In this material:

- Fuel briquettes: properties and classification Material advantages

- Company registration

- Project investment and maintenance costs

Biofuel production will become a profitable source of income. The production of such products will not only meet the demand of buyers, but also solve the problem of disposal of some waste.

Let's analyze this line of business

To open your own business, you need to carefully analyze it. The production of fuel briquettes currently creates one of the most efficient types of fuel for heating homes and buildings, which indicates a high demand for the product. The fuel briquettes themselves boast a significant heat transfer and small size, which makes them a convenient option for use in an ordinary country house.

Actually, this is precisely why the most frequent buyers of these briquettes are Denmark and Sweden - northern countries with a large number of private houses. Undoubtedly, many other European countries also often buy this material, which cannot be said about the CIS - for citizens of countries like Russia and Ukraine, such a product is too expensive.

That is why a novice entrepreneur should immediately focus on the European market, creating a product that meets the standards of these countries.

What is this product?

Typically, this type of fuel is made from various types of waste from wood processing enterprises. That is why most often you can see the production of fuel briquettes from sawdust, straw, plant waste, peat and branches.

The resulting product comes out versatile enough to be used both in baths and saunas, and in boiler rooms. Briquettes resemble ordinary firewood, but are more durable. The indisputable advantages of the material include:

- good environmental friendliness due to the release of a small amount of soot and smoke;

- the possibility of using ash as a good lime fertilizer;

- long burning time - on average three times longer than that of ordinary firewood;

- small size, which makes it easier to transport;

- no harmful substances and impurities.

Almost the only, but extremely unpleasant disadvantage is the high cost. The constant use of such briquettes at home is not available to an ordinary inhabitant of our villages and private houses, so it is extremely difficult to find a buyer here. But at the same time, having received a permanent channel for selling products, it will come out to earn really good money.

Straw boilers as a source of energy for agriculture

In modern conditions, it is a generally accepted fact that burning dry agricultural waste to generate heat is 2.5-5.0 times more profitable than using gas. However, you can burn various dry organic waste: crushed plant residues, sawdust, grain cleaning waste, sunflower husks, straw - the main thing is that they are dry. In this article, we will look at the possibilities of using straw as fuel.

It should be noted that straw can be used for heat production both in small agricultural enterprises and in powerful elevators. This energy supply option is especially relevant if the farm has its own crop production, which consistently produces a large amount of straw.

Grain straw in the form of straw bales, cutting or pellets (pellets) is a good energy source. In terms of its heat generating capacity, burning 2.34 kg of straw is equivalent to burning 1 m3 of natural gas. But using it to meet the energy needs of industrial enterprises, farms or elevators will cost them three times less than natural gas.

Straw is a by-product of growing various crops, primarily grain. The area under grain crops in Ukraine is almost 14 million hectares, and in the end, their cultivation, in addition to the main products, annually receive 78-95 million tons of straw (and this amount grows with an increase in the yield of various grain crops from year to year).

Most of the grain straw that is produced in Ukraine is a by-product and is not used in any way. Removing straw heaps from the field after harvesting winter wheat with a combine is then very problematic.

Types of briquettes for production

The usual technology for the production of fuel briquettes involves several formats at once for the release of their products. It is worth taking a closer look at each in order to decide which one to choose for your own enterprise:

- Pini & Kay - for the production of this type, screw presses are used, operating at a pressure of strictly 1100 bar. This product is thermally processed to a darker brown color. The briquettes look like polyhedral bars with a hole.

- RUF - These products are in the form of standard bricks without holes and are manufactured using a pressure of 400 bar.

- NESTRO - cylindrical bars are produced under the pressure of a mechanical impact press.

- Pellets are the most popular option for European boilers, often fired with pellets. The product is a fuel pellet produced by a pellet press exclusively from wood flour.

Novice manufacturers for the most part make the first and last options due to the greater profitability and rather simple production technology.

Here you can download a free sample of a business plan for the production of fuel briquettes.

We organize the site and production officially

When drawing up a complete business plan for the private production of fuel briquettes for sale, start by filling out the necessary documentation. For the operation of an enterprise in this direction, it is enough to register an Individual Entrepreneur and select the desired OKVED code during registration. Further, it is already worth going directly to the search for a site for the arrangement of production.

