How to choose an economical convector for a summer residence, criteria

When choosing a heating electric convector, first of all, the following are evaluated:

Electrical power

The power of the convector is selected depending on the intended area of use. If the equipment is used as the main heating system, the power of the installation is calculated based on the ratio of 1 kW per 10 m2 of heated area. To the calculated value, add 15 - 20% for possible heat losses.

If the device is used as a backup system, the convector power can be significantly less. The exact value depends on the characteristics of the main heating circuit, the quality of the building's thermal insulation and the outside temperature. As a rule, the power of such convectors ranges from 150 to 500 W.

Thermostat type

Both mechanical and electronic thermostats are used in the design of modern electric convectors. Devices with mechanical adjustment are simple and reliable, but the functionality of such convectors is minimal.

The use of electronic control units ensures precise adherence to the set temperature regime, the possibility of remote and software control, and also allows you to connect additional functional modules.

The use of electronic heating convectors is advisable as the main heating system. For a redundant system, it is more profitable to purchase an inexpensive convector with a bimetallic thermostat.

Heating element type

Electric convectors can have heating elements of both open and closed type. When using an open-type heating element, there is a high probability of burning out oxygen, and in addition, corrosive destruction of the wire spiral is possible under the influence of natural air humidity.

In closed-type heating elements, the filament is placed in a sealed tube with special aluminum fins designed to increase the efficiency of heat transfer. The use of such heating elements completely eliminates oxygen combustion and corrosion. Despite the higher cost, it is the closed heating elements that are most widely used.

Additional functions

As a rule, additional functions are available for convectors with an electronic control system, they are extremely rare in "mechanical" convectors. The most requested additional features include:

- Anti-freeze mode. When this function is enabled, the unit automatically maintains the room temperature at +5 C, preventing the building from completely freezing in the absence of the owners;

- Work in the programmed mode. The option allows you to automatically change the temperature mode in order to save energy. For example, in the absence of the owners, the convector can operate in the minimum heating mode, and at a certain time, an hour or two before their return, the device switches to the optimal temperature mode.

- The remote control makes operating the device comfortable.

- Switching the convector on and off using a timer can significantly reduce energy consumption.

Device security

To ensure safe operation, the convector must have a number of basic protective functions:

- Reliable protection against moisture ingress;

- Turning off the heating element in case of overturning will avoid a fire;

- Turning off the heating element in case of overheating of the device;

- Protection against freezing, which consists in maintaining the temperature within +5 - 7 C in autonomous mode in the absence of owners.

In addition, if the convector is installed in a children's room, the presence of sharp edges and corners that could injure the child are unacceptable.

Attention to the heating element (TEN)

In modern models of electric convectors, heating elements of three types are used:

- needle-like;

- tubular with aluminum fins;

- monolithic.

Needle-like in their appearance represent a plate of small thickness, which is made of a dielectric material. A chrome-nickel heating thread is installed on it. It forms loops on both sides of itself. And x heating and cooling occurs in a short period of time. In devices based on a needle heater, the convection process is carried out mainly due to the design of its body.

Thread in a needle heater has a varnish coating, but it is poorly protected from moisture. Therefore, electric convectors with this heating element are not recommended for use in rooms with high humidity levels. The main advantage of such installations is their reasonable price. However, their service life is short. Needle heaters are rarely used in convector equipment. But, if in the store you come across such a device, then it is better to pass by.

The tubular heating element is familiar to many. It is found not only in electric convectors, but also in water heaters. By myself he presents a steel tube, which is covered with nichrome thread. The tube is filled with a backfill with insulating properties, which in addition has good thermal conductivity. Aluminum fins are attached to the tube. They provide efficient heat transfer, and in addition, they enhance convection during the operation of the appliance.

Heating of the heating element is faster in comparison with the needle element. In addition, it is distinguished by its durable work. Many models of units are made in a splash-proof housing. Therefore, convectors with heating elements can be used in rooms with high humidity. For example, in bathrooms. However, these elements also have certain disadvantages. The most serious is that the tubes and fins have different amounts of thermal expansion, and this can lead to sounds that resemble crackling sounds during the operation of an electric convector.

Devices that are equipped with monolithic heating elements are distinguished by their quiet operation. This is due to the fact that convectors of this type have a solid-cast heater. Ribs are an integral part of the design of such installations. During the operation of these devices, minimal heat loss occurs. In addition, they are effective in solving space heating problems.

Among the types of electric convectors, experts recommend opting for equipment with a heating element or a monolithic heating element.

Convectors rating

Based on the models considered, we will make a rating of convectors in terms of reliability, quality and cost.

In terms of reliability, the leading position is occupied by Neurot convectors. Next come the models of the manufacturers Atlantik, Electrolux and Ballu.

The best wall convectors are Neurot and Timberk. Timberk is again the leader among floor heating manufacturers. Good models are also produced by Electrolux and Ballu.

But among the inexpensive brands, Atlantic convectors can be called. Cheap heating appliances are also produced by the Delonghi company. In general, the reviews about the models of this manufacturer are good. Therefore, if you want to buy a floor convector, the price for which is low, you can safely buy Delonghi products.

