What is the risk of excess moisture in the soil

You can see the results of this phenomenon yourself - trees and shrubs perish. Why is this happening?

- the oxygen content in the soil decreases and the carbon dioxide content increases, which leads to a violation of the air exchange processes, the water regime and the diet in the soil;

- oxygen starvation of the root-forming layer occurs, which leads to the death of plant roots;

- the intake of macro and microelements by plants (nitrogen, phosphorus, potassium, etc.) is disturbed, because excess water washes away mobile forms of elements from the soil, and they become inaccessible for assimilation;

- there is an intensive breakdown of proteins and, accordingly, the processes of putrefaction are activated.

Plants can tell you what level the groundwater is at

Take a closer look at the flora of your site. The species inhabiting it will tell you at what depth the groundwater layers are located:

- top water - in this place it is best to dig a reservoir;

- at a depth of up to 0.5 m - marigold, horsetails, varieties of sedges - bubbly, holly, fox, Langsdorf reed grass grow;

- at a depth of 0.5 m to 1 m - meadowsweet, canary grass,;

- from 1 m to 1.5 m - favorable conditions for meadow fescue, bluegrass, mouse peas, ranks;

- from 1.5 m - wheatgrass, clover, wormwood, plantain.

What is important to know when planning the drainage of the site

Each group of plants has its own moisture needs:

- at a depth of groundwater from 0.5 to 1 m, vegetables and annual flowers can grow in high beds;

- the depth of the water layer up to 1.5 m is well tolerated by vegetables, cereals, annuals and perennials (flowers), ornamental and fruit and berry shrubs, trees on a dwarf rootstock;

- if the groundwater is at a depth of more than 2 m, fruit trees can be grown;

- the optimum depth of groundwater for agriculture is from 3.5 m.

Do you need drainage of the site

Write down your observations at least for a while. You yourself can understand how much drainage is needed.

Maybe it makes sense to simply redirect melt and sedimentary water along a bypass channel, rather than letting them flow through your site?

Perhaps it is necessary to design and equip a storm drain and improve the composition of the soil and this will be enough?

Or is it worth making a drainage system only for fruit and ornamental trees?

The exact answer will be given to you by a specialist, whom we strongly recommend to call. But after reading this article, you will gain some awareness of this issue.

At the end of the technological and production tasks related to the arrangement of the sewer system in an apartment building, industrial building, as well as in a private household, it is required to test the involved system by the forced spill method. This task was applied to identify possible defects or improper installation of the entire sewer part involved, and the test report for internal sewerage systems and gutters will be material evidence of the acceptance of the facility.

Visual inspection should be accompanied by the introduction into the certificate of testing of internal sewage systems and gutters according to SNIP, which is currently represented by the current regulations of the series "D" appendix, which corresponds to SP 73.13330.2012 "Internal sanitary-technical systems of the building", recently a new one has been applied updated working edition for SNiP 3.05.01-85.

The vegetable pit is for storing vegetables and fruits. It is not difficult to build it with your own hands.Dryness and good air exchange are important criteria for saving crops. When creating conditions for a good microclimate, one must be wary of sudden temperature changes. Ventilation in the vegetable pit will help to avoid unpleasant odors and stale air, as well as mold.

Optimum temperature in the cellar

The optimum temperature for cellars is within + 2-5 ° C. Different products have their own optimal storage temperature and for some vegetables it is in the range from 0 to + 2 ° C. Sometimes, when storing vegetables and fruits, it turns out that in different sides of the room, the temperature is slightly different. This can be used and put a partition there, which will increase the temperature difference in one room. In this way, products can be stored in the most favorable conditions for each type.

Of course, food is well stored at the optimal temperature, but you need to remember that during storage, vitamins and minerals are lost in them. Some of the vitamins begin to break down within three hours after the vegetables or fruits have been plucked, and no even ideal storage conditions will return these vitamins.

The optimum temperature in the cellar is also maintained by ventilation. If the cellar gets very cold during ventilation, it is insulated.

I would be glad if the article was useful to you. Below I propose to view other useful articles on the topic.

Additional Information

Harvest storage can be a serious problem for a summer resident. The most reasonable way out is to build and equip a convenient basement for storing vegetables.

What is it intended for and what characteristics it should have

Fruit and vegetable products purchased or grown with their own hands must be stored somewhere in the winter. Refrigerators are used to store winter preparations and fresh vegetables in small quantities. However, a bag of potatoes and a few boxes of garlic and onions won't fit in the refrigerator. Therefore, you have to independently build a special room where you can place the twists with vegetables. The microclimate in such cellars allows keeping the harvest fresh for 4-5 months.

The constructed storage facility must have the following features and characteristics:

- temperature indicators should not exceed four degrees Celsius;

- the humidity level inside the cellar should be in the range of 90-95%;

- it should always be dark inside the vegetable pit, and therefore the lighting is turned on only when a person is inside;

- the cellar is equipped with a high-quality ventilation system that will ensure normal air circulation.

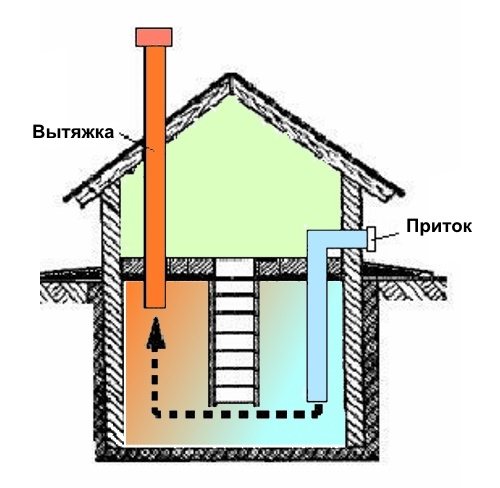

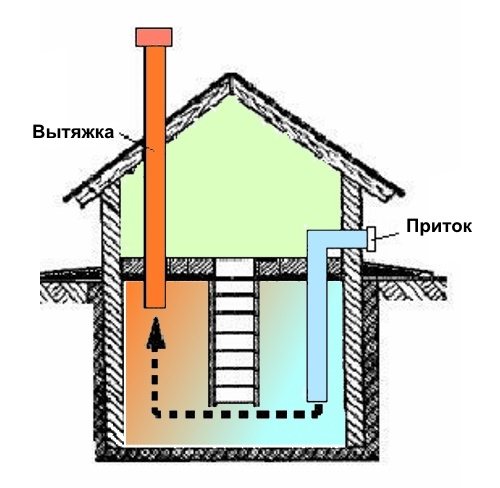

Natural ventilation of the cellar in the garage

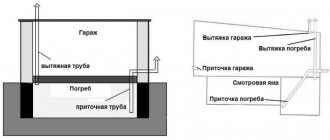

If the cellar is in the basement, then two types of ventilation can be used:

