What are LPG boilers?

It should be immediately clear that there are no special boilers designed to operate exclusively on liquefied fuel: for this purpose, standard gas units can be used, the factory design of which provides for the possibility of changeover from natural gas to LPG and vice versa.

In addition, a boiler suitable for LPG must have a low operating pressure (3-5 mbar) in order to ensure a more complete fuel production.

What are they for and how are they used?

Organization of operation of propane gas boilers using no more than 1-3 cylinders.

Actually, of the many reasons why homeowners prefer to heat their home with liquefied fuel, there are several main ones:

- temporary lack of supply or connection of a direct gas pipeline;

- inaccessibility or high cost of other resources in local conditions;

- the need to heat small households (40–100 m2).

The procedure for gasification of a site is often delayed (you need to save money, take a permit, approve a project, etc.), therefore, during such a period, LPG helps out.

If you do not consider the option that a person lives in a coal-mining region, then cylinders are cheaper than other fuels, especially electricity.

And best of all, a liquefied gas boiler is suitable for small houses, because the installation of 1-3 cylinders does not take up space and does not require approval.

Device and principle of operation

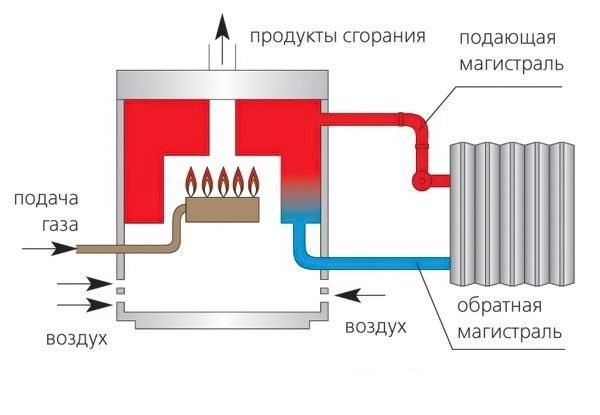

The principle of operation of the classic floor gas aspirated.

An LPG boiler functions like any similar device - it burns fuel and directs energy to warm up the circulating heat carrier (water).

But liquefied gas cannot be supplied directly. A standard injection burner has too large nozzles (holes), therefore, it is simply not designed for such a fuel: the gas is supplied in an excessive amount, which leads to overheating (later to deformation) of the equipment or even to an explosion.

Therefore, initially you need to put injectors (sprayers) of a smaller diameter and connect a reducer (pressure equalization device) - the pressure drop at the outlet of the cylinder will ensure the transition of the fuel from the liquid to the gaseous form. And already in this state, it enters the combustion chamber.

This is what a kit for converting a boiler to liquefied gas looks like. It can be ordered with the boiler or purchased separately. In some models, the replacement kit is already included in the basic configuration.

The liquefied gas boiler has no other design features: otherwise it is identical to a traditional unit.

Operation specifics

To ensure uninterrupted heating of the home, you will have to organize a storage facility, the capacity of which must correspond to the amount of gas reserves:

- a group of cylinders on the ramp - a combination of 4-15 cylinders with a volume of 0.2-0.7 m3;

- mobile gas tank - a movable tank with a capacity of 0.4–1.4 m3;

- stationary gas tank - built-in tank with a capacity of 3–50 m3.

Group of cylinders on the ramp together with the collectors, it is placed in a strong steel box, which is carried out at a distance of 1–2 m from the house or mounted to the wall of the building (with fire resistance higher than III degree). Short-term supplies (1-3 cylinders) are allowed to be stored directly at home, but not in underground levels.

It is forbidden to stockpile LPG in basements! In the event of a leak, the heavy gas settles at the lower building marks, which creates a fire and explosive situation.

An example of storing a group of cylinders in a steel box near the wall of a private house.

Mobile gas tank (mini-gas holder) is fixed to a trailer (like a car) and is located no closer than 10–12 m from a residential building. To avoid freezing of condensate during cold periods, the sealed container is equipped with an electric heater, which is included in the general heating network.

Stationary gas tank it is always installed underground - the tank is completely buried (only the cover and controls remain on top), and gas pipes are pulled to the house or to the boiler room. It, thanks to the surroundings of the walls with soil, does not need additional heating.

