How and with what to heat the boiler

From any solid fuel, carbon monoxide is released in a certain amount during combustion. Especially a lot of it is obtained when wood is burning.

That is why it is wiser to put firewood in a gas-generating boiler, designed to create a comfortable temperature in the house, and not any other fuel.

In order for the premises to be heated well, the gas-fired boiler must be used correctly:

- open the air damper and start a fire with a splinter;

- set the normal long burning mode, in which the fire in the boiler will be maintained until the temperature in the furnace rises to the desired level;

- switch the damper to a mode supplying air in a limited amount.

In modern wood-burning gas-fired boilers, all of the above actions do not need to be performed, since their work is fully automated.

The fuel is ignited by means of electric ignition, the automatic unit controls the supply of oxygen to the combustion chamber and the removal of gases resulting from the combustion of wood.

Wood-fired gas-fired boilers must be loaded with a certain type of fuel. Best suited for this are beech, oak and acacia wood.

Photos and diagrams:

Coal should be abandoned altogether, since it negatively affects the performance of heating equipment.

It is wiser to use only high-quality fuel to heat the house, since more heat is produced during its long burning.

As for the moisture content of firewood, the gas generating equipment will not function on frank raw fuel.

That is, the wood will burn as in a conventional stove, and the boiler will not operate in gas generation mode.

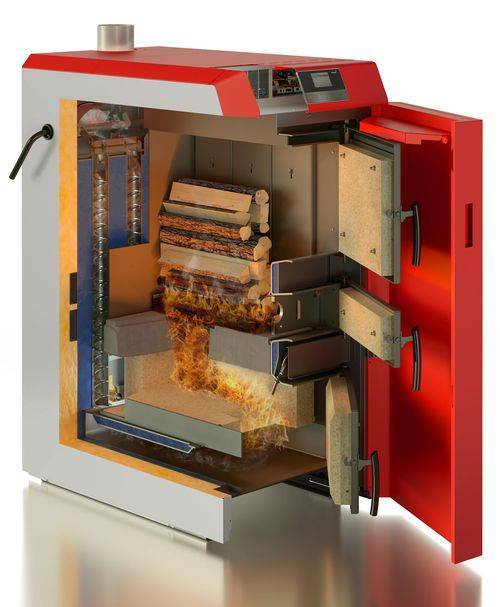

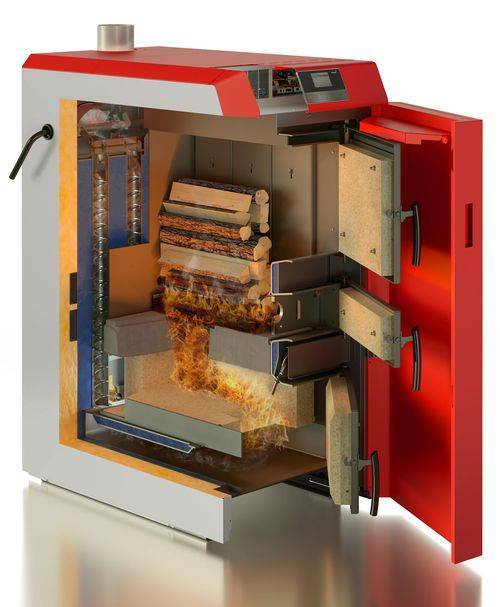

The design of the boiler itself affects the firewood with which moisture content can be put into the gas generating equipment.

If it has a side loading, then it is allowed to load only firewood with a moisture content of no more than 20%. Such equipment is very demanding on the quality of wood.

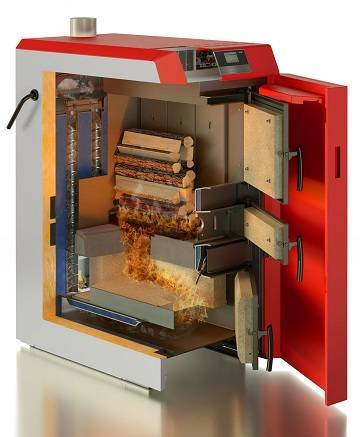

Top-loading wood-fired gas fired boilers burn fuel gradually. To do this, it is placed in a vertical firebox.

When the bottom layer of firewood burns out, they will go down, being dried by warm air. Boilers, into which fuel is loaded from the top, are transferred to gas generation mode, even if the moisture content of the wood is about 45 degrees.

What are the advantages of gas-fired boilers

The first advantage has already been announced - this is the efficiency, which reaches 90%. For solid fuel boilers, this is a high figure. If the heater uses the energy carrier more efficiently, accordingly, less firewood will be consumed for the heating season, this can be a good way to save money.

