Is it worth insulating the roof at all in a particular house?

Before you start choosing a material and installing a heat insulator, you need to decide whether insulation is required or you can and should do without it.

The main thing here is to make a fundamental decision - the attic will be used as a "not insulated" storage room for various small things, or it is still planned to make a living room there.

Insulate the roof along the rafters only in the second case, when arranging the attic. Snow lying on the roof must be insulated from the attic heat, otherwise it will begin to melt and turn into ice with subsequent damage to the roofing materials.

But in a situation with a non-residential attic, the overlap between the living rooms in the house and the under-roof space should be insulated. Otherwise, it will cease to perform the functions assigned to it and, plus, corrosive processes may begin on the rafters.

How to properly install insulation

Depending on the type of insulation chosen, there are options for arranging the roof:

- installation under the roofing material from the outside;

- laying from the inside between the rafters;

- blowing out between the rafters;

- installation inside the attic on the rafters.

It makes sense to consider the most popular installation methods.

Material selection

There are a lot of options for materials for insulating the roof between the rafters in the domestic market of heat-insulating materials:

- Polyfoam (extruded polystyrene foam) - excellent indicators of water absorption and thermal conductivity, but due to its rigidity it is not very suitable for roofs.

- Polyurethane foam - thermal conductivity is comparable to the first material, but there is more water absorption (you cannot do without arranging a high-quality waterproofing layer).

- Penoizol is a carbamide-formaldehyde foam in the form of a polyurethane foam (after foaming, it fills all holes and cracks, but under the influence of water and steam it quickly loses all its thermal insulation qualities and, moreover, is easily destroyed even by light pressure).

- Mineral wool (from basalt, glass or slag) - fibers obtained by extraction from mineral raw materials or industrial waste.

The main problem with all polymer heat insulators is their flammability.

Polyfoam tolerates moisture well, but it is tough in work and it will leave cracks at the rafters. Therefore, it is the last option, stone (basalt) mineral wool, with the best thermal conductivity among all mineral wool, is the most optimal choice for roof insulation along the rafters.

The main thing is to qualitatively perform its vapor-waterproofing so that moisture cannot get close to it. And it is easy to work with it, and with proper installation, any crevices for drafts are excluded.

Attic insulation materials

Let's take a closer look at glass and mineral wool. Glass wool fibers are produced from molten glass, and mineral wool fibers are obtained from molten basalt stones. Cotton wool fibers are held together by a special binder - phenol-formaldehyde resins. By the structure of the fibers, they are able to keep stationary air inside themselves, which simply perfectly retains heat.

It is worth discussing a number of differences between glass and mineral wool. You will need a respirator and a pair of gloves to lay the glass wool, and you do not need to use any self-defense devices for the rock wool slab.It is worth noting that mineral wool holds better in the inter-rafter space, its main disadvantage is its high cost, but if you want your attic not to let the cold pass for more than ten years, then you should pay attention to basalt wool.

Mineral wool is considered the best material for insulation, as it is easy to install, it holds better in the space between strips and serves for a long time.

The heat-shielding properties of expanded polystyrene (foam) are superior to the two previous types. Its features include zero water absorption, high rigidity and strength. With the help of special additives, expanded polystyrene is resistant to fire, but if it does catch fire, it will begin to emit substances hazardous to human health. Despite all the advantages, foam is not very popular. If you still use slabs of this material, you need to protect it from rodents.

For work we need:

- insulation - the amount depends on the size of the attic roof;

- several wooden blocks;

- a hammer;

- mallet;

- chisel;

