Intensive use of the chimney leads to clogging. The cross section decreases, the combustion products cannot pass quickly. As a result, the thrust decreases, the device starts to work in heavy duty, and the efficiency decreases.

To prevent the accumulation of soot, and the boiler functioned normally, the chimney must be made of appropriate materials according to well-executed drawings. In addition, it is very important to correctly calculate the diameter and section.

Thrust

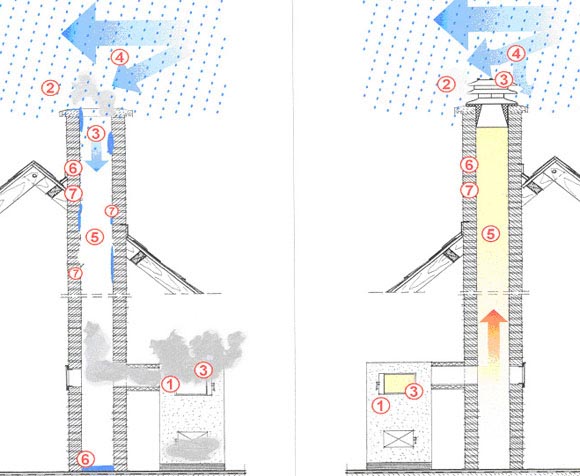

When the system has insufficient traction, poor fuel burnout occurs. The result is the formation of soot. It gradually clogs the pipe passage, reducing its cross section.

You can, of course, achieve an increase in traction by increasing the cross section of the chimney. But this will not lead to a positive result. The heat from the boiler will simply leave the room through the pipe. In order to be able to regulate the draft, the boiler is equipped with special dampers.

The appearance of draft is based on the difference in temperature between the room and the environment. The thrust becomes maximum when the cold weather sets in. A small temperature difference is enough so that the combustion products do not settle on the pipe surface, but go into the atmosphere. This can happen under one condition. The chimney must be properly designed and installed.

When the boiler starts to work, outside air is supplied to the combustion section. Thanks to this, the combustion process is supported. The exhaust gases are directed into the chimney and are rapidly thrown out.

With an insufficient pipe diameter, exhaust gases begin to accumulate inside the furnace. As a result, the hearth begins to fade, and there is strong smoke in the room.

The thrust force depends on several factors:

- Pipe length.

- The presence of turns.

- Bends.

For example, the presence of a right angle in a structure greatly reduces its permeability. This becomes noticeable when there is a decrease in atmospheric pressure. To remedy this situation, a special stabilizer is installed in the thrust.

To order or make a chimney for a solid fuel boiler with your own hands - which is more profitable?

DIY chimney

The answer to this question is not as obvious as it seems. By design, solid fuel boilers are similar to conventional stoves. And it may seem that arranging a chimney is a simple task for him. Do not succumb to this delusion. For high-quality removal of combustion products, a well-thought-out, durable and reliable design is required. Neglecting these rules is unacceptable, because the lives of people living in the room depend on it. Loose joining of materials or design errors lead to the penetration of carbon monoxide, hazardous to health.

Therefore, in the absence of furnace installation skills, it is wiser to entrust such a responsible job to a professional. If you have experience and self-confidence, you can do the installation yourself. However, it is better to order the calculation of chimneys for a solid fuel boiler from a specialized organization.

Additional features of the chimney

It should not react to high temperatures. Therefore, in a solid fuel boiler, a chimney is installed, made of especially heat-resistant materials. When coal or wood is burned in such a boiler, the smoke temperature is much higher than the gas combustion temperature.For example, the smoke temperature of a gas boiler does not exceed 200 degrees. When burning wood, the temperature can exceed 300 degrees. If the boiler is fired with coal, the temperature reaches 600 degrees. Sometimes there is a jump in temperature. It begins to rise when unpinning.

It is forbidden to strip the combustion chamber with solid fuel, gasoline, or other flammable substances. This option can cause soot to ignite due to a burnt-out chimney. It is strictly forbidden to try to remove dirt in this way.

How to calculate the cross-section of the chimney

When choosing, you must first measure the existing section of the branch pipe. It must be the same size. It is desirable that the sizes match. If the diameter is larger, there will be a drop in pressure, and the traction force will decrease. It is forbidden to operate two solid fuel boilers with one chimney. Each must be equipped with a separate pipe. With the correct selection of the diameter, as well as competently made installation, there will always be good traction.

