Wall mounted models of gas equipment

Mora's single and double-circuit wall-mounted gas boiler is represented by the following lines:

- Mora Meteor - this modification is the only one that does not have a control board. All commands for heating temperature and hot water generation are carried out by a non-volatile gas valve from the manufacturer Sit. Equipped with a room thermostat with the ability to control the room temperature. The equipment can be: with an open chamber (outlet to the chimney) or with a closed chamber (turbo outlet), also with the possibility of hot water supply (double-circuit boilers) or only for heating with the possible connection of an indirect heating boiler (single-circuit). The power of the units varies from 18 to 24 kW, the boilers are installed to heat rooms from 30 to 240 m² and prepare warm water 11 l / min and 14 l / min.

- Mora Meteor Plus - this line includes boilers for heating areas also from 30 to 240 m² and heating liquids 11 l / min and 14 l / min. However, these boilers are completely energy dependent and have the possibility of separate regulation of hot water supply and heating. The series includes one- and two-circuit modifications. The units have two possibilities of functioning with respect to exhaust gases: an open-type combustion chamber with a natural exit of exhaust gases into the chimney, a closed-type combustion chamber with a forced exit of gases into a coaxial chimney. Heating-only boilers can be operated in conjunction with an indirect heating boiler.

- Mora Sirius is a series of weather-controlled boilers with an electronic room thermostat. Power characteristics are presented in three groups - 20 kW, 25 kW and 35 kW. There are two types of boilers: with an open combustion chamber (outlet to the chimney) and a closed one (turbo outlet), with the possibility of hot water supply and only for heating with the possible connection of an indirect heating boiler. The gas boiler Mora Top Sirius does not over-consume gas. Electronic sensors accurately measure the temperature at the outlet of domestic water, and the control unit adjusts the gas flow in connection with the specified temperature and the speed of its measurement. When developing Mora Sirius, specialists paid attention to the use of innovative and high-quality elements, taking into account the comments and requirements that came from users, customers, as well as technical experts.

- The wall-hung gas boiler Mora Titan is made only with an open combustion chamber for heating areas up to 140 m². This unit is a worthy alternative to floor standing boilers from Russia with a capacity of up to 14 kW. It differs from domestic models in lightness, compactness and optimal performance for work. There is a possibility of forced removal of combustion products using a turbo nozzle (for places with a problematic chimney or its absence).

You can read more about Russian-made gas boilers in this article.

Wall hung gas boiler Mora Titan

Elimination of malfunctions of pestilence boilers. Questions to specialists on malfunctions of mora boilers

16.03.2019

Question:

Mora 20 boiler is non-volatile, the wick stopped burning in standby mode. It lights up normally without problems when the temperature is set, the thermostat turns off the boiler and then the wick goes out and everything turns off. This happened after purging the external gas lines.

Most likely, there was a contamination of the gas block of the boiler. You need to clean it up. Either the electrode for monitoring the presence of a flame is faulty. It either needs to be changed or cleaned out. Try cleaning it first - it might help.

Gas wall-mounted boiler MORA TOP PROXIMA 20 KT the coil on the gas block burned out (the solenoid closes the gas) the operation indicator blinks red or blue. When operating in heating mode, hot water drips from an open DHW tap (cold water is shut off) and the pressure in the boiler drops, recommend what to replace.

Judging by the description of the problem, the burned-out coil has nothing to do with it. It is very likely that you have a leaky DHW heat exchanger and water from the heating circuit enters the DHW circuit, but this should not be so. From this, you and the pressure drop in the system. So, most likely the reason is this.

Or (as an option, but unlikely) the three-way valve wedges and you see that the boiler is in heating mode, but since the valve is not fully closed (three-way), part of the boiler's power goes to heat the heat exchanger for DHW. But in this case, the pressure in the heating system should not drop.

Tell me please. Boiler wall-mounted mora tor titanium. when the thermostat is turned on, the burner does not light up immediately, when the desired temperature is reached, it does not go out at all, boiling occurs, you have to turn off the gas! Please tell me what could be the reason?

