In order to get electricity, you need to find a potential difference and a conductor People have always tried to save money, and in the era of constantly growing utility bills, this is not at all surprising. Today, there are already ways by which a person can get free electricity free for him. As a rule, these are certain do-it-yourself installations, which are based on an electric generator.

Thermoelectric generator and its device

A thermoelectric generator is a device that generates electrical energy from heat. It is an excellent steam source of electricity, albeit with low efficiency.

As a device for the direct conversion of heat into electrical energy, thermoelectric generators are used, which use the principle of operation of conventional thermocouples

In essence, thermoelectricity is the direct conversion of heat to electricity in liquid or solid conductors, and then the reverse process of heating and cooling the contact of various conductors using an electric current.

Heat generator device:

- A heat generator has two semiconductors, each of which consists of a certain number of electrons;

- They are also interconnected by a conductor, above which there is a layer capable of conducting heat;

- A thermionic conductor is also attached to it for transferring contacts;

- Next comes the cooling layer, followed by the semiconductor, whose contacts lead to the conductor.

Unfortunately, a heat and power generator is not always able to work with high capacities, therefore it is used mainly in everyday life, and not in production.

Today the thermoelectric converter is almost never used anywhere. It "asks" for a lot of resources, it also takes up space, but the voltage and current that it can generate and convert are very small, which is extremely unprofitable.

Converting heat into light and then into electricity

14.11.2019 924

"Thermal photons are photons emitted by a hot body." “If you look at something hot with an infrared camera, you can see that it is glowing. The camera shows these thermally excited photons. "

The invention is a hyperbolic heat emitter capable of absorbing intense heat that would otherwise be released into the environment, compressing it into a narrow bandwidth and emitting it as light for further conversion into electricity.

This discovery serves as a continuation of another researchconducted at the Brown School of Technology at Rice University back in 2020, when a simple method was found to create highly aligned, plate-like films from tightly packed carbon nanotubes.

Waste heat

Discussions led to the decision to see if these films could be used to channel "thermal photons".

"Thermal photons are photons emitted by a hot body." “If you look at something hot with an infrared camera, you can see that it is glowing. The camera shows these thermally excited photons. "

Infrared radiation - This is a component of sunlight that delivers heat to the planet, but this is only a small part of the entire electromagnetic spectrum.

"Any hot surface emits light in the form of thermal radiation."“The problem is that thermal radiation is broadband, and the conversion of light into electricity is effective only if the radiation is in a narrow band. The challenge was to squeeze broadband photons into a narrow band. "

Nanotube films made it possible to isolate mid-infrared photons that would otherwise be wasted. This may motivate the widespread use of waste heat, which accounts for about 20% of all industrial energy consumption.

Carbon nanotubes can transfer heat

"The most efficient way to convert heat into electricity right now is to use turbines and steam or some other liquid to power them." “They can deliver nearly 50 percent conversion efficiency. Not much of what is known today can come close to such efficiency, but these systems are difficult to implement. "

Aligned carbon nanotubes remain thermally stable up to 1600 ° C and exhibit extreme anisotropy: conductive in one direction and insulating in the other two - an effect called hyperbolic dispersion. Thermal photons can collide with the film, arriving from any direction, but leave only after one.

This extreme anisotropy results in extremely high photon density in the mid-infrared, manifesting itself as strong resonances in subwavelength-sized depth cavities.

"Instead of going from heat directly to electricity, the path goes first from heat to light and only then to electricity." "At first glance, it seems that two steps would be more effective than three, but in this case it is not."

Adding emitters to standard solar cells can increase their efficiency from their current peak of about 22% to 80%. "By compressing all of the waste heat energy into a small spectral region, it can be very efficiently converted into electricity." In addition, nanophotonic heat emitters with high photon density can significantly improve the efficiency of radiation cooling and waste heat recovery.

You can learn more about the technology to read For more information, see ACS Photonics.

A source: Rice University

Solar thermal generator of electricity and radio waves

Sources of electrical energy can be very different. Today, the production of solar thermoelectric generators has begun to gain popularity. Such installations can be used in lighthouses, in space, cars, as well as in other areas of life.