Section size (sq. M) is determined by the formula:

volume of consumed fuel (m3 / s) / gas velocity.

The chimney can have a different cross-sectional shape:

- A circle.

- Rectangle.

For normal operation, you can use any option, however, a circular section is still much preferable. When the smoke moves inside the pipe, it spirals around. Any foreign part in the pipe creates opposition to the movement of the gas flow.

If the inner surface of the pipe is rough, the gas velocity will decrease. When smoke, in circular motions, collides with a right angle, an abrupt change in trajectory occurs, mixing occurs. As a result, soot settles in the corners.

It will require constant, thorough cleaning.

Requirements for chimneys for solid fuel boilers

When equipping a dwelling with a water heating system, the source of which is a solid fuel boiler, one of the most important issues is the correct choice of a chimney. In many respects, it depends on the design features of the house and the performance of the boiler unit.

It should be borne in mind that the following requirements are imposed on any type of chimney:

- absolute tightness (preventing the penetration of flue gases into the premises);

- providing the necessary traction (creating a vacuum in the chimney that exceeds the gas resistance of the boiler);

- no difficulties during installation (manufacturability, no need for complex and expensive equipment, moderate labor costs);

- durability of the structure;

- low operating costs;

- thermal and corrosion resistance of the materials used;

- smooth inner surface (no seams, joints, drops);

- optimal aerodynamic section (circle or oval);

- high fire safety;

- minimum thermal conductivity of the chimney walls (to prevent the formation of condensation inside the chimney);

- successful design solutions.

Note! Round or oval cross-section and smooth inner surface prevents soot deposits in corners, joints and on rough edges of the chimney walls.

What materials should be made of exhaust pipes

With a wide variety of materials, only a few types can be used for the operation of the chimney. The main ones are:

- Brick.

- Metal.

- Ceramics.

The most popular are pipes made of bricks. They are able to withstand very high temperatures. Its maximum reaches 1000 degrees. Today, on the roof of modern expensive cottages, you can see the original chimney made of Eurobrick. However, upon closer examination, you will notice that pipes inserted inside are visible from the brick chimney.They can be made of steel or ceramic. The explanation is very simple. One brick is not good for normal work. In other words, it will work, but not for very long. It will be quickly destroyed by corrosive condensation. Therefore, an insert is inserted into the brick pipe. Free cavities are filled with insulating material.

Sandwich pipes made of ceramics are able to withstand very high temperatures. It can exceed 1200 degrees. This value is much higher than the maximum smoke temperature after coal combustion.

Such a pipe is not afraid of condensation and any atmospheric phenomena. Condensate drainage takes place through a special cream hole. Sometimes for this, an additional container is made under the end of the watering can. The ceramic chimney is installed on the facade or inside the building.

The Schiedel Uni chimney, if soot ignites, is able to cope with this thermal stress. When burning, the soot heats up to a temperature of 1100 - 1200 degrees.

Disadvantages of ceramics

They do not differ in their beautiful appearance. Their cost is much higher than their steel counterparts. Installation of such pipes requires construction skills and experience. These pipes remain popular with low-income consumers.

Metal chimney

For its manufacture, ordinary steel or stainless steel is used. Unfortunately, steel chimneys cannot withstand

aggressive environment. When the boiler is running continuously, the pipe will become unusable in a very short time, it can cause a fire.

The used stainless steel contains special additives consisting of several chemical elements

- Titanium.

- Nickel.

- Molybdenum.

It is they who save the stainless steel from corrosion. For installation

boilers use the following steel grades:

- 316.

- 316 L.

- 321.

They contain substances that allow steel to withstand temperatures in the range of 700 - 800 degrees. These steel grades are not afraid of condensation, they are neutral to acids, do not react with other aggressive substances.

The cost of a chimney made of stainless steel is available to the average buyer. It is considered the most suitable for installation in a solid fuel boiler.

Glass chimney

Very rare. Its positive qualities include:

- Low thermal inertness.

- Corrosion never occurs.

- Original look.

The cost of such a design is very high. Therefore, it is very rare. In addition, its installation is very laborious and costs a lot of money.