Not entirely clear from your question about inclusion. The boiler should work like this: first ignite its ignition wick with a piezoelectric element. Next, ignite the main burner (it will not light up if the flame sensor is in the boiler - it capillary will not open the gas valve completely).

At the same time, the pump turns on and water circulation begins. Also, according to the indications of the capillary sensor, the gas block is blocked. Most likely, you have it in him.

This is how the boiler firing up process is described in the instructions for it: Always before starting the boiler or after a long break it is necessary to perform the following steps - Check the water pressure on the boiler pressure gauge. Open the gas valve.

Turn the control knob to the ignition position and, by pressing it, turn it to the “asterisk” position. An ignition spark will appear - the pilot burner will ignite. From the moment of the ignition burner, hold the control knob for 10 seconds. After releasing the handle, the pilot burner should burn. If the pilot burner does not light, repeat the steps again.

I have a mora boiler top meteor plus 24 kt. Gives an error E1. What to do?

Error E1 indicates several types of malfunctions, namely:

Ignition error - Burner ignited after ignition finished - manual restart required.

Loss of flame - Loss of flame during heating - the boiler will automatically restart.

Program error - Boiler electronic board processor error - manual restart required.

How do we understand the third option for you? If the restart does not help, then most likely yes, you need to replace the electronic board of the boiler.

I have already asked a question about the Mora Top Meteor Plus 24 KT boiler malfunction code, the display read E1. I was advised to replace the control board. After the replacement, the boiler worked for 2 hours, turned off and issued an error code E6. Can you tell me what this means?

This error indicates an error in the combustion products removal path. Since you have a boiler with a closed combustion chamber, then, in principle, this error should not be. Check the electronic board, namely, whether the jumper on the board is installed correctly, which determines what type of boiler you have.

Boiler mora top proxima 20st, please tell me what pressure should be in the heating system and expansion tank with a water volume of 150 liters in the system.

For almost any domestic boiler, regardless of the volume of the system, the norm is a pressure of 1 to 2 bar. Anything over 3 Bars is already an accident. The pressure in the expansion vessel is exactly the same as in the entire system. The tank is part of the system.

Boiler MORA METEOR PLUS 18.24 new. 1. pops of gas during ignition.2-3 seconds piezo ignition crackle. E1 jumped out and all attempts by the rheostat to remove E1 are UNSUCCESSFUL. What is the reason?

Does your boiler work? If it does not work, then it is very likely that the electronic board of the boiler is faulty. We need to change it.

Such a question - the cauldron of mora Proxima has been in operation for 6 years. the relief valve was triggered during heating operation. she turned off the heating, but the pressure rose to 2.5 atm overnight. I closed the cold water tap on the boiler. the pressure did not rise above 2.0 atm.

The question is - do you have cold water from the water supply system or do you have your own pump? And what is the pressure in the cold water supply system? What you describe is very similar to the fact that the DHW heat exchanger has leaked and since the pressure in the heating circuit is less than in the DHW circuit, water from the DHW circuit gradually enters the heating circuit. Therefore, the relief valve worked.

My sea top boiler is working fine, there are pumps for each circuit, the water heating is turned off (there is a separate column), the warm floors are hot, the second floor is warming up, the first is practically cold. bleed air from each battery, restarted the result 0 system. Please tell me how to fix the problem.

A lot of things have been done wrong or maybe done with a margin, but it doesn't matter. In your case, it is important how the wiring goes. If the main flow of the coolant first goes to the warm floors, then to the second floor, and then only to the first, then the reason is the lack of heat.

Why not enough? But here you need to figure out how you made warm floors. Why we have a feeling that you have the same temperature in all circuits, but it should not be so. In warm floors, no more than 40-45 degrees, and in the main system 80-85 (possibly more and a little less, but this is not so common).