A more rational use of solid fuels entails another important advantage - you do not need to often clog the firebox with wood. This is true in houses where people live permanently, because you do not need to work on the boiler every four hours. In this case, it is generally unclear what to do for the workers. A hydrolysis boiler operates on one load for 8 or more hours, depending on the size of the furnace.

SNIP clearly defines what humidity should be in the room and these indicators are very important for your health.

Read about how to determine the humidity of the air at home in this article.

When the wood smolders slowly, there is almost no ash left from them, the heater will have to be cleaned less often. This will save you time and effort, which is important. So, to summarize, the hydrolysis boiler gives you the following benefits:

- saving money;

- saving time for cleaning;

- no need to throw firewood every 4 hours.

Minus one - the price, but a good thing cannot be cheap. When buying, pay attention to the size of the furnace, the volume of the coolant in the boiler, heat output and the ability to connect additional equipment.

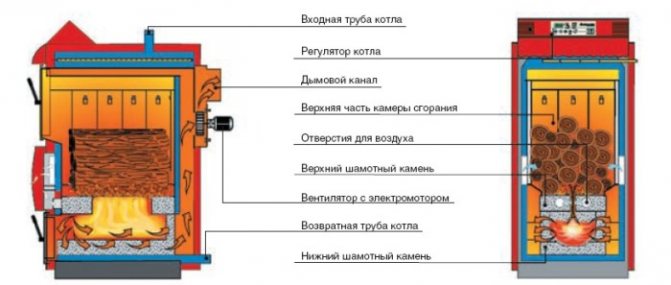

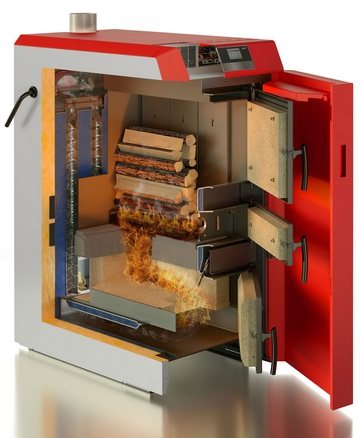

Principle of operation

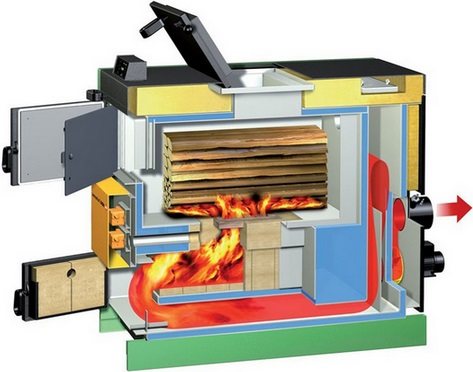

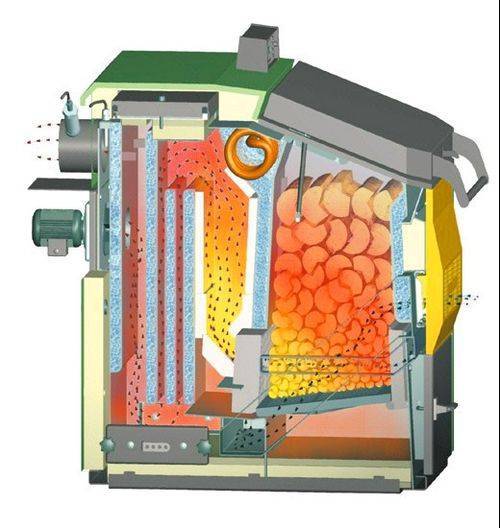

The scheme of a wood-fired gas-generating boiler has a preliminary gasification chamber in its structure. Also, a combustion chamber is installed in it, which is necessary for processing firewood into heat. The principle of operation of this chamber is aimed at moving the generated gases through the nozzles. A homemade boiler has an operating time of at least 25 hours.

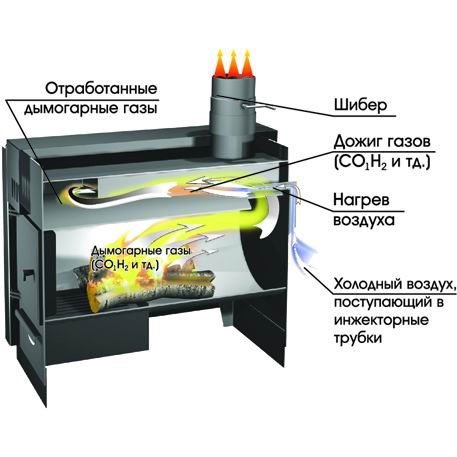

The gas generator consists of two chambers, the first one burns fuel. Due to the small amount of oxygen, the substances are divided into a volatile part, forming wood gas. Then the wood is left to burn out in the second chamber. In other words, the principle of operation of the design of the device allows you to achieve maximum heat output.