You will have to rent a room of at least 120 square meters in order to fit the necessary equipment and delimit different zones. At the planning stage, it is worth considering where the production workshop, the warehouse for finished products and raw materials, as well as auxiliary rooms for personnel will be located.

The warehouse must be in a dry, protected place, while the largest areas will have to be given for the workshop. It is extremely important to remember that the enterprise produces briquettes from straw, sawdust and other wood waste, therefore it is simply necessary to equip the entire premises with fire safety systems.

According to the requirements of the fire service and the SES, the site must have a water supply and sewerage system, as well as a working electrical network. In addition, in the absence of ventilation, you will have to spend money on its installation.

How to make fuel briquettes with your own hands, simple instructions

- 1 Key benefits

- 2 Equipment and raw materials

- 3 Production

Recently, it has become fashionable to use not only traditional fuel in the form of firewood for kindling stoves, but also other, alternative options. For example, fuel briquettes, natural materials pressed under a high temperature: sawdust, sunflower husks, peat, straw, etc. are becoming more and more popular. Created from biological waste, 100% natural and environmentally friendly, briquettes of fuel allow you to effectively and inexpensively drink a house, a bath.

We buy equipment for production

In the manufacture of the product of interest to us, whole sets of equipment are used. In our case, we need a complete line assembled specifically for the production of fuel briquettes.

These lines are often on sale, so it's easy to find them. As standard, it includes a set of:

- dryers for wood raw materials;

- crushers;

- auger for feeding raw materials;

- heat generator;

- screw mechanical press;

- cyclone;

- conveyor lines;

- apparatus for packaging finished products;

- control panel;

- programmed electronic scales.

Sometimes manufacturers allow themselves to buy used parts of equipment for the production of fuel briquettes. This significantly saves start-up funds for starting a business, but can greatly affect the quality of products. Official lines are also not worth buying from unknown suppliers, preferring organizations with a good reputation, but you should be prepared for the high cost of equipment.

Production technology

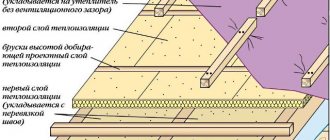

The first step is the preparation of raw materials. It is fed to the chipper, where the wood is crushed and passed through sieves, after this procedure, chips with a fraction of 5-30 mm are released. In an aerodynamic shredder dryer, the material undergoes final shredding and drying. The outlet size can be adjusted up to 1 mm.

Sawdust briquettes are produced on a screw press, which forms them under high pressure. No binder is required here, as wood contains a special substance, legnin, which is a natural glue. At the exit, briquettes with a density of 1.1-1.2 t / m3, cylindrical or rectangular, 10-30 cm long, 60-75 cm in diameter are obtained.

Raw material supply is provided by a belt conveyor. You should be aware that the augers on the press gradually wear out and need to be replaced, which, however, does not require much time and cost.

Prices for raw materials and equipment

The technological line includes the following equipment:

- dryer - from 100 thousand rubles;

- crusher - from 100 thousand rubles;

- screw press - from 250 thousand rubles;

- feed auger - from 13 to 80 thousand rubles;

- storage bunker - 50-100 thousand;

- ventilation equipment - 1.2 - 3.6 thousand rubles. per sq. m. with installation work;

- heat generator - 150 thousand rubles;

- cyclone - 10-30 thousand rubles;

- transporter - about 200 thousand rubles;

- control panel - about 10 thousand rubles;

- packing machine - 300-800 thousand rubles;

- electronic scales - from 5 thousand rubles;

The cost of sawdust depends on the region and ranges from 1 to 15 rubles. per cubic meter m. But now on the Internet you can find a lot of ads about free wood waste that you just need to pick up. Manufacturers of furniture and lumber are repeatedly faced with the problem of waste disposal, so you will even provide them a service. The same sawdust can be used as fuel for a heat generator.

Premises and staff To accommodate equipment, an administrative block, warehouses, utility rooms and a bathroom, you should find a room with an area of 120m2, with a 380V (100 KW) power grid and minimal aspiration equipment. It will take about 4 people to service the equipment in one shift.

