Author: Kolesnikov Yuri Fedorovich, heat and power engineer

The stove is erected once, and you need to heat it all the time, on the one hand. On the other hand, the design of the furnace is largely, if not completely, determined by the type of fuel used. And its availability depends significantly on the reserves of local resources in the region. So the stove is danced from the fuel.

Modern heating technology allows you to burn to carbon dioxide, water and ash everything that, in principle, can burn, and something that, in principle, cannot burn. This is not just a joke. What can you expect from burning fuel in a stove? And how simple and efficient can a stove be on such and such, or such and such types of fuel? It depends on its properties:

- Aggregate state - solid, liquid, gaseous;

- Specific calorific value, or heat of combustion;

- Specific cost;

- Combustion rates;

- Combustion temperatures;

- Ability to water up;

- Ash content;

- Content of higher organic compounds;

- Sulfur content;

- Activity.

Solid, liquid or gas?

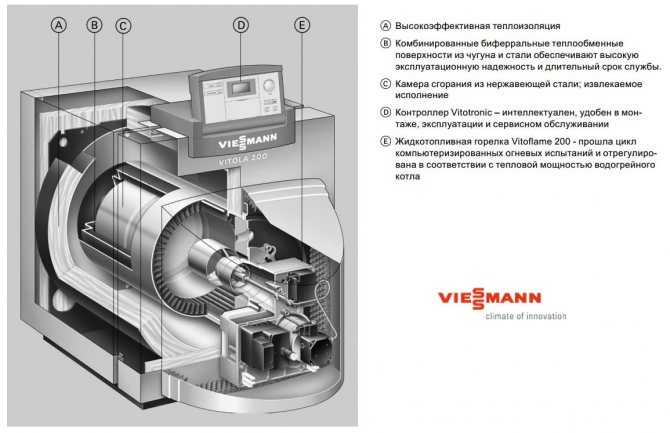

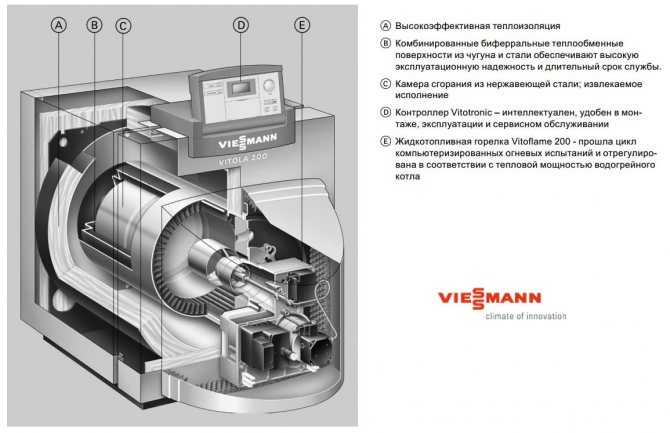

Mini-boiler room diagram

Upon careful consideration (for which, unfortunately, there is no place here), in terms of the totality of qualities, natural gas and liquid fuels are still the best. But it is better not to try to make a stove for them on your own: without industrial equipment and well-established technology, an experienced heating engineer will not undertake this either. More precisely, all the more it will not undertake, knowing what's what.

And there is a nuance: since this fuel gives off heat almost instantly, you cannot do with one stove. For incineration, a complex set of equipment is also needed. For an example, see fig. scheme of a mini-boiler room. It costs a lot, and it is economically (and environmentally) justified for households with a living area of more than 120-150 sq. m.

Note: The efficiency of even a small gas or fuel oil boiler with automation reaches 90% or more. Almost all losses in centralized boiler houses are due to pipelines.

A homemade stove can be heated and supplied with hot water up to 60-100 sq. m. residential. More - the complexity of the work and costs increase so much that it turns out to be cheaper and easier to install a double-circuit gas boiler. If, of course, there is a gas supply. In this case, you need to focus on the lowest of the indicated values; with bottled gas - for higher education.