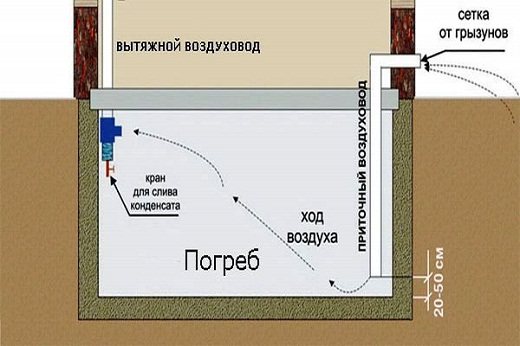

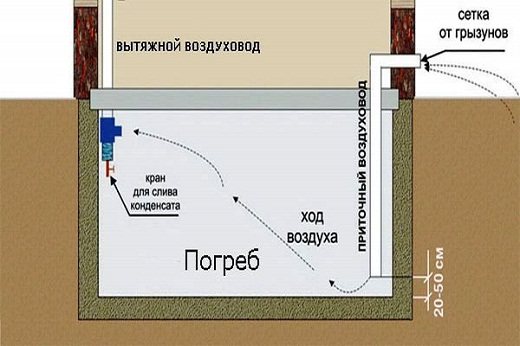

The latter is good in that it does not require large financial costs. She is preferred when the cellar is more than 20 m3 in volume. Natural ventilation consists of a supply pipe and an exhaust pipe. With the help of the first channel, fresh air enters from the street, with the help of the second, the basement air is discharged outside. So that there are no cooled places and stagnant air in the room, it is necessary to install pipes in opposite corners.

In the cellar, the hood is made as high as possible. It can be mounted in 2 ways:

- through and through, through the overlap of the garage floor with an outlet to the roof;

- make a hole in the wall of the cellar.

In the first option, the length of the chimney should be 50 cm higher than the ridge part of the roof. Finally, the ventilation duct should be installed with a visor or deflector. It will protect ventilation from precipitation and dust, create additional vacuum.

The pipes themselves can be chosen from any material, more often it is sewer plastic with a diameter of 10-20 cm. You can use asbestos.The diameter of the ventilation ducts is calculated according to the following formula: for every 1 m2 of the room, there should be 1.5 cm of the pipe diameter.

Important! The supply channel is installed 50 cm higher from the cellar floor. It is advisable to close its entrance with a fine mesh, which will prevent the penetration of harmful insects and rodents.

The channels are equipped with dampers so that during frost it is easy to shut off the pipes. It is important to install them correctly, the dampers are round and rectangular. Any type of ventilation is equipped with them, regardless of whether it is a residential or utility room.

Sizing

Before equipping the garage space with a vegetable pit, you need to decide on its size.

When determining the area of the cellar, the thickness of the base with the walls is taken into account. Also, when calculating the optimal area, it is taken into account that the dimensions of the room for the preservation of vegetables should be comfortable for the person inside. Therefore, experts advise to dig a pit, the width of which will be equal to 70-80 centimeters.

Since the pit must be located under the garage, its length directly depends on the length of the garage space, as well as on the amount of food that will be stored in it. For example, if a cellar is built for a small amount of salting, then its length can be 2-3 meters.

The minimum depth of the cellar for storing pickles is one and a half meters. However, if the owner of the premises is too tall, a pit is dug out with a depth of 160-170 centimeters.

Seat selection

A facility for storing stocks of vegetables and fruits should serve more than one year. For a high-quality building, you need to choose a suitable place. When carrying out such work, it is necessary to take into account some peculiarities. For example, the site should be on a hill so that groundwater does not fall into the pit, therefore, the level of their occurrence is determined in advance.

The check can be done independently by drilling a well with a depth of about 2.5 meters. In this form, it is left for several days and then it is checked whether water has appeared there. If the place is dry, then you can safely start arranging the storage. Another test option is to measure the depth in adjacent wells.

Experienced craftsmen advise you to make a plan for yourself before starting construction. It will allow you to better navigate when performing work.

Preparation for work

At first, building a cellar with your own hands may seem like an extremely difficult task, but even a novice builder can handle it. The most difficult step will be choosing the right place. Previously, it was believed that the cellar could be located exclusively under the house or in the summer cottage. But in reality it can even be organized in a garage. Therefore, apartment owners should not refuse to store their crops.

Before starting the construction of a vegetable pit, you need to work out the following questions:

- Checking the availability of utilities. If you are going to build a cellar within the city, make sure that you do not touch the electrical cables, piping and gas lines. In this regard, it is much better to make a hole in an already finished room - a garage or a cellar.

- Study of the soil. Most often, you will need the help of a specialist to carry out this stage. It will help to establish the characteristics of the soil and the level of groundwater occurrence. These factors cannot be ignored, as otherwise you risk getting a regularly flooded vegetable pit. Ideally, the groundwater should be well below the intended bottom of the storage facility, otherwise you will need a complex waterproofing system. This will entail a lot of money and time. Most professional builders believe that even waterproofing will not help - sooner or later, water will still seep into the pit.

- Project development.Before starting construction, it is worth spending time calculating the area of the future storage facility and creating a drawing. This will reduce possible shortcomings and greatly simplify your work.

Many people think that a cellar and a vegetable storage pit are interchangeable terms. This statement is true, however, the cellar is still a more complex structure, which is not always possible to build with your own hands. Mini vegetable storage can be made in the basement or garage. The only condition is the dryness and tightness of the selected room.

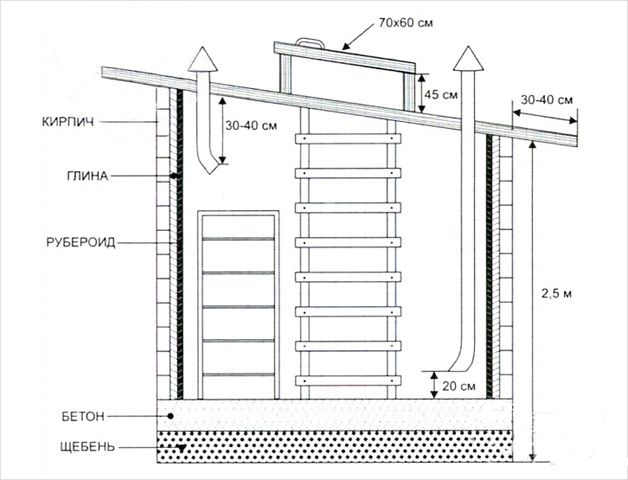

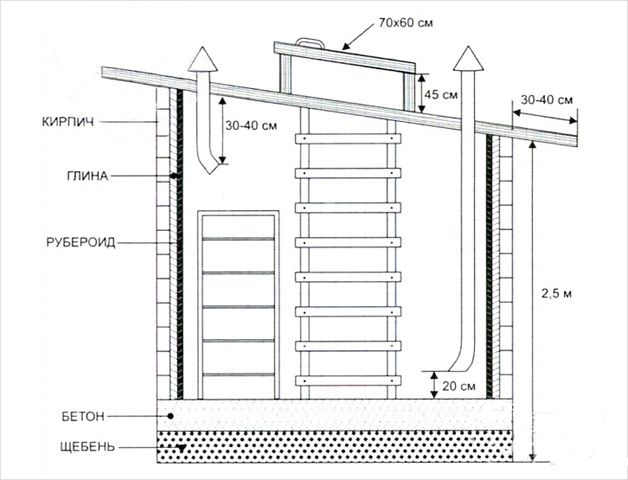

An example of a project for the device of a vegetable pit.

