The flue material must withstand the combustion temperature of the fuel and the action of aggressive substances.

Ventilation and chimney ducts must be periodically cleaned; this requirement is taken into account when developing a project.

Technical features of channel laying

It is recommended to lay the chimney parallel to the ventilation ducts.

The construction of canals is carried out according to the rules of SNiP:

- The construction of air ducts of any type without an approved project is strictly prohibited.

- Brickwork of both smoke and ventilation ducts is prohibited. They settle down separately.

- It is recommended to install the ventilation duct parallel to the chimney. The combustion products heat the air in the ventilation duct, which improves traction.

- The masonry depends on the thickness of the wall. With a size of 380 mm, the masonry is single-row, with a thickness of 640 mm - double-row.

The dimensions and nature of the masonry depend on the power of the heating system, the area of the room, and the purpose of the building. This is important when building a brick channel: after all, its parameters depend on the parameters of the brick.

Chimneys and ventilation: danger, operation and prevention

Today our story will be devoted to the elements of the heating system, which are associated with many tragic cases, and first of all we are talking about chimneys. If you have a bathhouse, summer cottage or a residential building where an autonomous boiler is used, then you can potentially suffer from poor draft, which does not remove combustion products outside.

The accumulation of CO in the body can lead to "silent" death. If you want to know how to protect yourself and your loved ones, read the article to the end.

Ventilation and chimneys in a private house made of metal

Alas, we so rarely pay attention to clogged chimneys and ventilation ducts that we could already be in the "other world" several times. This happens due to our carelessness, since we begin at least to do something when, due to the smoke in the room, we cannot see the picture on the TV.

However, this is not so bad, the main danger is invisible and is not felt by our receptors - it is carbon monoxide. It gradually begins to displace oxygen from below until it is completely squeezed out of the room.

In the photo - the symptoms of CO poisoning

Advice: the chimney and ventilation in one pipe are not installed in accordance with SNiP.

After that, there is very little time left so that you can save a person who does not even understand what is happening to him. It would seem that what could be easier than cleaning the chimney and ventilation duct in time, and then such a tragedy would never have happened.

Advice: set a time for yourself and regularly carry out ventilation and chimney prevention, doing the procedure yourself or hiring specialists.

Chimney and ventilation are allowed in one box

Malfunctions

Below we will consider the most common causes of malfunctions in chimneys and ventilation ducts. Although there are many more, almost all of them are associated with the usual irresponsibility of the owners:

| Project flaw | Quite often the operation of supply and exhaust ventilation in an apartment leaves much to be desired due to flaws in the design of the system. At the same time, there are frequent cases when during construction workers use smoke and ventilation ducts as a kind of garbage chute. When clogged, they will not be able to perform their tasks at full capacity. |

| Blockage | It happens that the system becomes clogged due to foreign objects:

|

| Deposits | Natural deposits on the walls of chimneys and ventilation ducts in the form of soot, dust and grease. The first ones should be cleaned of soot immediately after the appearance of such signs. |

| Humidity | The blockage can appear very quickly even after burning poorly dried, as well as with a lot of resin, firewood and household waste. In such cases, the cleaning of ventilation and smoke extraction systems is mandatory. |

| Other reasons | The instruction also says that traction can weaken due to:

|

Advice: if there is no draft immediately after connecting the fireplace or stove, you should make a claim to the builders who installed the ventilation or chimney on the roof.

Recommendations for use

The majority of fire poisoning from combustion derivatives is usually caused by poor ventilation and smoke extraction. Therefore, rules and requirements have been developed that must be followed when operating these systems.

Let's find out about them:

- The ducts of fireplaces and stoves using solid fuels must be checked and cleaned before and after the heating season. When the oven is running continuously, the check should be done once every three months. The ventilation ducts and flue pipes must be checked every quarter and also in summer and winter.

Be sure to carry out the prevention of chimneys and ventilation ducts according to the schedule

- If serious malfunctions requiring repair are revealed during the check, it is prohibited to use heating and gas appliances until the defect is completely eliminated.