An exception is a pyrolysis (more precisely, a gas-generating) furnace for working off or dark heating oil. It is easy to do it yourself, in compliance with safety conditions. But the heated area is up to 40-60 sq. m, the extraction of heat for hot water supply is difficult, and the device of a full-flow hot water circuit is hardly possible. Those. field of application - a garage, a summer residence, a small residential building, provided that the stove is in the annex.

Note: pyrolysis oil is not a fuel for pyrolysis ovens. It is a product of rapid (50-30 s) oxygen-free pyrolysis of woodworking waste at a temperature of about 600 degrees. The pyrolysis oil is quite heavily watered, has an acidic reaction, i.e. chemically aggressive components in its composition and contains up to 2% or more sulfur. It is burned in industrial boilers and furnaces using a special burner.

Pros and cons of ZHTKO

Actually, we have already mentioned all the advantages and disadvantages of liquid fuel boilers, but just in case we will repeat them:

Pros:

- A high degree of automation, the ability to create maximum thermal comfort.

- Full autonomy from other energy sources (in addition to electricity, but the needs for it are small, you can get by with a generator)

Minuses:

- High operating costs.

- The need to have a capacious fuel storage, to prevent it and pipelines from freezing.

- Fan burners make a lot of noise, their work is clearly audible through the wall.

- ZhTKO should be located in a separate room with good ventilation, preferably not connected in any way with living quarters - the "aroma" of diesel fuel is indestructible.

A modern liquid fuel boiler room is a clean room, you will not see puddles of "solarium" on the floor in it. But the specific smell of fuel still leaks out

So, who will install the ZHTKO in his house? First, the one who does not have and is not expected to lay a gas pipeline in the near future. Secondly, the person is not poor, who prefers to pay more money, but get comfortable living conditions. Thirdly, the one in whose house there is no electric power sufficient for organizing alternative heating, and he is not satisfied with drowning with firewood.

In conclusion, let us say that liquid fuel boilers are a rather complicated technique that requires professional maintenance. Therefore, installation, connection and service work must be carried out by qualified specialists.

Heat of combustion and cost

The formal content of this paragraph does not require special explanations: kilocalories or joules. It can only be recalled that 1 kcal = 4.3 kJ. That is, if the heat of combustion is 10,000 kcal / kg, then in joules it will be 43,000 kJ / kg or 43 MJ / kg for solid fuel. For gaseous - kilocalories or kilo / mega joules per cubic meter. For liquid, reference books are given either per kilogram or per liter / cubic meter.

The heat of combustion of commonly used fuels ranges from 1,800 kcal / kg (waste wood: alder, willow, rotten raw brushwood) to almost 11,000 kcal / kg (polyethylene and other organic polymers), which in megajoules will be from 7.74 MJ / kg to 47.14 MJ / kg for polyethylene.

A nuance is already revealed here: you can completely burn everything, but the price of a kilogram is different! Therefore, we do this:

- We make a heat engineering calculation of the heating capacity of the room.

- We give it a 10-20% margin for hot water supply.

- We give to the received another 50% margin for abnormal cold.

- The obtained value is DIVIDED by the efficiency of the selected furnace.

- According to the obtained required heat power of the furnace and the specific heating value of the fuel, we determine its mass / volumetric consumption.

- By multiplying the consumption by the cost, we get the unit cost of heating.

- We repeat the procedure for different stoves and fuels until we reach the minimum price.

Note: heating devices with an efficiency less than the threshold 70% can be ignored. Even if we personally have a purple ecology on the yellow side, there will be additional taxes and fines somewhere else. Required.

What to choose for heating a house - a boiler or a stove?

If you visit your country house on short-term visits, on weekends or on vacation, then you have no particular alternative - you will have to put a stove to heat the house. Since in the case of a boiler, you will have to constantly monitor the performance of the heating system and make sure that the CO does not freeze.

It is possible to supplement the air heating system of the house, which is any stove, with other heat generators of air heating - electric or gas convectors.

To install electric convectors, you will need a decent amount of dedicated electricity capacity. And gas convectors can be powered both from main gas and from "balloon" liquefied gas.