Solar thermal generators are a great way to save energy

RTG (stands for radionuclide thermoelectric generator) works by converting isotope energy into electrical energy. This is a very economical way to get almost free electricity and the possibility of lighting in the absence of electricity.

Features of the RTG:

- It is easier to obtain an energy source from isotope decays than, for example, to do the same by heating a burner or a kerosene lamp;

- The production of electricity and the decay of particles are possible in the presence of special isotopes, because the process of their decay can last for decades.

Using such an installation, you need to understand that when working with old models of equipment there is a risk of receiving a dose of radiation, and it is very difficult to dispose of such a device. If not properly destroyed, it can act as a radiation bomb.

Choosing the manufacturer of the installation, it is better to stay at the firms that have already proven themselves. Such as Global, Altec (Altec), TGM (Tgm), Cryotherm, Termiona.

By the way, another good way to get electricity for free is a generator for collecting radio waves.It consists of pairs of film and electrolytic capacitors, as well as low-power diodes. An insulated cable about 10-20 meters is taken as an antenna and another ground wire is attached to a water or gas pipe.

Russian scientists got warmth from the cold

Scientists from the Institute of Catalysis of the SB RAS have figured out how to get heat from the cold, which can be used for heating in harsh climatic conditions. To do this, they propose to absorb methanol vapors by a porous material at low temperatures. First results of a study supported by grant

Russian Science Foundation (RSF), were

published

in the journal Applied Thermal Engineering. Chemists have proposed a cycle called "Heat from Cold" ("TepHol"). Scientists convert heat using the process of adsorption of methanol into a porous material. Adsorption is the process of absorption of substances from a solution or gas mixture by another substance (adsorbent), which is used to separate and purify substances. The absorbed substance is called an adsorbate.

“The idea was to first theoretically predict what the optimal adsorbent should be, and then synthesize a real material with properties close to ideal,” commented one of the authors of the study, Doctor of Chemistry Yuri Aristov. - The working substance is methanol vapor, and is usually adsorbed with activated carbons. We first took commercially available activated carbons and used them. It turned out that most of them do not work very well, so we decided to synthesize new methanol adsorbents, specialized for the TepHol cycle, ourselves. These are two-component materials: they have a porous matrix, a relatively inert component, and the active component is a salt that absorbs methanol well ”.

Further, the scientists carried out a thermodynamic analysis of the TepHol cycle, which gives an approximate idea of the course of the transformation process, and determined the optimal conditions for the implementation of adsorption. Scientists were faced with the task of finding out if the new thermodynamic cycle can provide sufficient efficiency and power for generating heat. To answer this question, a laboratory prototype of the TepHol installation was designed with one adsorber, an evaporator and cryostats that simulated cold air and non-freezing water. The adsorbent was placed in a special large surface heat exchanger made of aluminum. This installation makes it possible to produce heat in an intermittent mode: it is released when the adsorbent absorbs methanol, and then it takes time to regenerate the latter. For this, the methanol pressure over the adsorbent is reduced, which is facilitated by the low ambient temperature. The tests of the TepHol prototype were carried out in laboratory conditions, where the temperature conditions of the Siberian winter were simulated, and the experiment was completed successfully.

“Using two natural thermostats (heat storage) in winter, for example ambient air (T = -20 - -40 ° C) and non-freezing water from a river, lake, sea or groundwater (T = 0 - 20 ° C), with a temperature difference 30-60 ° C, heat can be obtained to heat houses. Moreover, the colder it is outside, the easier it is to get useful heat, ”said Yuri Aristov.

To date, scientists have synthesized four new sorbents that are in the testing phase. The first results from these tests are very encouraging, the authors say.

“The proposed method allows you to get heat directly on site in regions with cold winters (northeastern Russia, northern Europe, the United States and Canada, as well as the Arctic), which can significantly accelerate their socio-economic development.The use of even a small amount of low-temperature heat of the environment can lead to a change in the structure of modern energy, reduce the dependence of society on fossil fuels and improve the ecology of our planet, ”concluded Aristov.