It is difficult to give an unequivocal answer which of the described convector models is worth purchasing.

It all depends on the operating conditions, your preferences regarding design, power and other technical parameters, as well as your financial situation. Of course, if the material condition allows, then it is better to purchase models from European manufacturers. In this case, you are guaranteed to get a quality device. If the budget is limited, then you can stop at cheaper Chinese brands.

Needle type heating elements

Needle heaters (also called tape heaters) are a plate made of a dielectric material. A chrome-nickel thread is attached to it, forming loops on each side. It is a conductive heating element and is coated with insulating varnish.

Heat transfer in convectors using a needle element occurs mostly through the body. A weak point of such devices can be called a heating thread that is practically not protected from moisture. Covered with a layer of insulating varnish, it easily deteriorates from water ingress. This circumstance makes needle heaters completely unsuitable for use in bathrooms and rooms with high humidity. The attractive side of a convector with a needle-type heating element is the price: the cost of such equipment is one and a half times lower than that of a similar device.

The presence of a thermostat in the convector

Thermostat device in the convector.

In modern electrical devices, both electromechanical and electronic thermostats (which have an air temperature sensor) are used. All convectors, regardless of the type of thermostat, are equipped with overheating protection.

Such devices with a mechanical thermostat have the following features:

- affordable price;

- accuracy in measuring air temperature (+/- 0.5-1 ° С);

- when the heating is turned off and on, a characteristic click is heard;

- high reliability during operation in conditions of unstable supply voltage (summer cottage, village, and so on).

In electronic thermostats, a microcontroller thermostat is installed. Its temperature sensors regularly measure the temperature of the cold incoming air and send a signal to the control element, which is able to maintain a given mode with an accuracy of +/- 0.1-0.3 ° C.

Features of similar devices with electronic thermostats:

- higher price;

- completely silent work;

- good temperature measurement accuracy.

Due to the higher accuracy of temperature measurement, the use of convectors with an electronic regulator can provide energy savings of 3-5% compared to electromechanical designs. Models that have an electronic thermostat most often support several operating modes: economical, comfort, anti-freezing (the temperature is regularly maintained at + 5-6 ° C) and automatic.

Heater selection recommendations

Heater type

... The most popular these days are convector and infrared devices.

- Convectors consist of a heating element and a casing, between which there are ventilation holes. Cold air enters the heating element area, heats up and is distributed throughout the room. This air exchange scheme does not require a fan.

- Infrared radiation favorably heats up the surrounding objects (walls, floor, ceiling). They, in turn, give off heat to the room. IR heaters are energy efficient and do not burn oxygen in the room.

Heating power

... When choosing a monolithic heater, you should pay attention to such an important parameter as the heating power.The indicator directly depends on the size of the room and the type of heater.

- If a convector is preferred, then a simple formula can be used to calculate the maximum power. For heating 1 sq. m premises with a ceiling height of 2.5 m requires 100 watts of power. Experts advise to give preference to models that exceed the calculated value by 10-15%.

- When buying infrared devices, a different rule applies. The area of the room is multiplied by 100, and then another number 200 is added. For example, to heat a room of 13 square meters. m, an IR device with a power of 13x100 + 200 = 1500 watts is required.

Functionality

... Modern heaters are equipped with a set of functions that make operation convenient.

- Temperature control allows you to select the most comfortable heating mode.

- A built-in thermostat helps automate the operation of the heater. It is only necessary to set the temperature range, after which the device will turn on and off the heating element itself.

- Electronic control is found in expensive models. The user can program the operation of the heater, make adjustments using the remote control.

- Security. Any electrical device is fraught with danger, so manufacturers equip their products with various security systems.

- Overheating protection turns off the device if the temperature of the heating element exceeds the set value.

- Roll-over protection is installed on floor-standing models. It is triggered when the device falls, turning off the heating.

- If you plan to operate the heater in bathrooms or garages, then preference should be given to models with moisture protection.

We have selected 8 best monolithic heaters for review. All of them are sold in the Russian trade network. When allocating seats, the editorial board of expertology magazine relied on the opinion of the expert community, taking into account the reviews of Russian consumers.

Which convector is better to choose

- Learn more about the housings of such a battery

- Heating element for convectors

- The presence of a thermostat in the convector

- Calculation of the power of such a heating device

How to choose a convector for a summer residence? Today the Russian convector market is incredibly large: both European and Asian manufacturers are represented there. With such a variety, a problem arises related to which convector is better to choose for a summer residence. The main criteria for choosing this device are: safety, economy, long service life, as well as its cost. All these parameters (with the exception of cost) are determined by the design features of the convectors.

The main parameters when choosing a convector: safety, environmental friendliness, good operation, low cost.

Electric or gas convector? It is necessary to figure out what convectors exist today and whether it makes sense to say that electric ones are the best, and not any others. A similar device can work on the following types of substances:

- with water;

- using electrical energy;

- using natural gas.

Due to the cost of natural gas, some consumers believe that the best gas convectors can be purchased in Russia. However, it is with this type of equipment that not everything is as simple as it seems. Finding such batteries is quite difficult when electrical units are sold everywhere.

Which convector is better to choose for a summer residence: wall-mounted or floor-standing?