Layout of a stationary gas tank on the territory of a private house.

The minimum distance from a stationary gas tank to a residential building is determined by the technical supervision authorities, depending on the volume of the tank:

- distance ≥ 10 m - volume from 3 to 10 m3;

- distance ≥ 15 m - volume from 10 to 20 m3;

- distance ≥ 20 m - volume from 20 to 50 m3.

Undoubtedly, a stationary gas storage is the best option for ensuring the continuous operation of the heating system: 1-2 fillings are enough for the entire season.

In general, any of these methods of organizing a storage location for liquefied fuel is considered acceptable, but subject to safety rules:

- the container with gas must not be exposed to direct sunlight;

- its constant external temperature should not exceed + 43 ... + 45 ° C;

- it is necessary to lay gas pipelines below the level of soil freezing.

For the gas boiler itself, you will also need to allocate a suitable place: units of 10-60 kW are allowed to be installed in residential areas next to gas stoves and radiators, that is, in a regular kitchen (10-15 m2), and for 70-350 kW appliances, a room with exit to the street, it is recommended - a separate boiler room (15-25 m2).

Poll: which of the options for organizing gas storage is closest to you?

The main elements of gas cylinder heating

For a gas heating system, the home owner needs to purchase the following:

- Boiler operating both on mains and on liquefied gas. Of course, if you have extra funds, you can buy 2 boilers, each of which will be adapted for a certain type of gas. But, as it turned out from user reviews, such a decision will only lead to a waste of money. You should be aware that before connecting another type of gas, the jets or the entire burner should be replaced on the boiler. In more modern devices, it is also necessary to reconfigure the automation and control system (see video below).

Gas boiler room in a private house

- Shut-off valves. It allows you to shut off the gas flow in emergency situations or as needed, for example, during repairs. A common element of any gas line is a standard valve.

Gas ball valve - handle painted yellow

- Automation and control system. There is no particular need to install this system, but automation eliminates human intervention. Also, such systems are very often equipped with additional protection elements.

Important! Cylinder gas is heavier than air and will accumulate in the lower part of the room if it leaks. For this reason, a ventilation system must be provided that will work effectively throughout the entire boiler room. Refer to the services of qualified specialists!

- A gas reducer is a device for reducing the pressure of a gas or a gas mixture at the outlet of a container (for example, in a cylinder or a gas pipeline) to a working one and for automatically maintaining this pressure constant regardless of changes in the gas pressure in the cylinder or gas pipeline. The correct functioning of the system is impossible without a gearbox.

Gas cylinder reducer

If possible, you should use gas cylinder units, one of the manufacturers of which is the German company GOK.

All of the above elements of the gas cylinder system have a different pricing policy.It all depends on the owner of the house, but it should be remembered that the operation of low-quality and cheap gas cylinders can lead to very bad consequences.

Liquefied gas consumption

The amount of fuel consumed for heating depends on the operating conditions of the device and its technical characteristics, as a rule, power and efficiency. So, for example, according to the passport data, for the Zhukovsky AOGV-17.4-3 boiler with a capacity of 17 kW with an efficiency of 90%, the consumption of liquefied gas is 0.7 kg / h or 1.3 l / h.

Knowing that the cost of refueling in 2020 is 17-18 rubles / liter, you can roughly calculate the cost of heating a house for a certain period of time:

- per day (24 hours) - 1.3 × 24 = 31 liters × 17 (18) ≈ 527–558 rubles;

- per month (30 days) - 31 × 30 = 930 liters × 17 (18) ≈ 15810-16740 rubles;

- for the season (half a year) - 930 × 6 = 5580 l × 17 (18) ≈ 94,860-100,440 rubles.

It should be borne in mind that in a 50 liter cylinder, in fact, there is 40–42 liters of propane-butane mixture: about 15–20% of the free volume is used to increase the gas evaporation area, and overfilling leads to a decrease in its production. This means that at a flow rate of 1.3 l / h, one cylinder is enough for about 1.5 days.

But not everything is so bad: the numbers in the passport are given on the assumption that the unit will always work at maximum power in 24/7 mode, but in reality this happens only in severe frost. In warm weather, the boiler is active only 10-14 hours daily, that is, the result obtained can be safely reduced by 30-50%.