Briquettes manufacturing technology

Many are interested in whether it is possible to make homemade fuel briquettes with their own hands. In fact, a very strong press, fine crusher and high temperatures are required in the manufacture of this product.

The industrial machine and furnaces will allow achieving such a result when finely crushed pieces of raw materials are pressed and bound to each other due to the release of lignin substance using high temperatures. This is how briquettes get their strength, and it is much easier to get a high-quality product in the shop.

By the way, for pellets, you cannot do without a special crusher machine that turns sawdust into real flour for further granulation, in which a special press for the production of fuel briquettes from wood flour will help. In any case, the products must come out even, without any external contamination and strictly defined shape.

By observing exactly these requirements, the manufacturer will be able to get a chance to enter the foreign European market. Do not forget to securely pack your briquetted goods in order not to receive complaints from the buyer.

Available articles in the section: "Gazprom blacksmith Davydov smells of manure." ; "Biogas both heats and cooks!"; How I built the pool

Building from straw blocks and firewood from straw!

Description of straw blocks.

Thatched blocks are a building material, serve as enclosing structures in the construction of houses and utility rooms. Straw blocks are obtained by pressing in special balers while harvesting straw from the field. Using European equipment, we produce straw blocks that meet the requirements listed below.

The density of our blocks ranges from 120 to 160 kg / m3. As practice has shown, for the convenience of construction, blocks of different sizes are needed. By prior arrangement, we can produce blocks of up to three standard sizes, say 0.5m, 0.7m and 1m lengths and higher density - up to 200kg / m3. Block section 0.4 * 0.46m (height * width) main length 1m. We mainly use rye and wheat straw for the production of blocks.

The cost of blocks regardless of the type of crop (rye, wheat, oats, barley) 4000 rubles / ton With an average density of 140kg / m3 and dimensions of 0.4 * 0.46 * 1m, 1 block weighs about 25 kg, respectively, its price is 100 rubles When paying for the order before May 1, 2012, we will provide a 10% discount. We will be able to fulfill the order in August-September.

Requirements for straw blocks, their transportation and storage (Evgeny Shirokov, Ecotechnology of bio-positive enclosing structures made of straw blocks).

What is a good straw block? A good thatch block for construction meets the following conditions: The dry block is relatively light when lifted by hand. When the fingers are deeply immersed inside it, moisture is not felt, there is no smell of rot. Straw quality. The trunk and stem are strong and flexible. Bend and pull individual straws to test their flexibility and strength. Mature, golden, harvested dry (and stored dry) straw produces the best blocks. Compressedness. A well-compressed block deforms slightly when it is lifted by the tight banding straps. Bandages - a plastic cord or wire - should wrap tightly around the straw block so that you can't get more than two or three fingers under them. Relatively uniform size. Block sizes vary, especially in length. A regular block has dimensions 50 * 40 * 30-120cm (width * height * length).

Transportation and storage. A fundamental rule of straw block construction is to keep the bales dry, from harvesting in the field to the end of construction. Always transport them under an awning - don't let them get wet. Always store the blocks in a dry place - in a warehouse or under a secure shelter. Plan the purchase of blocks and their transportation as a whole. As the construction experience shows, buying, transporting and storing straw are the most serious problems.The optimal strategy is to build a frame, bring straw into the house. Remember: it is fire hazardous until it is plastered.

Enemies of the straw. There are three main enemies of straw: rotting, fire, and small pests.

Rotting. Straw blocks with a moisture content of more than 20% begin to rot and decompose.

Fire. Well-compressed straw blocks are quite fire resistant, while loose straw can cause a fire. Be especially careful with straw in attics, attics and near fireplaces. Always keep the construction site clean and out of the reach of smokers. Have a full range of fire fighting and hand tools on site during construction. Do not use open sources of fire until the walls are plastered.

Small pests. Rodents, birds, and some insects can also find that straw is a good habitat. Isolate all possible access routes to the straw. Keep livestock and other livestock away from the warehouse.