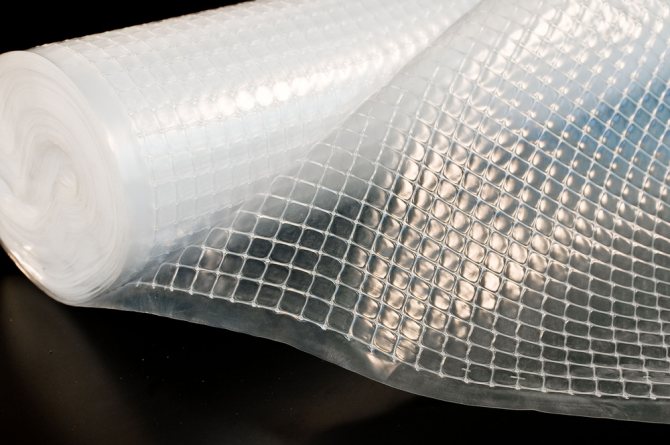

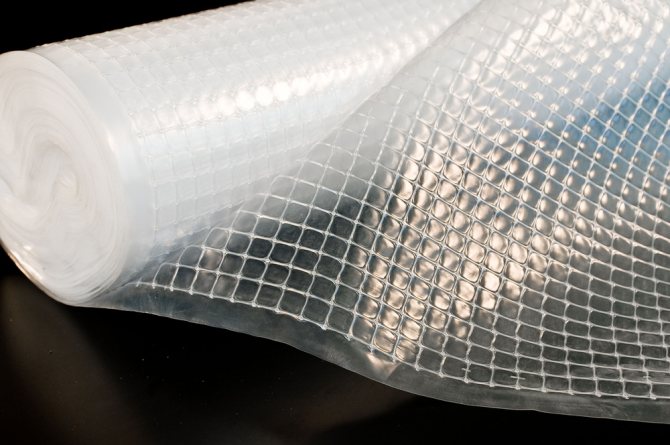

- polypropylene film.

