The house should be warm. This is the first condition for choosing the type and brand of the boiler. Not all boiler types are equally suitable for heating buildings with different heat capacities. Do not assume that the higher the boiler output, the better. To maximize the efficiency of the boiler, it needs to give off the nominal amount of heat, if this does not happen, then the situation is fraught with consequences: from too high fuel consumption by the boiler, to overgrowing of chimneys with a thick layer of soot.

Currently, the problem of matching boilers to a heated room looks somewhat paradoxical. A large number of types and brands of boilers have a very high power, while modern houses and cottages built of high-quality materials, competently insulated taking into account all climatic conditions, require much less energy for heating than houses built 20 years ago, and even more so , wooden huts of the last century, which nowadays often become not just summer cottages, but a year-round haven for young pensioners who decided to move to the countryside. The same applies to a huge number of houses built during the "garden boom" in dacha cooperatives and collective gardens, because now registration is allowed in SNT and many are moving to permanent residence on their 6 acres. Naturally, different types of buildings require boilers of different capacities, but not all homeowners know which one. In addition, boilers of higher power are more expensive than sellers often use, recommending a device that is redundant for your conditions.

It is important to remember that heating a well-insulated home does not require a huge amount of energy. And in order to burn all substances present in solid fuel, a sufficiently high temperature is needed in the boiler itself. And here it turns out to be a vicious circle: when burning, fuel releases an amount of heat that is excessive for your home. There is something to think about!

In order to heat a well-insulated house in accordance with modern standards, a thermal power of 60-70 W per square meter of heated area is sufficient. Thus, for a private house with an area of 150 square meters, a boiler with a nominal power of 10 kW is suitable. And such a boiler is not easy to find. The power of most of the boilers available on the market exceeds this figure, they provide a heat output of about 100 W / m2, which will be too much for your home. And then, most of the time, this boiler will operate at reduced power, which will definitely not improve its technical condition.

Moreover, these values are more likely to apply to very low temperatures. In autumn, spring, and in winter in the southern regions of our country, these values are significantly lower. Under such conditions, to heat a house with an area of 120-160 sq.m. built in compliance with all technical standards, 3-4 kW are enough. A simple manual boiler with a nominal output of a few kilowatts operates with only 40% efficiency under these conditions. So that the house is not too hot, it is necessary to limit the flow of oxygen into the boiler, which allows the fuel to burn longer, but this does not mean that then less fuel is consumed. Due to the lack of oxygen and low temperature in the chamber, unburned compounds settle on the walls of the boiler and chimney, forming a large amount of soot, tar and soot. You need to find a solution that will save you from such problems.

Types of solid fuel boilers

A solid fuel boiler is one of the most economical options for heating a private house. Heating a room with gas or electricity is not always cheap. And also in the absence of the possibility of connecting gas, the acquisition of a solid fuel boiler remains practically the only profitable option. This heating equipment is divided into several types:

- Heating boilers, into which you need to load fuel yourself. They are divided into 3 types: top-burning pyrolysis boilers, classic boilers and long-burning boilers.

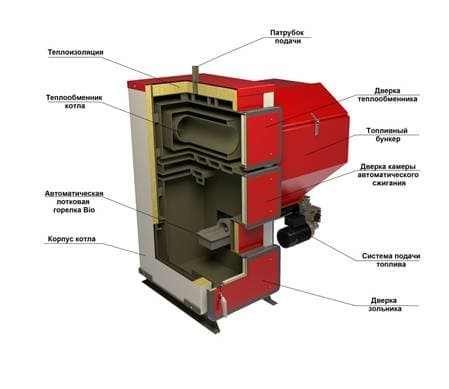

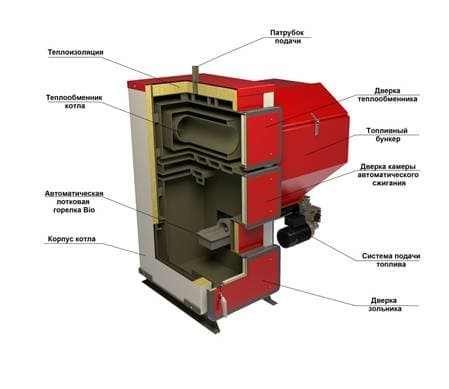

- Pellet boilers. They are also called boilers with automatic fuel supply. In such equipment, fuel is supplied automatically. The boiler operates on solid granular fuel.