Straw "thermos". A building covered with straw blocks can function as a thermos flask to effectively keep warm or cool inside. For this to be possible, your straw "thermos" must be provided with a complete layer of insulation. Windows should be of moderate size, preferably three-layer, oriented mainly towards the sun with the possibility of isolation at night with curtains or shutters. The straw "thermos" must be dry insulated. Outside there are well-plastered walls and a solid roof. The vapor permeability of the wall and from the inside should be lower than the outside (for example, drywall and cement-lime plaster). Do not use moisture-vapor-proof lenses (especially outside), although this is prescribed by SNiPs. The walls of the eco-houses made of straw are “breathable”, which ensures a high ecological quality of housing.

Description of fuel briquettes (firewood from straw).

Straw fuel briquettes are straw mass that is well chopped, dried and compressed on special equipment. In the manufacture of briquettes, no chemical binders are used, the binder here is a natural substance - lignin, released at a certain temperature and pressure.

Such briquettes are a real alternative to wood, coal and other fuels.

The main advantages of straw briquettes include:

1. Straw is an environmentally friendly, easily renewable product! Each year, tons of straw is left or burned in the fields. Why, if you can get high-quality fuel from this and not cut down forests for this in the old fashioned way or extract coal.

2. The calorific value of our briquettes is from 18 to 20 MJ / kg. For comparison, the calorific value of some solid fuels: - raw wood about 8-10 MJ / kg, - dry wood about 12-14 MJ / kg, - brown coal 16-20 MJ / kg, - black coal 20-25 MJ / kg ...

3. Bulk density of briquettes is about 500 kg / m3 (true density is 1100 kg / m3). For comparison, the bulk density of firewood is about 300 kg / m3 (true density 650 kg / m3, for birch). Based on the calorific value and bulk density, we can conclude that 5 cubic meters of firewood have a weight of about 1500 kg and when they burn, an average of 18000 MJ of thermal energy will be released. Fuel briquettes with a volume of 5 cubic meters have a weight of 2500 kg and when they are burned, an average of 45000 MJ of thermal energy will be released, which is 2.5 times more than when burning firewood. Accordingly, 1 ton of briquettes is equivalent to 2.5 tons or 8.3 cubic meters of firewood at bulk density. The cost of our briquettes in the warehouse is 6000 r / t, the average cost of firewood without delivery is 1000 r / m3. Accordingly, you get an economic benefit of 2300 r from each ton of briquettes, not counting all the benefits listed below.

4. The ash residue after combustion does not exceed 6%. For comparison, coal - 20-30%, firewood - 8-15%.

5. When burning straw briquettes, the chimneys do not clog !!!

6.When burning, briquettes do not spread an unpleasant odor, do not shoot or spark, practically do not emit smoke, soot and other harmful substances, unlike firewood or coal. One of the greatest advantages of briquettes is that when they burn, carbon monoxide CO2 is not emitted, which destroys the ozone layer of the atmosphere.

7. Fuel briquettes are ideally clean product in terms of sanitary and hygienic aspects. After thermal processing of biomass in the production process, a "dead" product is obtained for parasites (fungi, microbes, etc.), such fuel does not cause allergic reactions even in asthmatics.

8. Briquettes do not require expensive refurbishment of furnaces and boilers, as, for example, gas or fuel oil. It is an excellent alternative to coal and wood for solid fuel stoves with low (natural) draft, as well as for fireplaces.

Application of straw fuel briquettes:

1. Heating of living quarters. Fuel briquettes are ideal for any standard central heating boilers, stoves and fireplaces, all types of fireboxes. Gives a beautiful even flame. No sparking occurs during combustion.

2. Heating boilers using solid fuels. It is an alternative cheap biofuel for all types of heating equipment that use solid fuels (coal, wood). It is used for heating private houses, industrial premises, warehouses, boiler houses, summer cottages, greenhouses using boilers and solid fuel stoves. This environmentally friendly biofuel is gaining more and more popularity among ordinary people, for example, for kindling stoves, fireplaces, cooking kebabs on fires, in barbecues, barbecues.