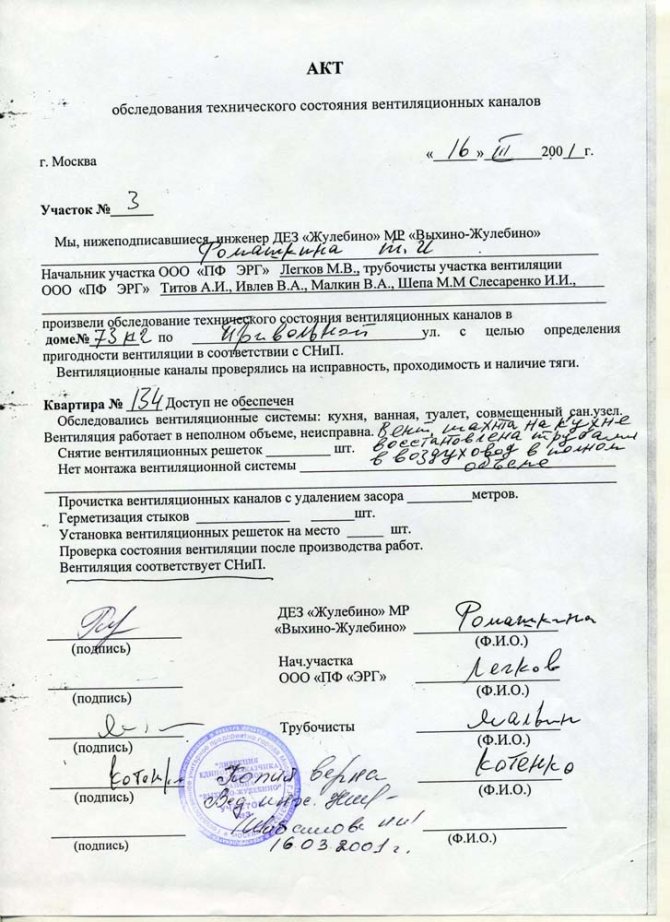

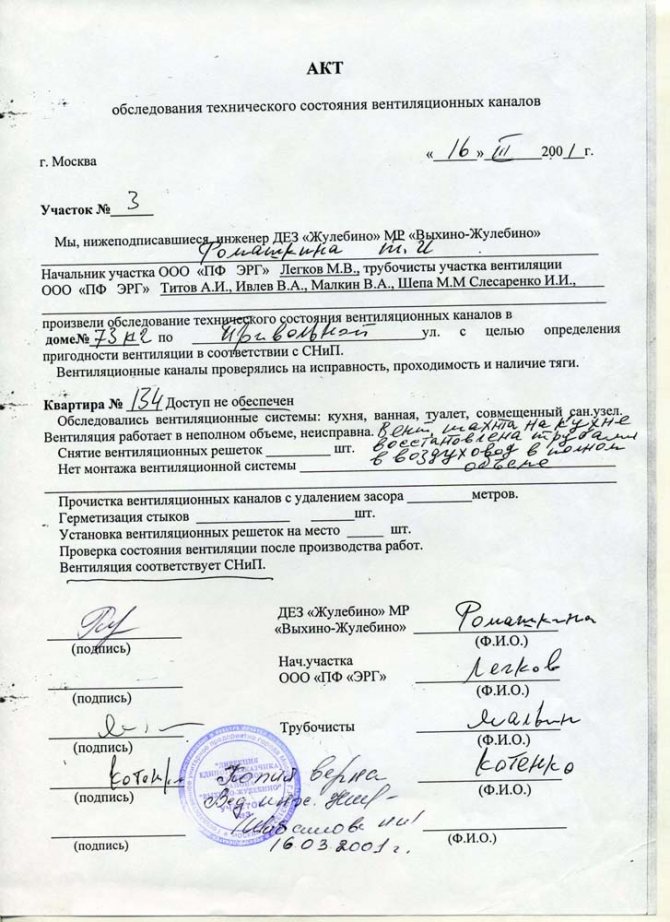

- Installations and repairs should be carried out by organizations that have the appropriate license, since their specialists usually have all the necessary skills for this. They should start work only after drawing up an act of checking ventilation and chimney.

Advice: these rules apply both to the owners of private houses and to the institutions responsible for the maintenance and maintenance of apartments and ventilation systems in them.

In addition to the above generally binding rules, we recommend that you pay attention to the following:

- use fully dried firewood in stoves and fireplaces, which have a low percentage of resin;

- it is forbidden to burn household waste in stoves and fireplaces, especially any plastic - bags or bottles;

- periodically clean the firebox and blower from ash, and roofing hoods - from dust and grease;

- purchase a roof fan that will help improve draft in a duct or pipe, its price depends on the power. This is especially necessary for those whose chimneys have a small internal section;

- do it yourself with a protective cap with a mesh on the chimney, which will prevent debris from entering the ventilation duct. In winter, regularly check this part of the system in order to clear it from blockages and freezing in time.

