Operation and construction of a hot water boiler

Regardless of the equipment model, all devices work in the same way: the coolant is heated to the required temperature and transfers heat to the heating system.

There are the following types of water heating units:

- Gas.

- Liquid fuel

- Electrical

- Solid fuel.

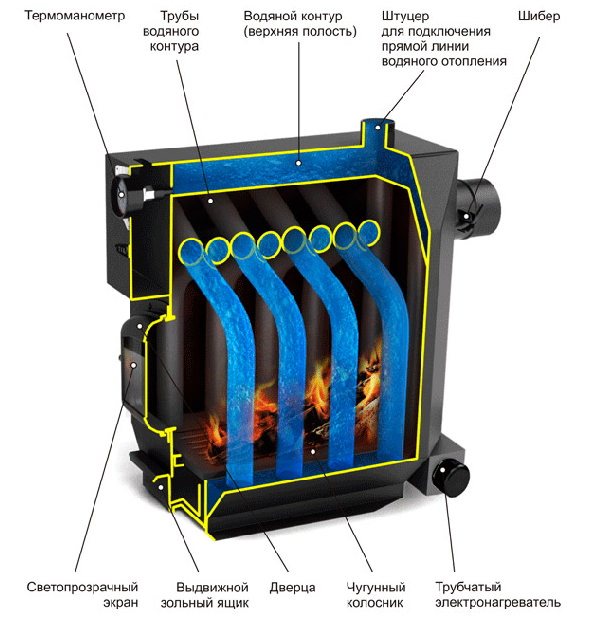

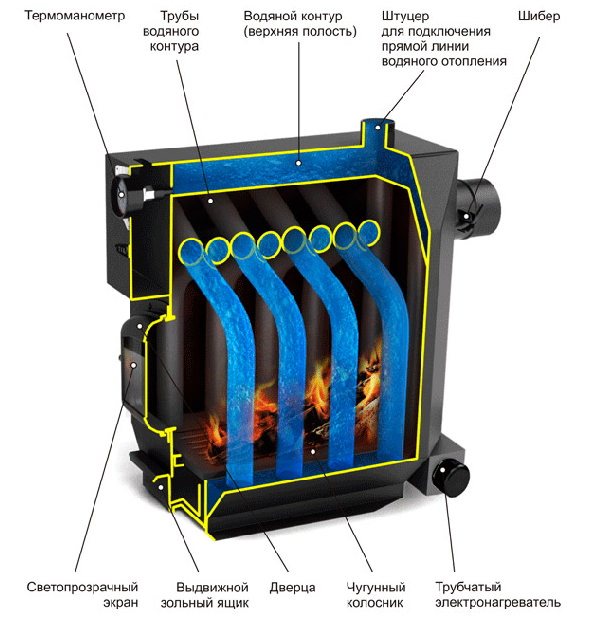

The device of a hot water boiler is structurally different depending on the type of boiler selected, and, accordingly, depending on the fuel used, different burners are used. They can be atmospheric built-in atmospheric or replaceable supercharged ones. Built-in burners are designed to use only a certain type of fuel. Replaceable burners are more convenient, since they allow, if necessary, to easily switch from one type of fuel to another.

Why is it profitable to use a hot water boiler house?

The task of hot water boilers is to provide heat and hot water to various construction and industrial facilities, educational and medical institutions, objects of agriculture and housing and communal services.

At the moment, such a boiler house is an economically viable solution, moreover, it is one of the most advanced modern heat-generating devices from an engineering point of view.

Today's hot water boilers of large, medium, and small capacity consume fuel and electricity quite efficiently and more economically. The cost of building a boiler house today is about the same cost as connecting to central heating.

But the main thing is that the boiler houses of the hot-water regime, located not far from the consumers, due to which they can significantly reduce the length of heating networks, and this can significantly reduce the length of heat losses, which has a beneficial effect on the efficiency of the entire system, in general.

The use of hot water boilers made of modern equipment is economically beneficial for the consumer for the following reasons:

- The efficiency of the boiler house is 92-93%, thanks to the automation of work processes, the use of hot water boilers, pumps, burners, valves and other modern equipment, which has a high reliability factor;

- funds are saved quite strongly due to a decrease in the cost of paying for energy carriers, a decrease in heat losses during transportation to the consumer, due to the fact that CWRs are mounted as close to the consumer as possible;

- the design of the boiler house itself can also be reduced by using standard assemblies and blocks that have already been tested at other facilities and have proven their reliability and efficiency;

- quite low costs for the transportation of boiler-house blocks to the installation site;

- low costs during installation, all blocks and modules are assembled from quickly assembled units and assemblies;

- the process of work, thanks to the automation of control, makes it possible to significantly reduce the cost of operating a hot-water boiler house;

- as a rule, a new hot water boiler house usually pays for itself in 2-3 years.

At the same time, the most popular are hot water boilers operating on electricity, since such units have a less complex design, unlike, for example, gas ones, and do not require constant maintenance. In addition, they are easy to operate and non-explosive.