How to choose a room thermostat and save up to 30% per month on heating

Popular models

As we already wrote, there are boilers with automatic switching to another type of fuel. Let's consider several options.

ZhMZ AOGV-29-3 Comfort N

The floor-standing unit is capable of heating a room up to 250 m². Uses a combined type of fuel: liquefied gas - 2.17 kg / h, natural - 3.18. This is a single-circuit device, so you can only rely on the heating function. But it is also presented with dignity: the power is 28.9 kW, the efficiency reaches 89%.

The advantage of AOGV-29-3 regardless of electricity. Mechanical control is easy to operate. The combustion chamber is open, therefore a connection to a stationary chimney is required.

An external thermometer records the temperature in the room and adjusts the operation of the device. Gas-control protection monitors that there is no fuel leakage. Dimensions: 420x1050x480 mm.

Cost - from 26,000 rubles.

Bosch Gaz 4000 W ZWA 24-2 K

The double-circuit device will provide hot water to the DHW system and pipes on an area of 250 m². Compact dimensions (400x750x355 mm) and hinged housing allow the model to be placed in any non-residential premises. It is necessary to take care of the availability of ventilation, because Bosch Gaz 4000 W ZWA 24-2 K has an open combustion chamber.

Thermal power is 24 kW. The fuel is used in bottled and mains. The bithermal copper heat exchanger simultaneously heats the water for both circuits. Management is represented by an informative display and convenient controls. Built-in self-diagnosis function.

Interestingly, the equipment is equipped with a remote control. For example, it is in the boiler room, and you can control the modes from home. Moreover, the regulator allows you to set the "Weekend" mode. When you are not at home, the device maintains the optimum temperature. And by the appointed time, he raises her to a comfortable one.

The water in the circuit circulates forcibly thanks to the pump. The security system includes: an expansion tank for 8 liters, traction, overheating, ionization sensors, a pressure relief valve.

Price - from 31,000 rubles.

Reviews of household boilers: advantages and disadvantages

Having studied the reviews of the owners of LPG boilers, one can understand that such devices are rather ambiguous - they have both strengths and obvious weaknesses.

Advantages and disadvantages of the unitat, working on reduced gas:

| pros | Minuses |

| autonomy - such devices do not depend on the growth of utility tariffs or on the stability of the gas pipeline | refueling price - if you do not bring the gas yourself, the price includes the amount spent on its transportation |

| versatility - reverse adjustment (for natural gas combustion) is possible at any time with minimal cost | regular maintenance - small jets are clogged with sulfurous substances, so they need to be cleaned often |

| preservation of purity - cylinder fuel, unlike solid fuel, does not form ash, dust, fumes, smoke, etc. | high fire hazard - storage of fuel stocks at the site requires strict adherence to safety measures |

| environmental friendliness - most (91–95%) of LPG waste is carbon dioxide, which is then absorbed by plants | weather dependence - in winter there is a problem of snowdrifts, preventing refueling, and icing of the gearbox |

| simplicity of the system - the absence of complex parts provides protection against accidents and breakdowns, as well as ease of maintenance | additional costs - the final price depends on the estimate of earthworks, the length of the gas pipeline, the volume of the vessel, etc. |

Users of a heating system operating on LPG are obliged to constantly check the remaining fuel in the connected tank. This creates certain inconveniences, because it is necessary to frequently update the contents of gas cylinders or immediately pump a sufficient amount of gas into the storage.

Despite its simplicity, the refueling process requires care: the slightest carelessness when connecting a gas line can lead to a leak.

How to choose a LPG gas boiler?

It is impossible to say in absentia which liquefied gas boiler is better to choose, because its characteristics must strictly correspond to the characteristics of a particular room. Therefore, before purchasing, it is recommended to consult with specialists or independently deal with the technical parameters.