Do you know how you have done it? If everything is done correctly, you still need to watch the system. The water flows where it is easier for it to flow - then the reason for not warming up is that something on the radiators of the first floor interferes with the flow of the coolant. Another option is possible - but this does not happen often - the heating system is more powerful than the boiler produces and there is simply not enough power.

The mora top 15 kw boiler began to randomly shut off the pump and tendencies, please tell me the reason.

Most likely, the reason is a malfunction of the electronic board of the More boiler. You need to check the master. The board is the "heart" of the boiler and, as a rule, it is precisely because of its breakdown that the boiler begins to "freak" like that. Make yourself a visual inspection of the board, you may see for yourself that something is burnt or melted.

I have a mora top 24kt meteor boiler today issued an error e2, I know that this is a monostat error, as usual, I tried to restart the boiler, but it issued e1 and nothing happens what can be done thanks in advance

The only thing that can be advised is manual restart of the boiler. If the problem persists, then the electronic board of the boiler may be faulty.

I have a boiler Sea Top TITAN 14SK single-circuit. After turning on the main burner, within 5-10 minutes, the flame gradually decreases and goes out, the pump is running, the igniter is on. What is the reason?

This is how the boiler should work. It heats up the system in 5-10 minutes and “understands” by the sensor that the burner needs to be turned off. In this case, the igniter in your boiler does not go out completely until you turn off the boiler completely. The pump must be running - otherwise the system will overheat. Then the cycle of switching on - switching off is repeated.

Gas boiler Mora Top Meteor PK24KT does not start. While holding the on / off button, the burner is in operation. But as soon as you release the key, the device immediately goes out. Explain the cause of the breakdown?

It looks like a defect in the thermocouple or a broken gas valve. There is also a decrease in gas pressure on the intake manifold. Sometimes the control board voltage is too low.

There is a problem. The start-up is very difficult. The igniter is on, but there is no flame on the main burner.Can anyone please explain what is the reason?

Apparently, damage to parts of the ignition mechanism. The boiler must be serviced and the ignition mechanism cleaned.

What is the problem if the Mora Titan boiler does not turn off after the heating reaches the required temperature? Heating goes up to 85C, followed by a malfunction. When restarting, the problem persists.

It looks like the board is out of order, the thermal sensor is damaged, the sensor is broken for overheating. It is possible that an automatic settings error has occurred.

Tell me why the boiler does not heat the water more than 70 C? I try to set more, but the display says it is the highest value. How should the heating be set?

If the appliance does not manage to increase the temperature of the heating circuit, the following causes are likely. In the adjustments, there is a limitation on the maximum heating temperature to 70 C. A decrease in the draft speed in the chimney duct is noted.

The Mora Top Proxima double-circuit boiler does not work correctly in the heating mode of the DHW system. From the tap can alternate between hot water and cold. Explain what is the problem?

The factors for the appearance of a functional failure are most likely the following. There is a mixing of cold water due to the fact that the 3-way valve is inoperative. The heat exchanger is heavily soiled. You need to clean it up.

Water leaks regularly from the tap under the boiler. The unit itself does not turn on. What do you need to do?

Perhaps there is a discharge of the heat carrier from the safety valve. This symptom indicates high pressure in the system. In addition, the system filling valve can be open, or it is recommended to pump the expander tank.

Tell me, what is the reason that the pressure increases rapidly, and the water discharge valve is also triggered? The heating symbol lights up indefinitely on the display in unit heating mode. What happened?

There is a breakdown of the heating circuit temperature sensor. There is no normal circulation in the heating system.

Why does the gas wall-mounted boiler Mora Meteor constantly turn off? Let's say that today the ignition did not work in any way. The apparatus was serviced at the beginning of the month. What is the malfunction?

There is a suspicion that functional disturbances have appeared in the smoke extraction system. You must perform a chimney inspection. Inoperability of the electric ignition will mean a malfunction of any component due to a voltage drop or water has entered it.

Can you help me fix my chimney problem? For two days now, reverse thrust has been observed, due to which the smoke enters the room immediately. I made the chimney myself. It looks like a pipe made of metal. There are probably omissions in the calculations.