Stages of installing a wall-mounted convector.

First of all, you need to decide how you plan to use the electric convector. Most often, electric convectors are installed permanently on the wall, under windows, or on a special bracket that comes with the kit.If you want to get a mobile heater that can be moved around the room, you will need to additionally purchase a set of legs (in most cases, it is sold separately for wall-mounted convectors) or buy a convector that is designed specifically for floor installation. Such batteries, which are originally intended for floor installation, are equipped with roller feet and a rollover sensor, which is quite an important factor for the operation of such a device. High quality floor-standing electric convectors can be found in the range of some German manufacturers.

Floor-standing electric convectors are narrow, low (20 cm) and long. Those that are fixed to the walls have a height of about 40-50 cm. There is a difference in the supply of heat. The most efficient heating devices are those that are located closer to the floor. This is due to the fact that warm air will go up. Therefore, wall mounted equipment is not very profitable to purchase.

What is a convector type heater

The main thing that distinguishes the convector from other types of heaters is its low cost, wide range of heating elements, ease of use and versatility in installation.

Electric convector: what is it?

The heater is designed to process cold air into hot air. This is achieved by the design features of the housing and the location of the heating element (TEN). On the bottom surface of the body there is a grill through which cold air enters. Then it passes through the heating element, which heats the air flow to 90 degrees and exits through the upper grill. According to its physical properties, it is known that hot air always tends upward, and when it cools down, it goes down, thus creating circulation for an electric heating radiator.

Purpose and principle of operation of the electric convector

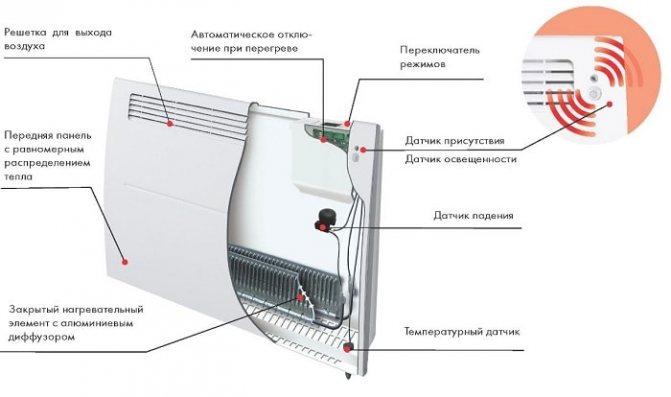

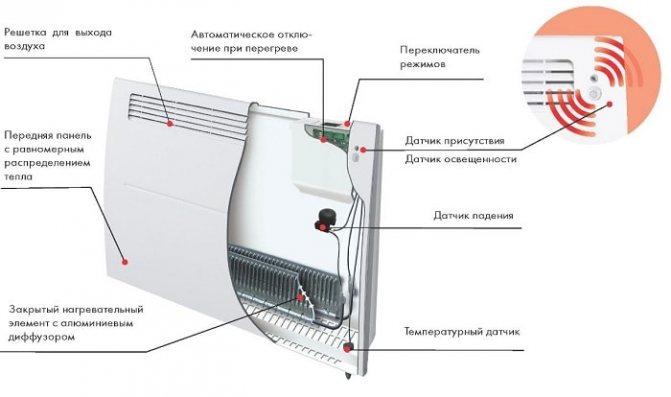

Before proceeding to consider the principle of operation of an electric convector, it is necessary to study its structure and design features. With this knowledge, it will not be difficult to understand the principle of operation of the device.

Design

Regardless of the manufacturer and modification, any electric convector includes the following main elements:

- Housing.

Most manufacturers give preference to metal cases, which provide high strength in operation and the safety of internal modules in the event of overturning or other mechanical stress. To facilitate the structure, light alloys based on aluminum are used in the manufacture of the case. In the lower and upper parts, there are grilles for the intake of cold and return of warm air. - Electric heating element

... Thanks to these devices, the air circulating in the device is heated. In modern convector installations, several types of heating elements are used:

- Monolithic.

The cast body of such a heating element allows you to achieve high efficiency and quiet operation; - Tubular.

The design is a metal pipe with a nichrome thread stretched inside. The space between the thread and the inner surface of the pipe is filled with a heat-conducting bulk insulator. There are aluminum fins on the outer surface of the pipe to increase the heat transfer efficiency. - Needle-like.

Such a heating element consists of a dielectric base on which a chromium-nickel thread is fixed, covered with a special insulator. Installations with a needle heating element provide the fastest possible heating of the room, but they do not differ in durability.

Temperature sensors, location, and other protective elements that ensure the safe operation of the device;

Models with high heat output can be equipped with a fan to increase the air circulation.

