In continental climatic conditions, winters are sometimes quite cold. That is why the owners of private houses prefer additional insulation of their home. Special coatings are intended not only for insulating the facade of a house or apartment, but also for ceilings, interior walls, roofs, floor surfaces, and even for a sauna and a bath. Insulation by Rockwool is one of the leaders in the market for these products and occupies a leading position in the niche of materials for insulating facades with glass wool.

Socket Rockwool Lite BATS SCANDIC

Rockwool specifications

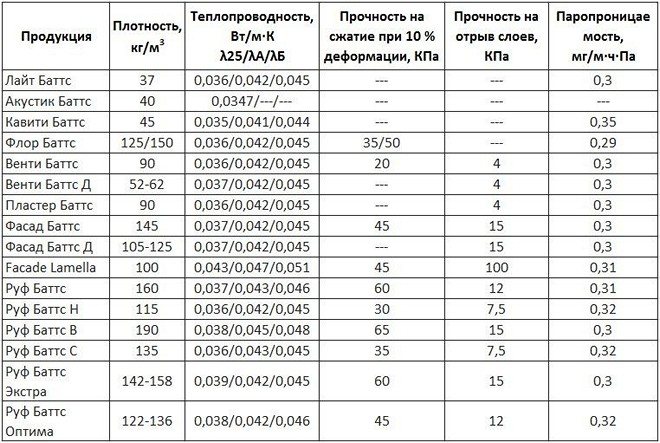

Insulation Rockwool Butts has high performance, which once again confirms its popularity among thermal insulation boards.

Rockwool Specifications

In addition, all products are manufactured according to special technologies and have the EcoMaterialGreen quality certificate, which confirms complete environmental friendliness and safety.

Benefits

Thermal insulation with this material has its significant advantages:

- slabs do not form gaps and crevices due to increased density during laying;

- reliably protects against the formation of mold, fungus, rodent penetration due to its high biostability;

- incombustibility of the material;

- moisture resistance;

- high sound and heat insulation;

- springy base, which is obtained as a result of the unique flexi technology, which makes installation quite easy and fast.

Scope of application

Light Butts are modern pressed slabs made of stone wool. It is obtained as a result of processing basalt rocks, which makes the material strong and resistant to various damages and influences. So, the scope of their application is quite diverse:

- building's facade;

- internal walls;

- interior partitions, balconies, loggias, attic;

- roof;

- floor slabs;

- entrance doors, garage doors;

- external and internal walls of the apartment.

Insulation Rockwool due to its technical characteristics has a wide range of applications

Specification and dimensions

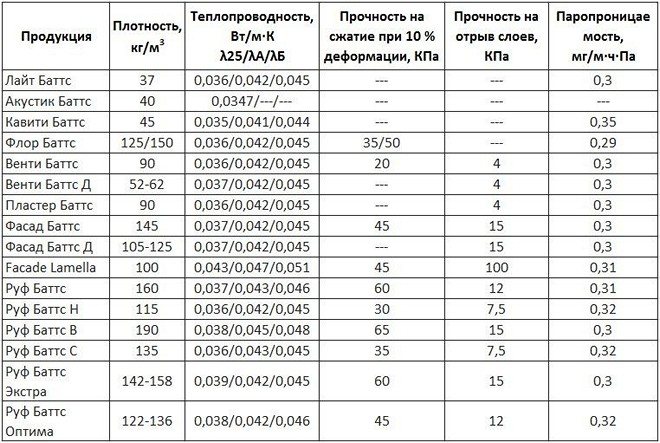

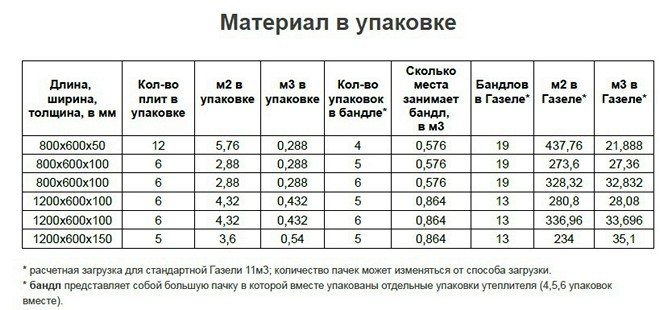

The manufacturer manufactures products in two types:

- standard - 60x80 cm (thickness - 5 or 10 cm) - this size is convenient for transportation by car;

- XL - 60x120 cm (thickness - 10 and 15 cm) - in case of transportation by trucks.