If you permanently live outside the city in your home, then installing a boiler and installing a liquid heating system are the most reasonable alternative to stove heating.

Combustion rate

In home-made stoves without complex automation, a clear correspondence is observed: the faster the fuel burns, the lower the efficiency of the stove can be achieved and the more complex its design is. The reason is simple: without technological tricks inaccessible to the home-builder, it is difficult to catch a large amount of heat released at once and send it into the room, or into the water heater, before it flies out into the pipe. Therefore, it makes sense only to make a homemade stove on slowly burning fuel - solid, oils, oil sludge, etc. Or a slow-burning furnace, where the combustion process is artificially slowed down.

In terms of combustion rate, coal is distinguished among solid fuels. He has it very uneven as it burns. In the beginning, when gasification is in progress, the flame rages. And then, when pure carbon (amorphous carbon, coke) remains, slow smoldering begins. And it is not so easy to make a furnace with high efficiency in either combustion mode.

Boiler or stove - how to heat the house?

For a small country house, it seems to me that the question of what to choose for heating - a boiler or a stove - will always remain relevant.

When the house is large, from 100-120 square meters, it becomes difficult to heat it with a stove. Especially if the house is built on 2 floors and divided by partitions into separate rooms.

In this case, for heating the house, it is reasonable to install a boiler with a liquid heating system or heat the house with any kind of convectors - gas or electric.

If a gas main runs along the border of the site, to which you can connect for little money, then the issue of installing the boiler becomes generally resolved and not subject to serious discussion.

The convenience that gas heating offers will not be given to you by any other type of heating except electric.

However, with the current electricity tariffs, only people with a constant good income can afford to be heated with electric boilers or convectors.

But in the case when the house has a small total area, from 40 to 100 square meters, the question of what to supply for heating it remains open.

Combustion temperature

This is a double-edged sword. One end - the higher the temperature, the easier it is to achieve complete combustion and high efficiency. On the other hand, again, it becomes more difficult to extract and direct the heat where needed; due to the large temperature gradient, it strives to fly into the pipe. Therefore, the design of the furnace becomes more complicated. In addition, high temperature combustion requires expensive heat-resistant materials.

In general, the lower the combustion temperature, the simpler and more efficient the stove is. Gnarled home-made designs on smoldering at 600 degrees (slow-burning furnaces) can give an efficiency of more than 85%. It is difficult to achieve an efficiency of more than 75% from a wood / coal stove (800-900 degrees) in an amateur design, and it often turns out that the construction shown in the video with pride burned out or cracked before the end of the heating season.

Note: the maximum combustion temperature achievable in home-made structures is about 1100 degrees; these are pyrolysis and gas generating furnaces. Above - without special steels and refractories, only a few test furnaces will withstand.

Stove or boiler?

Modern manufacturers are vying with each other to offer a huge selection of boilers: gas, electric, solid fuel, pellet, liquid fuel, waste, combined. If you are the happy owner of gas in the house, you can not consider other options for stoves or boilers.

I was provided with an open field without gas and electricity with unclear prospects (nothing has changed in three years). Heating a house with electricity using a diesel generator is the ruin of the purest water (plus or minus one hundred euros).However, the announced price of electricity consumption for the corresponding boiler did not inspire - more than fifteen thousand rubles in winter for one hundred and fifty square meters of a well-insulated house.

As a result, the choice arose between a long-burning solid fuel boiler (below we are talking about it) and a long-burning stove.

The advantages of such a long burning boiler:

- economical fuel consumption;

- high heat transfer;

- heating 1-2 times a day, depending on the model and the temperature outside;

- relatively even heat distribution.

- high cost (purchase plus turnkey installation with a guarantee of at least one hundred to one hundred and fifty thousand rubles);

- control, control and more control! (overheating of the system, undermining from radiators and pipes must not be allowed, uninterrupted electricity is needed for a variety of automation sensors, timely addition of antifreeze and much more);

- a separate boiler room, equipped according to all SNIPs;

- well, and the risk of an explosion (unmotivated from the point of view of logic and conscience), which more or less decent sellers of this equipment honestly warn about.