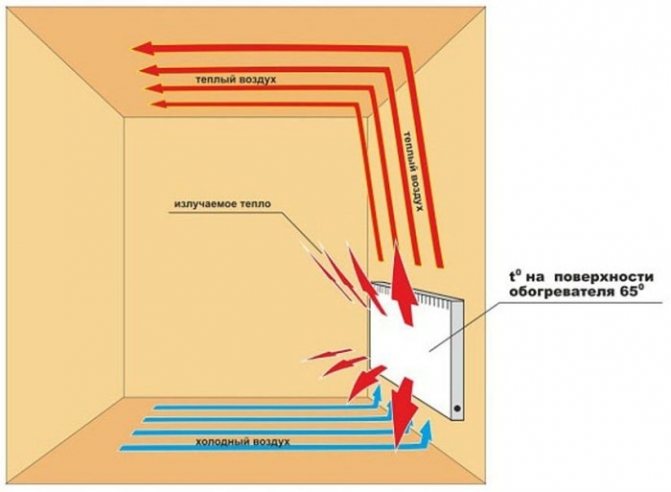

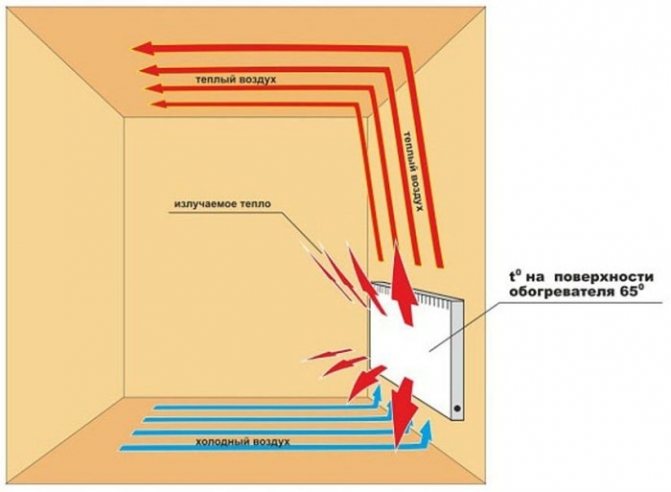

Principle of operation

The operation of an electric convector is based on the natural circulation of air masses. Cold air coming from below heats up and rises up through the convector grill. As the temperature decreases, the cooled air gradually moves downward and the cycle repeats.

In addition, a certain amount of heat can be transferred due to thermal radiation from the front panel of the device, which is in close proximity to the heating element. It is the simplicity of the design that ensures the reliability and durability of the convectors.

Some models with a high heating element capacity can be equipped with a fan to increase the air circulation rate, thereby significantly reducing the initial heating time. The forced movement of air masses increases the efficiency of the device, but is accompanied by an increase in the noise level.

Types of electric heaters

Structurally, heating elements are presented in different designs. Accordingly, from what kind of heating element is built in, the principle of operation and technical characteristics of the convector have their own distinctive features, advantages, disadvantages. Before choosing one or another convector radiator, it is important to familiarize yourself with these aspects in advance.

Stitch

The name of the heating element, translated from English, means "sew" or "quilt". In Russia, the concept of a needle heating element is more common. Structurally, the device is represented by a dielectric plate and a continuous conductive filament. It is made of nickel-chromium alloy, covered with heat-resistant varnish insulating from oxygen. The wire forms many loops on either side of the flat base.

Manufacturers usually install 2 similar heaters. An electric convector with needle heating elements has the following advantages:

- heating up to +250 and more degrees Celsius and cooling of the filament occurs within a few seconds;

- the operation of the equipment is accompanied by noiselessness;

- energy consumption is economical.

Of the shortcomings, direct contact with oxygen is noted, which contributes to a decrease in the humidity index in the room. If dust gets on the hot wire, there is a risk of sparking and fire. A thin filament is fragile, so radiators do not last long.

Important! Stich type heating elements have no additional protection against direct contact with water. This fact limits the scope of application only to dry rooms.

Tubular

Tubular elements are represented by a high-strength steel flask. The tank is filled with fine-grained sand made of quartz, ceramics or magnesium. To prevent the mixture from spilling out, the device is equipped with plugs. The heating of the mineral dielectric occurs by means of a nichrome thread passed inside.

To increase the range of covered air, in addition to the bulb, flat or spiral elements made of aluminum with a high heat conductivity coefficient are fixed. Each manufacturer develops fins according to their own technology. However, the heat transfer of convectors with tubular heaters of various designs is practically the same.

Compared to the needle heating element, the filament of the tubular element is isolated from dust, moisture and oxygen. This makes it possible to increase its service life by about 1.5-2 times. The use of the radiator in humid rooms is allowed, since manufacturers often provide the degree of protection with the IP24 marking.

Wall convectors

The wall-mounted convector is the most frequently chosen heating equipment.A thermal regulator with a maximum room heating temperature saves energy, because when the set temperature is reached, the device turns off.

The wall-mounted steel convector with a thermostat maintains the optimum temperature even in a heated room. With intermittent heating in country houses, the convector will maintain a stable temperature, saving fuel for full heating of the building.

Convectors built into the window sill reliably protect the room from cold penetration. They don't take up much space.

Floor convectors

Installation of floor convectors does not require special skills, the instructions describe the entire installation sequence.

Floor convectors are divided into several types:

- with natural convection;

- with forced convection;

- able to function in rooms with high humidity.

Floor convectors are large bodies, of various lengths, depending on the power of the convector. Easily fit into any interior, often made to order.

In the box itself there is a heat exchanger made of copper or aluminum with good thermal conductivity. Internal cleaning must be done every few years.