The unit produces hot water well, but if you start heating, the water quickly boils, and the device goes into failure. What is the problem and how to fix it?

Most likely, the circulation pump is damaged, the control board is damaged, the temperature sensor is faulty. The filter mesh may also become clogged with debris.

In the process of supplying hot water, the unit starts to dispense hot and cold water in turn. I don't understand what is the reason. How to set up the heating of the coolant yourself?

Obviously, the heating system is clogged or the heat exchanger needs to be cleaned. There may also be a defect in the sensor that monitors the pressure, or the circulation pump could fail.

The main factor may be an incorrectly made structure of the chimney duct. Soot deposits often occur on the pipe walls, which drastically reduce pipe performance. In addition, it is desirable to control the ventilation in the room.

Installed a Mora Top Sirius boiler a week ago. The unit instantly picks up temperature over 96C, but then it locks up with overheating. Later, when it cools down, it can turn on on its own. What is the reason for this?

Failure of overheating functions indicates a violation of the circulation process. First of all, you should inspect the faucets on the radiators. They must be left open. Then a check is carried out for contamination of the dirt filter, and it is also recommended to make sure that the heat exchanger is not clogged.

We installed this boiler in 2020. After about three months, the device began to emit a noise. Explain why there is noise in the boiler?

The presence of scale in the heat exchanger is likely. When the water is hard, limescale will subsequently be deposited in the wall of the radiator pipes.

I plan to connect the Mora 5106 gas boiler to the heating system. Interested in how to correctly put such a unit into operation?

For the correct commissioning of this apparatus, we recommend the following procedures. Connect the power supply to the device. We put the gas valve open. Then we start up the gas burner equipment. At the end, we set up the required theme.

We need repairs. Please advise how to drain the water from the device?

According to the instructions, this operation is implemented in this way. We disconnect the unit from electricity. Close the gas valve. We open the automatic air vent. We open the drain valve. Then remove any spilled water. If required, it is allowed to drain the liquid using the safety valve. This component is located at the bottom of the device.

Can you tell me how to check the 3-way valve? I think that this part is not fully open. The last batteries are not pumped for heating, and in the hot water supply mode, the heating pipe under the boiler heats up.

I installed and connected a wall-mounted boiler Meteor Plus PK18ST in the apartment. Has acted well until now. At the moment, 3 seconds after switching on, the device goes out.

There is an assumption that he is unable to drive the liquid into the system. Help, please, what is the problem? A possible cause of this damage may be an ionizing electrode that does not detect a flame, or there is no circulation.

There is a problem with this unit recently. During the heating cycle, it whistles. I tried to reboot - the attempt was successful, but no changes occurred. Perhaps someone will tell you why this is happening?

Very often, a strong whistle appears if the pressure on the nozzles of the gas burner device is not adjusted according to the instructions. It is necessary to check the established indicator and correct it, if appropriate.

The gas boiler has recently been filled with water and malfunctions. For example, if you set any temperature, and the heating mode occurs exclusively up to 22 degrees, and then the device stops. Explain what went wrong?

If water gets into the electronic board, it is most likely damaged. We recommend that you carry out its zeroing using a direct disconnection of the unit from the mains. Then re-launch and check its performance.

I have a Mora Proxima gas by-pass boiler installed. Now, at the start, the wick lights up for 10 seconds, the main burner does not catch the fire, and because of this, the unit goes out. How best to get out of the situation?

Probably, the automatic ignition is damaged or there is a problem with the burner. Just in case, you need to check if the phasing is correct when connecting to the power supply.

Completed the commissioning of the same device in early August. After about 3 months, a malfunction occurs in the DHW circuit, although the heating circuit operates without interruption. I tried to open a hot water tap, but it only displays the temperature, and does not want to heat at all. What is the problem?

The three-way valve may be broken. It needs to be replaced.

Explain why a safety temperature sensor is installed in the boiler system?

The temperature sensor stops the gas supply to the burner when the liquid in the primary heat exchanger overheats.