Site selection and subsequent planning

First, you need to decide on the choice of the place where it is planned to equip the vegetable pit. Traditionally, it is arranged under a storage room in a private house or under a garden house. For residents of apartment buildings, it is possible to organize a convenient storage place by equipping a vegetable pit in the garage.

It is important to note that despite the seeming simplicity of the design, just digging a pit is not enough to equip this kind of cellar.

If you are interested in the information on how to make a vegetable pit, you must take into account the following information

When planning construction, a number of points must be taken into account:

in order not to damage an electrical cable or pipes that accidentally lie in the ground, you will need to make sure that there are no engineering communications in this place

From this point of view, it is more convenient to equip a pit in the basement or garage; it is necessary to determine the features of the soil - it is important to collect information on the level of placement of groundwater at the planned construction site (for this you may need to contact a specialist for help). In order for the structure to be sufficiently durable, it is necessary to select a place with a groundwater level below the bottom of the planned storage facility - at least half a meter

If they are placed close enough, you should not ignore this problem - in this case, you will need to equip a reliable waterproofing system (otherwise you can get a vegetable pit, regularly heated with water). Such an arrangement will entail tangible financial and labor costs, and water can still find a loophole and seep inside over time; in a vegetable store, you will need to provide a suitable temperature and humidity regime. To prevent the fruits from wrinkling and drying out, a humidity of 85-95% is optimal, as well as a temperature regime slightly above zero (from 2 to 5 ° C). Storage in these conditions will protect products from spoilage and will allow you to preserve a maximum of useful substances in them. A thermometer placed there will help monitor the temperature in the vegetable pit; in order to ensure the flow of fresh air into the storage, it is necessary to equip ventilation in it - to bring out the supply and exhaust pipes; in addition, in order to exclude the germination of vegetables during storage, it will be required that this room be dark.

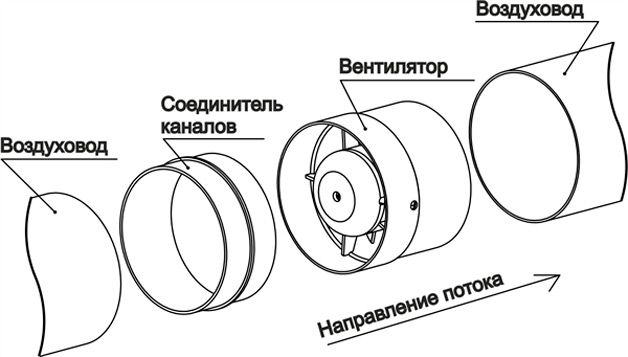

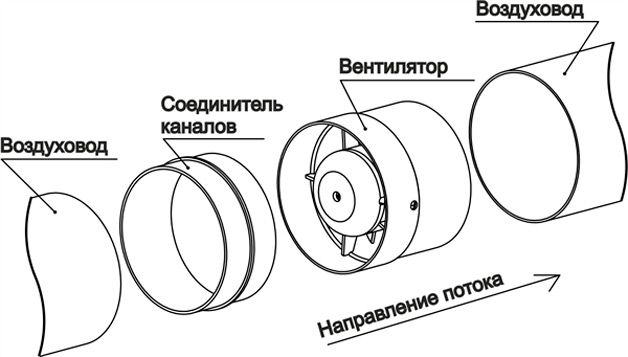

Organization of forced draft

Forced ventilation in the basement of the garage is arranged by adding electric fans to the system. It is not difficult to make such ventilation. Its main advantage is the maintenance of normal temperature and humidity conditions, regardless of the season and the vagaries of the weather.

Duct fan installation diagram.

The scheme of the controlled ventilation device practically does not differ from the principles of creating natural ventilation of the cellar under the garage: the pipes are attached according to a similar principle, after which a fan is mounted inside the exhaust pipe. The fan guarantees the availability of fresh air whenever it is needed. It should be noted that such a hood can be created not only with the help of a fan.

Here are some more ways:

- Rotary vane diffuser. This device is mounted on top of the supply pipe and operates under wind pressure.

- Effective ventilation in the cellar under the garage is also provided by a deflector that creates a rarefied air zone and improves air exchange. Deflectors are installed at the top of the chimney.

- The traditional option is to install a heating bulb in the chimney. This will improve the hood, which will be provided by heating the air moving through the pipe.

The fan is built into the chimney.

Of course, the most advanced method of organizing forced ventilation of the cellar under the garage can be called the mechanized type, when the air circulation is regulated by a monoblock. The software installed in it fully controls the modular system, so such a hood is the best option today. The only problem is the high cost of the system.

Site consultant, builder-installer with 8 years of experience. He started his career as an installer-finisher, currently works as a foreman in a company engaged in suburban construction.

The issue of preserving the vegetable harvest during the winter period has always been relevant. One of the options for preserving food, in particular vegetables, are vegetable pits (cellars) equipped in the garage. Read the instructions on how to make a cellar in the garage on this page.

The picture shows an example of a vegetable pit in the garage.

Specifications

Optimal conditions for storing food in a vegetable pit:

- the air temperature should be from two to five degrees Celsius;

- air humidity should be between 85% and 90%;

- darkening should always remain in the vegetable pit, lighting is used only when people are in the vegetable store;

- necessarily fresh air supply equipment.

Device

The layout of the inspection and vegetable pits in the garage begins with the elaboration of the following questions:

- determination of the type of soil characteristic of a given area;

- the level of soil freezing and the level of occurrence of groundwater;

- checking for the presence of underground communications, which is very important if the garage is located within the city;

- then a project for a garage with a vegetable pit is prepared.

The project should include the following items:

- estimated dimensions (depth and width);

- waterproofing, if necessary, equipment of the drainage system;

- arrangement of thermal insulation;

- arrangement of the floor;

- supply and exhaust ventilation equipment.