Floor convector

Floor convectors are radiators built into the floor. They are water and electric.

The skirting convector is used in rooms with an individual or central heating system.

Oil, water and other liquids are used as a heat source.

It successfully replaces the traditional heating radiator. It is a device consisting of a body made of various materials. As a rule, stainless or galvanized steel is used, which has increased resistance to corrosion.

In the body there is a heat exchanger made of a copper tube bent in the shape of a horseshoe. The aluminum fins increase the surface area of the heat exchanger.

The decorative grille, mounted on top of the convector, is made of steel, wood, aluminum.

The capacity depends on the temperature of the supplied heating medium and the intensity of the air flow around the heat exchanger.

They are used in various heating systems operating in a wide range of coolant temperatures - from 45 to 90 ° C. The built-in tangential fan, which provides an increase in the air flow rate, increases the performance and the rate of heat transfer to the convector.

What types of convectors are there?

Depending on the source of energy, there are:

- electrical;

- water;

- gas convectors.

The most practical gas appliances, but the most in demand are electric convectors. Even the most advanced models of equipment, endowed with a maximum of additional functions, usually cost less than water and gas heaters.

By the method of installation, the devices are:

- floor-standing;

- wall-mounted;

- skirting boards;

- built-in (in-floor, basement).

From the point of view of ease of use, wall-mounted units are the best. Connoisseurs of modern design solutions should pay attention to built-in and baseboard heaters. Electric floor convectors are good for their mobility.

By type of convection:

- with natural convection;

- with forced convection.

Forced convection is provided by a built-in fan. The advantage of its presence in the design of the convector is a faster heating of the air, the disadvantage is noise during operation.

By type of temperature control:

- mechanically controlled;

- electronically controlled.

Devices with mechanical control are more familiar and easier to use, with electronic ones - more convenient, but more expensive.

Types of electric convectors heating

When choosing climatic technology, it is important to take into account that electric convectors may differ from each other in the following characteristics:

- Mounting type.

- The heating element used.

You should also pay attention to the manufacturer of the product and the cost of electricity.

Types of electric convectors, according to installation features

Air convection heaters can be divided into three categories.

Wall mounted. Wall-mounted convectors are the most efficient. The location on the wall facilitates the convection process and increases the efficiency and heat transfer of the heaters.

Floor-standing version - used as an additional source of heat. Models with a built-in fan differ in performance. The convector with forced air circulation cannot boast of quiet operation, but it warms up the air well.

Universal models - can be installed on the floor and mounted on the wall using special mounts. When choosing, you should pay attention to the presence of wheels in the kit. By installing the wheels on the body, you can easily move the heater anywhere in the room.

The main advantage of the convector is the low heating of the device body. This allows you to install a heater for heating a wooden house.

Classification of convectors according to the heating element used

In total, three types of heating elements are used. The design of the heating element affects the ability to operate the heater.

- Needle heating element is a simple design, it is a chromium-nickel heating thread located in a dielectric plate. The top is covered with a special insulating varnish. The heater with a needle heating element is not suitable for wet rooms, since the heating element has absolutely no protection against the ingress of water, steam, condensation and other liquids. As a rule, budget models are equipped with a needle heating element.

- Tubular heating element - manufactured in a waterproof design. The structure consists of a steel tube filled with a heat-conducting backfill, which is also an insulator. To increase heat transfer, heat-distributing fins are fixed on the sides of the heating element, increasing convection. The heaters are equipped with overheating protection. As a disadvantage of the tubular heating element, one can single out the fact that the electric convector heats up for a long time. The operation of the appliance may be accompanied by sounds resembling the crackling of burning wood.

- Monolithic heating element - the most economical electric convectors for heating a private house use a monolithic type heating element. The body of the heating element has no seams, the work does not accompany extraneous noise. If it is planned to make the electric heating of the apartment with convectors the main one, then the models with a monolithic heating element are the best solution. During operation, minimal heat loss is observed. The heater efficiently and quickly heats the room. The only noticed drawback of a monolithic heating element is the high cost of the device.

For space heating using an electric convector, it is better to choose devices that have a tubular or monolithic heating element and are equipped with a built-in electronic or programmable thermostat.

Water convectors: efficient and effective

Convectors of water type are modern devices that are an excellent alternative to standard radiators. The devices are successfully used in autonomous heating systems of private houses and apartments, as well as in centralized heating networks. Water convectors are reliable, economical and durable, their efficiency is about 95%.

Varieties of water appliances

Water convection devices are the ideal solution for rooms with a large glazing area.Depending on the model, the water convector can be either an independent heating unit or a source of additional heating.

Thanks to various form factors of equipment, the heating issue can be solved not only efficiently, but also effectively.

Water convectors are:

- floor-standing;

- wall-mounted;

- skirting boards;

- indoor;

- built-in.

All of them take up a minimum of space, and in the case of a hidden installation, they even save usable space. Installation in the wall, floor, steps, under furniture allows you to save such valuable square meters and provide comfortable heating. Floor devices with a drainage outlet can be successfully used in rooms with swimming pools, greenhouses, conservatories, etc.

