Women tend to strive for perfection, especially when it comes to dining. A kitchen hood with an air duct is a key element of a well-organized space. With its help, the removal of soot, grease particles and unpleasant odors is ensured.

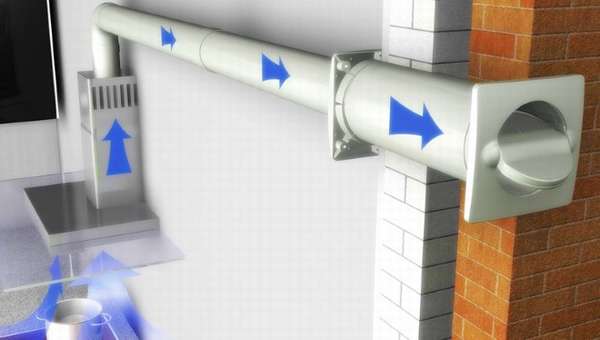

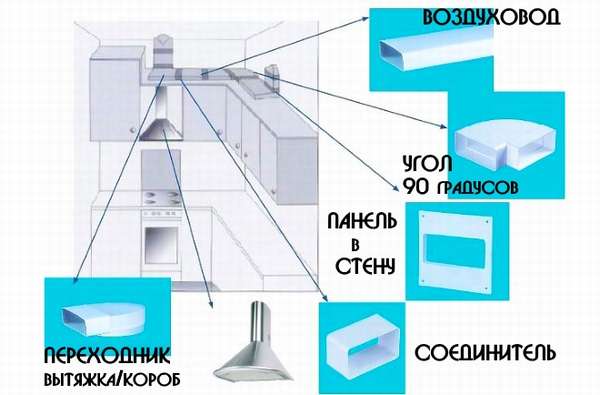

Exhaust-type household appliances consist of several functional units. One of the main ones is the air duct used to remove polluted air and soot from the cooking zone, eating food. We are talking about a special channel (in some cases it looks like a pipe), through which air is directed from the intake device to the outlet (ventilation duct shaft).

Obviously, the air duct for the hood is just as important as the lungs are for humans. Without this element, oxygen circulation is impossible in principle. However, there is a wide range of devices on the market that operate without air ducts. Carbon filters are used for cleaning. They are not very popular as they require regular replacement of their filter cartridges.

Types of air ducts

A kitchen hood with an air duct is classified according to several criteria. It is customary to select them taking into account:

- configurations of the structure,

- material used to manufacture products,

- differences in shape.

It is important to understand that when choosing, all the listed criteria are taken into account, a set of parameters for a particular unit. This is the only way to find an effective device that can easily cope with the function of air exchange in the room.

Kitchen hood with duct: duct configurations

Considering the configurational features, pipes are divided into 2 types. Note that they are equally successfully used in apartments and country houses.

- Rigid structures. We are talking about aluminum, steel or plastic products. The main feature of this type of device is that the inner surface always remains smooth, which is extremely important to prevent the accumulation of grease, soot and dirt. In addition, the installation of air ducts of this type takes a minimum of time and physical effort. Ease of use eliminates the key drawback - the high price.

- Flexible solutions. In 90% of cases, we are talking about corrugated aluminum ducts. Today, plastic models are popular, the angle of placement of which can be adjusted in any convenient way. The main advantage of these products is that they can be squeezed and stretched absolutely freely. The length of such a box cannot exceed 3 m, because each subsequent meter levels the performance level by 7%.

Without practical skills, it is extremely difficult to independently install metal or plastic air ducts for the hood. It is much easier to do this in the presence of flexible structures - corrugations.

Materials used for the production of air exchange channels

Modern production is based on several materials. More precisely, on three: steel, aluminum and plastic. Each of them has its pros and cons, which are worth dwelling on in more detail.

Steel

The main component is stainless or galvanized steel. When it comes to home kitchen applications, galvanized solutions are mostly in demand. However, products of this type are becoming less and less popular with consumers every day, the demand for them is falling.

The material has several obvious advantages:

- Absolutely flat and smooth surface (both inside and outside). Air exchange is high-speed, small particles of soot and fat do not get stuck, do not accumulate.

- Excellent resistance to high temperatures.No harmful impurities, vapors are released into the surrounding space.

- Exhaust air ducts belong to the products of the budget segment.

Steel products have several disadvantages like any other product. Only a few of them deserve special attention.

- They are characterized by significant (when compared with plastic) weight. For fixing against the wall, a number of additional fixing elements are required.