An example of a design scheme for a garage with a vegetable pit (cellar) in the figure

Arrangement of a vegetable pit make the cellar perfect

The storage pit in the garage, as we said, must be waterproofed. You may even need to make a circular drainage system in the cellar. Such measures are carried out in cases where groundwater is close to the bottom of the vegetable store.

Waterproofing the crop storage pit

The easiest way to protect the floor surface of a vegetable pit from moisture is as follows:

- you process the floor with a bituminous solution (for reliability - twice);

- lay sheets of roofing material on bitumen;

- reapply the solution;

- make a filling on roofing material using coarse sand.

The walls of the storage can also be coated with bitumen or a more expensive penetrating type waterproofing can be used.

The final touch is the installation of ventilation in the basement. The easiest way is to make a natural supply and exhaust system. To do this, you need to place two pipes (for exhaust and fresh air supply) at a certain height from the floor. The installation of forced ventilation will require more costs. You will need to buy a special electric fan and put it in a pipe with two flaps. Your vegetable cellar is ready!

This is interesting: How many bricks do you need for the garage - we will write in all the details

Add comment Cancel reply

You must be logged in to post a comment.

In the courtyards of private houses, as a rule, there are cellars. And where else to store stocks of vegetables, fruits and all kinds of canned yummy. In such an economic facility, ventilation of the cellar in winter must be provided. Correct air exchange will prevent dampness and mold in the room. After all, uncontrolled constant air circulation also spoils vegetables, they become lethargic and dry. In order to maximize the natural flow of fresh air, it is necessary to install supply and exhaust ventilation. Only then can the desired temperature and humidity be created.

Forced ventilation of the vegetable pit

If the vegetable pit is in the garage, forced air exchange should be preferred. The arrangement of such ventilation involves the installation of not only air ducts, but also fans.

Device Algorithm

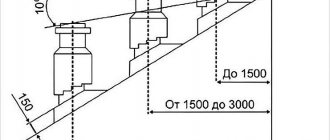

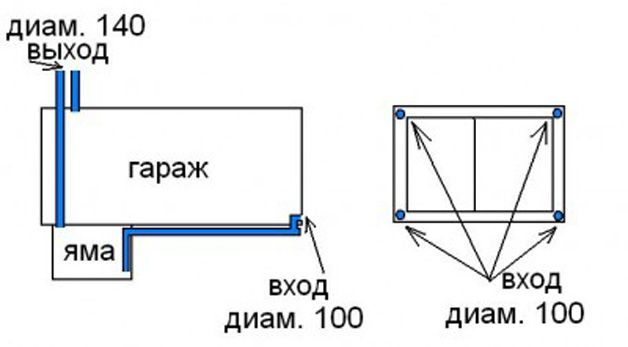

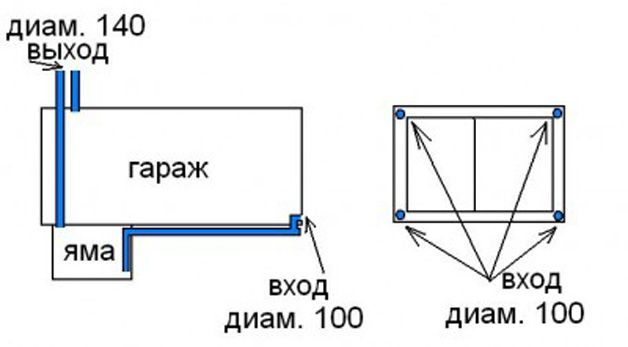

- An air duct is installed near the pit ceiling to remove air. The end of this pipe should be 0.5 m higher than the roof of the garage.

- At the very bottom of the vegetable pit, at a distance of 10 cm from the floor, a supply branch duct is installed. It extends 0.25 cm to the outside, connects to the elbow at a 90 ° angle and exits through the wall at the bottom of the building to the street.

- With forced ventilation, this circuit is amplified by fans. The performance of mechanical devices must correspond to the volume of the ventilated room.

- A good option may be a combination of natural and forced air exchange systems. For this, an exhaust fan is mounted in the ventilation duct intended for air removal. It creates an air vortex, forcibly expelling air currents from the vegetable pit. Therefore, while ensuring the flow of fresh air from the supply ventilation duct.

Construction stages

Digging a hole for storing vegetables is not too difficult. It is much more difficult to equip it correctly. When building a vegetable store, it is necessary to take into account the issues of arranging the floor and walls, the organization of hydro and thermal insulation, as well as the provision of ventilation.

If you are setting up a pit in an open area, and not in a finished basement or garage, first dig a pit of the right size.

Arrangement of floor, walls and ceiling

At the bottom of the pit, 10 cm of crushed stone and 15 cm of sand are laid. Each layer must be carefully tamped. After preparation, the layers must be filled with bitumen or another substance with similar properties. Ideally, pour a slab of reinforced concrete, having previously laid a layer of waterproofing material. If this option is not possible, you can cover the floor with wooden planks.

Then you need to tackle the walls and ceiling. Alternatively, you can lay out the walls of bricks. In this case, it is better to lay the ceiling of the pit with a vault, laying bricks on templates made of boards. You can also arrange a concrete floor. To do this, you need to prepare a wooden formwork and lay the reinforcement cage inside.

In the process of working with the ceiling, you need to leave room for a manhole. It is best to do it in the middle of the ceiling. In this case, you will have enough space to place the shelving. In place of the manhole, a stop for the cover should be installed.

When the ceiling is ready, it is necessary to insulate it. To do this, coat it with bitumen and insulate it using the existing insulating material (foam, expanded clay or slag).

Waterproofing

High-quality waterproofing is a prerequisite for long-term storage of crops. This issue should be taken especially seriously if the groundwater level in the area is high enough. In this case, you will have to build a circular drainage system.

Thermal insulation

Natural vegetable products do not tolerate sudden changes in temperature. Sudden warming can lead to rotting and disease, and freezing temperatures will cause dramatic changes in taste. For this reason, you must ensure that your storage is kept at a suitable temperature at all times.This is easiest to do with proper thermal insulation.

It is better to insulate the walls from both sides - external and internal. But often the owner of the already built vegetable pit gets it, so its external insulation is impossible. Then it remains to insulate its inner walls. This work can be done with your own hands using any plate insulation. Remember to make sure it is moisture resistant. Experts believe that expanded polystyrene will be the best choice.

Providing ventilation

Constant air circulation will help maintain the correct microclimate in the store. Therefore, the final stage of construction should be the organization of a balanced ventilation system.

A variant of the ventilation device in the vegetable pit located in the garage.