Prevention and repair

Two methods can be used to inspect smoke and ventilation ducts - classic and modern. In the first case, you will need a "ruff" on a long rope and a load. In the second, there are a lot of methods, including a video camera with spotlights.

Cleaning chimneys and ventilation ducts with a brush

The developed devices allow, in a short time and without much effort, to estimate quite accurately the draft in the ventilation and chimney. Based on the results of the check, an act of inspection of the channels is drawn up, drawn up in the form of a technical report of the established sample. Then a conclusion is issued, which contains recommendations for the device and repair work.

The check determines:

- materials used for the manufacture of channels, as well as their cross-section;

- the length of the channels, sections of connections, bends and constrictions, marks of cracks and congestions found in the system;

Checking ventilation ducts and chimneys with a video camera

- isolation and density of channels;

- the presence of traction, horizontal sections, zones with or without wind support;

- hatches for cleaning, fire-prevention cuts and tops;

- tightness of branch pipes;

- condition of ventilation ducts, exhaust shafts, as well as air intake grilles.

Output

Draft in the chimney and proper ventilation of the premises allow creating comfortable and safe living conditions in the apartment and house. We recommend that you do not ignore the proposed recommendations and try to follow them. Ultimately, your health and the health of those who live with you will depend on this.

The video in this article will help you find additional information on this topic.

gidroguru.com

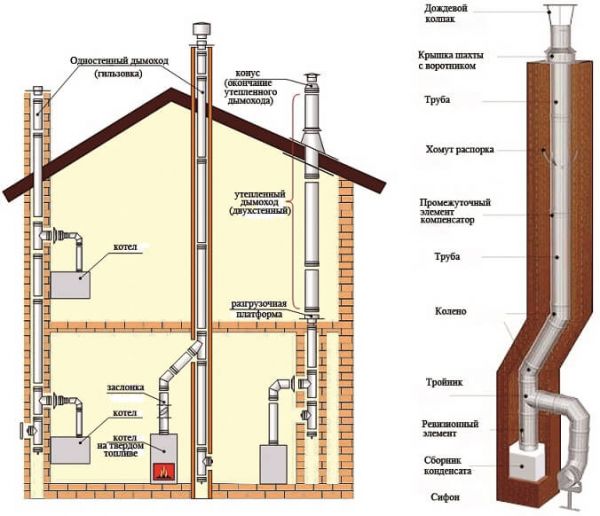

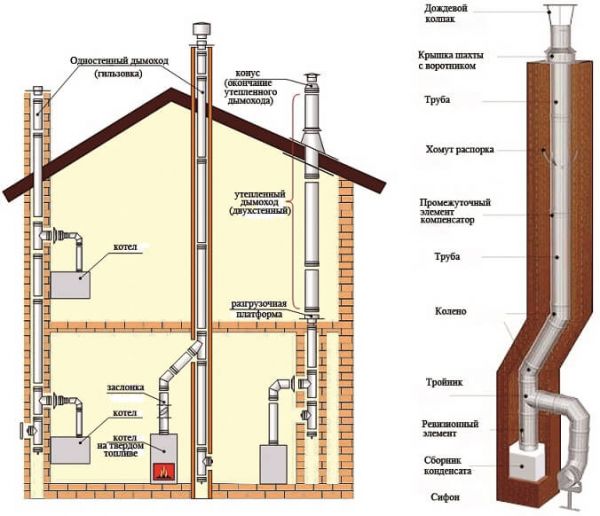

System design options

Ventilation ducts in a private brick house may have a different device. A design is chosen taking into account the characteristics of the rooms and one common feature for the hood. Heat is also removed along with the exhaust air. To prevent cooling, a brick ladder bend will be included in the ventilation system. It creates a barrier and prevents the premature removal of heated air: having lingered, the air flow has time to partially transfer heat into the room.

Conclusions from the premises

This design is used to equip complex ventilation. In the upper part of the building, all channels are combined into a common shaft and led out through the roof, like a chimney. Its height and diameter depend on the volume of the premises and the distance to the ridge of the roof.

Wall pipe

Brick chimney is mounted in the inner walls

The air duct is equipped directly in the inner wall. Installing ventilation ducts, and even more so chimney wall pipes in the outer walls is allowed only in exceptional cases. The wall is in contact with cold outside air. In this case, the exhaust gas, passing through the air duct, cools faster and does not warm up the room properly. For the same reason, condensation quickly forms inside the chimney or ventilation duct itself. This reduces thrust and accelerates wear, as acid anhydrides precipitate on the shaft walls. The wall pipe in the outer wall must be additionally insulated.