It is required to wash and clean the main water heat exchanger. Tell me how to detach this component without error?

This element can be easily disconnected from the boiler unit using a conventional screwdriver. Here is the dismantling process. We drain the water from the apparatus using the drain cock. The next step is to free the hot water supply system from water. Unfasten the fixing screws of the primary heat exchanger and pull it out of the frame.

I performed independently commissioning of the Mora Top Meteor Plus PK24SK boiler. Approximately three months later, the water pressure in the apparatus decreased. Often he slows it down and turns off. More precisely, it does not hold pressure at all. Why doesn't he hold up the pressure?

When the machine does not hold water pressure, the make-up tap is likely to leak. When shutdown occurs and the water pressure has dropped to zero, the three-way valve is damaged.

Tell me how to clean the cold water filter?

First, you need to drain the hot water system. Second, unscrew the flow sensor nut. Next, we take out the sensor together with the filter from the recess. After removal, we clean from debris and dirt.

The device, when launched, made a buzz before, and at this time it rumbles even more loudly. Initially, the sound appeared for a short time, but now it lasts much longer. Has anyone observed this issue?

The formation of an extraneous unpleasant sound indicates the presence of mineral deposits inside the heat exchanger, which does not heat up equally due to the unequal wall thickness. The more dirty the heat exchanger, the louder the rumble, and, accordingly, the lower the heat transfer.

The device seems to be working, although water, apparently, does not circulate in the system. Very hot return pump. What is the reason?

Apparently, the filter is clogged or the tap is closed in some place, which interferes with the passage of the coolant. The circulation pump could still be faulty.

Why did the hot water stop heating? The tap water is barely warm. Help me understand what happened?

Clarification of problems leads along several paths. If the DHW temperature sensor is damaged, it should be replaced. Perhaps the power settings of the device for heating the hot water supply are out of order.

From time to time it is possible to observe the breakdown of the flame during the ignition. The burner is clean, the chimney is in order, the draft is excellent. Where to watch the breakdown?

The unit does not detect a flame due to insufficient signal from the combustion mechanism. It is required to diagnose the wires from the ionization sensor to the electrode. You should probably tighten it up. There may also be damage to the sensor insulation, which must be replaced.

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

Features. Installation and assembly. Automation components.

Technical specifications. Installation. Adjustment and check. Maintenance.

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

If you turn off the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

Installed the Arderia esr 2.13 ffcd boiler.If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

_______________________________________________________________________________

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

Czech-made water heating and heating technology Mora brings warmth and comfort to the homes of many users. The devices are designed for a long service life, during which breakdowns can occur. The Mora gas boiler is prone to malfunctions, so we will point out typical brand problems. You will learn how to deal with breakdowns yourself.

A wide range of models allows even the most demanding customer to choose equipment to their liking. "Mora" presents wall-mounted, cast iron, gas, electricity, combined, indirect heating boilers.

Let's dwell on gas single-circuit and double-circuit boilers. Mora Top is presented in three variations:

- Ruler "Meteor"

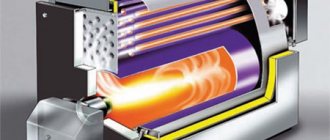

... These are double-circuit flow-type boilers. The removal of combustion products is carried out forcibly, as well as the injection of combustion air. The models are equipped with a modulating flame burner.

- Series "Titan"

... Conventional open combustion chamber. A chimney is required. Installed safety sensors. Built-in "Anti-freezing" mode: when the temperature drops to +5 degrees, heating is triggered.

- Line "Sirius".

This is a complex technique. Here you will find single-circuit and double-circuit models, with an open and closed chamber. They economically consume electricity - no more than 1–2 kW.

In case of a malfunction, an error code appears on the Mora Top display. Its value indicates the cause of the breakdown.

