What are pellet stoves?

Pellet boilers, or fireplaces, are called structures that heat the premises due to the combustion of a special type of fuel - pellets. The latter are small compressed pellets from wood waste. The fuel is completely safe - the absence of any harmful substances makes it environmentally friendly. Including glue.

There are two main types of pellets:

- industrial; they are made from different types of waste, therefore the consumption of granules is higher, and the efficiency of the furnace is lower;

- household; these are made from high quality raw materials, and therefore the thermal efficiency is much higher.

It is recommended to use only the latter type for loading boilers in private buildings. Moreover, it is advisable to select pellets based on the characteristics of a particular device - this will increase the heat transfer and the operating life of the furnace.

Which burns better: wood or pellets?

There is a misconception that firewood and pellets burn exactly the same, that the advantage of pellets is exclusively in their convenient form, which eliminates the need for sawing or chopping. In fact, this is not the case.

Since wood is much more humid than pellets, a very large part of the energy that is required when burning wood is spent on evaporating excess moisture. Only after the excess moisture has evaporated does combustion start directly.

In addition to combustible fiber, the composition also includes ash - the same non-combustible ash, as well as a certain amount of other non-combustible substances. The proportional composition of wood is well represented in the figure. Remarkably, the composition of the pellets is exactly the same, only the mass fractions of the substances differ significantly. As mentioned above, the ash volume ranges from 0.5 to 3%, and the water volume ranges from 5 to 8%. This means that the energy required for evaporation is several times less, respectively, more energy goes directly to heating.

Often the consumer has a question why a smaller amount of pellets is needed in comparison with firewood for heating. The reason lies in the fact that the granules have a higher density. The combustible fiber in the process of grinding and processing passes through the granulator, under pressure takes the form of small solid cylinders. If the wood is thrown into the water, it will float, but the pellets will drown due to the high density.

It is the ratio of the mass fractions of combustible fiber, water and ash that affects the combustion process and calorific value. It is significantly higher for pellets. Burning 1600 kg of wood produces the same amount of heat as burning 1000 kg of pellets. Accordingly, although it is more profitable when buying firewood by weight, savings are lost due to the fact that such fuel is needed 1.5-2 times more.

Separately, I would like to note that pellets are the result of competent disposal. The raw material for their production is material that no one needs anymore and is intended for disposal. Many enterprises generate biological waste in hundreds and even thousands of tons. And living conditioned forest is often cut for firewood. Such use of natural resources is far from the most reasonable.

The conclusion is clear: pellets are a much more modern, efficient and promising fuel. The only circumstances that still hold the lead for firewood are its familiarity and lower price.

Source: blog.flexyheat.ru

Types of pellet boilers

Heating equipment of this type is classified based on different criteria.

According to the materials from which the structure is made

Most fireplaces are made of high quality steel.Devices, the main material of which is cast iron, are much less common.

By type of burner

There are ovens:

- torch; the most popular "household" option; flare boilers are characterized by low power, ease of operation and adjustment, reliability; among the minuses of the type - sensitivity to fuel quality and unidirectional heating of the furnace walls;

- fireplaces; a special feature - the pellets are burned in a special pellet bowl; there are fewer regulation possibilities, and there is also a demand for fuel; but such stoves can be placed in rooms - the equipment is quiet and safe;

- volumetric combustion; much more often, similar burners are used in industrial-type devices, but they also have a place in household units; minus - increased bulkiness; advantages - higher power and undemandingness to granules (in Russian realities, the latter aspect is of considerable importance).

By type of fuel supply

Furnaces are divided into:

- mechanical; the operator of such a boiler turns into a stoker, forced to constantly monitor the combustion process;

- semi-automatic; manually only power is set here - the rest of the control falls on the shoulders of the automation; from the point of view of the ratio of cost and quality, this option is preferable to others;

- automatic; only a fuel load is required from the user - the automation will do the rest; but for the initial setup of the equipment, it is better to call specialists - they will make all the necessary calculations based on the size of the room, the required temperature and other parameters.