- Additionally, you will need sealants, degreasing compounds.

- To assemble a structure of complex shape, it may be necessary to cut pipes.

- They make a loud noise during operation.

These disadvantages are more than offset by the advantages and usability of the products.

Plastic (fiberglass, PVC, polyethylene)

The cooker hood with a plastic duct retains its leading position in the market due to its high popularity. These are round or rectangular solutions. As for round pipes, their key advantage is their high installation speed. But rectangular products look very aesthetically pleasing.

The plastic duct has several advantages:

- Low weight.

- The space in the canal is smooth. Grease, dirt and soot do not accumulate inside the system.

- During operation, PVC pipes do not rust.

- Ease of installation. Even inexperienced craftsmen do not have any problems with the assembly of the structure. You can assemble a structure of any size, complexity, configuration.

- The plastic duct does not generate noise or vibration.

- Affordable price.

The matter was not without its drawbacks. But they are nothing at all when compared with products made from other materials.

- Competent installation is possible only if there are connecting elements, adapters, couplings.

- At high temperatures, deformations are possible, the release of toxic substances into the room.

Plastic is best suited for kitchen hoods due to its accessibility, structural reliability and ease of installation.

Aluminum

Aluminum solutions are no less popular in the 21st century. The material is used for the production of corrugated pipes for air ducts. The pluses are traditionally ranked as:

- Heat resistance.

- The versatility of the material makes it easy to install.

- Low cost.

They also have some disadvantages. I would like to dwell on a few in more detail.

- An aluminum air duct for a kitchen hood does not look very nice, therefore they are often decorated with a protective casing.

- High probability of condensation accumulation due to the fact that aluminum is a thermally conductive material.

- Mechanical products are inferior to steel in strength, which is obvious. The material is prone to deformation.

A hood for a kitchen with an air duct of which material is one of the main criteria. Their choice is approached with full responsibility. In addition, attention is focused on the shape of the channels.

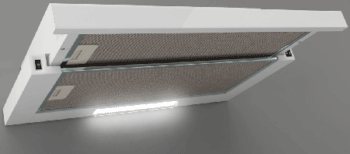

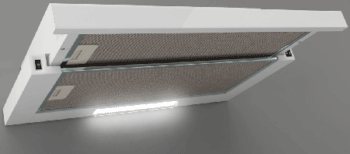

Pull-out hoods with air duct for kitchens

Slider hoods can be installed in any kitchens: large, small, combined with a room (studios). The main feature of the design of such devices is in the pull-out panel. That makes them very productive with their compact size. When the appliance is turned on, the panel is extended, and when it is turned off, the hood is almost invisible. The device, like most other types of hoods, can operate in two modes:

- direct when the device is connected to a ventilation shaft;

- recirculating, in this mode the air is cleaned by passing through filters and returning to the room.

The design of most models has two filters: the first cleans the air stream from grease vapors (grease filter), the second, installed inside, eliminates odors (charcoal filter).

When using a retractable hood in a recirculating mode of operation, it must be borne in mind that its efficiency will decrease, and you will also have to periodically change the carbon filter, on average, once every six months.

The slider can provide maximum performance if it is connected directly to the ventilation shaft. Considering that the hood with an air duct for the kitchen is able to realize better air circulation in the room, it is worth giving preference to this particular installation option. If it is not possible to connect the device to ventilation, then before choosing the model you like, the seller should clarify whether it is possible to purchase a separate charcoal filter for this type of hood from them. Since it happens that having bought a certain model, in the future it is very problematic to find a filter suitable for it.

The advantage of using the recirculation mode is the preservation of the natural movement of air masses in the room. Perhaps this is due to the fact that the ventilation hole of the mine is not covered by the air duct. Such an installation of the hood allows the air in the room to move without stagnation, regardless of whether the device is turned on or not. Maintaining natural air exchange in the kitchen also helps maintain a constant room temperature.

The fat filter is always active, no matter what mode the slider is in. But it is not required to change it throughout the entire service life of the hood. You just need to take care of it regularly, cleaning it from fatty deposits.

Kitchen hood with duct: duct shapes

Exhaust air ducts also differ in cross-sectional shape. In fact, there are 3 types of products.