Chimney device

All chimneys, regardless of the material used, location and design, have a similar structure.

They always contain the following components:

- Chimney - a vertical or partially inclined channel (pipeline) of rectangular, square or circular cross-section for the removal of combustion products. Manufactured from durable flame retardant material.

- Condensate trap - located in the lower part of the chimney after the boiler gas flue connection and serves to collect condensed vapors contained in the flue gases. Equipped with a dump valve. It is absent in double-walled chimneys with a heat-insulating layer.

- Draft adjustment device - rotary or retractable damper.

It is interesting! Unlike chimneys of gas-fired boilers, solid fuel ones are equipped with weather vans and various types of deflectors to improve draft and prevent precipitation.

Calculation of chimney parameters

Correctly selected height and cross-sectional area of the chimney is the key to its reliable operation. Almost all industrial boilers have recommendations for these values.

For equipment with a thermal power up to 90 kW, the following values are recommended:

| Boiler productivity, kW | Chimney diameter, cm | Pipe cross-sectional area, cm2 | Pipe height, m |

| 20 | 13 | 196 | 7 |

| 30 | 15 | 196 | 8 |

| 45 | 18 | 378 | 9 |

| 65 | 20 | 540 | 10 |

| 90 | 25 | 729 | 12 |

Device and installation

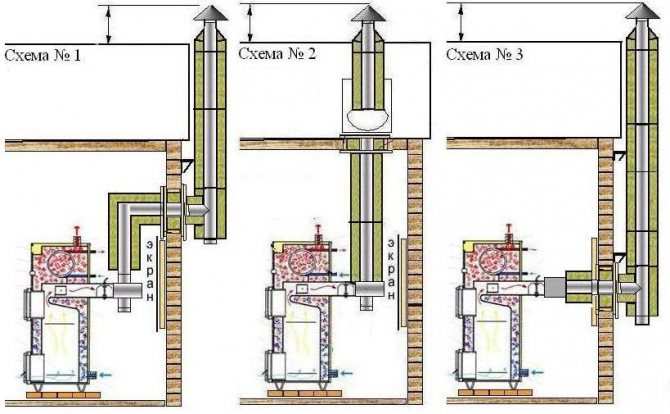

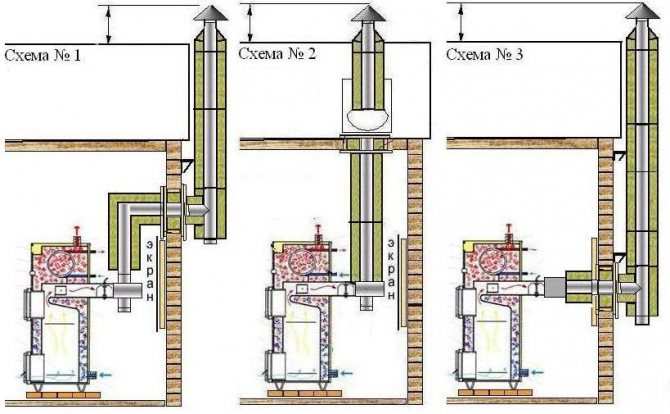

When the installation of a metal chimney is carried out, work begins from the bottom, gradually moving upward. Pipes can be connected in several ways:

- By the movement of smoke.

- Condensate

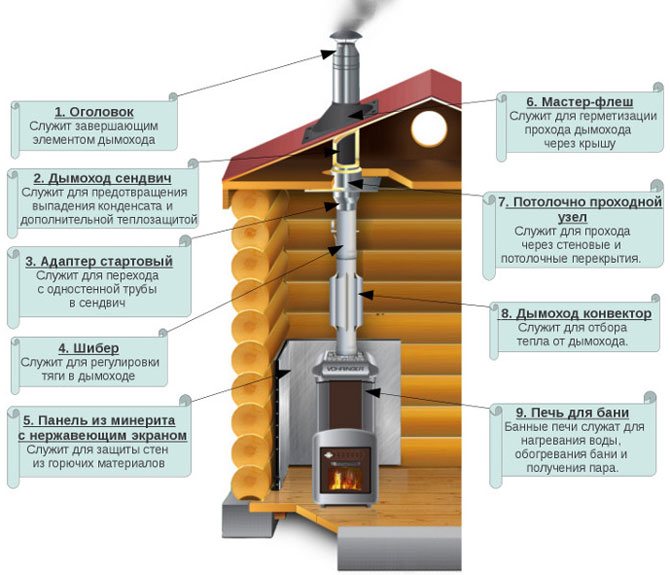

When the boiler is connected to the chimney according to the first option, the installation takes place from the boiler. The second option, on the contrary, is to the boiler. A metal structure consists of several parts:

- Glass.