The principle of operation of a gas-fired boiler is based on forced draft. Especially for this, a smoke exhauster or a fan is installed in the boilers. After the fuel reaches its highest combustion temperatures, the wood turns into a solid and volatile part. Boilers carry out the combustion process not only at maximum temperatures, but also if there is not enough air in it.

The principle of operation of the device is such that as soon as the resulting gases move through the nozzle, they are mixed with secondary oxygen, and the combustion temperature reaches 1200 degrees. Immediately after the gases release heat through the heat exchanger, they are removed from the chamber to the outside, moving through the chimney.

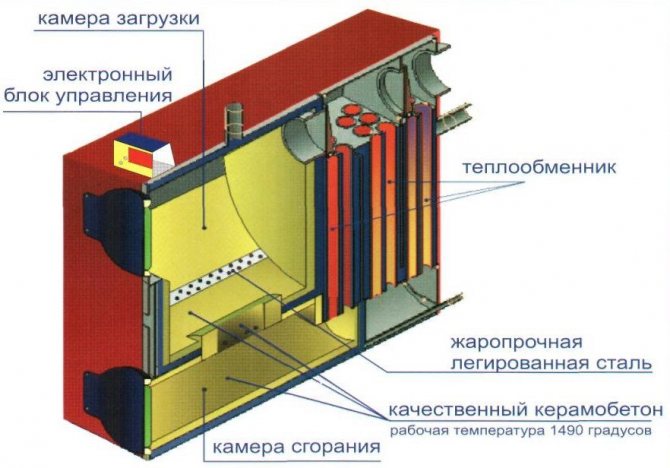

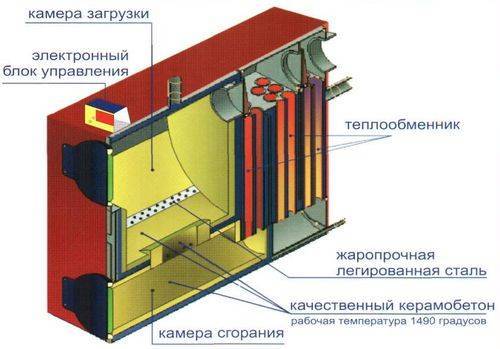

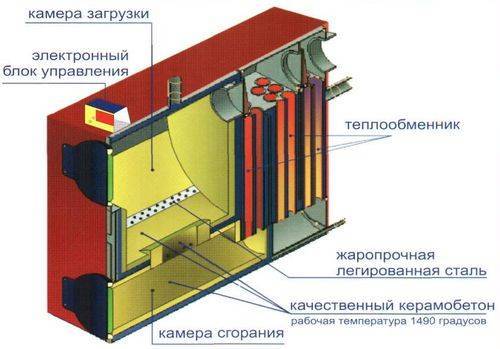

Unit device

The design of the gas generating boiler is a furnace with two chambers, which are separated by cast iron grates. The first chamber is designed for firewood pyrolysis, and the second one is for burning the emitted gas. In some designs, gas chambers are connected to cookers. The main details of such a device are:

- nozzle;

- fan;

- controllers;

- air ducts;

- water pipes;

- chimney.

Read more: do-it-yourself chimney.

In this video, we will consider the principle of operation of gas-fired boilers:

In addition, to ensure the safe operation of boiler equipment, the structure includes: safety valves, pressure measurement sensors, air supply regulators. General control and adjustment of the operational process is carried out using an electronic control unit. Some boiler models have a remote control.

Principle of operation

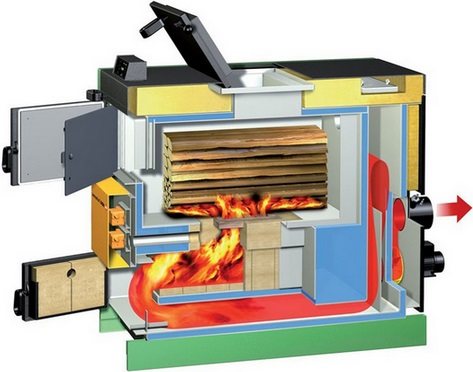

The gas generator boiler uses the principle of "pyrolysis" in its work. This equipment has two combustion chambers, and the fuel being put in goes through several stages of combustion:

- It is dried in a special chamber.

- In the first combustion chamber, the fuel slowly smolders at a temperature of 200-850 degrees Celsius without oxygen - pyrolysis. During pyrolysis, a large amount of "wood" gas is released from the fuel, which then enters the second chamber, where it is successfully burned using a burner and a large amount of air blowing.

- In this case, the coolant and water heating circuit (in double-circuit boilers) is designed and mounted in such a way as to take heat energy from both combustion chambers.