Choose solid fuel heating boilers according to the main parameters:

- The type of fuel on which the equipment will work efficiently;

- The time during which the fuel will burn with one load.

And also when buying a heating boiler, you should pay attention to the following nuances:

Unfortunately, solid fuel heating boilers are only of floor type. Wall-mounted boilers of this type are not produced. Perhaps this factor is a disadvantage of such equipment, since it will take up a lot of free space in the room.

We light the flame

The operation of the boiler without automatic loading is, in principle, the same in both cases - when it is a coal boiler and when it is a wood boiler. First, you light a small amount of fuel, and then, when the kindling is hot enough, add the main portion of coal or wood. You should check from time to time how the boiler burns, whether there is enough fuel. The intervals of such inspections depend on many parameters: fuel moisture, wood species, coal fraction, size of the loading chamber, even on the ambient temperature. Moreover, a new tab should be added when there is still enough heat in the firebox for the next batch to ignite without the use of additional ignition. It is just as easy to "stifle" the flame if you "throw in the wood" carelessly.

After refueling the boiler, the fuel requires an additional volume of air in order for it to ignite faster. The device of boilers with manual fuel supply, however, allows you to adjust the height of the flame, and therefore the combustion power. Temperature sensors and special fans, the so-called "smoke exhausters" (which, by the way, also facilitate the process of fuel ignition, especially if the natural draft in the chimney is too weak), also help in this.

And, of course, you should clean the ash from the boiler. How often - it depends on the type of fuel, in the case of wood, for example, before each new start of the boiler.

The operation of an automatic fuel feed boiler is obviously much simpler, but in this respect the differences between coal and biomass boilers are significant.

The task of automating the supply of coal to the boiler has been faced by the developers for a long time. The main problem is that it is practically impossible to achieve the same size of lumps of coal, even if we are talking about the same fraction. To solve this problem, various methods are used, for example, some boilers are equipped with a system for crushing larger pieces of coal. Nevertheless, any automatic coal boiler requires the use of fine coal, which is also a certain limitation in the choice for the consumer.

The coal boiler feeder should be filled every few days, depending on the size of the hopper, coal fraction and outside temperature. There are boilers in which the combustion process is fully automated - from fuel ignition to ash discharge, some are only partially automated. Currently, the control of boilers is taken over by electronic controllers, which "monitor" the precise implementation of all boiler settings.This is helped by a system of thermostats, which transmit the values of the set temperature and allow the boiler to automatically turn off when it is reached and start operation if the temperature has dropped. In any case, it is up to the user to define the required parameters and set them. The important point here is that this is ultimately controlled by the amount of fuel supplied to the chamber, and not by limiting or increasing the flow of air. This saves fuel and makes the boiler exhaust cleaner.

The operation of an automatic pellet boiler is much more pleasant than a similar coal-fired boiler. First of all, there are no problems with feeding the pellets into the firebox, because they are all the same size. Stuck pellets in the feeder or on the conveyor, unlike coal, is quite rare. Usually the size of the bunker is enough for 3-4 days, but this is far from the limit. If the boiler room does not have a place to store a large amount of pellets, this problem can be solved by using a conveyor that will move the pellets from the outside. By the way, using pellets instead of coal will save your home from the ubiquitous black dust, which is very important in itself.

Pellet boilers are equipped with a hopper and auger for fuel supply. Most often, the bunker in the basic configuration of the boiler is not too large, however, its volume can be increased, taking into account your requests, which will not be difficult. The meaning of increasing the volume of the bunker is to increase the period of autonomous operation of the boiler. When the boiler reaches the rated power, the temperature in the chamber reaches about 1200 degrees. Air is supplied through the holes in the thickness of the granules with the help of a fan. After reaching the operating temperature, the air supply is stopped by the air damper and the auger drive is turned off. Some boiler models can be in this state for up to 12 hours, since they are able to maintain a constant temperature in the burner. Equipped with a thermal sensor system, pellet boilers are just as easy to set up as coal ones.