- Sandwich pipes.

- Condensate collector.

- Spark arrester.

- Head.

- Cleaner.

To create a reliable connection the following are established:

- Adapters.

- Tees.

The joints are fastened with clamps from the outside.

Chimney installation recommendations

You can check the draft in the chimney before kindling with a lighted match

The installation of the chimney must be carried out in a certain sequence so that the structure is strong and stable.

This activity consists of the following stages:

- Preparation of the base and installation of a solid fuel boiler.

- Marking for making holes, fixing clamps and spacers.

- Drilling a hole in the wall or openings in ceilings, depending on the chosen installation method.

- Sealing of passages with heat-insulating plates with pre-made holes for the pipe.

- Chimney assembly. The technology is selected in accordance with the selected material.

- Sealing the remaining slots. Installation of a condensate collector. Installation of the cap on the upper cut of the pipe.

Checking the correctness of the installation is carried out by kindling the hearth with newspapers or grass, with the control of all joints for the appearance of smoke.

Technological requirements

The following technical requirements must be observed:

- A dedicated area should be provided to disperse the smoke. It is a vertical pipe installed behind the nozzle of a solid fuel boiler. The accelerating section is made one meter high.

- The chimney is installed only vertically. A deviation of no more than 30 degrees is allowed.

- The presence of deflections is prohibited.

- Length is very important (3 - 6 meters).

- Three horizontal sections are allowed. Moreover, the length of each should not exceed half a meter.

- The height of the head over the roof must exceed 100 cm.

- Fastening the pipe to the wall is carried out with a step of 1.5 meters.

- To create a sealed joint, the pipes are abundantly lubricated with a heat-resistant sealant.

To obtain ideal draft, it is necessary that the chimney design has a minimum number of turns. A flat pipe is considered the best.

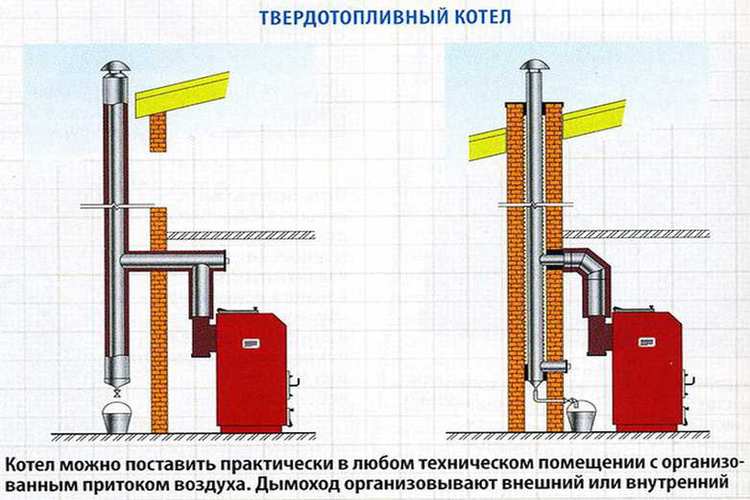

The chimney can be installed inside or outside the building. For the first option, it is necessary to protect the pipe so that it does not come into contact with combustible materials. A special metal screen is used, installed in the place where the pipe passes through the ceiling. The chimney must be at a distance of more than 25 cm from the wall.

Outdoor structures look much safer. They are much easier to maintain. Masters consider this method to be the most preferable one.

Some Connection Tips

One of the main conditions is that the diameter of the chimney of a solid fuel boiler must be no less than the outlet for exhaust gases of the installation itself. Otherwise, there is a lack of gas duct throughput when the unit is operating at medium and maximum power, which is unacceptable. If the shape of the vertical shaft is rectangular, and the outlet for gases from the heater is round, it is necessary to compare them with each other according to the flow area.