In the future, the development of Russian scientists can be useful for the rational use of low-temperature thermal waste from industry (for example, cooling water discharged by thermal power plants and gases that are a by-product of chemical and oil refining industries), transport and housing and communal services, as well as renewable thermal waste. energy, especially in regions of the Earth with harsh climatic conditions.

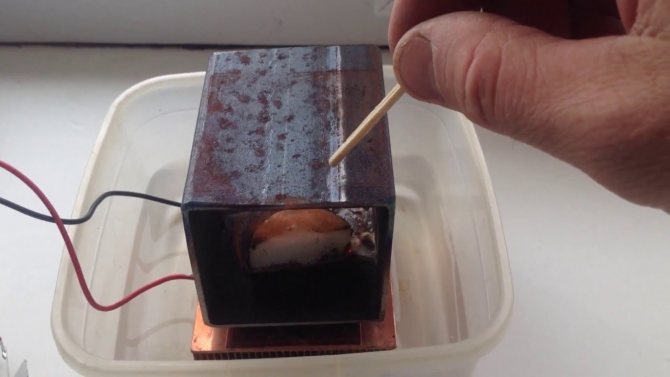

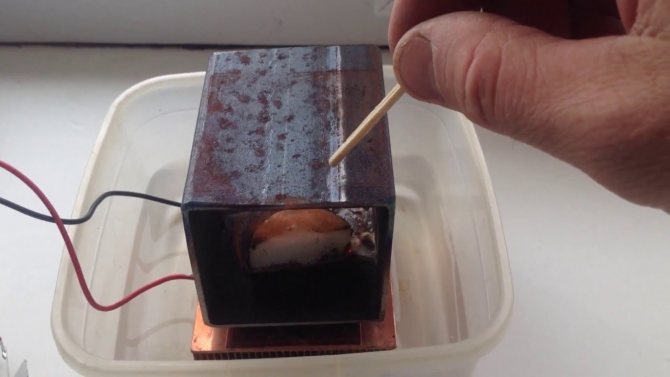

How to make a Peltier element with your own hands

A common Peltier element is a plate assembled from parts of various metals with connectors for connecting to a network. Such a plate passes a current through itself, heating up on one side (for example, up to 380 degrees) and working from the cold on the other.

The Peltier element is a special thermoelectric transducer that works according to the principle of the same name for supplying electric current.

Such a thermogenerator has the opposite principle:

- One side can be heated by burning fuel (for example, a fire on a wood or some other raw material);

- The other side, on the contrary, is cooled by a liquid or air heat exchanger;

- Thus, current is generated on the wires, which can be used according to your needs.

True, the device's performance is not very great, and the effect is not impressive, but, nevertheless, such a simple home-made module may well charge the phone or connect an LED flashlight.

This generator element has its advantages:

- Silent work;

- The ability to use what is at hand;

- Light weight and portability.

Such homemade stoves began to gain popularity among those who like to spend the night in the woods by the fire, using the gifts of the land and who are not averse to getting electricity for free.

The Peltier module is also used to cool computer boards: the element is connected to the board and as soon as the temperature becomes higher than the allowable temperature, it begins to cool the circuits. On the one hand, a cold air space enters the device, on the other, a hot one. The 50X50X4mm (270w) model is popular. You can buy such a device in a store or make it yourself.

By the way, connecting a stabilizer to such an element will allow you to get an excellent charger for household appliances at the output, and not just a thermal module.

To make a Peltier element at home, you need to take:

- Bimetal conductors (about 12 pieces or more);

- Two ceramic plates;

- Cables;

- Soldering iron.

The manufacturing scheme is as follows: the conductors are soldered and placed between the plates, after which they are tightly fixed. In this case, one must remember about the wires, which will then be attached to the current converter.

The scope of use of such an element is very diverse. Since one of its sides tends to cool, with the help of this device you can make a small camping refrigerator, or, for example, an auto-air conditioner.

But, like any device, this thermoelement has its pros and cons. The pluses include:

- Compact size;

- The ability to work with cooling or heating elements together or each separately;

- Quiet, virtually silent operation.