The maintenance of the pellet boiler is even easier: due to the low ash content and dryness, the pellets do not form a large amount of ash during combustion. Such a boiler can be cleaned once a week, and ash, unlike coal slag, is a valuable mineral fertilizer. It contains calcium, magnesium, potassium, phosphorus, sodium, which are extremely beneficial for plants, adding it to the soil helps to lower the pH level.

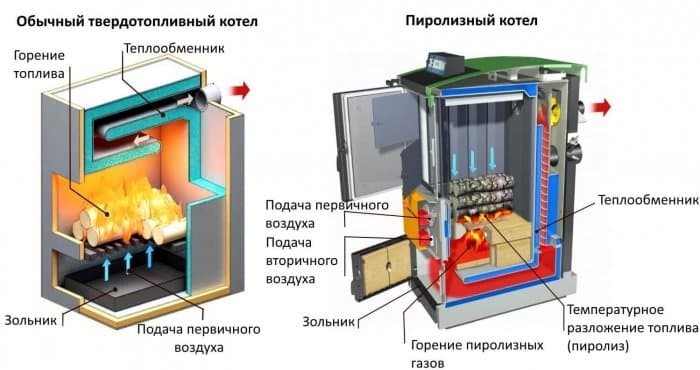

Pyrolysis boilers

This type of solid fuel boiler runs on gas, which is obtained by burning fuel and lack of oxygen. The device is equipped with two chambers, which are separated by grates. An upper combustion chamber and a lower chamber in which gas is burned. The upper chamber is used to load fuel. After it ignites, and then the fan automatically starts to work.

Under the influence of high temperature, the tree begins to burn and release gas. It, in turn, moves down through the nozzles, and then mixes with air. As a result, the mixture once again heats up the fuel in the upper chamber. Due to the lack of air, the fuel is gasified and decomposed.

Pyrolysis solid fuel boilers are complex devices. To increase the burning time, a tree with a thickness of less than 10 cm is used. In order not to disrupt the operation of the device, it is necessary to load it with a power of 50 to 100%. It is recommended to use other heating devices during the off-season.

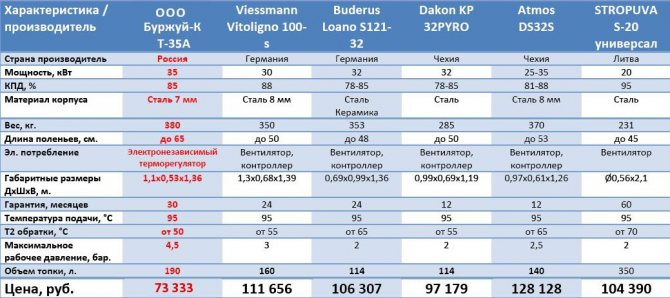

In pyrolysis boilers, some features are distinguished:

- The burning time of the fuel of one load is equal to 10 hours.

- Full boiler load is required.

- The wood must be dry.

- High price.

- High efficiency. It can be as high as 90%.

- Environmental friendliness of the equipment.

The pyrolysis boiler includes: controller, smoke exhauster and electronic control.

With a heated area of 150 sq. m.

Protherm Bober 50 DLO 39 kW

pros

- durability

- reliability

- does not need to be connected to the mains

- ease of use

- versatility

Minuses

- bottom heats up

From 105,000 ₽

A floor-standing boiler runs on coal or wood and is very often used in heating systems for small country houses. The large heating surface area of the two-wire cast iron heat exchanger ensures high efficiency.

ZOTA Master 20 20 kW

pros

- the ability to use long firewood up to half a meter long

- possibility of installing a gas burner

- installation of electric heating elements

- automatic traction regulator

- relatively low price

Minuses

- low efficiency when working on gas

- inconvenient in operation

- strong slag, blurring of the room during kindling

From 26500 ₽

The "Master" boiler is a new improved version of the "Dymok" boiler. The line consists of six models with a capacity of 12, 14, 18, 20, 25, 32 kW. This version of 20 kW is not equipped with a hob with a removable burner, unlike the others.