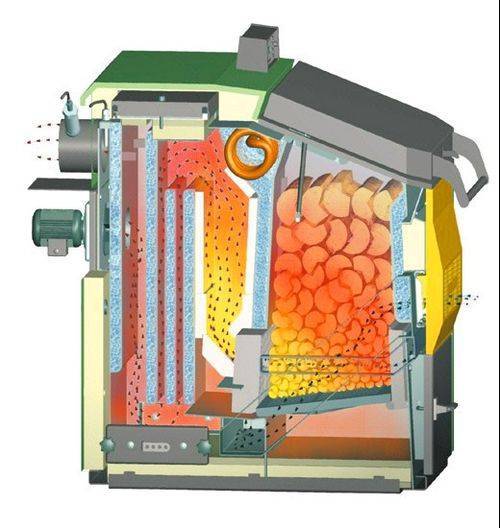

The gas generator boiler can work not only on trees, but also on any wood waste, as well as on briquettes and eco-granules - pellets.

Pyrolysis gas generating solid fuel boilers have the following advantages over other types of solid fuel equipment:

- High Efficiency and almost complete absence of solid combustion waste.

- Fuel availability and replenishment.

- A relatively long period of operation and the possibility of storing a large amount of fuel - the combustion chambers of pyrolysis boilers have a large capacity.

Operating principle

The appearance of pyrolysis or gas generating equipment has clearly shown that the world of high technologies is able to reach even such devices as simple household wood-fired boilers. The improvements to which these units were subjected can be safely called revolutionary. What are they all about? As it turned out, an ordinary wood ingot can be burned in a very tricky way, breaking the combustion process into two stages.

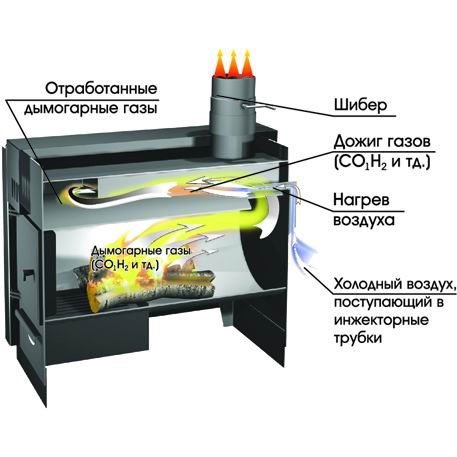

The first is wood smoldering, which is observed when there is a lack of oxygen in the combustion chamber. It is accompanied by the release of a certain amount of heat and, what pleased the inventors most of all, the formation of the so-called wood gas. This process is called pyrolysis or gas generation. Wood gas does not have a specific chemical formula, it is a mixture consisting of:

- carbon monoxide (CO3 - about 57%, CO - about 32%);

- hydrogen;

- methane;

- carbonic acid vapors;

- unsaturated aliphatic hydrocarbons.

About 200 g or 0.15 cubic meters (under normal conditions) of volatile substances are released from one kilogram of firewood. The great thing about wood gas is that it is also a fuel in itself. At various stages of gas generation, its calorific value can reach 4800 cal / cu. m. Combustion of this gas is the second stage of fuel combustion in the gas-generating boiler.

Since the process of formation of wood gas (first stage) and its afterburning (second stage) are carried out under different conditions, differing in the amount of supplied air, pyrolysis boilers are equipped with a two-chamber furnace. In the first chamber, the fuel smolders with gas generation, then the wood gas through the nozzle enters the second chamber, where air is supplied and where it (gas) is burned. The second chamber can be located both above the first (pyrolysis) and below it. Both options have their own advantages and disadvantages.

Units working on pyrolysis technology are a type of so-called long-burning boilers. This name is due to the fact that a portion of the fuel in such a boiler burns longer than in a conventional boiler, gradually releasing the thermal energy stored in it. The main advantage of long-burning boilers is their ability to work for a long time (compared to a conventional boiler) without user intervention, that is, without loading a new portion of fuel. In order to extend this period, a modern gas-fired boiler can combine pyrolysis with the principle of top combustion of fuel. The advantages of the latter can be demonstrated by an illustrative example with two simultaneously lit matches. If one of them is turned with the head up, and the second - with the head down, then the first one will burn a little longer.

The operation of gas-generating boilers on wood is the most effective, but these units can be fired with other types of fuel - coal (brown and stone) or peat.

Principle of operation

And now let's take a closer look at how a gas-fired boiler works.

First, the fuel is put into the combustion chamber and ignited. The fuel ignites, after which the amount of supplied oxygen is reduced so that the fuel does not burn, but smolders.

Pyrolysis gas is released from the fuel and rises to the top. There the gas is collected and oxygen is supplied to it, heated to a certain temperature. A thermochemical oxidation reaction occurs with pyrolysis gas. Pressurized gas is fed into a tube with calibrated holes and ignites when it interacts with oxygen.