Minuses:

- The need to control the temperature difference;

- High energy consumption;

- Low level of efficiency at high cost.

Types of solar collectors - what are they?

Collectors are understood as devices that are capable of absorbing solar energy, modifying it into heat, and then sending it to a coolant.A standard solar collector is made in the form of a plastic or metal case, in which black metal plates are installed. These plates can be heated to a specific temperature.

Depending on its size, the collectors are divided into high, medium and low temperature. It is unrealistic to make high-temperature devices at home. They are created using sophisticated technologies for operation at large industrial facilities. Medium-temperature structures that accumulate a sufficient amount of solar energy can be used for heating residential buildings, and low-temperature ones for heating water. It is quite possible to make these two types of collectors yourself.

The devices of interest to us are divided into the following types:

- flat;

- accumulative;

- air;

- liquid.

Solar collector on the roof

A flat collector is a box-like structure made of metal with a plate to absorb light from the Sun. It is covered with a glass lid with a small iron content, due to which almost all the sunlight falls on the heat-sensing plate. The structure is necessarily thermally insulated. The efficiency of such a collector is objectively small - about 10%. It can be increased by applying a special semiconductor with amorphous characteristics to the wafer. Such devices are suitable for heating water in everyday life.

A thermosyphon (storage) collector is considered more efficient. It is used to heat water and maintain the temperature at a given level in the room for some time. Structurally, it is made in the form of 1-3 tanks installed in a box with thermal insulation. Like a flat device, it is covered with a glass lid. In a cold season, it is difficult to use such a collector. But in the summer, when the light from the Sun is very strong, it can be used at home.

Liquid solar structures use water as a heat carrier. They are made with an open or closed principle of heat exchange, they can be without glass and glazed. The operation of such devices is fraught with inconvenience - they often leak and may well freeze during the winter months. Air collectors, which are most often used for drying fruits, vegetables and relatively small volumes of other agricultural products, are devoid of these problems. The aircraft is structurally simple, it is easy to maintain, therefore it enjoys well-deserved popularity.

Simple homemade generator

Despite the fact that these devices are not popular now, at the moment there is nothing more practical than a thermal generator unit, which is quite capable of replacing an electric stove, a lighting lamp on a trip, or help out, if the charging to a mobile phone breaks down, power up the power window. Such electricity will also help at home in case of a power outage. It can be obtained for free, one might say, for a ball.

So, to make a thermoelectric generator, you need to prepare:

- Voltage regulator;

- Soldering iron;

- Any body;

- Cooling radiators;

- Thermal paste;

- Peltier heating elements.

Assembling the device:

- First, the body of the device is made, which should be without a bottom, with holes at the bottom for air and at the top with a stand for the container (although this is not necessary, since the generator may not work on water);

- Next, a Peltier element is attached to the body, and a cooling radiator is attached to its cold side through thermal paste;

- Then you need to solder the stabilizer and the Peltier module, according to their poles;

- The stabilizer should be very well insulated so that moisture does not get there;

- It remains to check its work.

By the way, if there is no way to get a radiator, you can use a computer cooler or a car generator instead. Nothing terrible will happen from such a replacement.

The stabilizer can be bought with a diode indicator, which will give a light signal when the voltage reaches the specified value.

DIY thermocouple: process features

What is a thermocouple? A thermocouple is an electrical circuit made up of two different elements with an electrical contact.

The thermoEMF of a thermocouple with a temperature difference of 100 degrees at its edges is about 1 mV. To make it higher, several thermocouples can be connected in series. You will get a thermopile, the thermoEMF of which will be equal to the total sum of the EMF of the thermocouples included in it.

The manufacturing process for a thermocouple is as follows:

- A strong connection of two different materials is created;

- A voltage source (for example, a car battery) is taken and wires of different materials pre-twisted into a bundle are connected to one end of it;

- At this time, you need to bring a lead connected to the graphite to the other end (a regular pencil rod will do here).

By the way, it is very important for safety not to work under high voltage! The maximum indicator in this regard is 40-50 Volts. But it is better to start with small powers from 3 to 5 kW, gradually increasing them.