Diverse design - from laconic classic to bright modern - allows you to easily fit the units into any interior.

Features of various equipment modifications

Wall-mounted water convectors are made of a steel case with a perforated grill located on top, in which a copper-aluminum heat exchanger is located. The devices are mounted using a special mounting kit, which must be included in their factory complete set.

Wall-mounted convectors are an excellent choice for rooms that require fast and efficient heating and have enough free space for wall mounting. This is the most successful solution for children's rooms and bedrooms. They are not suitable for heating continuous glazing that extends into the floor.

Floor-standing water convectors are usually installed in rooms with a low window-sill space. It is also possible to install them near panoramic windows, if, due to the low height of the screed, it is not possible to mount the trench unit. In addition to the housing with a heat exchanger, such devices are structurally complemented by a steel support base.

Such convectors somewhat clutter up the space, nevertheless, they fit perfectly into rooms with a modern interior in the style of loft, modern, high-tech, avant-garde.

Skirting water heaters are practical and compact. The low thermal intensity of such convectors allows them to be mounted right next to furniture and various decorative elements. This gives a huge advantage in terms of organizing space.

Floor recessed structures are used to cut off cold air currents coming from windows. The units can effectively solve the problem of condensation on large window panes ("crying windows"). Built into the floor level, they do not take up space at all and do not interfere with enjoying the panoramic view.

Which company convector is better to choose

Of course, when choosing a convector, the buyer seeks to choose a device in which price and quality are ideally matched. But it is difficult to compare the quality and cost of different manufacturers. For example, European-made convectors are of high quality, long service life and a long warranty term. But the price for them will also be high.

Chinese options are also presented on the market, the cost of which is much lower than that of European manufacturers. But the quality of such devices leaves much to be desired.

European convectors are usually represented by products from Italy, France and Germany. As for domestic heaters, modern models can quite successfully compete with European counterparts. And besides, they have one big advantage - manufacturers take into account the climatic conditions of our country, which are very different from Asia and Europe.

Heating element types

The electric convector (there are also gas and water convectors) is the most popular heating device on the market today. It has earned its reputation not only for its ease of use, but also for its reliability.This equipment is able to provide a comfortable environment both in the living room and in the public area. Experts believe that the main design feature is the absence of intermediaries for heat transfer.

A modern convector uses one of three types of heating elements... He might be:

- needle, ribbon-shaped, stich-type heater;

- tubular electric heater with aluminum fins, abbreviated as it is called heating element;

- monolithic type.

Each type has its own characteristics and disadvantages. The decision about which one to choose should be made based on the characteristics of the heated room.

The best electric convectors 2018-2019 in the price ratio quality

Sometimes in a store it is difficult to decide which version of heating equipment is needed. Often, everyone prefers options whose quality matches the money spent. It is about such models that we will talk about in this section.

Convector ADAX VP 1020 KT - powerful and affordable

It is expensive to purchase electric convectors for a large multi-storey country house

Such a model is considered more functional, but, at the same time, it is distinguished by ease of management. Of course, this unit cannot be compared with premium analogues, but, nevertheless, it is not inferior to them in quality. This convector also has additional security. More details in the table.

| Power, W | Heating area, m2 | Control method | Mounting option | Additional options |

| 2000 | 15 | Mechanical | Wall | Temperature regulation, overtemperature shutdown, rollover protection |

ADAX VP 1020 KT

Convector Timberk TEC.PF10N DG 2000 IN

The metal body of the electric convector is heated up to 60 ° C

A model with an interesting facade. The back is made in the traditional way. The control panel contains control keys and a power regulator. This device is more convenient to use when installed on the floor. There are many interesting additions to this model.

| Power, W | Heating area, m2 | The presence of a thermostat | Control method | Additional options |

| 2000 | 23 | Yes | Mechanical | Temperature control, splash-proof housing, front glass panel |

Timberk TEC PF10N

Convector Hyundai H-HV15-10-UI617 - model with simple parameters

When using an electric convector, there is no need to install a fan in the room.

Simple in execution, easy to use and of high quality. All these characteristics can be safely assigned to the declared unit. The device is suitable for small rooms, but has excellent heat dissipation. Therefore, its use in everyday life is fully justified.

| Power, W | Heating area, m2 | The presence of a thermostat | Control method | Additional options |

| 1000 | 13 | Yes | Mechanical | Not |

Hyundai H HV15 10 UI617

GOOD TO KNOW!

Additional accessories can be connected to multifunctional models of electric convectors.

Installation options

According to possible installation options, convectors can be divided into the following groups:

- floor models;

- wall models;

- plinth models.

The height of floor-standing and wall-mounted heaters, as a rule, varies from 40 to 45 cm. The skirting-type device differs in a small (about 20-30 cm) height, but in length it significantly exceeds other models.

To choose a suitable convector heater, decide whether you will only use it in one room or plan to move the appliance throughout the apartment.

The mobile floor unit with wide stable legs or casters can be easily transported to another room or put away for storage after the need for additional heating is gone.

For regular use in only one room, it is better to choose a wall or baseboard model.For small rooms, a compact wall heater is ideal, while larger rooms are quickly heated by a powerful skirting-type appliance. It fits perfectly even under low window sills, but at the same time it has a significant drawback: the cost of such a device is usually higher than its counterparts.