At the same time, up to 90% of the small particles contained in the gas burns, which means that harmful oxides (carbon dioxide) slightly pollute the environment. At the outlet, the gas temperature does not exceed 140-160 degrees Celsius. This means that most of the heat goes to heating the premises, and does not go out through the pipe to the street.

On average, one furnace in a solid fuel gasifier is enough for 12-13 hours, and conventional direct-burning stoves support the combustion process for no more than 4-6 hours. At the very bottom there is a sump in which all the remains of the burnt fuel are collected. If necessary, it will be very easy to throw out the remains. Below you can watch a very good video that shows the whole cycle of work.

Summing up

Thus, solid fuel gas generating boilers are very convenient and most likely this direction will develop, and old projects will become a thing of the past. The main plus is the ability to regulate the heat in the house, and not add firewood to the stove by eye. So the house will never be stuffy or cold, which is especially good for sensitive people and small children. New systems will replace old ones, as their use is more economical, environmentally friendly, efficiency becomes higher and power is greater.

Varieties of wood-burning generators

There is a fairly large range of gas generators that run on wood. Here, there are very simple designs in the form of burzhuikas, there are also complex units in which all processes are carried out: from burning wood to cleaning flue gases and their combustion.

For example, a solid fuel potbelly stove. In fact, this is an ordinary potbelly stove with a horizontal jumper divided in half, one end of which does not reach the wall of the stove. A small gap remains, through which the flue gases move into the upper combustion chamber. The second furnace is a system of channels through which gases move from bottom to top. In doing so, they capture fresh cold air entering the boiler from the lower nozzles. It is here that mixing and obtaining of an air-gas mixture takes place. By the way, cold air, passing through nozzles and channels, also heats up, so there is no reason to worry that the mixture will not ignite.

Such a potbelly stove, although it has a good efficiency, is still a low-performance heating unit. It is not recommended to use it for the main radiator heating system. But for warm floors, it is just right.

Pyrolysis oven potbelly stove

For the main heating system, solid fuel pyrolysis boilers of long burning are best suited. The basis of their effective work is a correctly carried out pyrolysis process in the first combustion chamber, where firewood is laid. As mentioned above, they should simply smolder in the firebox, because a small amount of fresh air enters here.

The quality of its combustion will depend on how the fuel will be placed correctly. Therefore, it is recommended to lay firewood as close to each other as possible, leaving minimal gaps between them. The less free space left, the better. There are two types of stacking firewood:

- In rows in a horizontal plane.

- In the form of a cage or well.

So let's summarize. Wood-fired gas generators are undeniably the best option from the category of "solid fuel boilers". They have a fairly large number of advantages over other models in this category. But I would like to note the high efficiency. Even only because of him, it was possible to make a choice in the direction of the gas generator.

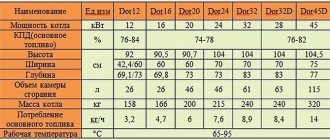

How to choose long-burning gas-fired boilers

First you need to decide what kind of fuel you have at your disposal to a greater extent - wood or coal. If coal is a more acceptable option, you should opt for boilers with upper combustion, and if heating is planned with firewood, it is more profitable to purchase a boiler with lower combustion, since its efficiency is higher than that of the previous one.

Bottom combustion boilers are the most environmentally friendly and economical. This is due to the presence of two or three combustion chambers in them, which provide additional combustion of fuel particles.

A cast iron boiler is more durable, since condensate from coal combustion causes corrosion of steel. In addition, steel heat exchangers burn out faster. Cast iron boilers consist of sections, which, in case of possible depressurization, makes it possible to simply replace the damaged part (while steel boilers require complete replacement); also, this fact provides ease of transportation in disassembled form (however, it should be remembered that cast iron parts are fragile and sensitive to shock).

If you need a boiler that provides heating and and supply of hot water to the house, a double-circuit solid fuel boiler is suitable. The principle of its operation is as follows: the first circuit (for heating the room) turns on when the heat sensor is triggered; the second (for hot water supply) is activated when the pressure drops.

If the house has a working boiler, then it can be connected to a heating boiler. On the one hand, this will give great savings on the heat source, on the other hand, it will ensure a stable water supply.

To determine what boiler power you need, proceed from the calculation of 1 kW for every 10 sq. m (with wall heights up to 3 m). It should be remembered that the boiler power itself varies depending on the calorific value of the fuel and its moisture content.