There is also a "water" way to create a thermocouple. It consists in ensuring the heating of the connected wires of the future structure with an arc discharge that appears between them and a strong solution of water and salt. In the process of such interaction, "water" vapors hold the materials together, after which the thermocouple can be considered ready. In this case, it matters what diameter the harness of the product is. It shouldn't be too big.

Free electricity with your own hands (video)

Getting free electricity isn't as tricky as it sounds. Thanks to various types of generators working with different sources, it is no longer scary to be left without light during a power outage. A little skill and you already have your own mini-station for generating electricity ready.

A wood-fired power plant is one of the alternative ways to supply electricity to consumers.

Such a device is capable of obtaining electricity at minimal cost of energy resources, even in those places where there is no supply of power grids at all.

A power plant that uses firewood can be an excellent option for owners of summer cottages and country houses.

There are also miniature versions that are suitable for lovers of long hikes and spending time in nature. But first things first.

CONTENTS (click on the button on the right):

Features of the

A wood-fired power plant is far from a new invention, but modern technologies have made it possible to somewhat improve the devices developed earlier. Moreover, several different technologies are used to generate electricity.

In addition, the concept "on wood" is somewhat inaccurate, since any solid fuel (wood, wood chips, pallets, coal, coke), in general, anything that can burn, is suitable for the operation of such a station.

Immediately, we note that firewood, or rather the process of their combustion, acts only as a source of energy that ensures the functioning of the device in which electricity is generated.

The main advantages of such power plants are:

- The ability to use a wide variety of solid fuels and their availability;

- Getting electricity anywhere;

- The use of different technologies allows you to receive electricity with a wide variety of parameters (sufficient only for regular recharging of the phone and before powering industrial equipment);

- It can also act as an alternative if power outages are common, and as the main source of electricity.

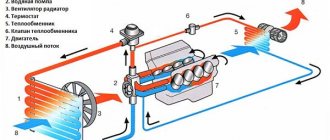

Classic version

As noted, a wood-fired power plant uses several technologies to generate electricity. The classic among them is the energy of steam, or simply the steam engine.

Everything is simple here - wood or any other fuel, burning, heats up the water, as a result of which it turns into a gaseous state - steam.

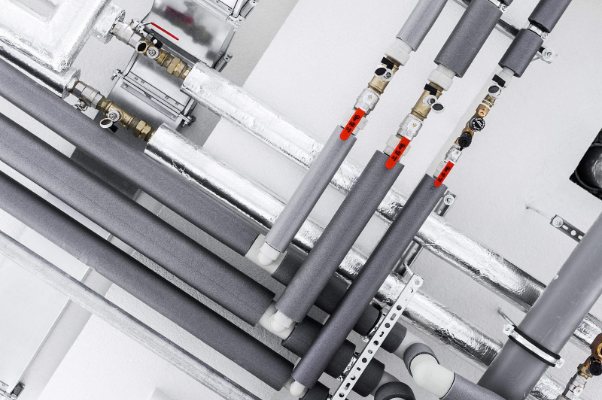

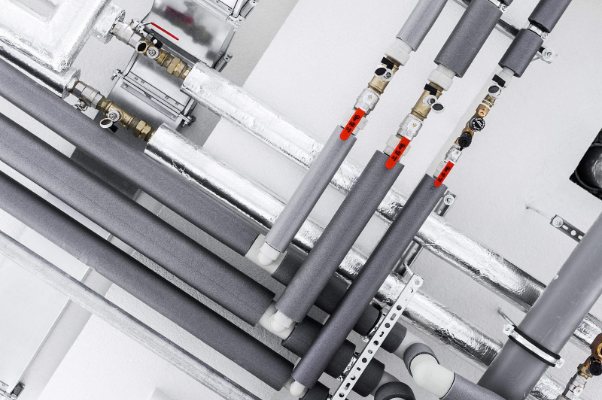

The resulting steam is fed to the turbine of the generator set, and by rotating the generator generates electricity.