3. Briquettes are excellent fuel for Buleryan stoves.

4. Fuel briquettes are ideal fuel for baths and saunas. Fuel briquettes are characterized by the possibility of long burning, but if desired, you can make them give off heat very quickly. For this it is necessary to increase the air supply. This is sometimes necessary to quickly bring baths and saunas to the required temperature. Practice shows that with the help of our fuel briquettes, you can prepare a bath in half an hour instead of the usual one and a half when using firewood. In general, slow combustion should be used for conventional heating. To do this, you need to adjust the traction. Briquettes, unlike coal or firewood, need less air for combustion, therefore, after obtaining stable combustion, it is necessary to fix the positions of the dampers and dampers.

Conclusion: keep up with the times! Use environmentally friendly and safe fuel briquettes made of straw as solid fuel!

Yaroslavl masters.

Bee hive type "Deck"

Instructions for use:

This hive is a house for bees as close as possible to natural conditions. Keeping bees in such a hive is very easy. It is necessary to collect and install the beehive on your site with the entrances to the south, southeast. Next, a bee swarm should be poured through the top cover inside the log. In the future, the bees will do everything themselves. After the holiday "Honey Spas", you need to open the bottom cover and take the excess honey from the bees, leaving some for the winter, approximately 30%. You do not need to clean the hive for the winter. As practice shows, bees in such hives do not get sick, bee colonies are very strong and not aggressive. Observations have shown that the yield on the site increases by an average of 20-30%, while 10-15 kg of mature honey is obtained, which is significantly superior in quality to honey from frame hives. The deck is easy to transport, assemble and operate on site.

Technical description: The deck is a parallelepiped structure made of 60 mm thick hardwood planks. The product is made without a single nail, installed at an angle of inclination relative to the ground 25-30 and equipped with a roof.At the bottom of the deck there is a lid for removing honey, sealed with a cloth. The lid at the top can also be removed to populate the bee colony. The assembled weight is about 100 kg. Internal size 400 * 400 * 1200. Price RUB 3000 (aspen) 8000 rubles. (oak)

It is supposed to give information about various environmentally friendly techniques and materials in construction.

A deck with a stand and a roof made of shingles costs 21t rubles. A deck with a stand and a shingle roof costs 34t rubles. Write

The first construction caravan "Toloka" is being created in Ukraine.

The guys are ready to come to you and build a common house with their team. In order for them to come, you need to prepare building materials, a list of which will be sent to you and a small amount of money to pay for their work. There is one condition - participation in construction, comprehensive assistance and training for everyone! of the settlers of this emerging settlement. Others who wish can join the caravan to help and master construction technologies.

Caravan "Toloka".

Friends, we have embarked on the bright path of gaining eternity - the opportunity to realize ourselves as much as possible by building the Family Estate - our space of Love. Obviously, everyone has their own degree of readiness, the speed of thought, and hence the progress towards the desired Image. We are still children, we understand intellectually: it turns out we are not yet able to create on all planes of being, even on the material - the ancestral memory of crafts is sleeping. Probably, this is the most difficult thing - to build a living image of your happy life on the estate. Questions arise: what about work, an apartment and, first of all, money. But, for example, how can you learn to drive a car without sitting behind the wheel? Building an image of your future life in the Family Estate can be accelerated by real actions with your neighbors, specific people from all over the Earth, having felt, and therefore, falling in love with them, because many of us, living in the hustle and bustle, can only feel everyone next to them in material embodiment. The birth of the idea of helping a loved one in creating the Space of Love was helped by participation in the Bard Caravan. The sunny songs of friends helped to purify, causing tears of joy, united in a circle more and more people intending to live on earth, who needed a house in life. We intend to create the Space of Love and live in it forever, to build living adobe houses in the Family Homes all over Ukraine, on specific sites with friends. Then everything is simple: we will create a team, find funds, master the technology. The idea of the construction caravan "Toloka", having arisen as a desire to learn to create living adobe houses together, grows overgrown with other ideas: the Image of the spiritual and educational process is born.

And yet ... Motivation.