By type of fuel

Picture 2. Pellet boiler

Pellet boilers operate on different types of fuel. There are ovens:

- working exclusively on wood pellets; in the absence of the opportunity to regularly provide oneself with pressed fuel, it makes no sense to purchase such equipment; even at the stage of choosing a furnace, it is necessary to think over options for supplying granules of a suitable type;

- partially combined; the use of briquettes and firewood is allowed - this is facilitated by the format of the firebox; but the main role of fuel is played by pellets, while other options are helpful in situations where there is no access to pellets; ignoring this rule leads to equipment failure;

- combined; these units have several furnaces of different formats; therefore, it is allowed to use both pellets and firewood with briquettes on a regular basis; the disadvantages of the combined devices are the high price and decent dimensions.

By appointment

Depending on the goals, the equipment is divided into:

- fireplaces-convectors; their task is to heat the air; the most popular option - such stoves take up little space, have the "right" to be placed in residential premises and easily "get along" with any interior design;

- water heating boilers; differ in solid size and expressionless appearance; they are usually installed in utility rooms or basements;

- hybrid aggregates; the task of combined devices is both direct heating of air and heating of the coolant; in terms of design, they are close to convection equipment.

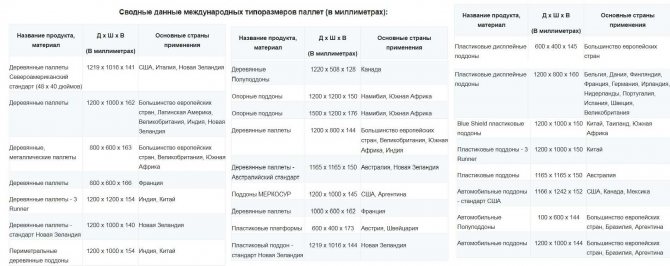

Pallet and Pallet Standards

Various pallet standards are used in industry and manufacturing. The most common:

| EUR pallet | has a corresponding stamp |

| dimensions - 800x1200x145 mm | |

| there is a marking of the country of the manufacturer in letter | |

| the frame is made of two wide and one narrow boards without chamfers | |

| the deck consists of 5 planks, two narrow and three wide | |

| Finnish pallet | has a stamp, as well as the date of issue and the manufacturer's code |

| size - 800x1200x145 mm | |

| frame of three boards - one wide and two narrow | |

| flooring of 7 boards, alternating in width - one wide, two narrow | |

| American pallet | size - 1200х1200х145 mm |

| bottom of three boards | |

| top of seven boards | |

| board thickness - at least 6 mm | |

| Cargo pallet 800x1200 or 1000x1200 mm | no stigma |

| board thickness - from 20 to 22 mm | |

| product 800x1200 is analogous to a euro pallet | |

| product 1000x1200 is analogous to the Finnish flight | |

| Pallet 1000x1000 | has an equilateral base |

At the moment, there are a large number of types of pallets with various design features - rigid, folding, with additional removable or non-removable elements. An example is pallets designed for packing, storing and transporting tires, equipped with folding racks located at the corners of the structure. They are necessary for stacking pallets on top of each other and prevent products from creasing. When storing containers, the racks are folded, as a result of which the pallets take up a minimum of space.

In commercial premises and halls, pallets-trolleys with two walls of one and a half to two meters are used, on which it is convenient to transport a large volume of cargo.

According to the classification, pallets and pallets can be divided into industrial, transportation, construction and trade and exhibition. Shipping pallets are also used in commercial processes, but only partially.

There are also specialized pallets that are integrated for a specific product or process. They have additional devices to facilitate unloading / loading, storage and transportation.

Businesses and industries often use custom pallets and pallets. Their characteristics are determined by the product being manufactured, the requirements of the production process, the size of the conveyor belt and other features of the work activities. Such products are also relevant in automated warehouses.