Correct inter-rafter insulation technology

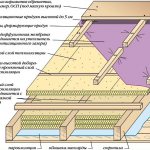

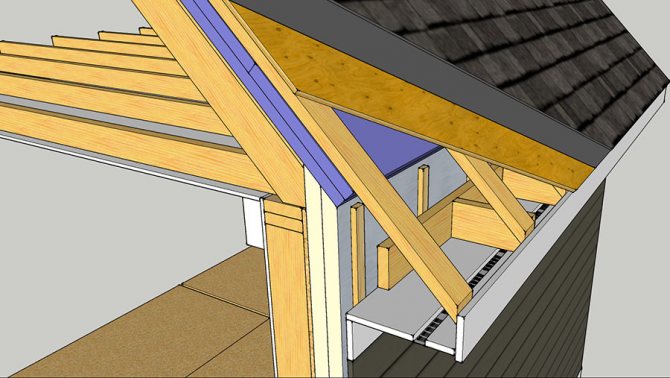

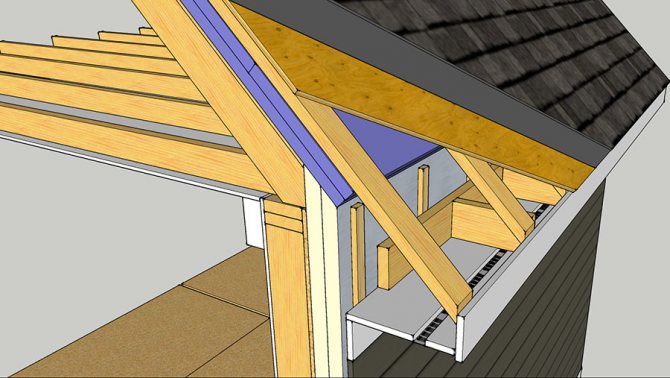

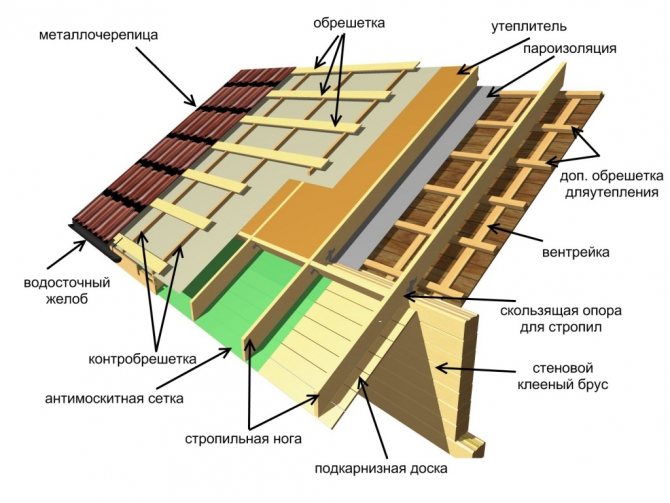

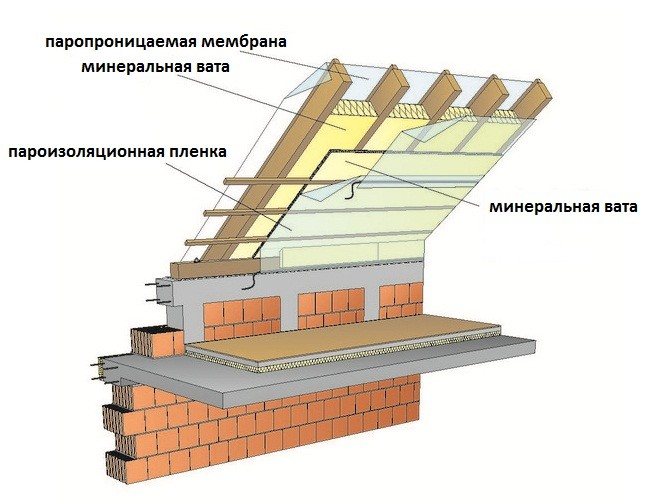

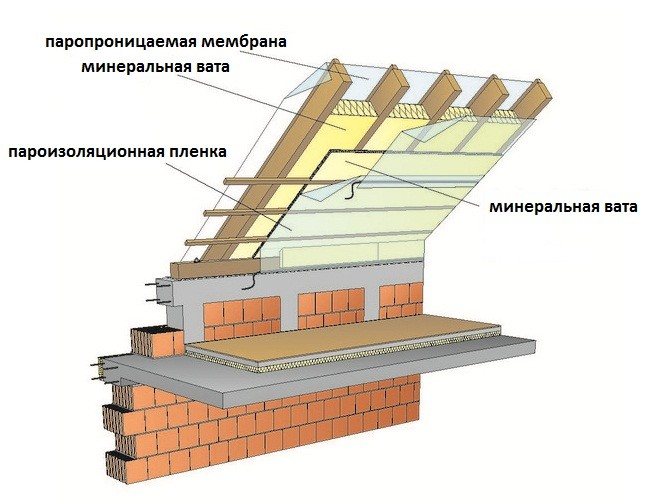

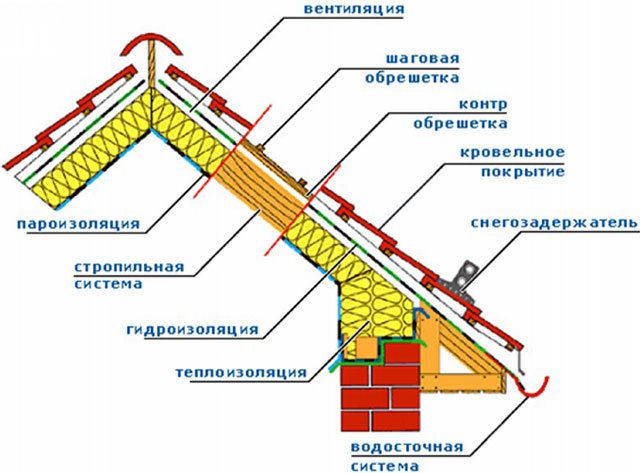

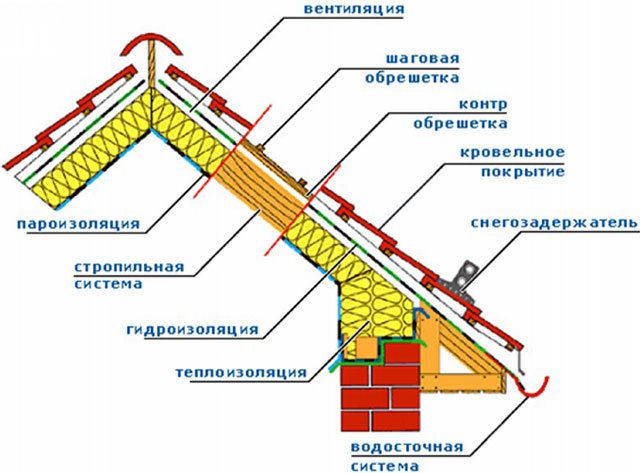

Upon completion of the laying of the mineral wool between the stacks, a "puff cake" should be obtained, in which layers successively go out from the attic:

- Decor (plasterboard or lining).

- Ventilation gap.

- Vapor barrier (cotton wool must be protected from steam).

- Minvata.

- A waterproofing pad that releases steam to the outside, but does not let water through to the mineral wool.

- Second ventilation gap

- Roof material.

It is most convenient to carry out work on roof insulation even at the stage of arranging the roof during the construction of a house, otherwise then you will have to remove the roofing material.

Roof insulation technology

In the process of performing the preparatory measures, the thermal insulation material was unpacked and cut into pieces of the required dimensions. All that's left to do is place it in its intended location. After the layers of insulation have taken their places, it is necessary to protect the material from vapors coming from the living quarters. For these purposes, you can use the same waterproofing film. The rules for its installation are no different from those described above.