Since the steam engine and the generator set are connected in a single closed circuit, after passing through the turbine, the steam is cooled, again fed into the boiler, and the whole process is repeated.

Such a power plant layout is one of the simplest, but it has a number of significant drawbacks, one of which is explosion hazard.

After the transition of water to a gaseous state, the pressure in the circuit increases significantly, and if it is not regulated, then there is a high probability of pipeline rupture.

And although modern systems use a whole set of pressure control valves, the operation of a steam engine still requires constant monitoring.

In addition, ordinary water used in this engine can cause scale formation on the pipe walls, which lowers the efficiency of the station (scale impairs heat transfer and reduces the throughput of pipes).

But now this problem is solved by using distilled water, liquids, purified impurities that precipitate, or special gases.

But on the other hand, this power plant can perform another function - to heat the room.

Everything is simple here - after fulfilling its function (rotation of the turbine), the steam must be cooled so that it again goes into a liquid state, which requires a cooling system or, simply, a radiator.

And if we place this radiator indoors, then in the end we will get not only electricity from such a station, but also heat.

Savings methods

One of the options here is the use of automated control units for the heating system in the house. Such equipment itself monitors the temperature outside, and, depending on it, selects the mode of heat supply in the apartments.

Residents of such houses no longer face a situation when it is already relatively warm, and the batteries in the apartment are hot - it becomes too hot in the room and they have to open the windows. Residents experience discomfort and at the same time have to pay for the "extra" heat energy.

So far, only four percent of homes have automatic heating control. It allows apartment owners to save on utility bills on a monthly basis.

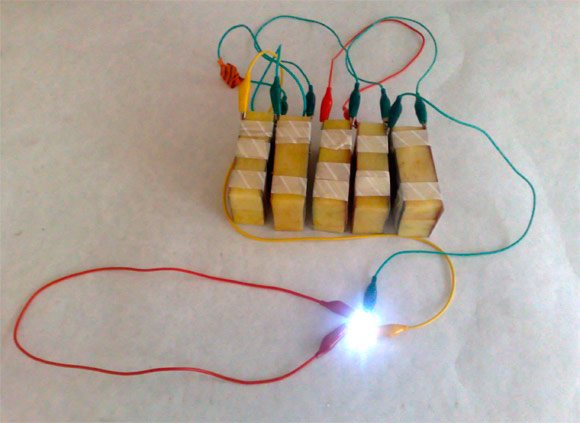

Thermoelectric generators

Power plants with generators built according to the Peltier principle are quite an interesting option.

Physicist Peltier discovered the effect that when electricity is passed through conductors consisting of two dissimilar materials, heat is absorbed on one of the contacts, and heat is released on the second.

Moreover, this effect is the opposite - if on one side the conductor is heated, and on the other - cooled, then electricity will be generated in it.

It is the opposite effect that is used in wood-fired power plants. When burned, they heat up one half of the plate (which is a thermoelectric generator), consisting of cubes made of different metals, and the second part of it is cooled (for which heat exchangers are used), as a result of which electricity appears on the plate terminals.

Gas generators

The second type is gas generators. Such a device can be used in several directions, including generating electricity.

It is worth noting here that such a generator itself has nothing to do with electricity, since its main task is to generate combustible gas.

The essence of the operation of such a device boils down to the fact that in the process of solid fuel oxidation (combustion), gases are emitted, including combustible gases - hydrogen, methane, CO, which can be used for a variety of purposes.

For example, such generators were previously used on cars, where conventional internal combustion engines worked perfectly on the emitted gas.

Due to the constant tremors of the fuel, some motorists and motorcyclists have already begun to install these devices on their cars.

That is, to get a power plant, it is enough to have a gas generator, an internal combustion engine and a conventional generator.

In the first element, gas will be released, which will become the fuel for the engine, and that, in turn, will rotate the rotor of the generator in order to obtain electricity at the output.

The advantages of gas-fired power plants include:

- Reliability of the design of the gas generator itself;

- The resulting gas can be used to operate an internal combustion engine (which will become a drive for an electric generator), a gas boiler, a furnace;

- Depending on the internal combustion engine and generator used, electricity can be obtained even for industrial purposes.