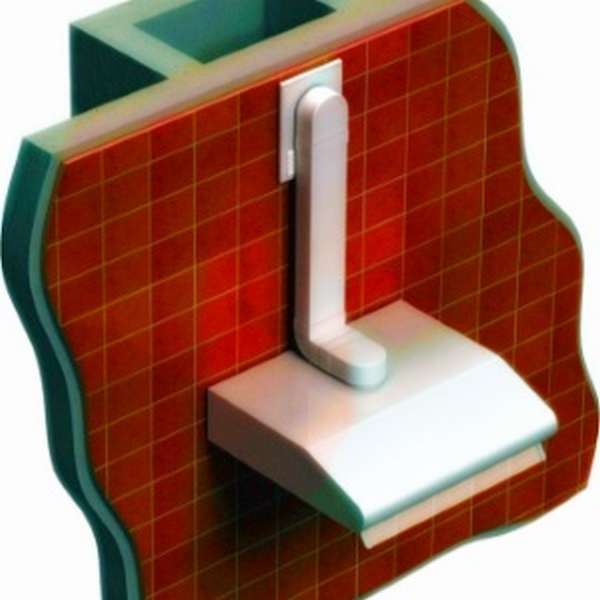

- Round. Ideal for rooms with high ceilings. They are not used for kitchens with a low ceiling area due to their bulkiness. If the outlet of the ventilation system has a rectangular shape, additional adapters, couplings, connecting elements will be required.

- Rectangular. A rectangular duct is traditionally placed behind cabinets. The structures are sectional with adapters. Due to this, it is possible to design products of any level of complexity. They have proven themselves well for hoods in kitchens with low ceilings. The main disadvantage is low productivity in comparison with other products in shape.

- Oval. These are combined solutions that combine the advantages and disadvantages of circular ducts.

A flat duct is a branch of rectangular products. Their main advantages are compact size, so they can be easily hidden from prying eyes. Traditionally produced in 3 standard sizes:

- 20660 mm - one of the largest structures on the market. Mostly such solutions are completed with powerful exhaust systems that provide air exchange of large volumes.

- 120x60 mm - flat air ducts for hoods with a capacity of up to 350 m3 / h.

- 110x55 mm - the most popular household products. The maximum capacity does not exceed 300 m3 / h.

There are a huge number, thanks to which it will not be difficult to install an air duct. It is very important to correctly select the design and dimensions of the air ducts for the kitchen hood.

teplomex.ru

Please tell me, which of you will enjoy the unpleasant odor that is constantly present in your kitchen? How many of you would like to watch kitchen furniture, once sparkling with cleanliness, become covered with a brown layer of soot and grease?

I think that such a picture is familiar to many, but not pleasant to anyone, what should be done? Purchase a good kitchen hood, which will not only save you from the problems listed above, but also make your kitchen design more interesting and add the necessary coziness to it.

The choice of hoods for the kitchen is very wide and varied, there are different types and sizes. In order for your choice to be made correctly, you need to know the principles of operation of this very important and necessary household appliances, which we will now talk about.

If all hoods are divided according to the principle of their operation, then we will get two main types of these devices: flow hoods, requiring an air duct, and recirculation hoods, operating on the principle of filtering polluted air.

Hood to the kitchen without an air duct: advantages and disadvantages

The hoods of the second type (air cleaners) do not have an air duct, they have a powerful motor and a double filtration system. First, the motor draws in polluted air and removes small impurities of burning, grease and soot, then, passing through a double filter, the air is further purified and returned to your favorite kitchen space.

Hood without air duct

For some reason, many housewives and kitchen owners are sure that such an air purification system is not effective and consider hoods with an air duct to be more preferable in their kitchen facilities, but this is not so.

Air that has passed through the ventilation system of your home, i.e. with the help of a flow-through hood, it is removed directly into the street, from where clean air enters your kitchen.

But no one can have any guarantees that the ventilation system itself in the house is absolutely operational, that it has not reduced the efficiency of work due to increased loads. If you use the hood without an air duct, this problem will not affect you. This is perhaps the most important advantage of the second type of hoods.

The next, important advantage of the recirculation hood is that for its operation it is not necessary to mount additional structures in the form of pipes, and also to think about their fastening and installation. As they say, bought, attached and works.

Contrary to the doubts of many, the filters of this hood not only deeply clean the air, but can also be easily washed by hand or in a dishwasher. One of the important advantages of a hood without an air duct is its relatively low price.

It turns out that you save not only on the product, but also on the installation of additional equipment. Those who assure us of the low quality of such hoods are wrong: they clean the polluted air efficiently and do not create an additional load on the ventilation system of your home.