The simplest option that you can build yourself is natural ventilation using two pipes. One of them will be inlet and the other outlet. They need to be placed at different heights in opposite corners of the cellar. You can use any pipes you have, but plastic or asbestos-cement pipes with a diameter of 10-15 cm are better suited for a vegetable pit. The supply pipe should start 20 cm from the floor and go out at a height of about 20 cm above the level of the cellar lid. The exhaust should start just below the ceiling and run out as high as possible above the roof of the room.

Valves should be installed on the pipes, which will allow you to regulate the air flow. To protect the storage from the penetration of pests, the end of the supply air duct is closed with a fine metal mesh. To protect against precipitation, the upper end of the chimney is placed under a special umbrella-cap.

The difference in temperature and pressure will ensure a constant flow of fresh air into the room.

Separately, it should be said about the need for high-quality ventilation of the pit located in the garage. Exhaust gases from the car must be removed in a timely manner and not get on food.

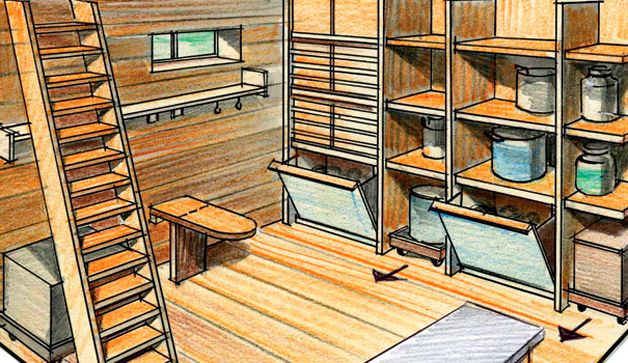

Installation of shelving

Due to the fact that the area of the pit is often small, one should reasonably approach the organization of its space. Practice shows that a rack system is perfect for storing crops and products.

Taking into account the peculiarities of the microclimate of the cellar, some homeowners purposefully make shelving from wood. In this case, preference should be given to pine, since, due to its special properties, it will protect products from pests and rot. Some owners prefer plastic or metal, but it does not solve the problem of condensation. When it forms on the shelves, it will not be absorbed, but will fall directly onto your stocks.

Instead of shelving, you can use ordinary boxes stacked on top of each other.

Most often, it is not possible to find ready-made furniture that fits perfectly into the dimensions of the pit. There are two possible solutions. Firstly, you can make shelves yourself or order them according to individual sketches. Secondly, you can abandon the idea of shelving and prefer drawers. They can be filled with food and stacked on top of each other. This way they won't take up much space.

Thus, a harvest storage pit is a building that you can build with your own hands. The main conditions for the successful storage of food are dryness, constant air circulation and the absence of sudden changes in temperature. If you choose the right space and follow the advice in this article, you can be sure that your fruits and vegetables will stay fresh and tasty for a long time.

Natural ventilation in the vegetable pit

A vegetable pit can be built in a garage or outdoors. If it is located in the garage, it will probably be divided by a partition with a viewing hole. However, wherever it is built, it is necessary to think over the ventilation system. An important point is the material from which it was equipped. This could be:

- wood;

- concrete plates;

- brick.

High-quality natural ventilation of vegetable pits largely depends on the insulation of the room.

The simplest option, if the pit is located on the street, may be the installation of two air ducts of the same cross-sectional diameter. They must be fitted in opposite corners. The ventilation duct for the air supply is mounted at a distance of 0.2 m from the floor. This duct will run through the ceiling. Outside, the chimney should rise above the ground by at least 0.2 m. The chimney is installed under the ceiling in the ceiling. It is brought out as high as possible from the ceiling surface.

Due to the inflow and outflow of air through the ventilation ducts, natural air circulation will be carried out. It is based on the difference in pressure inside and outside the room. If there are severe frosts outside in winter, then the ventilation is shut off with the help of dampers.

The only drawback of natural air exchange is the dependence on weather conditions. In the warm season, the air can stagnate due to the lack of normal draft. Another important point is the protection of ventilation pipes from pests and precipitation. In the first version, you can use a mesh, in the second, a special umbrella made of metal or plastic.

Vegetable pit waterproofing

Stage 1. Surface preparation

- Remove loose concrete mechanically (using a jackhammer, perforator or high-pressure apparatus (HPA) of the KERCHER type).

- Clean the concrete surface with a metal bristle brush from dust, dirt, laitance, tile glue, paint and other materials that prevent the penetration of active chemical components into concrete.

- Along the entire length of cracks, seams, joints, abutments and around the input of utilities, make dovetail strips with a depth of 30 and an outer width of 20 mm. With heavily damaged concrete, the size of the penalty increases.

- Clean the shafts with a metal-bristled brush, high pressure wire.

- If the reinforcement is exposed, remove sufficient concrete behind the reinforcing bars until they are completely cleaned. Remove rust mechanically or chemically (to clean metal) and apply an anti-corrosion coating (mineral, epoxy or zinc) before applying the material or

Stage 2. Waterproofing of structural elements

b) joints, cracks.

- Moisten the strobe thoroughly.

- Prepare material solution

- Fill it tightly into the line (with a line of 20 X 30 mm, material consumption 1.35 kg / m.p.)

The material has a penetrating effect, so the strobe for it does not need preliminary treatment with penetrating compounds, which favorably distinguishes the KT Tron line of materials from other brands.

Stage 3. Application of waterproofing coating

Waterproofing of concrete with a penetrating compound:

- Moisten the concrete surface thoroughly.

- Prepare a solution of waterproofing material, apply it in two layers with a synthetic fiber brush.

- Apply the first layer on damp concrete with a brush, applying strokes in one direction (without smearing).

- Moisten the surface before applying the second layer. Apply the second coat on a fresh, but already set first coat; it is recommended to apply the coats in perpendicular directions.

- Calculation of the material for a two-layer application on a smooth surface of 0.8 kg / m2, on a rough surface - 1.0 kg / m2.

Step 4. Surface care

It is necessary to ensure that the surfaces treated with the waterproofing materials of the "KT Tron" system remain wet for 3 days, no cracking and peeling of the coating should be observed, the temperature regime is observed.

To moisten the treated surfaces when waterproofing vegetable pits, the following methods are usually used: water spraying, covering the concrete surface with plastic wrap.

Foreword

... Self-waterproofing of the inspection pit in the garage is a whole range of works that are aimed at protecting the structure from moisture from the soil. But what materials to choose, how to waterproof the inspection pit and install it correctly? All this will be told and shown in the video by this article, which contains only information verified by our own experience.

Every car owner wants his iron horse to serve for a long time, and for this it is necessary to provide the car with timely repair and maintenance. Many car enthusiasts, based on their experience, prefer to do their own small repairs in the garage. And this requires a garage equipped with tools and accessories.