The main disadvantage of the gas generator is the cumbersome structure, since it must include a boiler, where all the processes for gas production, its cooling and purification system take place.

And if this device is to be used to generate electricity, then in addition the station should also include an internal combustion engine and an electric generator.

Who is eligible for the heat subsidy?

The abolition of the principle of cross-subsidization back in 2012, under which enterprises mainly paid for the heat energy used by the population, caused a sharp increase in heating tariffs. In order to smooth out the inevitable jump in citizens' expenses, it was decided to pay subsidies for heating. Their size directly depends on the total family income. The lower it is, the greater the amount of assistance from the budget. The calculation of the amount of subsidies is carried out on an individual basis, depending on the specifics of a particular situation.

As a general rule, the degree of reimbursement of heating costs is calculated based on the applied coefficient, which in turn is set depending on the family income per person. Not every family can claim to be eligible for a subsidy for the heating season. To do this, you should have an average per capita income of no more than thirty thousand rubles. Those citizens who do not have even ten thousand rubles per person receive full compensation for their heat energy costs. For those who are located between these two points and have an income of ten to thirty thousand for each family member, their own coefficients are set.

Prefabricated Power Plant Representatives

Note that these options - a thermoelectric generator and a gas generator are now a priority, therefore, ready-made stations for use, both domestic and industrial, are being produced.

Below are a few of them:

- Indigirka stove;

- Tourist oven "BioLite CampStove";

- Power plant "BioKIBOR";

- Power plant "Eco" with gas generator "Cube".

An ordinary household solid fuel stove (made according to the type of the "Burzhaika" stove), equipped with a Peltier thermoelectric generator.

Perfect for summer cottages and small houses, since it is compact enough and can be transported in a car.

The main energy during the combustion of firewood is used for heating, but at the same time, the existing generator also allows you to obtain electricity with a voltage of 12 V and a power of 60 W.

Oven "BioLite CampStove".

It also uses the Peltier principle, but it is even more compact (weight is only 1 kg), which allows you to take it on hiking trips, but the amount of energy generated by the generator is even less, but it will be enough to charge a flashlight or phone.

A thermoelectric generator is also used, but this is already an industrial version.

The manufacturer, on request, can manufacture a device that provides an output of electricity with a capacity of 5 kW to 1 MW. But this affects the size of the station as well as the amount of fuel consumed.

For example, an installation that produces 100 kW consumes 200 kg of firewood per hour.

But the Eco power plant is a gas generator. Its design uses a gas generator "Cube", a gasoline internal combustion engine and an electric generator with a capacity of 15 kW.

In addition to industrial ready-made solutions, you can separately buy the same Peltier thermoelectric generators, but without a stove and use it with any heat source.

Benefits of beneficial heat recovery

Using a by-product from mining and computing equipment is a universal solution for most users, and here's why:

- saving on energy resources and ensuring energy autonomy. Decentralization and independence from monopoly suppliers of heat energy will reduce costs, especially in regions with cold climates;

- no need to organize hot and cold corridors, additionally install air conditioners and other auxiliary equipment. The solution we offer is an “all-in-one” complex that connects to the existing infrastructure;

- receiving additional income not only from mining, but also through entrepreneurial activity using the generated heat or from its sale;

- integration into the existing infrastructure. The unification we have applied and ease of installation allow us to connect to the existing facilities, and not create a new infrastructure complex;

- there is no negative impact on the environment in the form of thermal pollution, the appearance of heat islands, artificial temperature inversion over the heat source. There is no microcirculation of the atmosphere and no complication of the pollution transfer mechanism.

Homemade stations

Also, many craftsmen create self-made stations (usually based on a gas generator), which are then sold.

All this indicates that you can independently make a power plant from available tools and use it for your own purposes.

Next, let's look at how you can make the device yourself.

Based on thermoelectric generator.

The first option is a power plant based on a Peltier plate. Immediately, we note that a home-made device is suitable only for charging a phone, a flashlight or for lighting using LED lamps.