Reviews of household gas-fired boilers: advantages and disadvantages

The concern of the world community with the problem of environmental pollution has strengthened the position of pyrolysis boilers in the market for long-burning units for heating. According to the operating practice and reviews of the owners, with the correct functioning of this type of boilers, a small amount of carbon dioxide and steam gets into the atmosphere. Burning any organic fuel, from the chimney such a unit produces a minimum of unburned substances without burning, without smoke, odor and color. The result is also manifested in emissions into the boiler room, for example, when refueling fuel, and especially in the pollution of the boiler itself and the frequency of its cleaning.

| Benefits | disadvantages |

| Due to the afterburning of pyrolysis gases, the efficiency can reach 95%. | The cost of equipment is 1.5-2 times higher, although it pays off relatively quickly |

| The enlarged loading chamber allows you to work longer with one bookmark (1.5-3 times) than with conventional units | High costs for the preparation of fuel for moisture. It should not exceed 20%, otherwise the pyrolysis process will not take place |

| The fuel burns out almost without residues and the design of the combustion chambers makes cleaning and maintenance less frequent and easier. | Most industrial and domestic highly automated units use blower fans and smoke exhausters, which makes them dependent on power supply |

| High temperatures require a heat exchanger made of heat-resistant steels, which makes it possible to heat the building faster | At a low temperature of the coolant in the return pipe, the boiler may go out, it is necessary to add hot water through a three-way valve or bypass. |

| Combustion product emissions are minimal | Overall dimensions and weight are significantly higher than those of other types of boilers |

| Units can operate on any fossil fuel without significant alteration, but with different efficiency | At low loads (less than 50%), it is difficult to obtain stable combustion |

| High efficiency assumes economical fuel consumption and lowers fuel costs | |

| The high level of automation of the boiler operation allows less frequent monitoring of the combustion process |

Self-assembly

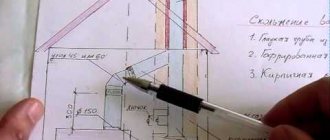

To independently install a solid fuel boiler, you must take into account several rules.

- It is better to place such a boiler in a separate room. This can be a room inside the house or in the basement. A former children's bedroom or any other small room (the required area is 8-10 square meters) is suitable for this, if a special room for heating devices is not allocated during construction.In the most extreme case, you can simply partition a large room in half (it is advisable to make the partition brick, and not use drywall), making one or two exits - inside the room, on the street, or both at once.

- The floor of the room where the installation is planned must be made of fire-resistant materials. And the boiler itself should be installed directly on a concrete screed (about 10 cm thick).

- It is necessary to provide the room with forced ventilation, power supply and water supply, if they are not available.

- If the boiler is not installed in a specially designed boiler room, a chimney must be purchased and installed in advance.

Getting started with the installation, you need to prepare the tools and equipment that you will need for this: electrodes, welding, level, keys, screwdrivers, meter, saw for metal, screws, - as well as materials: plumbing tape, metal sheet and sealant.

- Unpack and prepare for assembly the parts that come with the boiler.

- Place a metal sheet on the floor at a distance of at least 0.5 m from the side wall (s) and 1 meter from the front and fix it securely.

- Place the boiler evenly on a metal sheet, checking that it is level.

After the preparatory work, the boiler itself is assembled directly:

- Wrap the combustion regulator with one turn of plumbing tape, fasten with a screw, set the temperature to 30 degrees.

- Install the thermostat and ten or their plugs.

- Assemble the air and safety valves, pressure gauge into a safety group.

- Install the tap and connect it to the pipes.

- Connect a security group in front of the locking device.

- Connect the boiler to the chimney using sealant.

- Push in the draft flap and the cleaning plug.

- Connect the water and check the tightness of the system.

- Light the boiler by closing the damper.

- It remains only to check the quality of the installation and operation of the boiler and to carry out pilot heating.

In order to determine the approximate cost of materials and equipment required for installation, below is their approximate price.

- Heat-resistant sealant 100-200 rubles.

- Sheet of metal (3 x 1,250 x 250) about 3,000 rubles.

- Plumbing tape about 500 rubles.

- Long-burning boilers 60,000–120,000 rubles.

- Transition steel 57-32 30 rubles.

- Steel bend Du-5016 from 100 rubles.

- Ball valve Du-15 from 100 to 1,000 rubles.

- Ball valve with squeegee Du-50 about 2,000 rubles.

- Chimney for a solid fuel boiler 20,000-50,000 rubles.

The choice of heating boilers should be based on the availability of a particular type of fuel in the region or its availability in the home. Heating with solid fuel boilers using firewood is second only to gas-powered devices in cost, electricity and diesel fuel are more expensive, and coal-dependent units round out the top five. Last but not least, this is due to the fact that solid fuel boilers have insufficiently high efficiency rates (compared to electric ones, for example). However, two-tier combustion systems can save fuel consumption by up to 9%.

The most environmentally friendly heating devices among solid fuel ones are pyrolysis gas-generating boilers, since the fuel they use burns out almost completely, which reduces the level of air pollution.