Pit construction

After careful planning, you can start building your own vegetable pit. The first step is to dig a pit for the future cellar. Then you need to dig a trench in it, in which the foundation will be installed. Crushed stone is poured at the bottom (the thickness of its layer should be at least ten centimeters), and on top of it - building sand with a layer of fifteen centimeters. Both levels need to be properly tamped and leveled.

Then you can fill the base with heated bitumen or other similar composition. If you want to make the storage very reliable, you can put a waterproofing material right on the sand - for example, roofing material - and cover it with reinforced concrete on top. However, such work will be more time consuming and cost much more. Not in all cases such a powerful waterproofing is needed. Sometimes wooden planks are placed on the floor on top of the concrete.

After the floor in the vegetable pit of a garage or private house is poured, you can move on to the walls. They are most often built from concrete or brick. The following requirements are established for them:

- for strength, concrete must be tied with rods of steel reinforcement;

- brickwork should be at least half a brick thick, but better - a whole or even one and a half.

The strength of the ceiling is especially important if there is a building above the cellar. Having made a vegetable pit in the garage, it is worth remembering that there will be a car over it. In the case of a private house, everything is even more serious. If the section at the top is empty, then the requirements for the structure are somewhat reduced - the main thing is that it is reliable and does not collapse downward.

The ceiling can be laid out either from bricks laid on boards, or from concrete - in this case, you will need a frame made of reinforcement. At this stage, it is necessary to provide for all the required openings: the entrance, where the ladder and hatch will be installed, and the ventilation passage places. The most convenient place for a manhole is in the center of the subfloor. At the same time, all walls will remain free, along which it will be possible to install many racks. The final stage is ceiling insulation. To do this, it is coated with bitumen and insulated with foam or expanded clay.

Do-it-yourself water heating in a private house and its installation

Vegetable pit: manufacturing features

The construction of a vegetable pit in a garage begins with choosing the right place at which the groundwater level will be correspondingly lower than the intended pit, because this is an important condition. If, however, there is no such place, then you will need to think about waterproofing (see

).

After all, garages, as a rule, do not have a large area and the choice in place will not be large. All the work will be done by hand and therefore everything must be done efficiently and correctly.

So:

- As soon as the issue with water is resolved, you can begin to dig a pit, which naturally should have the required dimensions, a trench is made in it under the foundation, after which rubble is poured. All this needs to be tamped and concreted.

- Now you need to lay out the walls one and a half bricks thick, coating them with hot bitumen. Here we need to make high-quality masonry. Remember that there will be a car on the ceiling of the pit and it should not be carried out.

- If there is a desire, then the ceiling can be simply concreted, as many owners often do.

- Masonry in this version is done on cement mortar. For this, for example, for M300, it is necessary to provide for a ratio of sand and cement 3/1.

- When laying bricks, you need to monitor the dressing. The seam must not match. Otherwise, the structure will not last long.

- After laying the walls, let them dry completely. And after that we start making the ceiling. For this we need a channel and fittings. We also do not forget about the shalevka. It will be needed for the formwork.

- We cut the shalyov to a size equal to the width of the pit. Preferably no clearance.

- We spread it on a flat plane and knock it into a shield.

- Now we need to make supports. Any logs are best suited for this.

- We put up the shield and support it with logs. We have a wooden ceiling in the pit.

- Now we cut the channel and fittings to the desired size. This is done with a grinder and a cut-off wheel.

- We put a channel along the perimeter of the pit and weld it together.

How to design a vegetable pit in the garage with your own hands

To build a vegetable pit correctly, you will have to deal with the main stages of construction.

We build a pit

The cellar begins to be created by digging a pit, in which a basement will be built for storing vegetables with preserves. After that, they carry out the arrangement of the floor. To make the flooring reliable, it is made of several layers. First, the bottom is covered with a small layer of gravel, which is tamped with a vibrating plate. Then the compacted crushed stone is filled with construction sand and poured with concrete.

When the flooring hardens, the walls are finished. For this, a solid brick is suitable, which is resistant to high humidity. The walls are laid out in such a way that the seams of each subsequent row of bricks do not coincide with the previous one.

After creating the walls, a reliable ceiling is made that can withstand any load. In the manufacture of the ceiling, boards are laid at the top of the pit, on which reinforcement is laid and concrete is poured. Having finished with the ceiling, you can make a staircase, which is installed near the entrance to the inside.

Dehumidification

Before operating the vegetable pit, the room is dried so that the walls with the ceiling and floor are completely dry. There are several methods that help dry the cellar:

- Place a metal bucket in the center of the basement, fill it with wood and make a fire. Using this method will have to keep the fire going for an hour and a half.

- Take a metal pipe outside and install a burning candle under it, which will provide natural draft.

Waterproofing

Sometimes vegetable pits are made in an area with a high level of groundwater, due to which the humidity increases. In this case, waterproofing should be installed inside the basement, which will help keep the humidity level within normal limits.

The choice of insulation

In order to maintain the optimal temperature inside the cellar, additional thermal insulation will be required. The selected thermal insulation material must have the following properties:

- environmental friendliness;

- chemical safety;

- reliability;

- moisture protection.

To insulate a storage for vegetables, use polystyrene or expanded polystyrene.

Ventilation device

In any cellar there should be ventilation, since it is she who is responsible for the circulation of oxygen inside. When organizing the ventilation system, they are installing the supply and exhaust pipes. The supply air is located near the floor, and the exhaust is led out through the roof.

Metal pit for storing vegetables and ventilation system in it

Today metal caissons are in great demand. The popularity of iron pits for storing vegetables is due to the fact that this design completely protects the contents of the tank from external irritants.

Today metal caissons are quite popular for storing crops.

Basically, they buy ready-made metal structures and install them on the site using special equipment. The advantage of the iron pit over other vegetable stores is in durability.

If possible, the space between the pit and the metal container should be covered with a gravel mixture. Two drainage tubes are installed vertically along the walls. During the design of the pit, you should think about what kind of ventilation system you will install. The safety of vegetables will depend on how well the ventilation is made. If there is insufficient air circulation, condensation will collect at the bottom of the container.

Most often, they give preference to supply and exhaust systems. Iron pipes are used for ventilation. They are welded directly into the metal structure. As in the previous versions, the supply pipe is fixed as close as possible to the floor on one side of the room, the exhaust pipe on the other side of the room, as close to the ceiling as possible. The higher the difference in height between the supply and exhaust pipes, the better the ventilation will be. The air humidity can be reduced by additionally installing a box with table salt in the room.