But, like any product, recirculation hoods have their drawbacks. The biggest drawback is that carbon filtersused in these devices must be changed regularly, at a frequency of approximately every three to six months, depending on the intensity of your gas stove.

Replacement filters for hoods

Another relative drawback is that hoods of this type do not differ in a variety of designs, they look quite simple and modest. For this reason, using them in rooms with an author's design or in kitchens with a special style is not possible for many.

In order not to be mistaken in choosing a hood without an air duct, consider some rules:

1. To correctly calculate the required performance of the hood, you need to multiply the area of your kitchen by the value of its height, and then multiply the resulting figure by 12. This will be the number corresponding to the performance of the appliance.

2. Do not buy a hood with a higher capacity, hoping it will be more effective in cleaning the air. The larger the device, the more noise its motor will produce. When buying a product, give preference to a hood that has low noise performance.

Hood for kitchen with air duct

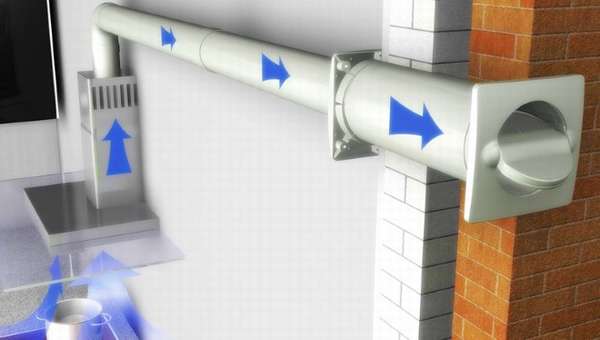

Now it's time to talk about hoods with an air duct, i.e. about flow devices. As mentioned above, such hoods work on the principle of complete air replacement.First, the powerful motor draws in the polluted air, and then completely expels it through the ventilation system directly into the street.

Hood with air duct

Such hoods have a much higher power, but also much more noise from them.

What are the advantages of these devices?

Firstly, in a high efficiency (up to 100%).

Secondly, in high power and in the absence of the need for constant cleaning and replacement of filters.

If a lot of food is being prepared in your home, then such a hood will suit you very much, if the design of your kitchen meets your high demands, you also need to pay attention to the hood with an air duct.

With all the advantages of this device, it also has disadvantages that must be taken into account when buying a product:

1. The need to install an air exhaust system

2. High noise level

3. Difficulty in installation

4. Quite high price

5. When operating this type of hood, when clean air comes directly from the street, it is possible that the temperature of the air mass in your kitchen rises in the summer and decreases in winter days.

What pipes for hoods in the kitchen are better to use?

In order to create an air extraction system, it is necessary to choose the right pipes for it, which differ in the types of material and in the shape of the section.

Exhaust pipes

Pipes are:

- plastic - metal - corrugated

Plastic pipes have a round or rectangular cross-section. Round pipes have a higher efficiency level, but rectangular pipes fit more easily into the interior of the kitchen, since they can be placed both above the furniture and under the ceiling, wherever you like.

Plastic pipes are good at absorbing noise during the operation of the hood, and metal pipes, for example, even amplify it. Plastic pipes do not get clogged with dirt like corrugated pipes.

But at the same time, their main drawback is that corrugated pipes have a number of indisputable advantages: they can be stretched to the amount you need, they do not require additional connecting parts, they can be of large diameter, and have a lower price.

As for the diameter of any exhaust pipe, it must exactly match the diameter of the outlet, no more, no less. Please note that pipes are installed only at an obtuse angle; any bend up to 90 degrees will reduce the efficiency of the hood by 10 percent or more. We watch the video review.

How to choose the size and design of the duct

A wide range of structures used for the supply and removal of oxygen is presented in hardware stores. Products of the following type are more common:

- aluminum corrugations,

- round pipes made of heat-resistant plastic,

- corrugated plastic,

- rectangular structures (often flat air ducts for hoods),

- products made of galvanized or stainless steel.

For household ventilation, plastic rectangular pipes, aluminum corrugations of a circular cross-section are often used. The choice is due to the ease and simplicity of installation, even an inexperienced master can cope with this task.