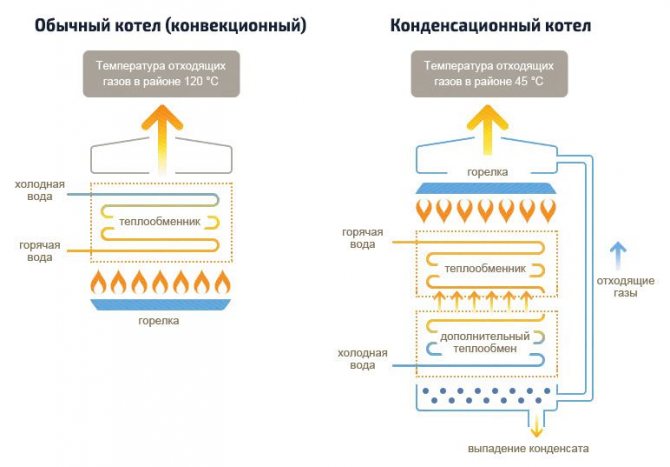

Convection or condensing

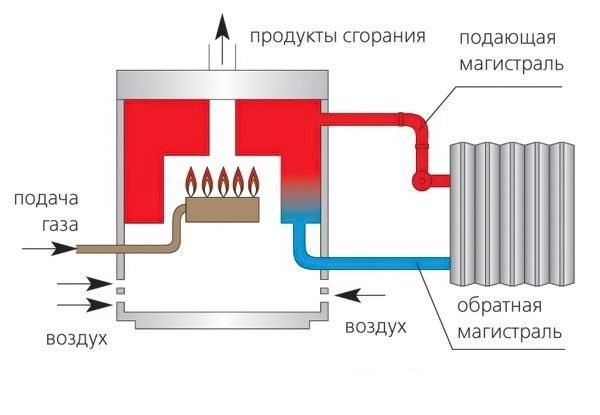

The principle of operation of conventional convection (efficiency 88-92%) and condensing (efficiency 104-109%) gas boilers.

The efficiency of the unit consuming LPG largely depends on the method of using the thermal energy released during the combustion of fuel:

- convection - heats the coolant due to the energy received from the direct combustion of gas, while part of the heat is lost, leaving with the exhaust gases;

- condensing - “extracts” additional heat by cooling the smoke and condensing steam in a low-temperature heat exchanger (economizer).

Obviously, a condensing boiler is more profitable - it saves 15–20% of fuel, but at the same time the device itself costs 1.5–2 times more than usual.

Differences and criteria for the competent choice of condensing gas boilers

Wall-mounted or floor-mounted

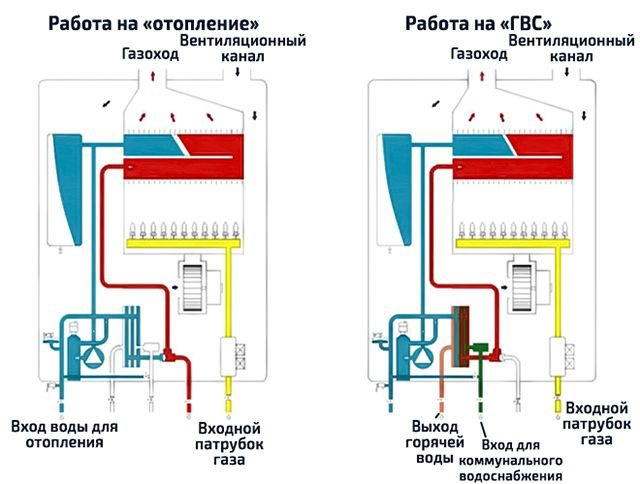

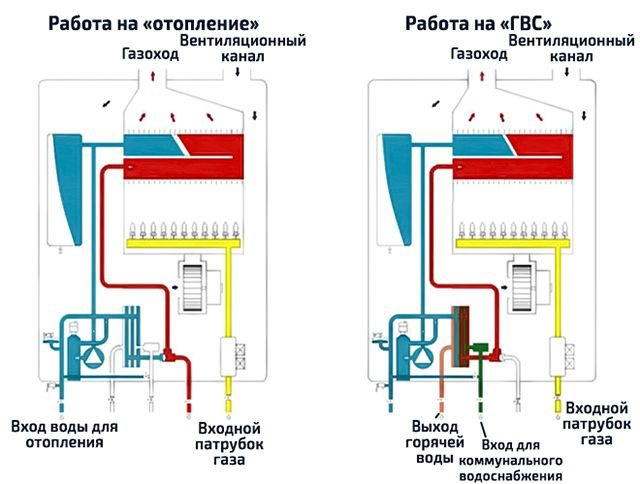

The fundamental difference between suspended and floor-standing equipment lies not only in the way it is placed, but also in the structural arrangement:

- wall-mounted models - should "fit" into a compact lightweight body, they differ in a steel / copper heat exchanger, usually more functional automation;

- floor-standing models are not limited in weight and size, therefore they can have a cast-iron heat exchanger, as well as a wider power range (10-60 kW).