How does an electric convector work

In nature, there is a natural process of movement of warm and cold air masses. The heated air rises until it cools down, after which it goes down. The principle behind the movement of air currents is called convection.

In this regard, the question arises, an electric convector - what is it? This is a device using the principle of convection of air masses. The air heated with the heating element rises upward. After cooling down, it goes down and again falls into the heating block of the device.

To ensure continuous convection, air ducts are provided in the housing through which air is drawn in and out.

The principle of operation of the electric convector may differ slightly depending on the type of heating element used and the presence or absence of pressure equipment (fan).

The device and the principle of operation of the equipment

Having all the necessary information about devices with a convector heating principle, it will be much easier to make a purchase.

The main structural elements of the device are a housing, a heating element (heat exchanger) and a thermostat with a regulator brought out to the external panel. Many convectors are "equipped" with various additional features to improve the comfort and safety of the device.

The operation of the devices is based on the process of natural air circulation - convection. Cold air enters the inside of the convector body, where, upon contact with the heating element, it quickly heats up and rushes up.

Elementary physics: warm air is lighter than cold air. When it cools down, it goes down and enters the heater again - and the cycle repeats.

Thus, thanks to convection in the premises, a constant circulation of warm air masses occurs and a comfortable temperature is maintained. This principle of operation allows the equipment to heat the air not only efficiently, but also as evenly as possible.

The best manufacturers of electric convectors

Currently, the most demanded electric convectors are:

- Ballu

... The company's products are presented on the market by both serial and exclusive designer units. The power of the devices can be from 0.5 to 2 kW. Ballu convectors are highly reliable and safe to use. The presence of a large number of additional functions and a reliable security system, in combination with an affordable price, have ensured wide popularity of the company's products. - Noirot

... Electric heaters from this company are characterized, above all, by high reliability. The average service life of the unit is at least 10 years. In addition, Noirot convectors are distinguished by reliable automation and great functionality. The various author's design of the units allows them to be used in any interior not only as a heating device, but also as a decorative element. - Electrolux

... All household appliances manufactured under this brand are distinguished by high performance characteristics, reliability and original design solutions. Electric convectors were no exception. Most of the models produced by the company have electronic control with a wide range of additional functions and reliable closed-type heating elements. Only the high cost of the equipment is a little confusing. - Timberk

... Convectors of this company are distinguished by exquisite design, variety of colors and shapes.As for the technical side of the issue, one can note the high build quality and reliability of the heating elements. The use of innovative materials and technologies allowed the company to achieve flawless operation of the units in high humidity conditions. Timberk convectors are affordable for most private home owners. - Neoclima

... The company is focused on the production of low-cost models of units. The power of the produced convectors makes it possible to efficiently heat a small house in the country. Despite the low cost, Neoclima units are distinguished by their reliability and long service life.

Currently, the choice of convectors makes it easy to select a model of the required power and appropriate design.

The best monolithic infrared heaters

Infrared heaters are gaining popularity for their efficiency, safety and comfort. The devices do not burn air, consume energy economically, and serve their owners for a long time. Experts have noticed two monolithic models.

Hintek IW-03

Rating: 4.9

To increase the air temperature in a small room or in a limited area of up to 5 sq. m, you can use the Hintek IW-03 infrared heater. This lightweight (3.3 kg) and compact device is easy to use, with only 300 watts of power. Experts praised the domestic development for its economical energy consumption and low price. The advantages of the heater include moisture protection, overheating shutdown function. The manufacturer has provided only for wall mounting, since the surface of the device gets very hot during operation (up to 100 ° C). The heater becomes the winner of our review.

Russian consumers liked the qualities of the IR device most of all, such as fast heating, ease of use and stylish design.

Dignity

- lightness and compactness;

- low price;

- fast heating;

- stylish design.

disadvantages

- low power.

Noirot Verplus 1500

Rating: 4.8

The unique design of the heater was developed by French specialists. The Noirot Verplus 1500 combines the benefits of infrared and convective heating. But for this, the developers had to apply two innovative technologies. The entire front of the device is given to the Resistance Surfacique radiant panel, which is characterized by directional action and economical energy consumption. It was possible to increase the intensity of heat transfer due to the one-piece heating element RS-Silence. The device has protection against frost and power surges, and this modern heater can be controlled using a remote control or a special Memoprog-2 module.

So far, the French device is not in high demand among the inhabitants of our country. Experts attribute this fact to a high price.

Dignity

- high performance;

- economical energy consumption;

- does not dry the air;

- electronic control.

Tubular heating elements

The tubular heater is made of nichrome filament integrated into a quartz tube with steel. In addition, the design provides for a magnesium backfill with aluminum fins attached to it. The ribs serve as a heat exchange element.

Most often, the shape and distribution of the ribbing plates is specific for each company, however, this does not affect the function of the ribs in any way. The advanced design of such an aluminum diffuser makes it possible to achieve intense heat transfer from the heating element to the air masses and make the convection process more efficient.

The glow of these elements is much lower than that of needle elements, but they are more unpretentious and reliable.