Mora gas boilers error codes

If you notice a code on the display, restart the equipment. Did the symbols light up on the screen again? Then start looking for the reasons for their appearance.

| Malfunction code | Value | Reason for appearance | Self repair |

| E0 | The technique doesn't work. |

|

|

| E1 | The boiler is not functioning. The switch does not close. | There is not enough water in the system:

| What to do:

|

| Error E2 | Burner extinguishing. |

| Turn on the gas cock. Then press RESET. Diagnose and clean / replace:

|

| E3 | The thermal sensor is open. The equipment does not work for hot water supply and heating. | Incorrect operation of the heating temperature sensor. | Monitor the condition of the sensor wiring. Its connections to the control board. Installing a serviceable element |

| E4 | The DHW temperature sensor contacts are open. | Actions are similar to E3. | |

| E5 | There is a problem with the security module. |

|

|

The following codes are typical for Mora Electra models:

- 01 - pressure drop.

- 02 - the system is overheating.

- 03 - reserve.

- 04 - the thermostat is faulty.

- 05 - EEPROM memory block is not working correctly.

- 06 - malfunction of RAM + RTC memory.

- 07 - control problems.

These problems are corrected by checking and repairing the components. There are other errors that indicate minor malfunctions:

- 08 - the boiler is working as usual, everything is fine.

- 09 - the DHW temperature sensor is out of order.

- 10 - external thermometer failed.

- 11 - the cascade line is broken.

- 12 - the modem is giving a bad signal.

- 13 - heater insulation is damaged.

In case of minor breakdowns of Mora Proxima and other models, the ALM LED-diode blinks on the panel with a frequency of 1 Hz. At the same time, the technique works, but with malfunctions.

Serious malfunctions are indicated by the constant flashing of the yellow ALM LED. The heater does not work, all functions are disabled.

Other problems

During operation, there are malfunctions that are not displayed on the display, their description cannot be found in the instructions. Therefore, we will tell you how to act in a similar situation:

- Control LED does not light up on the panel

whether. Make sure there is electricity to the part. Install a working light bulb or switch. - Heater does not start

... The ignition electrode does not work, the circuit is broken. Check the tightness of the contacts between the electrode and the VN output. If you hear sparks when starting up, you need to check the connection with the ignition and ground wire. - Burner works 50 seconds

... Fuel supply problems. Diagnose the valve, remove the accumulated air. - The burner ignites and goes out

... In this case, "unblocking" is on. The diameter of the nozzles does not correspond to the instructions. Gas supply cut off. Clean or install new nozzles. - Safety valve prevents starting

j. A diode on the panel lights up (insufficient heating). Add water to the system. - No DHW heating

... The three-way valve is broken. Replace it. - There is no heating in the boiler connected to the boiler

... Adjust the temperature, diagnose the temperature sensor, replace it if it is faulty. - Smoke fuse interlock

... Clean the flue duct (sometimes gusts of wind interfere with normal operation). Remove the fuse lock while holding down the TS button of the network module.

Share the article:

Similar articles

- 17 april 2015

Restoring an old wardrobe

- April 17, 2015

Diy barbell: economy and simplicity

- 17 april 2015

"Tape maze" - a positive attraction for all ages

- 17 april 2015

Useful tips for home and summer cottages (do it yourself)

| Security The boiler safety system is designed in such a way that any failure is practically excluded.

Control Panel DHW flow and temperature sensors Specific properties of the secondary heat exchanger basic information

* - Reduction of combustion products from 130 mm to 120 mm can be supplied at the request of the customer. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Floor models

Mora's floor-standing gas boiler is presented in more than ten versions, the main difference of which is the type of burner and furnace used:

- Atmospheric burner. Installed in the line of ELITE boilers - the best, by recognition, models of heating technology. The burner device is made of high quality steel and has a long service life. For more convenient use, it is possible to connect an indirect heating boiler (for hot water supply) and install temperature sensors. Thanks to their technical characteristics, the energy-independent floor-standing boilers Mora are a good solution for equipping a cottage or private house with heat.