Teplodar Kupper Praktik 20 20 kW

pros

- fast heating of the coolant

- relatively low weight

- large internal load

- firewood up to 40 cm

- the ability to insulate the sides if convection is not needed

- additionally a draft regulator is installed

Minuses

- The efficiency does not correspond to the declared

- too hot gas outlet

From 18 800 ₽

The "Kupper PRAKTIK" boiler is universal. It works in both closed and open forced circulation heating systems. The main fuel is wood and coal. The additional equipment of the boiler includes a 6 kW heating element unit.

Classic boilers

The most popular type of solid fuel boilers is considered to be classic. Heat is spread by burning solid fuels. Such boilers are made of steel or cast iron. Moreover, heat-resistant steel is used. Classic boilers can heat the house and heat the water. This boiler can operate on wood, coal, pellets or peat. The most profitable option is coal heating. Since when using firewood as fuel, the combustion process will be much faster. The boiler with one load can work from 2 to 6 hours.

Using a temperature sensor, you can maintain a certain temperature regime and adjust the air damper. If the temperature drops, the damper will open with the help of the sensor. On the contrary, if the price rises, an opening will occur. Classic boilers are independent of gas and electricity.

For more efficient heating, some models have a built-in fan, control panel and an electronic temperature control sensor.

The advantages of this solid fuel boiler include:

- Large selection of manufacturers, models.

- Low cost of equipment.

- High-quality manufacturing technology.

- Easy to operate.

- Low fuel costs.

- Large selection of fuels.

- No electrical connection required.

But there are also several disadvantages:

- Self-loading fuel.

- Fuel delivery and preparation.

- Frequent loading of fuel.

- Availability of a place where fuel will be stored.

- The inertia of fuel combustion.

Despite some shortcomings of this model, it is the most demanded due to its high efficiency and low cost.

Buderus Logano G221-25

Main characteristics:

- the use of coke, coal or dry wood;

- Efficiency in the range of 75–78%;

- equipment performance when operating on wood, coke and coal 23 kW, 26 kW and 24 kW, respectively;

- outdoor installation;

- the length of the logs placed in the firebox: up to 41 cm;

- dimensions: 110 × 60.5 × 92 cm;

- boiler weight: 278 kg.

Description

The G221-25 boiler is completely autonomous, and its operation does not depend on voltage surges, or on gas or electricity cuts.It is equipped with an open combustion chamber, which implies air intake directly from the room and removal of flue gases due to the draft of a vertical chimney.

The operating time of the equipment on one fuel load reaches several hours - it can be increased by switching to an economical mode of operation or by additionally installing a loading hopper. And due to the stylish painting with heat-resistant blue enamel, the boiler of the new generation looks great in the interior of any room where it is installed.

Advantages and disadvantages

The main advantages of the model are the increased corrosion resistance of the body and heat exchanger material (cast iron), ease of use and increased dimensions of the furnace. In addition, for ease of use, the firebox door can be hung on both the left and right sides. And the disadvantages of the model can only be called a significant weight (310 kg) and a high cost.

Installation nuances

The boiler can be installed both separately and together with other types of heating equipment (gas, liquid fuel or electric) in residential, domestic and industrial premises. And Buderus Logano G221-25 can be used in pumping and gravitational water heating systems.

The equipment can be mounted independently, even without welding. However, due to the need to comply with a number of rules, this is not recommended. And the installation should be carried out by qualified specialists familiar with the process of installing solid fuel boilers in heating systems.

Price

The average cost of a boiler is approximately 80 thousand rubles, depending on the store. If you wish, you can find this model for 75 thousand.

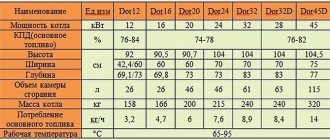

Long burning boilers

Long-burning boilers can operate on different types of fuel: wood, sawdust, drill, coal, etc. But there are models that are designed to work on wood. They differ from other boilers in the material from which the combustion chamber is made, as well as in the air supply system.