Factors that ensure the efficient operation of the device

There are several requirements that must be met for the efficient operation of a hot water boiler.

Before describing the main structural and technical characteristics, it is worth highlighting several main indicators that affect the quality of work, which are considered common and suitable for any device.

These include the operation of a hot water boiler and parameters such as:

- Equipment manufacturer.

- The quality of the device and its elements.

- Availability of a warranty period for the operation and maintenance of equipment.

For effective work, you need to pay special attention to the firebox. It must have a sufficient volume to burn the entire volume of the loaded fuel.

According to experts, it is this parameter that is an important calculated indicator that determines the total amount of mechanical fuel.

What is the difference between fire tube and water tube structures?

Hot water boilers that can be found on the market these days do not differ much in the device. The more significant differences lie in the maximum power of the devices and the specific manufacturers.

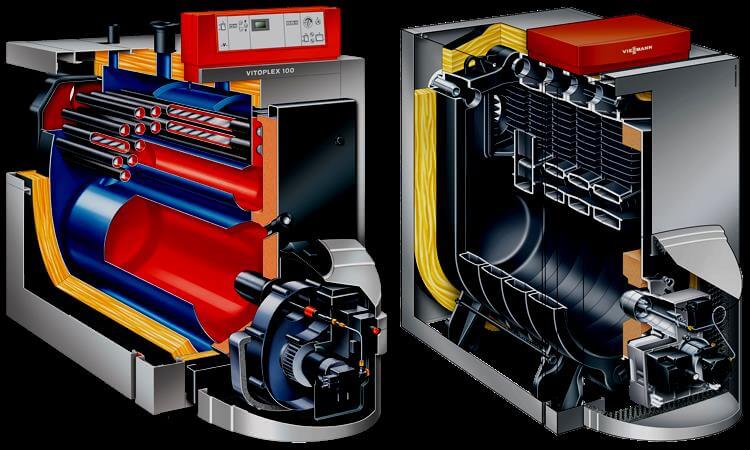

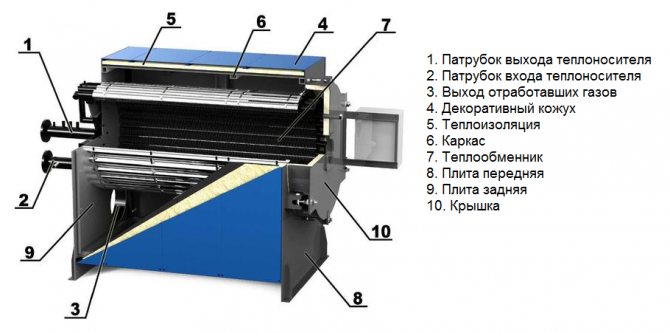

If we consider the design features, then boilers can be divided into gas-tube (another name is fire-tube) and water-tube:

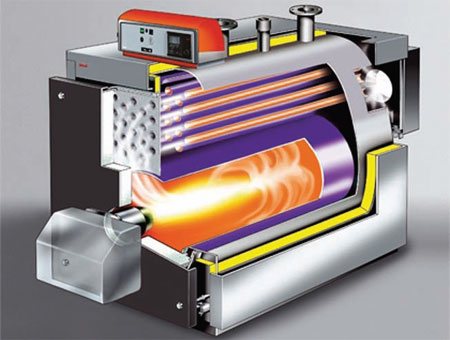

- Fire-tube models. The main distinguishing feature is the presence of special tubes, with the help of which the heated products of the combustion of the energy carrier move. If we consider the principle of operation of this equipment, then its basis can be considered the use of automated burners, which are equipped with blowing fans. The water is heated with the help of smoke tubes located outside. It is necessary to take into account the fact that, as everyday, such models are practically never used.

- Water tube models. Their design feature is special heating pipes, with the help of which the coolant moves. And these tubes are heated with the help of fuel combustion products. Boilers of this type warm up rather quickly, and in case of changes in loads, they are quite easy to regulate. In addition, such equipment is quite resistant to serious overloads. If we consider from the point of view of explosiveness, then its probability is quite low.

All hot water heating equipment is also divided according to its temperature level. For low-temperature models, the maximum permissible maximum temperature is 115 degrees, and for overheating hot water boilers, this temperature is from 150 degrees or more.

It should be noted that the low-temperature mode of operation consumes fuel rather economically, but at the same time the surface of the unit is covered with condensate, which does not in the best way affect materials that are in direct contact with the products of combustion of energy resources. Because of this, rather high requirements are imposed on the materials that are used in the manufacture of boilers.

Devices generating superheated water can be characterized by a sufficiently long service life and a high degree of reliability. The process of operation of such units is practically silent, and the emission of waste is minimal. Also, this equipment is equipped with simple and convenient control systems. Installation is fast enough, does not require complex maintenance.

Most of the heat and water tube units are double-circuit, but there are many single-circuit hot water boilers. In the event that the device is equipped with two circuits, then the heated liquid will be used not only for heating the room, but for domestic needs (water supply).

It is also worth noting that the design of these units implies special circulators, the task of which is to intensify the water circulation, and membrane-type expansion tanks can also be included in the design.