Wall-mounted units are equipped with automatic equipment, a circulation pump and other volatile elements - in practice, the consumer is provided with a ready-to-operate mini-heating station. Floor standing boilers are less independent, but many of them are completely independent of electricity.

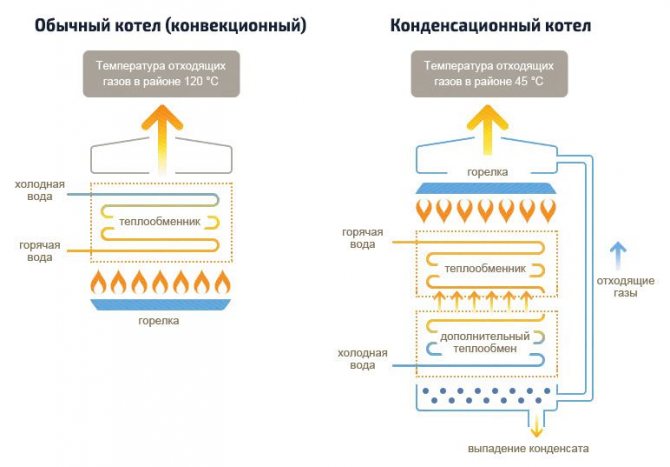

Single-circuit or double-circuit

A clear principle of operation of double-circuit boilers with the priority of hot water supply (DHW).

The number of circuits determines what tasks the gas equipment is designed for, what exactly the generated heat will be distributed to:

- single-circuit - designed directly for space heating;

- double-circuit - responsible for both heating and hot water supply (DHW).

Given the high consumption of LPG, in order to avoid unnecessary expenses, it is reasonable to take a single-circuit boiler, and connect an indirect heating boiler to it for hot water supply. However, dual-circuit models continue to be in demand as well.

Efficiency

The coefficient of performance (COP) is an indicator that determines the efficiency of the device and the economy of using energy resources.

For boilers that mainly consume reduced fuel, the efficiency value is critical: although there are samples from 85% to 97% on sale, it makes no sense to purchase units with an efficiency below 88% - otherwise, due to the relatively high fuel consumption, the cost of gas heating of the dwelling will "catch up" with electricity.

Minimum required power

To approximately calculate the power of the boiler, you can use a simplified formula, where for every 10 m2 of area there is 1* kW of energy.

*an approximate value, taking into account the temperate climate and ceilings of 2.5-3 m.

So, for example, for heating an average house of 120 m2 located in Moscow or Moscow region, the minimum required power of the unit will be 120 ÷ 10 × 1 = 12 kW.

We also recommend making allowances for possible severe frosts and buying a boiler with a margin of 15–20%, that is, for a house of 120 m2 ≈ 14 kW. Otherwise, in cold winter, a comfortable temperature will not always be maintained or working at the limit will lead to premature wear of parts.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Additional criteria

You should also pay attention to additional characteristics: they together will help make the gas boiler more productive and safe:

- protective kit - consists of a safety valve, a draft controller, an active flame sensor, an air vent and a backup power unit;

- functional automation - includes modules for auto-ignition, flame control, self-diagnostics, programming modes and external control;

- heat and sound insulation - specially selected casing prevents heat losses (increases the efficiency of the device) and reduces the noise from the burner operation.

High-quality insulation helps to get rid of the pops accompanying auto-ignition, crackling and vibrations, which is important when the boiler is in the room.

The advantages of heating with gas cylinders

Heating with bottled gas has many advantages:

- environmentally friendly fuel is used;

- autonomy;

- fuel consumption;

- pressure stability in pipes;

- simplicity of operation and ease of management.