As a result, after comprehending and weighing, I decided to install the oven. But which one?

Water cut

Watering the fuel removes heat not only and not so much for the evaporation of water. At high temperatures in the presence of a catalyst - carbon - even more energy is spent on the chemical reduction of water and the combination of the released oxygen with atmospheric nitrogen. The water content of the fuel in percent by weight is denoted as W.

The ability of the fuel to absorb moisture, firstly, reduces its heat of combustion. For firewood - twice or more with an increase in humidity from 20% to 50%. Watered fuel oil can also be explosive. And barely wet brown coal ignites spontaneously, so it is not transported from the mining sites, thermal power plants on brown coal are built near mining pits.

A furnace operating on watered liquid fuel must be equipped with a special burner and a fuel preparation system. Solid fuel - a complex smoke path in which the reduced components and oxidized nitrogen do not cool down before decaying to the original ones and giving back heat.

Heat exchangers for oil boilers

A heat exchanger is a device in which fuel is burned and the coolant is heated. In modern boilers, it has developed fins, which allows the maximum amount of heat to be taken off during combustion. Condensation liquid waste heat exchangers with an additional heat exchanger section have also appeared, which makes it possible to utilize the secondary heat of waste gases. The circulation of the coolant is organized according to the "water jacket" principle.

Heat exchangers can be made of cast iron or steel. Cast-iron roads are heavy, they are afraid of thermal and mechanical shocks, but with careful handling they are very durable, they serve for at least half a century.

Even steel heat exchangers for liquid fuel boilers are very heavy, not to mention cast-iron ones, therefore ZhTKO are produced only in floor-standing design.

There are also combined heat exchangers made of cast iron and steel.

Activity

Fuel activity is a conditional parameter. It characterizes the ability of a fuel to ignite and burn on its own.

The fuel that flashes from a spark is considered to be extremely active, and the combustion zone immediately spreads over its entire surface. Highly active fuel requires a small amount of fire, or with the help of a wick, but then, in the open air, it flares up quickly and over the entire surface. Medium active requires ignition with more active fuel and does not completely burn out without additional measures (joke, turn) or pressurization in the open air. Low-level fuel combustion can only take place in special devices after ignition.

Fuel activity depends little on its calorific value, but much more on the state of aggregation, boiling point (for liquid fuel) and the degree of fineness (dispersion) for solid fuel. For example, gasoline and ethyl alcohol are extremely active at room temperature. In diesel fuel at room temperature, the torch goes out, but, sprayed with a nozzle, it flashes itself at 90 degrees in the open air. Wood in the form of firewood is moderately active, in the form of dry shavings it is highly active, and in the form of sawdust it is very weakly active.

Note: according to TU, the flash point of summer diesel fuel is 62 degrees. But this is in a closed crucible.