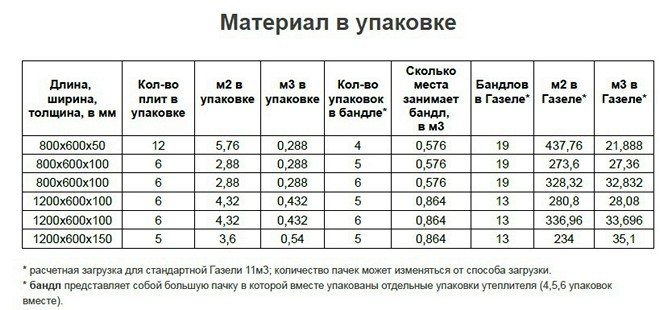

To roughly understand how much space one package takes and to facilitate the process of loading and delivering material, you can use the table:

Insulation size Rockwool

Scope of application

The use of material in the insulation of the facade of the house

Due to its characteristics, the insulation has a wide range of applications.

- In construction. Use the material in this direction of steel primarily due to the positive properties and effectiveness of thermal insulation. Raw materials are used in the design of partitions and ceilings in multi-storey buildings. It is also used during the construction of cottages and private houses under a concrete screed.

- In ventilated and non-ventilated façade systems. For the construction of partitions, which in the future will be formed under the facade, they try to use ROCKWOOL with sufficient elasticity. They carry out not only thermal insulation, but also a load-bearing function.

Internal thermal insulation of the house with Rockwool insulation - When insulated from the inside. For this purpose, Rockwool basalt insulation is used. It is mounted indoors on the walls facing the street. Also suitable for insulating other types of partitions, ceilings, floors of any design.

- For the roof.Most often it is used for insulation when organizing a roof. Shows excellent performance properties for thermal insulation of mansard rooms and attics.

- ROCWOOL in the form of cylinders has special properties for thermal insulation of pipelines of any size. Such material is securely attached to the surface of the line, does not require preliminary preparation.

The assortment includes Rockwool slabs of increased rigidity. They are suitable for insulating wall wells, as well as for insulating street walls or interfloor layers.

When calculating the amount of material for thermal insulation, it is necessary to be guided by the SNiP standards and the formula R = R1 + R2 + R3.

Calculate your home's insulation

A cozy home is, of course, a warm home. The level of heat loss depends on the correctly calculated thermal insulation. To reduce it, it is necessary to correctly calculate the required amount of material for wall insulation and, in fact, calculate the optimal thickness of wool for insulation. Calculation of rockwool insulation for a facade can be determined in three ways:

- by contacting special construction organizations;

- on your own;

- using an online calculator.

Of course, the easiest way is to choose the first option and save a lot of time by getting just a number. But in this case, you will have to pay a considerable amount for such services, and this, as you know, is an extra expense during construction or repair, because you can calculate the amount of insulation yourself. It will certainly take some time, but the result will be just as accurate.

The calculation of the insulation (Scandic, Light Butts or any other) occurs according to a certain formula, and there is nothing complicated about it. It can be produced for absolutely any kind of material. But first, let's look at it with a specific example.