The final stage of roof insulation between the rafters is the installation of finishing material. Most often, it is attached to the surface of the rafters. This completes the insulation. If the materials are located correctly, in compliance with all the above rules, then they will be able to perform their functions regularly for a long time.

By following the sequence of actions and technology of using materials, you can achieve excellent results and significantly reduce the cost of fuel required to heat the room. It should be noted that the created structure is subject to repair, which can be performed at any time.

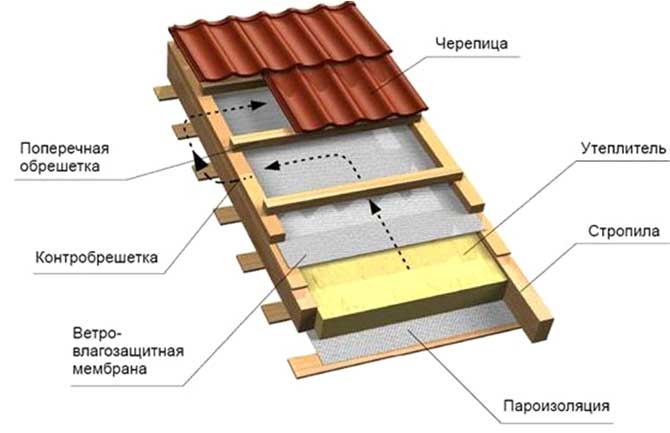

Work outside

After the installation of the system is completed, even before the installation of the roof itself, waterproofing should be installed from a special superdiffusion membrane. The main thing is not to confuse her sides. Outside, it spreads with a moisture-proof layer. Laying is done from the eaves up, the canvases overlap by 10-15 cm and all joints will need to be glued with construction tape. To attach the film to the rafters, it is most convenient to use a construction stapler, or you will have to work with a hammer. The main thing is that the carnations are galvanized.

It is not recommended to stretch the waterproofing film on the rafters. With a decrease in temperatures, it will begin to shrink a little and will simply be damaged in the places of fasteners, and the canvases may also disperse with the formation of gaps.

Next, a crate is packed over the superdiffusion membrane.It will require wooden slats of 2.5-5 cm, depending on the planned space for ventilation and the type of roofing material. Galvanized self-tapping screws are quite suitable as fasteners. At the end, the roofing is installed on top of the crate.

If the insulation is carried out in the attic with the roof already laid and if the waterproofing was missed during its installation, then it will be necessary to remove the roofing material and lay the film. Otherwise, the under-roof insulation will get wet and lose all its thermal insulation properties.

If the membranes are laid from the inside and the rafters are wrapped around them, then they will simply start to rot from an excess of moisture.

The considered technology involves the use of sheet roofing materials (slate, metal, corrugated board). To insulate the soft roof on the rafters, you will need to nail moisture-resistant plywood on top of the sheathing, and the topcoat should already be attached to it.

Insulation between the rafters

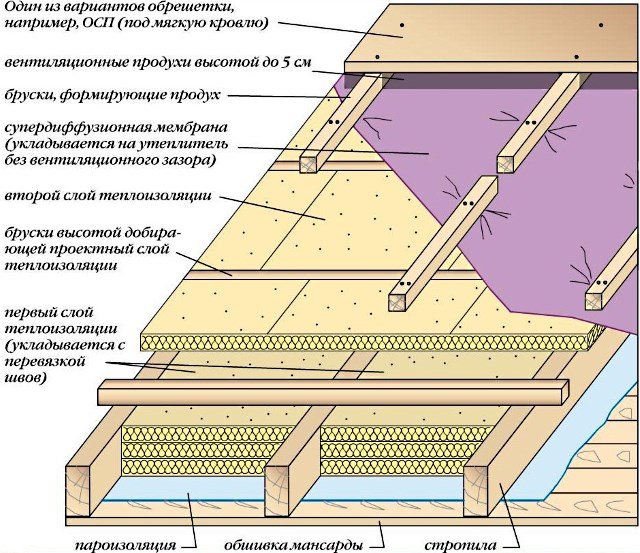

The traditional way to insulate a sloped roof is to position the insulation between the rafters. In this case, you can arrange a flat ceiling of the attic room.

Before starting insulation, you need to mount a waterproof film over the rafters. It will protect the premises from possible precipitation and will allow work to be carried out in any weather. It is better to choose a diffusion membrane. When installing a microperforated or anti-condensation coating, a two-sided gap is arranged. Condensation often forms on the films. Its hit on the insulation:

- will increase the coefficient of thermal conductivity;

- will lead to deterioration of insulation;

- promotes the development of mold;

- will reduce the bearing capacity of the roofing elements.