For the most part, tubular heaters with tubular heating elements are protected against moisture penetration, which allows them to be installed in the bathroom. Despite this, it is not recommended to mount the device closer than 1 meter from the water source.

Heating element types

The electric convector (there are also gas and water convectors) is the most popular heating device on the market today. It has earned its reputation not only for its ease of use, but also for its reliability. This equipment is able to provide a comfortable environment both in the living room and in the public area. Experts believe that the main design feature is the absence of intermediaries for heat transfer.

A modern convector uses one of three types of heating elements... He might be:

- needle, ribbon-shaped, stich-type heater;

- tubular electric heater with aluminum fins, abbreviated as it is called heating element;

- monolithic type.

Each type has its own characteristics and disadvantages. The decision about which one to choose should be made based on the characteristics of the heated room.

Needle type heating elements

Needle heaters (also called tape heaters) are a plate made of a dielectric material. A chrome-nickel thread is attached to it, forming loops on each side. It is a conductive heating element and is coated with insulating varnish.

The characteristic feature of the needle element is the high temperature of the heater. At the same time, this type of device has the lowest heat inertia, which means almost instant heating and cooling.

Heat transfer in convectors using a needle element occurs mostly through the body. A weak point of such devices can be called a heating thread that is practically not protected from moisture. Covered with a layer of insulating varnish, it easily deteriorates from water ingress. This circumstance makes needle heaters completely unsuitable for use in bathrooms and rooms with high humidity. The attractive side of a convector with a needle-type heating element is the price: the cost of such equipment is one and a half times lower than that of a similar device.

Monolithic heating elements

Heating elements of a monolithic type are used for a convector with a protection degree of IP 24. They have a nichrome thread filled with a dielectric material. All "stuffing" is packed in a die-cast aluminum case with metal ribs.

During heating and cooling, each part of the monoblock expands and contracts in volume. This feature allows you to avoid friction, as well as the development of microcracks. A good monolithic convector is silent, very reliable and durable. The monolithic body minimizes intermediate heat loss and also reduces heating of the fin structure.

Monolithic heating elements

Heating elements of a monolithic type are used for a convector with a protection degree of IP 24. They have a nichrome thread filled with a dielectric material. All "stuffing" is packed in a die-cast aluminum case with metal ribs.

During heating and cooling, each part of the monoblock expands and contracts in volume. This feature allows you to avoid friction, as well as the development of microcracks. A good monolithic convector is silent, very reliable and durable. The monolithic body minimizes intermediate heat loss and also reduces heating of the fin structure.

Tubular heating elements

The tubular heater is made of nichrome filament integrated into a quartz tube with steel. In addition, the design provides for a magnesium backfill with aluminum fins attached to it. The ribs serve as a heat exchange element.

Most often, the shape and distribution of the ribbing plates is specific for each company, however, this does not affect the function of the ribs in any way. The advanced design of such an aluminum diffuser makes it possible to achieve intense heat transfer from the heating element to the air masses and make the convection process more efficient.

For the most part, tubular heaters with tubular heating elements are protected against moisture penetration, which allows them to be installed in the bathroom. Despite this, it is not recommended to mount the device closer than 1 meter from the water source.

What kind of heaters are there in convectors?

One of the factors that affect the price of a convector is the type of heater used in it. Today there are three types:

Needle (tape, stich-element, etc.)

The cheapest heating elements used in convectors. Owners of convectors with just such heating elements say that “convectors dry the air” or “burn out oxygen”. It is a thin dielectric plate (tape), on which a chromium-nickel thread is installed in such a way that loops are formed on each side. This heating conductive thread is coated with a special insulating varnish. Due to the high temperature of the heating filament, dust, and therefore oxygen, really burns out on them. They differ in the minimum price (convectors with a needle heater will cost one and a half times less in relation to devices of the same power with a different type of heating element) and thermal inertia - it heats up and cools down almost instantly. Not recommended for long-term autonomous heating of the house.

Tubular electric heaters (TEN) with aluminum fins

Tubular electric heaters (TENs) are a nichrome thread installed in a steel tube with quartz, ceramic or magnesium backing, on which aluminum fins are stamped, for effective heat removal. The type of aluminum fins is different for each manufacturer, but this does not change the essence. The developed ribbing of such an aluminum diffuser provides intensive heat transfer from the heater to the air and enhances convection. The temperature of such heaters is significantly lower than that of needle heaters, they are more unpretentious and more durable. Over time, due to the different expansion coefficients of the aluminum and the steel tube, the adhesion of the fins to the heating element deteriorates, while reducing the heat output of the convector. It is with such heaters that convectors Thermor EVIDENCE 2.

Monolithic heating elements

In monolithic heating elements, a heating nichrome thread with a dielectric filler is located in a solid body with developed fins (X-shaped heating element). When heated and cooled, all parts of the monoblock equally expand and contract, which eliminates friction and the appearance of microcracks. They are quiet in operation and very durable. The monolithic design made it possible to minimize intermediate heat losses and further reduce the temperature on the surface of the ribs in comparison with heating elements. All leading manufacturers of electric convectors have switched to just such a heating element. This type of heating elements is equipped with convectors ENSTO BETA.