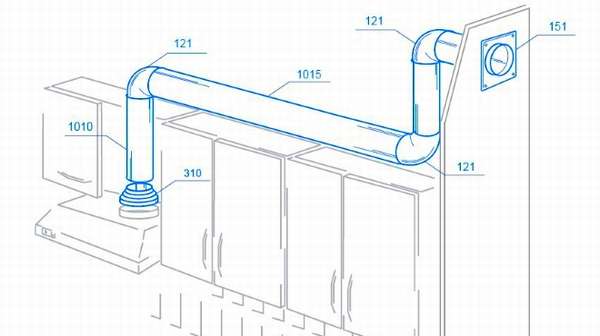

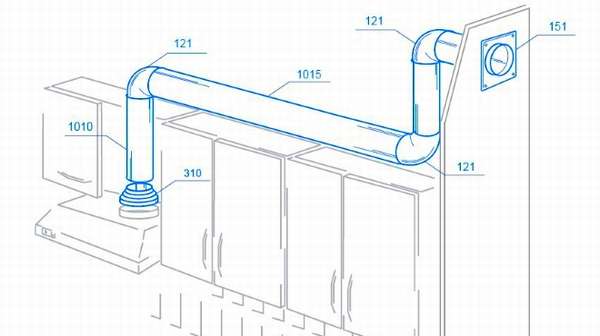

Determining the design and diameter

The task of paramount importance is to determine the design of the pipes, their diameter. It is very important to adhere to a few simple rules:

- The diameter of the duct should correspond to or slightly larger than the outlet of the cooker hood. It must also match the outlet of the ventilation duct. If the dimensions turn out to be smaller, then the performance of the ventilation system will deteriorate. Inside the structure, additional resistance to air flow will arise. This will certainly provoke an increase in noise. As a result, the hood with an air duct will fail very quickly. All parts and structural elements must be measured prior to purchasing a fume hood.

- The maximum duct length is 3 meters, while for each extra meter, the ventilation efficiency is reduced by 10%.

- An important condition for the correct installation and operation of the exhaust device is the minimum number of bends. The maximum angle should not exceed 90 degrees, as each angle results in a 10% drop in performance. If the structure is installed at an angle of more than 90 degrees, a reverse thrust effect may occur, and a check valve cannot be dispensed with.

Regardless of which air duct you have chosen, it is important to realize that installing an exhaust hood will not replace a full-fledged ventilation system. These products must function in an integrated manner, together. Check valves are indispensable.

It doesn't make much sense to enlarge the section. There is no benefit from this, since it will not entail an increase in the capacity of the hood. The installed channel will become heavier, the weight of the structure will increase, which will certainly hit the family budget.

Round air ducts

With a comparable cross-sectional area, round air ducts take up more space in height than rectangular ones, but if the building height allows, then it is better to use air ducts with a circular cross section. Less noise, less resistance and the entire ventilation system will be more energy efficient. This is important to reduce operating costs as well as initial capital costs (smaller fan sizes).

The interior can also be added to the requirements for choosing a ventilation system. And this criterion can become a decisive choice of the duct cross-section.

Indeed, in order to hide a round duct, much more space is needed, which may require a change in the design of the room, which is not always acceptable. This is not to mention placing them outside, which will completely ruin the look of the building. In this case, rectangular air ducts will help you.

Recommendations: Entrust the design to professional engineers and invite a specialist who, by virtue of his experience, will offer proven solutions.

Hood for kitchen with duct: installation of the duct

Installation of an air duct for a kitchen hood begins with the assembly of the structure, provided that all dimensions are selected correctly. Below are some important rules. The material from which the channel is made is of key importance.

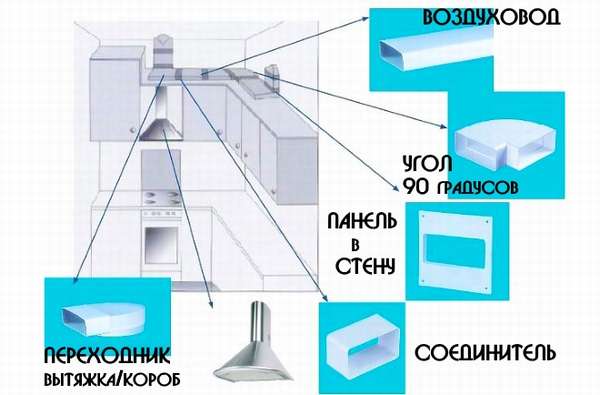

- Plastic solutions. For these designs, the installation process is extremely simple. The air duct can be easily adjusted in size by sawing it with a hacksaw, and then assembled very quickly. To increase the insulation of the structure, a special sealant is used. To connect a rectangular pipe to a round opening of the ventilation duct, use special couplings and adapters.