For manufacturing you will need:

- Metal body, which will play the role of a furnace;

- Peltier plate (sold separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make a stove. We take a metal box (for example, a computer case), unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top, you can install a grate on which you can place a kettle, etc.

- Mount the plate on the back wall;

- Mount the cooler on top of the plate;

- We connect a voltage regulator to the terminals from the plate, from which we power the cooler, and also draw conclusions for connecting consumers.

Everything works simply: we fire up the wood, as the plate heats up, electricity will be generated at its terminals, which will be supplied to the voltage regulator. The cooler will start and work from it, providing cooling of the plate.

It remains only to connect consumers and monitor the combustion process in the stove (throw up firewood in a timely manner).

Based on a gas generator.

The second way to make a power plant is to make a gasifier. Such a device is much more difficult to manufacture, but the output of electricity is much higher.

To make it you will need:

- Cylindrical container (for example, a disassembled gas cylinder). It will play the role of a stove, therefore, hatches should be provided for loading fuel and cleaning solid combustion products, as well as an air supply (a forced fan will be required to ensure a better combustion process) and a gas outlet;

- Cooling radiator (can be made in the form of a coil), in which the gas will be cooled;

- Capacity for creating a filter of the "Cyclone" type;

- Capacity for creating a fine gas filter;

- Gasoline generator set (but you can just take any gasoline engine, as well as a regular 220 V asynchronous electric motor).

Where can the heat from the equipment be directed?

Using the BiXBiT unit, you can use excess heat for the following needs:

- heating the supply air or water entering the room, which is part of the heating system (including the "warm floor" system) or hot water supply of a residential building;

- transition of a medium from one phase state to another, steam generation. We are talking, for example, about the phase transition of the working mixture to ensure the cycles of heat engines or vapor compression refrigeration machines;

- heating the drying agent;

- heating of technological raw materials;

- brewing (boiling wort);

- agriculture (greenhouse complexes, cultivation of heat-loving plants, breeding of exotic animals, etc.).

Here are three examples of the placement of our installation in specific conditions.

Industrial workshop. Productions of this type most often receive electricity at cheap tariffs for enterprises. There are also standby transformer stations, which are idle most of the time. The rooms are heated using fossil fuels or electricity.

The location of our installation will allow more efficient use of the backup power line, as well as save the company's resources on space heating by connecting to the central heating system.

Warehouse, shopping center, office building. These types of premises use an average electricity tariff, and also have a power reserve for power supply. The rooms are heated using fossil fuels or electricity.

Our computer unit supplies heat to the room through air ducts or is connected to a central heating system.

Greenhouses. Private agricultural companies use cheap tariffs or electricity from solar panels. Greenhouses are also heated mainly by electricity.

Electricity for heating is directed to the power supply of our installation, which generates the heat necessary to maintain a high temperature. The installation operates 24/7, and accordingly the plants (animals) receive the required supply of thermal energy stably.

Pros and cons of a wood-fired power plant

A wood-fired power plant is:

- Fuel availability;

- The ability to get electricity anywhere;

- The parameters of the electricity received are very different;

- You can make the device yourself.

- Among the shortcomings, it is noted:

- Not always high efficiency;

- The bulkiness of the structure;

- In some cases, generating electricity is just a side effect;

- To generate electricity for industrial use, a large amount of fuel must be burned.

In general, the manufacture and use of solid fuel power plants is an option that deserves attention, and it can become not only an alternative to power grids, but also help in places remote from civilization.

Briefly about the principle of action

So that in the future you understand why certain parts are needed when assembling a homemade thermoelectric generator, first let's talk about the device of the Peltier element and how it works. This module consists of thermocouples connected in series between ceramic plates, as shown in the picture below.

When an electric current passes through such a circuit, the so-called Peltier effect occurs - one side of the module heats up, and the other cools down. Why do we need it? Everything is very simple, if you act in the reverse order: heat one side of the plate, and cool the other, respectively, you can generate electricity of small voltage and current. We hope that at this stage everything is clear, so we turn to master classes that will clearly show what and how to make a thermoelectric generator with our own hands.