When connecting a solid fuel boiler, make sure that the length of the chimney at its outlet is at least two diameters before the first turn, and the latter is as small as possible along the entire length of the flue. Each turn creates additional flow disturbance and turbulence, causing increased local drag. Accordingly, the traction force deteriorates.

In order for the flow of gases passing through the circular section of the chimney to flow smoothly into the vertical shaft, it is better to place the horizontal section from it to the heating installation at an angle. Ideally, this angle is 45º, however, this is not always possible, therefore a value of 30 or even 15º with an inclination towards the unit is acceptable. If the latter is equipped with a blower or a smoke exhauster, then observance of the slope becomes not so important, since the combustion products are forced out.

Pipe height

This size is determined by SNiP, which sets certain parameters:

- If the roof is flat, the chimney should rise 1.2 meters above it.

- If the chimney is located near the ridge, and the distance is less than 1.5 meters, it should rise 0.5 meters or more above the ridge.

- When the pipe is located in the range of 1.5 - 3 meters to the ridge, it should not be below the ridge line.

- If the location of the chimney from the ridge exceeds 3 meters, its height should be on a line passing from the ridge, maintaining an angle of 10 degrees, relative to the horizon.

To determine the height of the chimney, a large number of indicators are taken into account. The parameters presented above apply only to gas equipment. To make an accurate calculation, you must use the services of a specialized company.

Fire safety engineering

Installing a chimney is allowed in accordance with the requirements:

SNiP 2.04.05-91U.

DBN V 2.5-20-200.

NAPB A.01.001-2004.

Installation should only be carried out by professionals. The chimney cross-section must correspond to the value indicated by the manufacturer in the instructions supplied with the boiler.

The required chimney height is usually recommended by the manufacturer, or should exceed 5 meters.

If there is a horizontal section, its length should not exceed one meter.

The design must provide for the possibility of condensate drainage, as well as cleaning the flue gas duct.

How to connect a chimney

All connections of parts to the nozzle of a solid fuel boiler are made with a heat-resistant sealant that can withstand temperatures in the range of 1250-1500 degrees.

When there is no correspondence between the diameter of the chimney and the size of the chimney outlet, an adapter is installed to create a tight joint.

How the parts are collected

Any single-wall, as well as a sandwich with insulation, are assembled with only one option: "the pipe is inserted into the pipe." The joints of the chimney parts do not require the installation of additional clamps.

If the structure is made of special, stainless steel, the assembly is carried out only by condensation. In this case, condensate, as well as the resulting tarry deposits, will never get outside, they will drain along the pipe walls directly into the condensate drain.

If a revision is used in the chimney and tees are installed, the assembly of all parts is performed "by smoke". The assembly of vertical parts extending from the tee is carried out "by condensate".

If it is necessary to make a sleeve for the channel, the gap formed between the pipe and the channel must be more than 4 cm. It is necessary when the metal expands during heating.

In order for the parts of the chimney sandwich to have a more rigid fastening, rivets are installed or self-tapping screws are screwed in.

Chimney fixation

The pipe is attached to the wall only with special materials.

The single-wall structure must be fastened with an attachment pitch of 1.5 meters on all vertical pipe sections.

If the sandwich chimney does not have a supporting structure, it is necessary to secure each element with fixation.

If the system uses a 45-87 degree tee, or a 45-90 degree elbow, the installation is carried out so that the load on the rotating parts of these parts is completely eliminated.

If an additional support is required for installation, use a floor stand installed under the revision.

When the chimney rises above the roof more than 1.5 meters, a bracket is mandatory installed under the stretch.

Passage through ceilings

To make a passage through the wall of a house or its overlap, you need to use the building codes that are in force in Ukraine today.

If a sandwich chimney with insulation passes through wooden walls, a travel sleeve must be installed and another layer of thermal insulation is applied.

When the chimney is installed through the roof, the builders must install a special additional part of the pipe, the so-called "roof". Another additional layer is created, consisting of fireproof insulation materials.

The final stage of construction

When a brick chimney is wired, its upper part is closed with an additional part - an end.

Usually the top of the pipe is covered with a deflector or a beautiful fungus.

If the roof covering of the building is made of a fire hazardous material, such as bitumen shingles, a special spark arrestor is mounted on the top of the chimney.

If a gas boiler is installed in the house, installation of the deflector is strictly prohibited. According to current regulations, the top of the pipe of the gas appliance is always kept open.