One load can be 50 kg of fuel, and the burning time of firewood varies from 12 to 48 hours. If coal is used as fuel, then it will burn from 4 to 7 days. If you reduce the combustion rate of the fuel, the boiler output will decrease. This option is suitable for light frosts.

The fuel burns from top to bottom. Therefore, these boilers work for a long time with one load.

Long burning boilers have the following advantages:

- Low cost of the boiler in comparison with pyrolysis ones.

- Long fuel combustion.

- They do not depend on the mains supply.

- Ash does not need to be removed more often 2-3 times a month.

- The power regulation is deep, in contrast to the classic boiler.

The disadvantages include:

- Low efficiency.

- Installation of a circulation pump.

- The boiler operates in a full cycle. This means that it is impossible to add fuel to the equipment.

When changing the burner, you can easily switch to another type of fuel. To do this, it is necessary to change the burner, and then reconfigure the automation.

Views

Consider the main types of solid fuel boilers. Among them, the main 4 types can be distinguished: classic, pyrolysis, long-burning boilers and automatic.

- Classic boilers. In such devices, the basic principle is that heat is supplied through the fiery combustion of the fuel. It has two doors: one is intended for loading fuel, the other for cleaning from ash and other combustion products. They work on wood and coal, and they can be distinguished by the material used in the manufacture - cast iron or steel.

- Pyrolysis. The principle of pyrolysis - it is on it that the work of the next type of boiler is built. This principle is the decomposition and gasification of solid fuels. This process takes place only with a closed chimney and combustion chamber. Pyrolysis boilers have a high level of efficiency (90%), and the duration of combustion can reach 10 hours.Very easy to operate: the courtyards completely burn out on their own, autonomous regulation of the coolant temperature.

- Long burning time. How is the duration of the combustion process ensured? It's very simple. Now there are two combustion systems: Canadian and Baltic. The Baltic one is not used too often, as it is too expensive, but the Canadian one has quite good indicators. The cost of such heating systems is absolutely adequate, there is a wide range of products. In general, any whim for your money.

- Automatic. Fully automated boiler operation: from loading fuel to cleaning the device from combustion products. Such boilers, as a rule, are equipped with an auger or conveyor hopper (which is why the automatic cleaning of the apparatus from ash is ensured). They are easy to operate, they do not require constant supervision, they often come with a temperature regulator. An excellent option for any private home.

Boilers with automatic fuel supply

Such boilers are quite popular for heating private houses. With the help of a screw or transport bunker, the fuel is automatically fed. Fuel burns with one load from 3 to 10 days. Boilers with automatic fuel supply are highly efficient. It can be 85%.

For safe operation, it is necessary to install the boiler in a separate room and install a fireproof ash collector. This boiler has a high cost, and is also dependent on the power grid. As fuel, you can use: wood or other pellets of combustible materials and granular coal. Such fuel is more expensive than others.

In order to prevent overheating of the boiler, it is necessary to fill the firebox with firewood gradually. Since they quickly ignite, and this leads to the release of a large amount of heat. If you use coal as a heat carrier, then it burns slowly and gradually. Therefore, the temperature in the furnace will be the same throughout the entire combustion.

disadvantages

Despite the obvious advantages over similar gas and electric devices, solid fuel boilers also have a number of disadvantages.

For example, the owner of a private house will have to equip a place to store a solid supply of fuel in order to ensure the smooth operation of a solid fuel unit.

Such a boiler needs constant fuel loading.

You will often have to visit the boiler room to throw firewood and coal. If a long-burning boiler is used, the efficiency may be equal to only 70% - this indicator may not be enough to maintain a comfortable temperature inside the room.

In some cases, it may be necessary to install additional equipment. For example, to create additional thrust, a turbine is often installed, which consumes electricity during operation. As a consequence, additional costs for paying bills.

A solid fuel boiler must be regularly cleaned and preventive maintenance, while gas and electrical equipment practically does not need maintenance.

You will also have to equip a separate room (boiler room) for the boiler, in accordance with fire safety standards.