Heating with bottled gas of a private house also makes it possible to heat hot water for domestic needs. This heating method is highly efficient because the gas quickly changes from a liquid form to its normal state. Despite this, gas cylinders are used only if it is not possible to connect the boiler to the main gas pipeline. Thus, this heating method is completely autonomous - the cylinder can be brought anywhere.

Gas heating boilers from a gas cylinder allow not only heating rooms, but also heating water for domestic purposes (this requires a heat exchanger).

It is possible to organize gas heating from cylinders not only in a new house, but also in the one in which they have been living for a long time - for this you do not have to carry out any work. But in order to connect to the main gas pipeline, it is necessary to lay pipes and carry out repairs in the house.

You can switch to heating the house with gas cylinders even if it has become unprofitable or inconvenient to use other resources.

The best manufacturers and models: characteristics and prices

The country of manufacture determines the functionality and quality of the unit: given that it is purchased for many years to come, you should not exchange for dubious equipment offered by the Chinese market. It is better to opt for proven options from European or Russian manufacturers.

Protherm Gepard 23 MOV

The well-known two-circuit mounted model with a power of 23 kW. It has an open combustion chamber (natural draft) and a copper plate heat exchanger: more heat conductive and resistant to corrosion. Excellent, considering the price category, the automation allows you to fine-tune the operation of the boiler and efficiently consume fuel (max 1.9 l / h).

The cost: 39 870 - 42 480 rubles.

Manufacturer: Protherm (Proterm), Slovakia.

Bosch Gaz WBN6000-24C RN S5700

The German BOSCH with a capacity of 24 kW is made of better materials, is not picky about the quality of fuel and coolant. It is fully adapted to Russian conditions: it is resistant to voltage drops, pressure drops and sudden cold snaps (up to -35 ° C). Economical gas consumption (max 1.5 l / h) is ensured by a modulating fan, a three-speed pump, as well as thermal insulation of the casing.

The cost: 36,900 - 38,460 rubles.

Manufacturer: Bosch Thermotechnik, Germany-Russia.

Buderus Logamax U072-18K

We can say that this inexpensive single-circuit boiler is one of the best gas boilers for liquefied gas for heating a private house: with a power of 18 kW, it consumes fuel very moderately (max 1.5 l / h). A built-in diaphragm expansion tank and a three-way valve make it easy to transfer it to DHW. At the same time, the model is known for high reliability, the nature

The cost: 26,200–31,840 rubles.

Manufacturer: Buderus (Buderus), Germany-Russia.

BAXI SLIM 1.150 I

The famous Italian floor-standing boiler of low power (15 kW) is known for the minimum gas consumption (max 1.1 l / h). From the factory, it is equipped with weather-dependent automation, a cast iron heat exchanger and a control module with an integrated self-diagnosis option. And another important plus is its modest dimensions: for example, its width is only 35 cm.

The cost: 62,090 - 71,300 rubles.

Manufacturer: Baxi, Italy.

Wester Lemax Clever-30

Domestic single-circuit wall-mounted device with a power of 30 kW, which does not depend on the availability of electricity. It can operate in a system with both forced and natural circulation of the coolant, and continuous smooth flame modulation from 30% to 100% can significantly reduce the volume of fuel consumption (max 1.7 l / h). With such a high efficiency, it also differs in reliability close to European manufacturers.

The only significant drawback is the steel heat exchanger, which is characterized by a limited resource (10-14 years).

The cost: 34 250 - 40 500 rubles.

Manufacturer: Lemax (Lemax), Russia.

Can a conventional gas boiler work from a cylinder

Propane devices are produced by domestic and foreign manufacturers. There are combined models that are successfully connected to a common highway, and, if necessary, switch to liquefied fuel.

It is possible to modify the heating circuit by replacing the burner or nozzles. Of course, not all models can be converted to LPG. The device should work stably at a pressure of 3-4 mbar. The gas valve must flow up to 1.8–2 m³ per hour.

Condensing boilers are great for rework. Their already high efficiency will increase thanks to bottled fuel.

How to reconnect a device

To switch equipment from main fuel to liquid fuel, follow these recommendations:

- Change nozzles or cartridge (depending on model).

- Connect a reducer that will reduce the pressure in the system. If the installation includes several tanks, a different gearbox can be used for each.