How the chimney works

Principle of operation

The principle of operation of the smoke exhaust system is based on the effect of draft arising from the temperature difference between hot gases in the pipe and cold outside air entering the boiler.

Hot exhaust gases are rarefied and rise upward, leave the pipe and disperse. Cold air is sucked into the firebox.

Types and designs

According to the material of manufacture, chimneys are:

- brick;

- ceramic;

- metal.

By design, chimneys are:

- wall - structurally built into the wall, made of red brick, resting on the foundation of the wall;

- indigenous - are a structure that stands apart from the wall and has its own foundation;

- shell-mounted - lightweight structures made of steel, ceramics, sandwich, installed directly on the heating unit (not used for solid fuel boilers);

- not having their own foundation and requiring fixing on supporting structures - boxes made of ceramic steel, "sandwich".

The design of pipes for a solid fuel heating boiler varies greatly depending on the material, but always includes the following elements:

- horizontal section (branch pipe leaving the boiler);

- vertical pipe - the actual gas outlet;

- condensate collector - a vertical section of the pipe, located below the horizontal level, condensate flows into it from the main part;

- thermal insulation;

- there should be cleaning hatches on the pipe bends;

- deflector.

Modern boilers have a very high efficiency (up to 87% for pyrolysis boilers and 92% for pellet boilers) and the fuel burns out in them almost completely, while a small amount of acids is released, which, together with moisture from the air, fall out in the form of condensate on the pipe walls. Therefore, the inner surface of the pipe must be acid-resistant (steel or modern ceramics) and have a condensate reservoir.

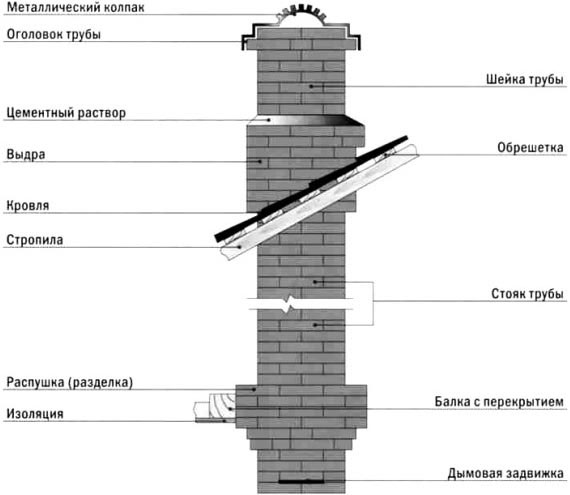

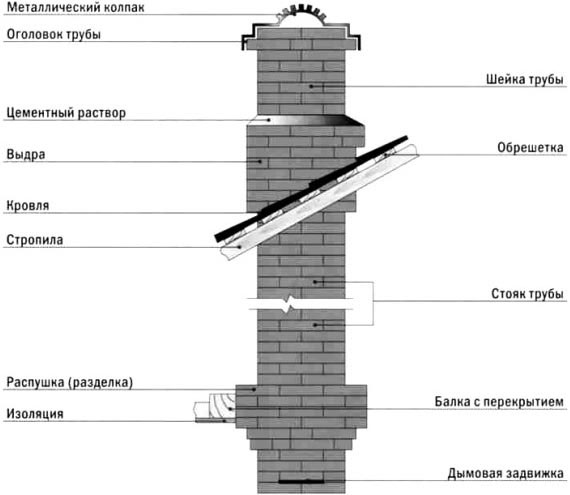

A brick pipe is the most complex structurally, it includes:

- cap or deflector;

- headband;

- neck;

- otter - an expansion of the walls above the roof, covering the cracks between the roof and brickwork from precipitation;

- riser;

- gate valves;

- neck for connection to the boiler;

- foundation;

- stainless steel liner;

- in modern chimneys, a container for collecting condensate and a hatch for freeing it from accumulated condensate are provided at the bottom.

Ceramic and metal pipes are assembled from prefabricated elements.Ceramic pipes consist of an inner channel made of refractory ceramics, thermal insulation made of non-combustible insulation, and an outer protective box made of lightweight aerated concrete. Steel hogs are single-layer and sandwich type (inner and outer layers are made of steel, between them there is a layer of insulation.