The construction of any house, with a systematic approach, is practically divided into several chronologically justified stages: »buying a typical, most often expensive, project and linking it to an inconvenient site, burdened by the conventions offered by the system; »Long-term, martyrdom, depriving health, process of construction from super-expensive, very harmful, even for unborn children, artificial materials (doctors around the world have been shouting about this for a long time), moreover, with the formation of a huge amount of garbage; »Then a stormy, long-suffering housewarming and life darkened by numerous repairs, payments for utilities, with elements of disappointment about cleaning, the difficulty or impossibility of changing the house due to the design features proposed by the system; »Life in such a house can end in tears for everyone: the sale of the house or the death of the owners, and then, of course, the house itself. In the Ancestral Estates - our Spaces of Love, when building a house from adobe - the cheapest, most environmentally friendly,which means that these stages can undergo significant changes in a joyful and healthy material: "can be rearranged: for example, a roof can be made before the walls are erected, housewarming and life in the house can be inserted in the next moment - this is already interesting! »Their complete exclusion is possible: garbage removal - in view of its absence, sale - due to a complete lack of intention, backed up, again, by the lack of documents; »As well as a wonderful addition: the possibility of growth - adobe, due to its design features, it allows; a joint creation, and, accordingly, joy for everyone (I wanted to insert: your future descendants, including) from contemplating it. The vitality of the house will be facilitated by a vital necessity: for example, the desire to provide all three planes of being to your joint creation - a lit Star.

Friends, you can get acquainted with the technology of adobe construction in more detail at a practical seminar, and the most interesting thing is that it can last, repeat itself on the site you have chosen in the course of promoting the spiritual, construction and educational, as well as the merchant and bard caravan "Toloka". Freedom of choice is the main thing in your life !!! Everyone's activity in building an Image is his program of returning to himself!

WE ARE WAITING FOR YOUR APPLICATIONS.

So, the address: 70650, Zaporozhye region, Pologovskiy district, p. Horse Rozdory, st. Stadium, 33, Fedorovsky Nikolay. Location: my site for the conduct of a personal peasant farm, the adjacent territory, where there will be a guest yard, a beautiful park and already there is a picturesque pond, river, woods, rocks and steep slopes. Purpose: to learn to live happily.

We recruit staff

Whatever the production plan may be, you can't complete it alone. Any enterprise or plant recruits a whole team of workers, depending on the scale of production. In any case, it is important for an enterprise to have:

- Several shop workers.

- Chief shift supervisor.

- Accountant.

- The driver.

- A couple of movers.

- Storekeeper.

- Mechanics.

The owner of this project is strongly advised to fulfill the duties of not only the general director, but also the storekeeper in order to constantly be in the know about the production and reduce personnel costs. An accountant can be hired once a month to compile the necessary counts.

Staff

To ensure the design parameters of production at the initial stage of the project, the following employees are involved:

- Process engineer.

- Accountant manager.

- Locksmith for the maintenance of technological equipment.

- Workers (4 people).

The duties of the head of the enterprise are performed by the founder.

Calculation of the salary fund for specialists:

| Position | Monthly salary (in rubles) | Labor costs per year (in rubles) |

| Process Engineer | 25 000 | 300 000 |

| Manager | 15 000 | 180 000 |

| Technological equipment service technician | 20 000 | 240 000 |

| Workers (4 people) | 20 000 | 960 000 |

| Total | 140 000 | 1 680 000 |

The selection of specialists is carried out on the basis of standard qualification requirements established for these professions, and taking into account the experience of work on the technological equipment used at the enterprise.

We sell the produced

It has already been mentioned above about a potential audience wishing to purchase fuel briquettes. It is not so easy for a budding entrepreneur to enter the foreign market, and it is difficult to find a buyer on the Russian market, especially in the region, wherever the project is located. That is why modern manufacturers sell products via the Internet, creating a website specifically for the enterprise itself and receiving orders over the network.

This method allows you to give full information about the project itself and the production of the product, talk about the terms of sale and delivery, and also get a buyer even from the other end of the country.

In addition to this option, the business owner can turn to various large fuel companies, such as the sauna chain, to offer regular deliveries at wholesale prices. By the way, it is worth entering the market by the beginning of autumn, because in the spring-summer period the demand for products drops significantly, as does the price on the market.

Video: the production of fuel briquettes or Eurowood as a business idea.