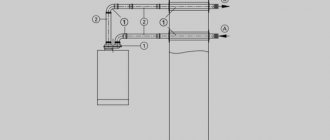

The principle of operation and diagram of a hot water boiler

The coolant heats up to 115 degrees and then transfers heat to the heating system. Water becomes steam at a temperature of 100 degrees, therefore, to prevent boiling, a high pressure is constantly maintained in the boiler.

The higher it is, the better, since then the likelihood of wall boiling decreases, which means less scale is formed.

Regardless of the type of fuel, the principle of operation of hot water boilers is the same: the fuel is burned in the firebox, and through its walls, heat is transferred to the water, which circulates through the heating pipes. Each design is designed to provide maximum fuel combustion and efficient heat transfer.

Deaerators of atmospheric pressure are used in the schemes for the preparation of feed water for steam boilers and make-up water for heat supply and hot water supply systems at TPPs and in boiler houses.

You can find out what vacuum deaerators are here.

Special convective packages may be present in the design of a hot water boiler. They are designed to effectively cool the flue gases and reduce their temperature.

The surface of the bags in high-quality systems is able to reduce the temperature regime to 190-200 degrees. Lower temperature indicators should not be allowed, as there will be a possibility of condensation formation.

If after some time it mixes with ash deposits, which contain sulfur, this can lead to destructive sulfurous corrosion, respectively, the boiler will fail very quickly.

High-quality and at the same time the most efficient operation of the equipment is determined by high indicators of reliability and durability of the device. In the process of work, the water on all panels and screens carries out a multi-way movement.

A similar result is achieved through the installed plugs in the manifolds. Their quantity regulates the parameters of the speed of movement of the coolant in the device. In more detail, this process reflects the scheme of operation of a hot water boiler.

Waste heat boilers have the following principle of operation: they generate energy in the form of heated water, steam or air flow.

You can find out more about gas recovery boilers here.

If you purchase a hot water boiler from a serious manufacturer, you can be sure of the quality and durability of the device.

This is largely based on the correct selection of the speed of movement of the water, which gives the minimum resistance of the circuit. This will minimize salt build-up and scale formation.

Industrial gas boilers of the REP Boiler Plant

GO TO THE CATALOG OF WATER GAS BOILERS

GO TO STEAM GAS BOILERS CATALOG

Industrial gas boilers are designed to generate thermal energy, with the help of which heating and supply of hot water, and, if necessary, steam to industrial facilities is carried out.

Advantages of industrial gas boilers:

- high efficiency;

- cheap gaseous fuel;

- compact size;

- ease of installation and operation;

- various power characteristics of boilers;

- quick access to the set power;

- ecological cleanliness of emissions.

Industrial boilers are mainly produced in horizontal design. The design of all types of gas boilers is based on the boiler body, gas burner and heat exchanger. The combustion chamber is insulated from the boiler walls with heat-insulating materials in order to protect the walls from overheating, and the personnel from burns.

Industrial gas boilers differ from household models in appearance, overall dimensions and internal structure. The body of industrial boilers is made of high quality alloy steel.This grade of steel is able to withstand the high pressure that occurs inside the boiler.

According to the location of the heat exchanger inside the boiler, industrial gas boilers are divided into two groups. The first group is represented by boilers with a fire-tube or gas-tube heat exchanger. Pipes, inside of which the movement of hot gases occurs, are located horizontally in the water column. Glowing, the pipes give their heat to the water. This design is capable of heating significant volumes of water in a short time.

The second type of industrial boilers is boilers where the heat carrier (water) moves along the inside of the heat exchanger tubes placed around the gas burner. Heat exchangers of both types are made of materials with high thermal conductivity.

By the type of heat carrier, industrial gas boilers are divided into hot water and steam. The greatest demand is for gas hot water boilers capable of solving the problems of heating objects and supplying them with hot water. The boiler plant produces a wide range of hot water gas boilers of the KVa series with a capacity of 0.4 to 4 MW.

Models of industrial gas boilers KVA:

- Boiler 400 kW;

- Boiler 500 kW;

- Boiler 600 kW;

- Boiler 800 kW;

- Boiler 1000 kW;

- Boiler 1100 kW;

- Boiler 1500 kW;

- Boiler 2000 kW;

- Boiler 2500 kW;

- Boiler 3000 kW;

- Boiler 3500 kW;

- Boiler 4000 kW.

What is chemical water treatment for a boiler plant for?

Due to the high dissolution capacity of mineral and organic substances, water from natural sources is not chemically pure. It contains impurities of natural and man-made origin. They can be divided into three groups according to their physicochemical properties and the effect on heat exchangers of boiler installations:

- Mechanical.

- Corrosive.

- Dissolved sediment-forming.

The main task of water treatment at boiler houses is to obtain technically pure water suitable for use as a heat carrier in steam and hot water boilers, as well as in pipeline networks. It is about removing unwanted impurities. In most cases, mechanical cleaning is not enough, and deeper processing is required - chemical water treatment for boilers.