A separate chimney is installed for each stove. In exceptional cases, equip 1 chimney for 2 stoves. The ventilation duct is installed for every 2 chimneys.

The chimney ends at the top floor and turns into a regular chimney.The height of the chimney and the head of the ventilation duct depends on the exit point.

Root pipe

Brick chimney on its own foundation

It is usually set up in wooden buildings. A brick chimney is erected on its own foundation, and the latter does not adjoin the foundation of the building. The wall thickness is equal to half a brick.

The root pipe can be connected to two hearths. For this, crossover sleeves are installed.

Attachment pipe

It is built directly on the furnace. Experts recommend placing a brick chimney not directly on the neck of the furnace, but after laying a reinforced concrete slab with holes on it. This device allows you to repair the stove in the future without disassembling the chimney.

Checking act

What does the chimney or ventilation duct inspection report include? Let's list its points:

- Date.

- Name of the person who conducted the survey.

- The name of the object where the inspection was carried out.

- Position and name of the person representing the object.

- The legal details of the entity that owns the object.

- A list of factors that were assessed - from the availability of the necessary documentation to checking the state of the microclimate.

- Conclusion.

We recommend that you familiarize yourself with: Organization of the ventilation system for the roof

When might this act be required? Many organizations, including gas service, housing inspection and UGPS, may want to look at this document during one of the inspections. Its absence will entail legal consequences that any of us would like to avoid.

For such cases, a special package of documents should be prepared, including:

- Completed act with a special hologram.

- A copy of the license issued by the Ministry of Emergencies, with a seal.

- Copies of protocols confirming the level of training of the specialists who carried out the inspection.

Materials for smoke and ventilation ducts

The air ducts are under heavy stress. Warm air comes out through the shaft. When in contact with cold outside air, the gas inside quickly cools. Since its humidity is noticeably higher, condensate is deposited on the channel walls. In this case, the difference between the temperature inside the ventilation duct or chimney and the temperature outside becomes even greater.

Unoxidized combustion products, acid anhydrides and oxides are removed with the exhaust gas. When condensation occurs, they turn into acids and destroy the wall material. So the latter must be resistant to temperature and acids.

Brick

Solid ceramic bricks withstand high temperatures

A brick ventshaft is a traditional solution. Ventilation and chimney ducts of any kind are constructed from building stone. When arranging, the following rules are followed:

- Not every brick is resistant to temperature. For chimney channels, only full-bodied ceramic is taken. Silicate and hollow temperature changes do not withstand and is unstable to the action of acids.

- The section of the shaft is rectangular, which reduces traction. You need to accurately calculate the height of the pipe.

- The inner surface of the duct is carefully leveled. The smoother the surface, the less soot, soot, and sulfur oxide are deposited on it.

- Tightness is a prerequisite. This is also true for ventilation, since with cracks, irregularities, good traction cannot be achieved.

The laying of brick ventilation ducts and chimneys is paid at high prices compared to the construction of a partition.

Prefabricated single-circuit galvanized and steel systems

Steel chimney with one elbow when leaving the boiler

With high ceilings, wall piping is not possible. It is also almost impossible to draw up an effective overall ventilation scheme if the building is intended for rent, since each owner has his own needs.In this case, single-circuit systems are mounted.

The structure is assembled from metal pipes and elbows. The connection is sealed - in a lock or on screw connections. There are round and square pipes. The first ones are taken for the chimney, the second ones for ventilation, where the traction force does not matter so much.

There are several restrictions:

- The chimney can only include 1 elbow - when leaving the furnace or boiler.

- The pipe gets very hot. It can be laid in a brick or stone wall, but not in a wooden one. If the pipe is not hidden, it is thermally insulated to prevent fire.

- You cannot take galvanized steel for the chimney: the alloy actively interacts with acids and will quickly fail. The best option is stainless steel.

The service life of a single-circuit system is short - up to 15 years. However, it is very easy to replace the pipes.

Dual-circuit systems

Chimney option. The system includes 2 steel pipes - for the air supply and for the removal of combustion products. The pipes are insulated from each other and from the outside air with mineral wool. The system is fireproof and lasts much longer. Due to thermal insulation, less condensation is formed.