The video shows how gas-fired boilers work:

Installation and maintenance rules

To install a solid fuel heating boiler, it is necessary to prepare a special room. Its area should be at least 15 m2, a ventilation system is installed with a circulation rate of 3 furnace volumes per hour. The entrance to the premises is separate. Walls and floors of the boiler installation site are protected with non-combustible materials.

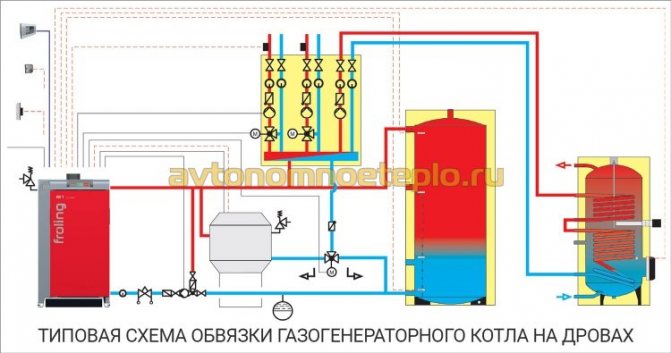

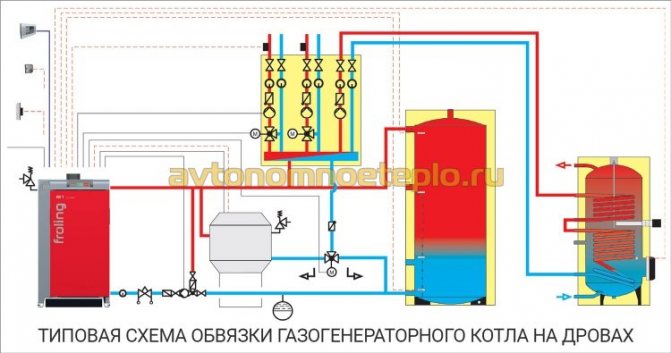

Gas generating equipment is used only for the forced heating system. Recommended strapping is shown in the figure.

Additionally, during installation, the following factors must be taken into account:

- The location of the boiler in relation to the level of the heating radiators does not matter. But it is desirable that it is below them.

- Fuel storage in a separate room. It is allowed to store a small amount of firewood in the furnace, but in a protected place.

- For automatic regulation of heating power, it is recommended to install temperature sensors in the rooms of the house connected to the boiler control system.

After installation, the heating is pressurized and a test run of the system is done. Subject to the rules of installation and operation, system maintenance will not take much time. It is important to promptly clean the ash pan of combustion products, monitor the water level in the pipes and check the performance of protective components: air vents, drain valves and an expansion tank.

Which boiler is better

Considering solid fuel boilers of long burning, the rating of the best on the Internet or from the lips of a representative for their sale will be somewhat ambiguous. There are numerous ratings of solid fuel heating boilers for a private house, which are based on different criteria. For example, the volume of sales in the market, surveys of owners, expert assessments of specialists in reliability and efficiency. But to say unequivocally that some model is "the best" is at least incorrect. At least because of the different principle of operation and a subjective approach when choosing boiler equipment.

Russian boilers are simple, but reliable, and are considered by specialists to be one of the best in their class in terms of price / quality ratio

If energy independence, low price and unpretentiousness to the type of fuel are important, then this should be a traditional boiler design with natural draft. And in this case, you can limit yourself to a choice among domestic manufacturers, such as ZOTA, Bourgeois K or Lemax.

Advice!

In order to get the maximum efficiency of the heating system, it is necessary to choose a pyrolysis boiler. But if you "give up" the efficiency indicators a little in order to get in return more reliable and stable equipment with a long operating cycle from one load, then the best option is a long-burning boiler.

And for lovers of comfort, and simply busy people who have little time to care and maintain the heating system, we can recommend pellet boilers.

The pellet boiler, even in compact form, is capable of operating autonomously for a long time.

But even with this division, there are also additional criteria. So, for example, according to one of the specialized online publications, the rating of pellet heating boilers for a private house looks like this:

the best in terms of price / quality ratio - ZOTA PELLET 100A (Russia);

the best in terms of reliability and a set of options - ACV TKAN 100 (Belgium);

the best compact model (without a bunker) in terms of price and efficiency (when switching to firewood, it can work as a pyrolysis boiler) - PELLUX COMPACT (Sweden).

This might be interesting!

In the article at the following link, read about wood-fired boilers for home heating.