- Change the inlet valve if it does not fit the new system.

- When connecting 10 to 15 containers, use a special ramp. The organization is carried out either through separate gearboxes or through converters. As soon as one tank runs out of content, the system will automatically switch to the next tank.

- Adjust the settings to “tune” the instrument to propane. To do this, select G31 in the settings.

During operation, adhere to the requirements:

- The tanks should be located in a room separate from the boiler or outdoors in a cabinet. The distance from the device is at least 2 meters. Additionally, the cabinets are insulated with a layer of thermal insulation so that the containers do not freeze.

- Store the tanks outside the building unless you refuel immediately.

- Monitor the residual amount of fuel carefully. Complete development of the content is prohibited. A tightness inspection is carried out every four years.

It is equally important to store gas containers correctly. If you decide to make a supply of cylinders, then place them in a separate room at a distance of 10 meters from a residential building. The room should be well ventilated and not have a basement. Propane is heavier than air, so it will accumulate at the bottom if it leaks. Under unfavorable conditions, an explosion will occur.

Prices: summary table

Comparative rating boilers consuming liquefied fuel:

| Boiler model name | Efficiency,% | power, kWt | LPG consumption, l / h | price, rub. |

| Protherm Gepard 23 MOV | 90 | 23 | ≤ 1,9 | 40 000 |

| Bosch Gaz WBN6000-24C RN | 92 | 24 | ≤ 1,5 | 37 500 |

| Buderus Logamax U072-18K | 92 | 18 | ≤ 1,5 | 28 500 |

| BAXI SLIM 1.150 I | 90 | 15 | ≤ 1,1 | 67 000 |

| Wester Lemax Clever-30 | 90 | 30 | ≤ 1,7 | 37 000 |

Converting the boiler unit to bottled gas

Theoretically, converting the boiler to liquefied gas is not difficult: the most important thing is to replace the nozzles responsible for fuel consumption, or the entire burner. This is followed by the alteration of the gas valve (in accordance with the enclosed operating instructions) and the readjustment of the electronic board, if the unit is automated.

But you should not interfere with the internal structure of the boiler on your own; it is better to contact a licensed gas company. Specially trained personnel will cope with the task in half an hour - the maximum, while the cost of work with the purchase of all consumables will cost about 2.5-3.5 thousand rubles.

How to calculate fuel consumption

When choosing, the question arises: how much propane is needed to heat a house? The instruction manual, which indicates the characteristics of your model, will help to make accurate calculations.

It turns out that butane-fueled devices emit three times as much energy. In this case, the gas is not necessarily stored in cylinders. These can be large tanks with a capacity of several thousand kilograms. They are installed in basements.

Let's take averages. For heating an area of 100 m² with normal thermal insulation, the consumption of propane gas will be 2 cylinders for 7 days. You will need 9-10 cylinders for one month. In order not to frequently change capacities, a double-arm collector is used. 10 containers are connected to it at the same time.

Where to buy a gas boiler for liquefied gas

In Moscow and Moscow region

- MirCli (mircli.ru/kotly-otopleniya/nastennye-gazovye-kotly/odnokoturnye-kotly) - Leningradskiy Ave. 80, building G, tel. +7 (863) 303–35–06, +7 (800) 775–29–90.

- IM "Gas boilers" (https://msk.kotel-gazoviy.ru/na-szhizhennom-gaze/) - Moscow, st. Podolsk Cadets, 22, tel ..

In St. Petersburg

- ProTeplo (https://www.proteplo-spb.ru/products/kotly-na-szhizhennom-gaze) - st. Pig-iron, 14, lit. K (entrance from Mendeleevskaya 5), tel. +7 (812) 241-12-06.

- TechnoDOM (https://www.teh-dom.ru/gazovye_kotly_na_sgigennom_gaze#0) - Marshal Govorov Ave., 35, BC Yellow Corner, p. 119, tel. +7 (812) 671–00–88.

In conclusion, I would like to remind you that, despite all the advantages, liquefied fuel is not a competitor to natural gas. Nevertheless, if the connection to the pipeline is not available, then it can be argued that the LPG boiler is the most profitable and convenient option for organizing the heating of a country house.

Gas boilers