The insulation is not laid to the full height of the rafter leg. A gap of 2-3 cm is sufficient for air flow and natural drying.

With this technology, low density insulation is often used. For proper operation, such heaters need to be additionally fastened, which leads to overspending of the frame material.

Soft insulation often shrinks during operation. Deformations occur both in width and height. As a result, some areas become bare, becoming defenseless against the cold.

It is not recommended to use insulation in the form of dense materials: foam, polyurethane foam. Due to dimensional instability, gaps are formed between the rafters and the slabs. The use of polyurethane foam does not save the situation. Blowdowns are formed.

Mineral wool insulation Stone (basalt) wool Glass wool

Mineral wool of a slab type is best suited for insulation inside the rafters. When laying, the joints of the slabs are shifted by half the width of the product. In this case, the appearance of cold bridges is prevented.

The dressing of the seams is also important for multi-layered styling. The next product should overlap the seams of the previous flooring. For multi-layer laying, products of maximum thickness are used. For example, for insulation with a layer of 150 mm, it is better to take a material of 100 and 50 mm than three plates of 50 mm each.

When the slope angle is less than 30 °, an additional frame is arranged for insulation. It will prevent slabs from slipping and caking. The frame keeps the boards in the assembly position during their entire service life.

The accepted width of the slabs should be 1-1.5 cm greater than the clear distance between the rafters. In this case, a tight abutment will be ensured. With a smaller width, gaps will appear due to defects in wood or oversight of builders. Large thickness contributes to the deformation of the board and its bending.

Inside the insulation of pitched roofs on wooden rafters, there should be no air gaps and cracks. The layers should be tightly adjacent to each other. This also applies to interlayer spaces and joints. Professionals lay the slabs by cutting them into two trapezoidal pieces.

Polyurethane foam (PPU)

Another innovative way of insulation is polyurethane foam. It is possible to arrange the coating both after waterproofing and after installing the roof covering.

The application process takes place by spraying. The work is carried out using special equipment. Protection is mandatory for the employee in the form of:

- suit;

- masks;

- respirator.

Foam is applied both in the gap between the rafters and on the supporting elements of the roof. They must first be treated with antiseptics or anti-corrosion solution. Foam:

- clogs the smallest blows and cracks;

- hides bolt holes;

- covers all metal elements, protecting them from corrosion.

The continuous layer excludes the penetration of drafts and moisture. Low thermal conductivity allows you to reduce the consumption of heating the under-roof space.

The second innovative continuous coating material is ecowool. The name itself speaks of environmental friendliness and safety of use.

Ecowool

The composition includes fire retardants and antiseptics. The first ones prevent the fire of the layer, the second ones spread inside fungi and mold. The bulk of the composition is waste paper and cardboard production waste.

Laying is done dry and wet. In dry installation, the rafters are sewn up from the inside with facing material. The material is placed in the resulting boxes. In the wet method, wet cotton wool is applied to the surface under pressure. High adhesion of the material allows you to cover the surface with a dense, uniform layer.

Works inside

After arranging the roof, the laying of mineral wool between the rafters inside the attic begins. Minvata must be unpacked, allowed to lie down a little and straighten out, and then cut into pieces equal to the inter-rafter distance with the addition of 3-4 cm.

The material should be pressed with little effort between the rafters to fill the entire space.

On top of the mineral wool, a vapor barrier film is stuffed to the rafters, using the same technology as outside. Then again a gap is made for ventilation, on the crate of which the internal decor of the ceiling and walls of the attic is mounted.

It can be drywall for further finishing or lining for painting.

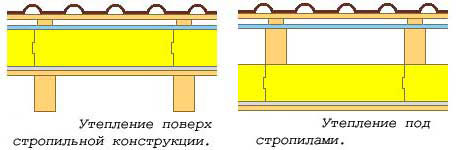

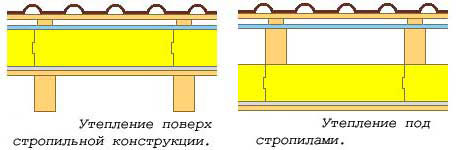

Insulation under the roof rafters

Insulation schemes above and below the roof rafters

The insulation scheme under the rafters is used very rarely in residential buildings; it is usually resorted to when building industrial structures with strong metal load-bearing elements. Such a scheme of the attic is possible during the reconstruction of objects, when it is possible to reduce the internal space of the room. Similar insulation options can be used with increased requirements for ventilation of the entire structure or when building rooms with high humidity. Such a roof insulation scheme differs from all others in that it is quite simple and reliable, requires a minimum number of joints when using roll material.