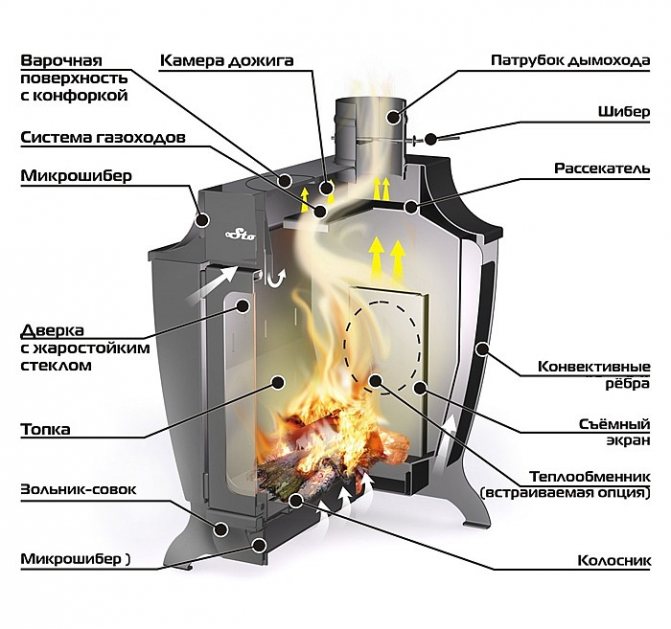

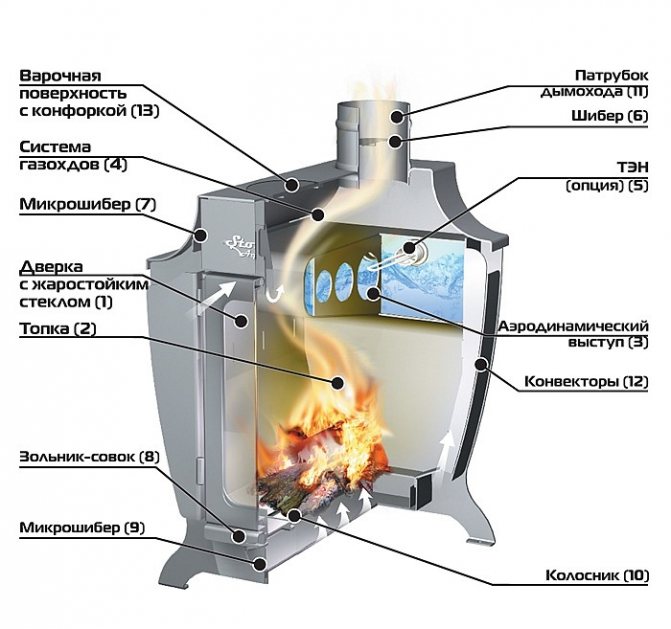

The device of furnaces operating on fuel pellets

Figure 3. Pellet stove device

Pellet stoves have the following design:

- metal body - quality stainless steel or cast iron;

- bunker area for filling fuel; some models are designed for external silos;

- an electric screw feeding granules in portions into the combustion chamber;

- fan; its purpose is to supply cold air from the room to the device and remove hot air (together with working off) to the outside;

- firebox;

- burner;

- ash pan - an element for collecting wood waste;

- a heat exchanger designed to circulate cold / hot air;

- thermostat and control panel.

Furnace working principle

Picture 4. Pellet boiler of industrial type

For the operation of pellet boilers, electricity is needed. Thanks to him, the control unit, fan and auger work. After loading the granules, they are fed into the combustion chamber in portions - by means of a screw. Due to the suction of air from the room, the fuel is ignited. It takes a maximum of 10 minutes to start the system.

Important! The independence of stoves from power systems is conditional. The operation of boilers is impossible without electricity

The gases formed during the combustion process enter the heat exchanger. From here, a fan distributes them around the room. The smoke goes into the chimney. Most modern models are equipped with a thermostat that sets and controls a certain temperature in the room.

The resulting ash goes to the ash pan. There is very little waste from the burnt pellets. The average cleaning frequency is once a month. Advanced models require even rarer attention to this aspect - even to the extent of disposing of waste every two months.

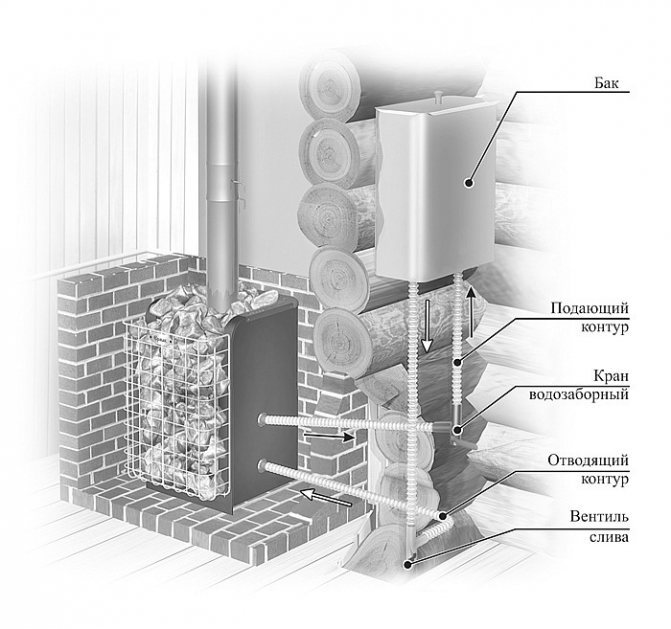

In the presence of a water heating system, along with air, the liquid also heats up. Water circulates through pipes, if necessary, entering special containers.