Market analysis

The rapid development of the biofuel market is associated, first of all, with the energy challenges that exist in European countries and a significant rise in the cost of traditional fuels. In Russia, interest in the production of fuel briquettes began to appear at the turn of the 21st century, when the country's first pallet manufacturing enterprises were organized. In 2004, the biofuel industry emerged as an independent business area, which has undergone a number of significant structural and qualitative changes in recent years.

If at the initial stage of the formation of the industry in the country there were only about 30 operating manufacturers, and of them only 3-4 trading companies were able to enter the international market, now their number has not only increased significantly. Industry magazines and reference books appeared in Russia, conferences and seminars on topical issues of the development of the alternative fuel market began to be held.

These efforts have led to the fact that since 2002 the number of producers of eurodrops has doubled annually. According to experts, this trend will continue in the next period. This happens even under such conditions that domestic enterprises for the production of briquettes are constantly experiencing a shortage of raw materials. If this fact in itself is paradoxical for Russia, then other restraining barriers are quite natural: the country does not yet have a well-established production of special equipment, there are no qualified specialists, and the entrepreneurs themselves have a lack of experience in operating this product market.

The consequence of all these circumstances is a constant rise in the cost (by 5-80%, depending on the region) purchase prices for fuel briquettes.

Abroad, Russian products in this industry cost 80-230 euros per 1 ton. This is facilitated by the gradual accumulation of experience by domestic entrepreneurs in the industry market, wide popularization of this type of fuel among the population, high profitability of the production itself (at least 15%), active investment in the domestic industry of funds of foreign companies.

At the moment, the colossal potential of domestic bioenergy is undeniable. But, according to experts, in order for the market to continue to grow, it is necessary to comply with two main conditions:

- It requires a transition from competition between domestic producers to cooperation, which will lead to the exchange of experience and knowledge.

- State support for the industry is required.

To date, certain steps have already been taken in this direction. Thus, the Federal Energy Strategy for the period up to 2020 was adopted, which provides for the creation of a more favorable investment climate for producers of renewable energy sources, the widespread introduction of modern technologies for the production of biofuels, and the organization of the production of domestic equipment for this industry.

It is expected that as a result of the implementation of the measures of this strategy in 2020, the share of renewable energy sources in the country's fuel and energy complex will reach 0.6% (in European countries, this figure is going to be increased to 15%). There is a special commission in the State Duma of the Russian Federation that is engaged in the development of draft laws in the field of alternative energy.

In short, bioenergy in Russia has the necessary prospects in order to soon become a developed, environmentally friendly, competitive and profitable branch of the national economy. In the foreseeable future, the demand for fuel briquettes will only increase, which will lead to increased competition and the survival of only efficient producers in the market, the number of which will also grow.

We calculate the profitability of the project

Any business, even a mini-factory set up at home, has its own profitability and benefits. To determine it, it is necessary to calculate the costs of opening this project and the approximate income of the enterprise. Let's look at a sample business plan for the production of fuel briquettes to determine the profitability of this project:

| Expense line | Cost amount, thousand rubles | |

| 1 | Premises for rent | 80 |

| 2 | Purchase of the necessary briquetting equipment | 5 500 |

| 3 | Equipment installation and transportation | 1 200 |

| 4 | Buying a forklift | 800 |

| 5 | Paperwork | 5 |

| 6 | Salary of all staff | 350 |

| 7 | Purchase of raw materials | 500 |

| 8 | Utilities and transportation of goods | 200 |

| 9 | Payment of taxes | 50 |

| 10 | Unexpected expenses | 25 |

| Total: | 8 710 |

The average cost of products on the market is approximately 7.5 thousand rubles per ton. The above-described enterprise, due to successful marketing and high-quality equipment, is ready to carry out and sell about 180 tons of product per month, which will allow it to receive about 1,350 thousand rubles a month.

The initial project costs are indeed very high, but the monthly costs are much lower. The project's net monthly profit will be about 350 thousand rubles, which will fully recoup the start-up costs in two years. Undoubtedly, the project will expand, and the profit will also increase, which will make it possible to recoup the costs much earlier.