Asbestos cement pipes

Asbestos-cement chimney pipes

Not too resistant to temperature, but insensitive to the action of chemically aggressive substances. The cost is low. Suitable for the construction of ventilation ducts and chimneys for devices with low temperature output.

Asbestos-cement pipes are inconvenient: installation of corners or transitions is impossible, the material is fragile, it is difficult to work with it.

Sand cement pipes

Such mines are built from a special type of building blocks. Their shape is traditional - 20 * 20 * 40 cm, but they include 1, 2 or 3 channels. Sizes can be large. The blocks are used in the construction of wall ventilation. They are not suitable for a chimney, since they are rarely of sufficiently high quality and do not always provide tightness.

Prefabricated ceramic systems

They consist of a round ceramic tube, mineral wool insulation and a concrete cover. Such blocks are easy to install, serve for a very long time and are very promising. The downside is the high cost.

Ceramic systems are used in the construction of chimneys, such ventilation is too expensive. If desired, the blocks can be built into the wall and hide the chimney.

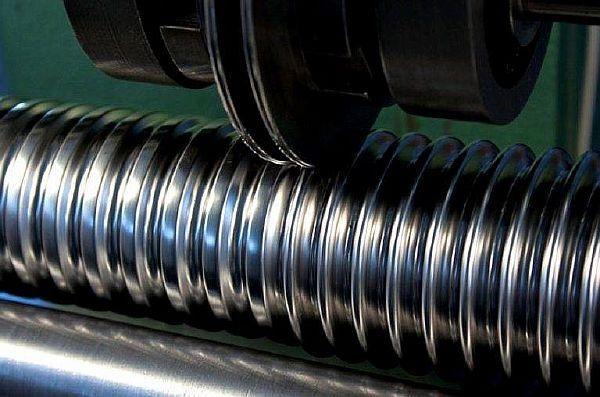

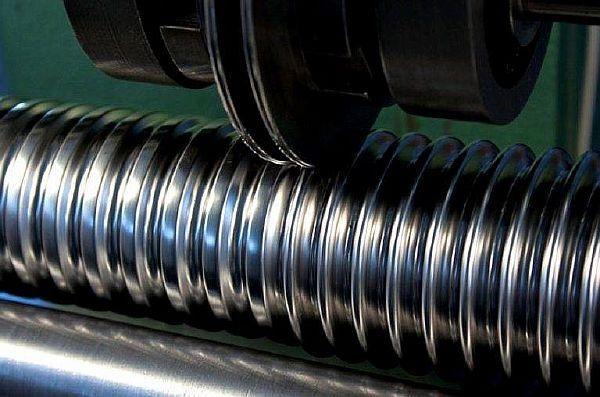

Corrugations

Corrugated steel pipes allow the construction of complex exhaust systems, where it is impossible to do without turns and transitions. They are often used as sleeves and to connect wall chimneys with boilers. A corrugated pipe is not suitable for smoke extraction: a lot of soot and soot is deposited on such a wall, the pipe quickly breaks down.

Polymer pipes

They are of limited use. Plastic is not distinguished by high heat resistance, therefore they are used for exhaust and for chimney removal from boilers on liquid fuel or gas: there is a relatively low combustion temperature of fuel.

Plastic pipes are used to modify an old brick chimney. Introduced into the channel as a sleeve.

Ceramic pipes

Corrugated stainless steel

Installation of smoke and ventilation ducts

The chimney should be located at the highest point of the roof

Chimneys and ventilation ducts in masonry work only under one condition - sufficient draft. It arises due to the difference between the air pressure at different heights. In a one-story house, it is quite small, but this is enough to ensure that the more rarefied heated air is drawn out.

To provide traction, the following requirements are met:

- The ventilation and chimney pipes go out to the roof and reach a certain height. The value depends on the distance between the exit and the ridge. If the distance is less than 1.5 m, the pipe should be 50 cm higher than the ridge; if from 1.5 to 3 m, it should be level with the ridge.If the distance is more than 3 m, the height is calculated: the line from the ridge to the pipe head is 10 degrees below the horizon. If there is a parapet on the roof, there is a higher structure nearby, the height of the pipe is increased.

- The ventilation ducts can be combined. Chimneys are combined only in exceptional cases - when constructing a stove with a fireplace.

- If the chimney ducts are not located in the wall, they are insulated along their entire length. Any conclusions in the places of transition through the roof are insulated. Use asbestos or safer mineral wool.

It is recommended to waterproof the pipe between the roof and the otter. If this is not done, the entire wall will get wet.