Automation greatly simplifies the interaction of the user with the oven. The computerized system makes every stage of the boiler more efficient and safer.

Figure 5. Boiler operation diagram

Pallet recipe

Manufacturing of pallets for heating takes place in accordance with GOST R 54220-2010 and includes the stages of raw material grinding, drying, water treatment, pressing and drying:

- Primary crushing of raw materials into fragments of 25x25x2 mm, which will facilitate their drying.

- In a dryer, drum or belt type, using electricity, the moisture content of the crushed material is brought to 8–12%.

- After secondary crushing, pieces of raw material are crushed to a size of no more than 1.5 mm... The bulk density of 150 kg / m3 ± 5% will indicate the high quality of the product. Sawdust, shavings and wood chips are processed in hammer mills.

- Too dry / wet fine-grained material is difficult to press... Stirring the bio-mixture in screw mixers, water is dosed to it - for soft wood species, or hot steam - for hard ones.

- Pressing with flat / cylindrical dies produces familiar pellets with a diameter of 6 mm for the consumer and 10 for the industry.

- Cooling, in addition to direct use, also dries the granules that come out of the press heated to 70–80 ° C.

- Finished products are sieved and packed in 20 kg bags or stored in bins.

The complexity of the technological process makes the production of fuel at home difficult - when making equipment with your own hands, the main problem is making a matrix.

And energy-intensive, which is important - for drying, for example, 1 ton of sawdust is spent 1 MW of energy / 1 ton of moisture. If there are available funds, it will be cheaper to buy a mini-pellet plant in order to receive a guaranteed profit.

Advantages and disadvantages of pellet boilers

The popularity of pellet boilers is growing due to a series of advantages. Among them:

- efficient heat dissipation; The efficiency of such devices is comparable to the efficiency of gas heating devices and is significantly higher than the efficiency of wood-burning stoves;

- fuel economy;

- complete environmental friendliness; the absence of any harmful substances in the granules;

- autonomy; subject to the availability of an automated system, the user is deprived of the need to control the combustion process - the automation does almost everything for a person;

- independence from main power systems;

- almost complete zero waste - when burned, the granules leave a very small amount of ash; ash pan cleaning is rarely required;

- equipment safety and no need to coordinate the installation with the relevant services;

- aesthetic design of boilers-fireplaces - the ability to "fit" the unit into any interior.

Figure 6. Furnace with a modern aesthetic design

Not without its drawbacks. These include:

- the need for electricity, without which it is impossible to ignite fuel, the operation of the auger and the control unit;

- high cost of equipment; average price range - 100,000-1,000,000 rubles;

- dependence of European models on Russian energy systems and pellet quality; devices can be sensitive to power surges and demanding fuel; when choosing a stove, you should definitely consider protection against voltage surges and the possibility of purchasing granules suitable for a particular model.

Given the financial resources, the advantages of stoves outweigh their disadvantages.

Small pallet, but flammable

Renewable energy sources - land, water, sun, are becoming more and more popular as a fuel material for country houses.

Particularly noteworthy is heating with pillets - cylindrical pressed granules, which are produced from biological raw materials:

- husks;

- wood;

- household waste;

- sea grass;

- peat;

- straw.

The extraordinary hardness of the pellets is given by lignin - a substance originally contained in the material.If oak wood has a density of 640, birch - 570, aspen - 370 kg / m3, then for finished granules the indicator increases to 1100-1400. Due to this density, the granules are so heavy that they sink in water.

This physical quantity promises undeniable advantages when it comes to:

- fuel quality - “fresh” firewood contains from 40 to 50% moisture, which cannot be said about pellets;

- heat transfer - up to 19 MJ / kg. For clarity, 1 kg of granules is enough to heat about 45 liters of water from 0 ° C to boiling;

- efficiency - 1 ton of pellets is equivalent to 1.5 tons of firewood or 500 liters of diesel fuel;

- waste-free - low ash content - up to 1%, contributes to the formation of a minimum of ash (15 - 20 times lower than after coal combustion), but it can also be used as a valuable mineral fertilizer;

- health safety - pellets emit a minimum of carbon monoxide.