Supply pipe device

The correct location of the pipe is close, but not close to the cellar wall. The end of the channel will be about 20-50 centimeters from the floor. The end of the pipe must be brought out through the foundation block of the garage. To protect the room from the penetration of rodents and other pests, a fine-mesh mesh must be installed at the ventilation outlet. The exit should be located just above the foundation blocks, a little further than the main walls of the building. In this way, an optimal flow of fresh air into the cellar can be obtained. This scheme is used when organizing forced and natural ventilation.

Important tips when installing fresh air ventilation:

- Air intake should take place outside the walls of the garage and other premises, preferably away from the gate, so that exhaust gases do not enter the chimney when entering the chimney. You can think of an option for the supply pipe to be located farther from the walls of the garage, but you need to think about placement without bends and right angles.

- You can make such a ventilation duct even at the stage of building the cellar. To do this, the space in the brickwork is limited in the wall, with dimensions of about half a brick. The masonry must be done according to all the rules, using the same mortar, but at the bottom have a sufficiently large hole, the end of which will be brought out into the street through the garage block.

- The hole in the masonry wall or pipe must be at least 25 centimeters from the garage walls. Thus, normal air exchange is ensured.

- Pipe diameter also matters. Too small will not provide a normal air flow, and a large diameter will make operation ineffective due to heat loss. The calculation can be taken as follows: for each cubic meter of the room, there must be at least 15 mm of pipe. Simple calculations will allow you to get a more or less correct section size. The same rules apply to the design of the chimney, so it is better that they are the same. This will additionally help to properly organize air exchange without unnecessary problems.

- For winter time, it is necessary to provide for insulation of the outer part of the pipe. For these purposes, you can use any insulation material, up to rags. With regular freezing, you can consider a quick defrosting system, for example, insulate the end with non-combustible materials and make a fire under it.

- From the inside of the supply ventilation, a damper must be provided to prevent food from freezing at negative outside temperatures.It is advisable not to completely close the hole, even in severe frost, fresh air should get into the cellar.

- In order to prevent snow from covering the hole in winter, you need to periodically clean the area or use a large plywood box. It will provide the necessary protection, and the air will not be so cold compared to the other option.

The plastic version can be used as a suitable material for installing the supply pipe. The cross-section of the pipe should be from 8 centimeters, depending on the size of the cellar, you can take more. Plastic pipes have proven to be excellent for such work. They do not corrode, mold or rot. Even if fungus or mold appears on the surface, it is quite easy to process them with the annual disinfection of the basement.

The simplest design of the chimney: in the foundation block of the garage, you need to make a hole with a diameter of at least 8 - 10 cm. Then bring out a pipe of a suitable cross-section, and also install a net from pests. Such a scheme will not help to ensure a good air flow, but in the absence of another, basement ventilation will be provided.

The peculiarity of air exchange in the cellar in winter

In the cellars, the ventilation system consists of pipes, the number of which depends on the size of the cellar. In small areas, 1 pipe with two gate valves is sufficient. With the help of them, it is possible to regulate the removal of air and its supply.

Ventilation of the cellar for the winter requires certain maintenance - before seasonal changes, it is recommended to insulate the box with mineral wool and cover it with waterproofing material. This will ensure the normal, trouble-free operation of the ventilation system.

On frosty days, cold air circulates faster, so the temperature in the room can drop sharply. Because of this, it is recommended to adjust the valves on the supply and exhaust pipes. In severe frosts, the valves are closed. Depending on temperature differences, whether to close the ventilation of the cellar in winter partially or completely, the owner decides on his own, taking into account the characteristics of a particular object.

Sometimes even with good ventilation insulation, in winter frost can form on the chimney or condensation freezes. Naturally, this will interfere with normal air circulation. You can make this part of the pipe removable for easier cleaning. Alternatively, an elbow can be installed at the end of the pipe.

Condensation of cause and effect

Condensation in a vegetable pit is a danger to humans

How to make ventilation in a vegetable pit so that condensation does not occur in the room during demi-season periods. Indeed, due to its formation, not only air ducts can collapse, but also the wet walls of the vegetable pit can collapse. To protect yourself, you need to insulate the ventilation pipe. Ideally along the entire length. If this is not possible, thermal insulation is carried out only in the area from the ceiling to the umbrella installed at the end of the duct. With proper insulation, the service life of the ventilation duct will increase, plus condensate will also be removed.

Do not forget about the insulation of the walls of the vegetable pit, because this factor also prevents the formation of condensation. This can be done with polyurethane foam. It helps to achieve complete sealing of the pit. It has a foamed consistency. When hit on the surface, freezes. Does not form seams and joints, retains its properties for up to 50 years.

Proper ventilation contributes to the preservation of vegetables in the autumn-spring period. In order for the air exchange to be carried out as expected, you need to know that its frequency in the garage and other outbuildings must comply with the SNiP standards and be equal to 180 m3 / per hour.

n is the rate of air exchange in a given room

V is the volume of the vegetable pit, expressed in m3.

L is the air flow.

After all the work done, it is worth testing the ventilation system - check the traction with a piece of paper.

At the end of the gardening period, the problem arises of long-term storage of vitamin preparations. Getting a suitable place to place your crops is not difficult by equipping a vegetable pit - it can be placed under a house, in a basement, a garage, and even under a loggia. Your supplies will stay fresh for a long time without the need for any energy costs. It is quite possible to equip such a storage for vegetables yourself, while you can use the simplest tools and materials.

Hand-grown or purchased for the winter fruit and vegetable products will need to be stored somewhere. No refrigerator can hold several boxes of onions and carrots, or sacks of potatoes. It is possible to make your life easier by arranging a convenient cellar for placing vegetables - in a similar way, you can organize a storage space in natural conditions, with a certain microclimate. In such a storage, the crop will remain fresh for a long time.

The most convenient to use is the so-called underground - a vegetable pit in the house or in the garage, because it will not take up additional space on the site, moreover, it will be much more convenient to use such a storage for vitamin preparations, including in the cold, than a cellar on the street ...

Installation of ventilation in a vegetable store

Before you start doing ventilation in the vegetable pit of the garage, everything should be calculated and all the necessary materials should be prepared in advance. Also, one should not neglect the drawing up of a small room plan indicating the points of the location of the air ducts.

It seems that we only need to make a couple of ventilation ducts. But without a preliminary drawing, even with their installation, you can trick something.

To organize natural ventilation in the room under consideration, pipes 8–9 meters long will be required (3.5–4 m for the inflow and at least 4 m for the exhaust). This is taking into account the presence of a viewing hole.

If it is not there, then it is necessary to build on the depth of the cellar and the height of the ceiling of the garage box. Plus, you will need a glass for condensate with a drain valve, metal grilles for ventilation openings from the street and a cap or a deflector.