Insulation of the roof slopes is also necessary. There are also disadvantages, and quite large ones. Due to simplicity and reliability, thermal insulation is lost, due to openness, damage to the vapor barrier layer is possible. Premises with such a roof are very difficult to ventilate and require the installation of additional roof fans or high power aerators. If there is a need for an insulated attic roof for a house or summer cottage, then it is better not to use this option.

Features of insulation with different materials

Mineral wool. For installation you will need:

- Installation of a frame made of profiles or wood.

- Vapor barrier film to protect cotton wool from moisture.

The vapor barrier material should overlap at the joints by 10 cm. Lay double-layer thermal insulation so that the lines of the joints do not coincide. The main feature of the installation is the complete insulation of mineral wool from moisture. Then the service life and the effectiveness of the insulation will be tangible.

Extruded polystyrene foam is widely used in various construction works. Popularity has not been spared in the insulation of the roof. The installation method depends on the type of roof. The slabs are laid on top of the waterproofing foil between the rafters. For fasteners, special glue, screws and dowels are used. The sheets should fit snugly against each other and the rafters.

For a convenient location of the material, you can make a frame crate according to the size of the foam sheets. All cracks after installation must be carefully filled with polyurethane foam. For greater efficiency, the work surface can be supplemented with penoizol. The excellent characteristics of the material will provide reliable thermal protection when paired with foam. Fine finishing can be done with plasterboard or plywood.

Roof insulation process

Fulfillment of all technology requirements guarantees a positive insulation result.

The planned actions will help determine the sequence of work:

- Monitoring the condition of the roof structure. Repair damaged areas if necessary.

- If necessary, treat all wooden elements with an antiseptic. For fire-fighting measures, treat the wood with a fire retardant.

- Remove the wiring, if any.

- Draw up an insulation plan, including a list of materials and their parameters.

- When purchasing, you should pay attention to the quality of the insulation. Savings in this case are unacceptable.

- Cleaning the work surface from debris and dust.

- If there is no waterproofing, it will be done taking into account the ventilation gap (5-10 cm).

- If necessary, make additional lathing for thermal insulation.

- Laying insulation in the cells between the rafters. The size of the plates should exceed the dimensions of the cells by 5 cm for a snug fit. You can use special glue to increase the strength of the attachment.

- Fix the vapor barrier foil with a stapler.

- Surface finishing.

The need for roof insulation

In such cases, you have to insulate the roof from the inside with mineral wool - this allows you to compensate for the level of heat loss. How the roof is insulated from the inside with mineral wool is discussed in this article.

There are two fundamental technologies for insulating the roof from the inside:

- Laying insulation between the frame rafters;

- Laying insulation over the rafters.

Each roof insulation technology with mineral wool will be considered in more detail.

Features of the insulation of a pitched roof

The pitched roof structure has a slope of over 10 °. Component elements:

The gap between the rafters is from 600 to 1000 mm. The thermal insulation material has a certain width, which does not always fit this distance. With the help of a lath or wire lathing, you can create a reliable frame for fixing the slabs. The insulation layer for the pitched roof must be at least 10 cm.

The order of placing the layers of insulation:

- Roofing surface.

- Ventilation clearance.

- Waterproofing.

- Ventilation clearance.

- Insulation.

- Vapor barrier.

- Finishing.

The place of special sealing is the abutment of the roof to the ceiling. Insulation should be carefully filled in all corners and joints with beams, and the cracks should be filled with construction foam.

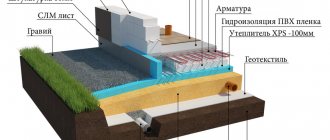

Features of flat roof insulation

The flat design is installed with a slight slope to drain precipitation. As an overlap, plates or metal-profile sheets are used. The type of insulation and its thickness depend on the material of the floor.

The joints are filled with polyurethane foam. Thermal protection methods differ in the amount of installed thermal insulation material and the place of work (inside or outside).

Flat roof roofing cake includes:

- Roofing surface.

- Waterproofing.

- Thermal insulation.

- Vapor barrier.

- Finishing.

The type of flat roof structures affects the sequence of laying the insulation layers during outdoor work. In traditional ceilings, waterproofing is located on top, which affects its wear and tear under the influence of the environment. Inverted roofing includes a good protective layer of drainage, geotextile and decking.