- Pressurized burner. It has closed-type units. There is an automatic blocking of ignition, two separate circuits. The primary heat exchanger is made of steel, the secondary one is made of copper. Gas is consumed very economically, it is not difficult to notice when changing the fuel. Conversion to liquefied gas is possible when replacing the burner.

An overview of different types of burners for boilers is presented here

To increase performance and heat output, experts recommend using antifreeze. The heat exchanger and the internal structure have been designed taking into account the use of this fluid as a heat transfer medium.

The gas boiler Mora Top has proven its efficiency and reliability, therefore it is an excellent solution for equipping houses with heat and hot water outside the city. The design does not have complex automation, volatile units. It is characterized by high performance.

Installation of gas boilers Mora Top

Experts have thought over the design of the boiler and made it as simple as possible for installation and maintenance. All electricity dependent models have a built-in self-diagnosis option. Any malfunctions are displayed on the LCD. The boilers are equipped with Mohr equipment.Therefore, the automatics, burner and other components work for a long time and stably.

Boiler start-up and adjustment works:

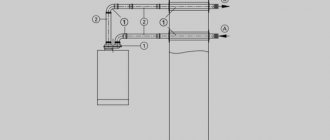

- Models dependent on electricity are connected to the network. The self-diagnosis function is automatically started immediately. The sensor analyzes the presence of pressure in the heating system and in the gas pipeline. When a malfunction is detected, a signal in the form of an "error code" is issued on the display. After adjusting the work, the boiler starts up.

- In boilers independent of energy, there is no option for self-diagnosis, auto ignition of the flame, etc. Therefore, before starting the equipment, the company's specialist must check that all recommendations regarding installation work have been complied with. It is necessary to install a water treatment system and a security group, it may be necessary to connect an expansion tank and a circulation pump.

Mora gas boilers, as a rule, start without difficulty, however, there are still exceptions, and they are usually associated with improper installation or transportation.

A common malfunction of a 2-circuit boiler is a breakdown of a thermocouple. After its replacement, the functionality of the equipment is fully restored.

Gas water heater Mora Top: installation and operating instructions

The line of Czech wall-mounted speakers Mora Top consists of several models with different performance characteristics. In the floor-standing series, the Mora 100 NTR boiler stands out for quality and efficiency. The most powerful wall-mounted model is considered the Vega 16, capable of passing up to 15.2 liters of water through itself per minute. The most affordable of the Top line is the Vega 10 gas boiler. All models are available in a compact body and differ only in the type of ignition (models marked “E” have electric ignition).

When installing and putting the column into operation, you must follow these recommendations:

- Equipment that has been in a cold environment for a long time should be connected no earlier than after 120 minutes;

- When installing the boiler, it is necessary to leave at least 10 cm from its side walls to the nearest objects and adjacent walls;

- There must be a distance of 40 cm or more above the boiler;

- When installing a thermostat, a device with a potential-free output contact should be used: the thermostat should not supply voltage to the water heater;

- It is strictly forbidden to store explosive substances near the boiler.

The instructions for installing and operating the water heater do not recommend connecting the equipment with your own hands. It is better to install a strainer at the entrance to the system. It will allow to extend the term of operation of the membrane and filter of the water intake unit of the column, heat exchanger tubes.

Mora Top gas boiler malfunctions

In case of any malfunctions in the operation of the heating structure of this brand, the display will show the so-called "error code" and notify the owner.

All possible error codes for gas boilers Mora Top you can see here

The error can be knocked out due to a pump malfunction, a switch closed, a gas supply to the burner, a malfunction in the safety module, etc. However, the display may not appear, but you will understand that there is a malfunction. In this case, analyze what exactly the problem is, find its description in the article (above link), read a possible solution to this problem and fix it.

Gas boilers of the Czech manufacturer Mora Top are adapted to domestic working conditions, which many boilers from other manufacturers with similar technical characteristics cannot boast of. The buyer has the opportunity to choose a suitable heating model. The product range is huge: from 15 to 750 kW. You can choose a fully automatic installation and a classic boiler without built-in complex automation. Elementary rules of use are also at the heart of the popularity of Mora models.