Choosing a gas fired wood burning boiler

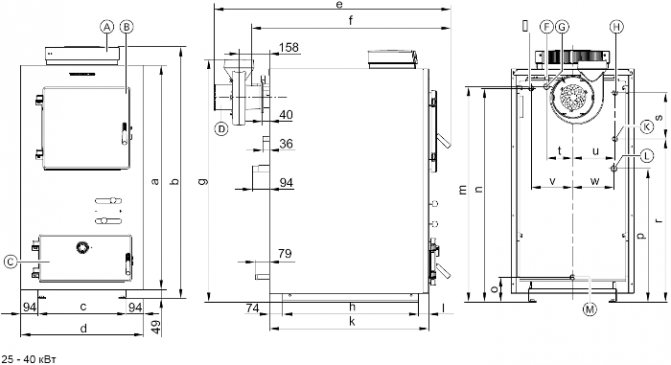

The correct choice of a gas-fired wood-burning boiler, due to the wide range of products offered, can be quite difficult. Various nuances are taken into account: power, operating time from one tab, the presence of additional functions and automation of the combustion process.

It will not be superfluous to pay attention to the presence of a backup heat source in the design, in the form of an electric heater.

For heating and hot water, double-circuit units are suitable. In some models, there is no DHW circuit. Then, in addition, an indirect heating boiler is purchased and connected to the structure, which requires additional costs. All this is taken into account even before purchasing the boiler model you like.

Recommendations for calculating power

Calculations are made according to the formula 1 kW = 10 m².This ratio takes into account the parameters of a building with an average amount of heat loss and a ceiling height of no more than 2.7 m.In addition, the following aspects are taken into account:

- The presence of a DHW circuit - a wood-fired gas-fired heating boiler for 10 kW, suitable for a house of 100 m². But, if you plan to additionally heat up hot water, add 10-20% to the result. Accordingly, a heat generator with a capacity of at least 12 kW is required.

- Additional heat loss - with independent calculations, the lack of good thermal insulation of the building, the presence of a large number of doorways and windows are often overlooked. All this affects the heat costs.

Accurate calculations are performed using online calculators that take into account all sorts of nuances: the quality of the house insulation, the number of window and door openings, the location of the heated building, etc.

Selection by country to manufacturer

The best gas-fired boilers are made by German and Czech companies. Despite the high cost, the same Buderus or Viessmann remain one of the most demanded units.

Domestic boilers Bastion, ZOTA, Topol M are significantly inferior in their heat engineering characteristics and service life to Western counterparts.

The cost of a gas-generating wood-burning heating boiler of German production, for 20 kW, will cost approximately 100-120 thousand rubles. Domestic analogue of approximately 40 thousand rubles.

Pros and cons of gas-fired boilers

The main advantage of gas generating equipment is the ability to connect to an existing hot water heating system. Installation work does not require serious material costs. Once connected, a savings of about 30% is achieved in reducing fuel consumption.

New technologies are widely used in the design of European units that increase the comfort of operation, make kindling and control of combustion as convenient as possible.

The disadvantages are the high cost of production (which especially concerns German and Czech boilers), as well as high requirements for the quality of fuel. The experience of operating a domestic consumer shows that the use of gas generating equipment in the conditions of Russian realities is not only a possible, but also an economically profitable solution.

Pros and cons of solid fuel boilers

Now let's look at the advantages and disadvantages that solid fuel boilers have.

Positive points

- For the price they have superiority over gas and electric.

- Long service life.

- Safe use.

- There is no need for additional electricity or gas.

- Fuel is affordable and can be purchased in the required quantity.

- Some models can work for about three days with a single load.

- An environmentally friendly heating method.

Negative points

- Insufficiently high level of efficiency.

- It takes time and effort to clean the device, as well as to prepare and load fuel.

- The need for multiple loads, in which smoke may enter the room.

- Lack of thermoregulation.

- It needs a long warm-up after a long pause in work.

- There is no way to quickly increase or decrease the temperature.

Installation and fire safety

The indication of the correctness of the assembly is the indication of the exit to the mode of the heat-generating device. This process should take a few minutes, and the heating of the entire heating system should take no more than half an hour. There is also a rather sharp rise in temperature in the heated room.

At the first start-up, you need to set the efficiency of the new unit. This indicator indicates the absence of deviations and shortcomings in the installation work.It is determined by the state of the flue gases coming out, which should not have a suffocating odor of carbon monoxide (carbon monoxide). This condition must be met in all operating modes.

Gas generating boilers are installed in a separate non-residential area that meets all fire safety requirements. They suggest:

- the presence of ventilation (opening with an area of at least 10 cm2);

- installation of a protective cover in front of the combustion chamber (metal sheet 2 mm thick);

- pouring a concrete foundation for a boiler or creating a solid brickwork;

- the presence of a space between the wall and the boiler of at least 20 cm, as well as pieces of furniture and other structures.

Also, the room must have access to the power supply to connect the fan. If it is not possible to supply electricity, you can mount a long chimney. But then there is a problem with its fixation and the sufficiency of the resulting thrust. Pyrolysis boilers have become a successful symbiosis of a rustic stove and progressive energy-saving technologies.