Two sides of the coin

Every thing in the world contains positive and negative qualities and pellets are no exception.

Disadvantages include:

- the high price of boilers, especially compared to gas or electric boilers. A boiler with a capacity of 15–20 kW costs from 4000 cu. e.

Note! In solid fuel boilers, it is possible to replace the burner with a pallet burner, which will help save up to 1000 USD. e.

- the possibility of servicing equipment, which can become a headache if the corresponding center is located too far away;

- hypothetical possibility of inhaling harmful substances exuded by granules, if they were made from low-quality raw materials. However, there is a risk of getting caught by an unscrupulous manufacturer even when buying toilet paper.

Note! In solid fuel boilers, it is possible to replace the burner with a pallet burner, which will help save up to 1000 USD. e.

Pellet fuel has more bright sides and it pleases:

- environmental Safety;

- the use of biofuel has no restrictions - from boiler houses and power plants to an ordinary rural house;

- ergonomic dimensions of euro fuel allow convenient storage of large quantities in small areas;

- lack of possible spontaneous combustion;

- a wide range of prices, allowing the buyer to make his choice - on average from 3200 to 7000 rubles per ton;

- relative autonomy of the heating system;

- high calorific value.

Note! The absorbent properties of the granules are useful for alternative applications such as cat litter or to collect spilled engine oil.

Your own expert

Having the minimum necessary knowledge about the properties of Euro fuel and the main requirements that are imposed on it, you can avoid annoying mistakes.

The instructions for determining the quality of fuel are simple:

- the surface of the cylinders should be perfectly smooth, polished and shiny. A gray coating indicates staleness of the product;

- standard diameter from 6 to 8 mm;

- mild sweet smell, which depends on the raw materials used;

- in water, after a while the granule becomes soaked, but if it does not lose its shape, it means that a foreign binder was used in the production process;

- having arranged a storm in a glass of water, impurities will be clearly visible - sand, dust from grinders;

- we look at information about the manufacturer - a large production, as a rule, uses raw materials from one supplier and values its reputation.

How to choose a pellet stove?

Furnace selection criteria:

- power; the most important aspect - when choosing a device, you need to build on the volume of the room; average required power - 1 kW / 10 m2; the calculation scheme is valid for rooms with a ceiling height of up to 3 m;

- type and consumption of granules; the need for pellets is variable and tied to the design of the stove and the volume of the room; average consumption of pressed fuel - ton / month;

- manufacturer and distributor; it is recommended to buy equipment from a seller who provides comprehensive or at least service;

- heat exchanger material; branded manufacturers produce furnaces only with steel heat exchangers; less popular manufacturers allow the manufacture of elements from cast iron; the cast iron option is less preferable - it is heavier and is characterized by greater thermal inertness.

Errors in the operation of pellet stoves

A pellet boiler can be expensive and of high quality, but if the choice of the appliance was wrong, disappointment is inevitable. The main mistake lies in the general non-compliance of the boiler with the goals of consumers. It is necessary to be clearly aware of your needs and how the oven is able to satisfy them. First of all, the equipment must be evaluated in terms of its type and selection criteria.

A common mistake is the incorrect calculation of the boiler power and the heat loss of the room. The result is too low or high temperature. Better to spend more time, but make the right calculations. Better yet, entrust it to a specialist.

Poor oven performance is another annoying problem. It is usually connected (if we are not talking about low-quality equipment) with realities typical for Russia - the mentioned unimportant quality of power grids and fuel.

Let's briefly list three more possible troubles:

- chimney sparking; the reason is the wrong choice of the latter;

- wood dust scattering around the room; the reason is the incorrect choice of a place for the oven;

- increased frequency of filling the ash pan; the reason is incorrect setting of the pellet burner.

Summarizing

Heating with pallets is not the cheapest pleasure, especially at the stage of installing equipment or re-equipping an existing boiler. But everyone chooses his own path and sometimes, what seems unprofitable and expensive now, in the future will become convenient and feasible.

By using biofuels, if it is comforting, you will make a significant contribution to the protection of the environment. And the vagaries of the weather - warm winter, early spring, can lead to significant fuel savings.

If you nevertheless decide to make pallets yourself, the video will help solve the main problem - to make a matrix.

Did you like the article? Subscribe to our channel Yandex.Zen