- Corrugated channels. It is easiest to connect the corrugated pipe to the ventilation duct, since the aluminum stretches, which makes the product flexible. The corrugation has special fixing clamps on each side, which greatly simplifies installation. Fastening is easy with a household tool.

- Hardware. The installation of an exhaust duct is often more difficult than plastic solutions. The structure is assembled using overlapping technology. To ensure the structure with optimal tightness, special adhesives are used. The fasteners are inserted into the holes made in the wall. For low strength, the structure is sealed with a sealant.

When completing the installation of a kitchen hood with your own hands, it is important to take care of masking the connecting elements, metal structures. This is done with furniture or special decorative elements.

Which air ducts are better - plastic or corrugated?

Now two types of air duct pipes are used: plastic and aluminum corrugated. The cross section of plastic products can be round or rectangular.Round plastic air ducts have less air resistance than rectangular ones, so they work more efficiently. But rectangular air ducts in the interior look more natural, they merge with furniture and other kitchen equipment.

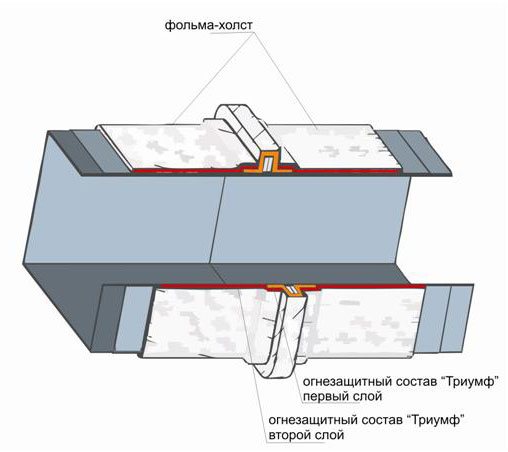

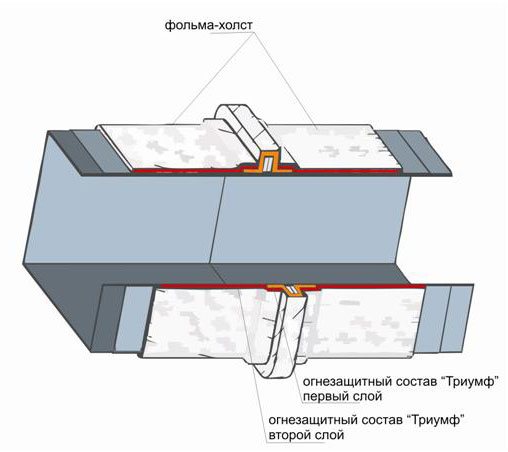

Diagram of the air duct fire protection system.

Great attention should be paid to the quality of the connections when installing the elements of the air pipe. Therefore, it is better to buy all the components for the system together with plastic pipes, so that there are no problems when joining the elements. Corrugated pipes do not need connecting elements, they can be easily bent at any angle, as well as stretch and contract. Their installation is reduced to fixing one end of the pipe to the opening of the ventilation duct, and the opposite - to the outlet of the exhaust device. In addition to ease of installation, another advantage of corrugated pipes over plastic ones is their low weight. And the disadvantages include noise during the operation of the exhaust system, the accumulation of fat and soot on the inner walls of the pipe. Plastic air ducts have a lot of advantages:

- noiselessness of work;

- low air resistance due to smooth inner walls;

- are not clogged with dirt, all waste is discharged into the ventilation shaft.

The disadvantages of plastic pipes include more complex installation and the need for connecting components, as well as a higher cost in comparison with corrugated pipes.

How to effectively hide the structure

To give the kitchen a presentable look, you should not only fix the products, but also know how to hide the fruits of your creativity. Experts have developed several effective ways to hide the duct. The following methods deserve special attention:

- The use of decorative boxes. In fact, we are talking about modified casings that differ not only in the manufacturing method, but also in shape and color. In some cases, it is better to install several decorative lights.

- False ceiling installation. Horizontal pipes are easiest to hide if they are mounted in a false ceiling. As for the vertical sections, protective decorative covers are made for them from a material that echoes the ceiling.

- Making a decorative plasterboard box. The box is matched to the design of the kitchen, while the design itself is painted in the color of the wallpaper.

- Laying pipes inside furniture. Installation is reduced to an internal gasket.

There are many pipes and ducts on the market through which you can install and connect a kitchen hood for a kitchen with an air duct to ventilation. The choice comes down not only to the selection of products with optimal design characteristics. They take into account the personal preferences of the owners, ease of installation, productivity.