The supply and exhaust pipes should be bred diagonally to opposite corners of the vegetable store so that air circulation captures all its corners

Installation of ventilation in the garage and vegetable pit is as follows:

- Holes for the supply pipe are made in the wall near the garage door at a distance of 20–30 cm from the ground and through the ceilings down into the cellar.

- Holes for the hood are made in the roof of the garage and the ceiling of the pit.

- Ventilation pipes are mounted (a condensate collector is installed at the bottom of the hood).

- A valve is installed on the air intake pipe.

- If necessary, ventilation ducts are insulated with moisture-resistant foam or foam.

- A rain hood is installed on top of the exhaust pipe.

To prevent rodents from getting in through the ventilation in the vegetable store, a metal grate should be installed on the vents of the air flow from the street. In this case, the distance from the edge of the exhaust pipe to the ceiling of the vegetable pit should not exceed 20 cm, and the supply pipe should rise to a maximum of 50 cm above its floor.

The inflow duct in the pit should be positioned so that the incoming outside air does not get onto cans and vegetables. It is cold in winter and should warm up a little at first.

Otherwise, the total temperature in the cellar will be at + 5 ° C, and locally, near the ventilation pipe, everything will freeze. For the same reason, this ventilation duct should be removed from the wall by at least 30-50 cm so that a frost coat does not grow next to it.

The following article will familiarize you with the rules and formulas for calculating the area of air ducts, which we recommend to independent home craftsmen.

Basic requirements for construction technology

There are several key requirements for a vegetable pit

When executing a project, it is necessary to indicate in it the dimensions of the future pit. Its depth, ideally, should be approximately 2-2.2 meters, width - 1.5. It will be quite convenient to be in it, and the temperature can be easily maintained at +5 degrees.

This is optimal for storing vegetables - they will not deteriorate and retain a maximum of useful substances. Humidity must be maintained at 90% - vegetables will not wrinkle and dry out.

If the groundwater level fluctuates at around 1-1.5 meters from the surface, and it is difficult to choose another place for the pit, you can try to arrange a drainage system. In some cases, it may also be necessary to arrange a good waterproofing.

Of course, this will result in some costs, both in terms of finance and labor. But if you neglect this stage, you should prepare for the fact that sooner or later the water will find a loophole for itself and penetrate inside.

It is recommended to insulate the walls - any heat-insulating material in the form of plates that resists moisture well, for example, expanded polystyrene, is suitable for this.

Sand and crushed stone are laid at the bottom, then bitumen or other similar material is poured onto this pillow. It is best to arrange the flooring in the form of a reinforced concrete slab. If it is impossible to provide such an option, strong boards are laid on the base.

The simplest option is the construction of natural ventilation, for which two pipes are used, placing them at different heights from the floor surface in the garage. One pipe is inlet, the other is exhaust, and their outer ends should be brought out as high as possible.

This ensures a constant supply of fresh air. This helps keep vegetables fit for consumption longer.

Installation of the structure in the pit

The metal box must first be covered with an anti-corrosion compound, as well as waterproofing materials, for which you can use mastic or bitumen. The dimensions of the pit to be prepared should be more than the box itself by 50 centimeters on each side. The bottom of the dug hole is leveled and compacted, then a waterproofing clay pad 25 centimeters thick is placed on it. A layer of concrete of insignificant thickness is additionally poured on top. Do-it-yourself construction of a vegetable pit is accompanied by the installation of wooden formwork between the metal cellar and the pit wall. Clay is laid between the box and the boards, which is cut into plates in advance. After filling the hollow space and tamping the material, you can start backfilling the excavated soil.

Characteristics and types

Flexible hose for connecting plumbing is a hose of different lengths made of non-toxic synthetic rubber. Due to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, there is an upper reinforcing layer in the form of a braid, which is made of the following materials:

- Aluminum. Such models can withstand no more than +80 ° C and remain functional for 3 years. At high humidity, the aluminum braid is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water hose is at least 10 years, and the maximum temperature of the transported medium is +95 ° C.

- Nylon. This braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 ° C and are designed for intensive use for 15 years.

As fasteners, nut-nut and nut-union pairs are used, which are made of brass or stainless steel. Devices with different permissible temperatures differ in the color of the braid.The blue ones are used to connect to the cold water pipeline, and the red ones are used with hot water.

When choosing an eyeliner for water, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that excludes the emission of toxic components by rubber during operation.

Fall asleep, ram and level the floor

If several types of backfill are used, each backfilled layer must be compacted with a manual rammer. Consider a situation where crushed stone with sand is used. First, crushed stone is poured onto the bottom of the pit, tamping is carried out. The thickness of the compacted layer must be at least one hundred millimeters.

Then sand is poured and rammed (layer thickness - fifty millimeters). After that, crushed stone is poured (layer thickness - five centimeters). You can only make 2 layers of one hundred millimeters. It all depends on how wet the soil is. After filling and tamping, the floor is leveled, for which you can use the same manual tamping.

Share link:

Technical features of ventilation ducts

When designing ventilation, it is necessary to decide from which material to install the ventilation pipe. It can be:

- metal pipes;

- PVC pipes;

- asbestos pipes.

The options for metal ventilation ducts are varied. It can be stainless steel, galvanized steel, aluminum.

Stainless steel channels

Stainless steel pipes withstand temperature extremes well, do not corrode, are durable, fire-resistant. Therefore, by installing such an air duct, you can protect the ventilation system from the growth of fungi and mold in it.

Galvanized pipes

Air ducts made of galvanized steel can withstand temperatures up to +85 C °, are resistant to moderate air humidity - up to 60%. Relatively light in weight, so no additional effort is required when installing the ventilation duct. They are often installed in dry rooms with ventilation equipment.

Aluminum pipes

They are semi-rigid and flexible. They are made of aluminum foil with a thickness of 0.08-012 mm. They can bend easily. They are heat-resistant, withstand + 135 ° C, flexible, and rigid air ducts can withstand temperatures up to + 300 ° C. According to all characteristics, semi-rigid air ducts can be installed outdoors.

Asbestos air ducts

An asbestos-cement pipe can be up to 5 m in length. Section diameters ranging from 100 to 500 mm. They are classified into pressure and non-pressure. The pipes can withstand temperatures of + 300 ° C. Condensation is absorbed into them. These ducts are not subject to corrosion, but they are very fragile. There is a version that asbestos is harmful to health (directive 1999/77 / EC on the prohibition of the use of asbestos).

PVC pipes

PVC ventilation ducts are often used for arranging ventilation in residential and business premises. The pipes can withstand temperatures from -30 ° C to + 70 ° C. The smooth inner surface of the inner part creates low dynamic resistance during the passage of air currents. The pipes are resistant to moisture. The range of cross-sectional diameters and lengths of air ducts is very wide.