Furnaces and boilers in operation

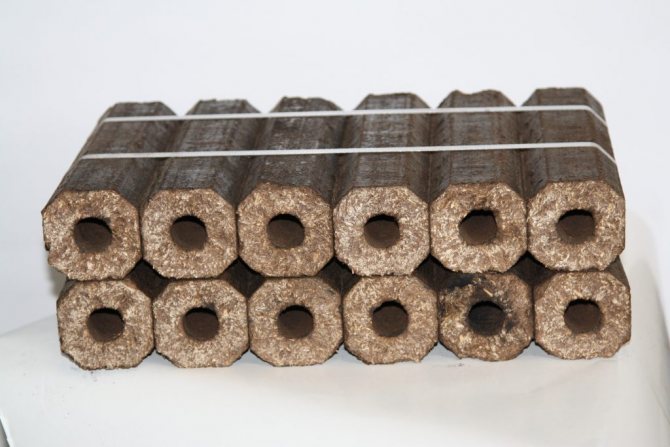

Any solid fuel heat sources are inconvenient in that they require periodic loading of fuel and cleaning the ash pan. Automatic fuel supply can be organized only in boilers operating on pellets (boilers with automatic supply of firewood, coal, briquettes also exist, but they are considered not so reliable), but this does not exempt from the need to clean the ash box. The payment for energy independence and the relative availability of solid fuel is the physical maintenance of the boiler, which requires the presence of a person. If we talk about stoves that heat the cottage, then the fuel filling must be repeated up to 7-8 times a day. Traditional stoves consume more fuel than modern solid fuel boilers. In addition, the latter are distinguished by a longer operating interval at one load. On average, 2-3 hours pass between fuel inserts. This became possible due to the increased volume of the combustion chamber, as well as the secondary air supply system for the afterburning of combustible gases released by solid fuel. Thus, the number of fuel inserts into the boiler furnace can be reduced to 2-3 times a day, which is quite acceptable.

What is better stove or solid fuel boiler

Related Products

MaxiTerm (12-20 kW) - Boiler on wood and coal MaxiTerm

Free shipping. Payment upon receipt of the boiler. The buyer of the boiler gets a discount.

Kronas Eko (12-24 kW) - Solid fuel boiler Kronas

Free shipping. Payment upon receipt. Solid fuel boiler Kronas EKO is suitable ..

Marten Base (12-18 kW) - Boiler on wood and coal Marten

Free delivery to your door. Payment upon receipt, no commissions. Buyer cat ..

Proskurov AOTV (16-100 kW) - Solid fuel boiler Proskurov

Free shipping. Payment upon receipt of the boiler. The buyer of the boiler receives a discount on the purchase.

Buleryan Canada (7-64 kW)

Free shipping! Payment upon receipt! Buleryan's buyer gets a discount on ..

Which coal to choose for the furnace?

What is coal? It is a vegetable product that contains carbon and non-combustible impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is it, as well as the "age" of the natural fuel, that determines the coal grade. Experts distinguish between several varieties.

The "youngest" type of coal is lingitis. It has a rather loose structure. If you pick up a lump of lingitis, it quickly crumbles and loses its shape. Such coal is most often used in thermal power plants, but lingitis is not suitable for heating a house.

In addition to lingite, brown coal, coal, anthracite are also mined.

—the oldest carbon deposits. All varieties have different moisture levels.

In brown coal, for example, the moisture content is 50%, in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal / kg. Coal has a lower indicator - 5.5 kcal / kg. In the brown variety, the specific heat is only 3 kcal / kg. Considering all this, it is easy to understand what type of fuel to purchase for heating a house.

Terms of use and precautions

Bioethanol, which is part of biofuel, belongs to highly flammable substances, and when using it, you must be guided and observe some safety measures:

- Never add fuel to an open flame or hot fuel tank. Before refueling, put out the device and wait for it to cool down (about 15-20 minutes).

- It is forbidden to use straw, paper, wood and other combustible materials to ignite biofuel. It is allowed to use only a special long metal lighter, electric ignition or a long match.

- It is forbidden to store a can of fuel near a burning fireplace or other open flame.

- It is recommended to store biofuels out of the reach of children.

- If in the process of filling the biofireplace fuel has been spilled, it is necessary to wipe it thoroughly with an absorbent cloth.

General operating rules:

- It is necessary to store a container with biofuel in a place far from open fire and heating appliances.

- The ignition of biofuel in the burner should be done with a special lighter.

- If biofuel gets on the surface of the fireplace, the floor or any other surface, it is necessary to carefully wipe the drops with a dry absorbent cloth.

- You can add biofuel only to an extinguished and cooled eco-fireplace.

In order for the eco-fireplace to please its owners with an even and pleasant burning, it is necessary to properly supply it with high-quality fuel.

There are several criteria due to which it will be extremely difficult to make the wrong choice.

- First of all, you need to choose those products for the fireplace that have been on the market for more than one year and have proven themselves well. The seller must have the necessary documents for biofuel on hand.

- It is also worth paying attention to the performance indicator and choosing a biofuel that will meet the needs of the owner of the fireplace.

- When opened, the liquid should not emit unpleasant odors that hit the nose sharply. It is important that the expiration date shown on the label has a sufficient expiration date.

Only by choosing quality products, you can be sure that the ecological fireplace will decorate your home and will work as safely as possible.