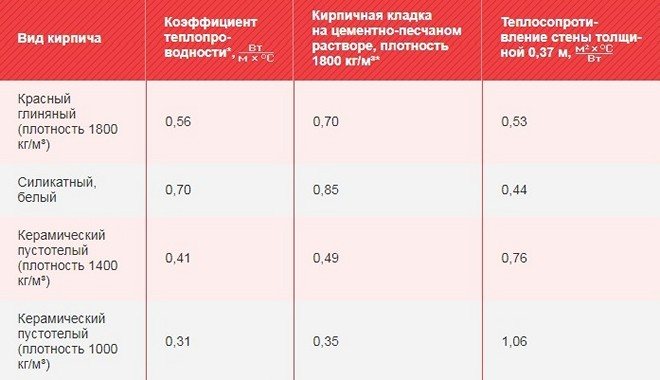

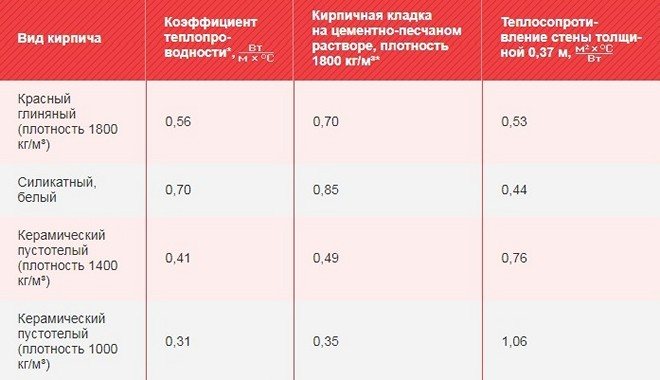

For example, we have a house made of bricks, the wall thickness is one and a half bricks. The work is planned to be done with the help of "Light Butts" or "Scandic". In order for thermal insulation to be effective and heat to be retained in the cold season, the wall must have a thermal resistance equal to at least 3.5 m2 * K / W. To determine the optimal thermal insulation, it is necessary to make certain calculations:

- To begin with, we determine the current thermal resistance of the existing wall. Its thickness is 37 cm, and the coefficient of thermal conductivity is 0.56. This applies to red clay bricks. So, for different types of material, thermal conductivity is usually different.

- We calculate the current thermal resistance. For this, the wall thickness in meters must be divided by the thermal conductivity coefficient. As a result, we get: 0.37 / 0.56 = 0.66 m2 * K / W.

- We do not have enough up to the optimal value of 3.5 m2 * K / W: 3.5-0.66 = 2.84 m2 * K / W.

- Further, it became possible to calculate the required thickness of the stone wool layer: 2.84 * 0.045, where the second value is the coefficient of thermal conductivity of the insulation itself. Thus, we get the value in meters - 0.127. We find the value in millimeters - 127 mm. This is the required layer thickness for thermal insulation with Rockwool Light Butts and Scandic stone wool.

If you are still afraid of making a mistake in the calculations, you can use the online calculator, which are offered by many construction sites.

Thermal insulation of the bath from the inside ↑

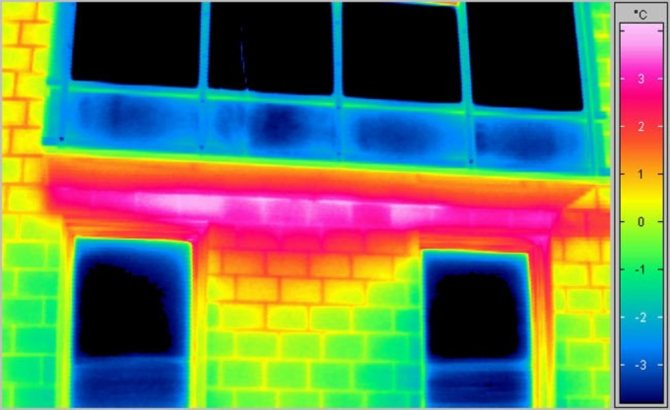

How to insulate the walls of the bathhouse from the inside is a question that does not go off the agenda, because this is a special room, and dampness in it is not only acceptable, but implied. So what kind of thermal insulation of the walls of the bath should you prefer? How are different insulation materials used? There is a common myth: the denser the insulation, the better. This is only partly true. Density is an important, but not the only factor when choosing thermal insulation. Density alone does not characterize the quality of the material. The technologies for the production of today's thermal insulation materials are different.For example, the mechanical characteristics of materials in the case of stone wool are provided at a much higher density than in mineral wool products. Strictly speaking, the high density of materials is often perceived more as a disadvantage than an advantage: transportation and storage become more complicated, and the insulation work itself becomes more laborious. What really requires our attention when choosing a heater for a bath is such parameters as thermal conductivity, durability, incombustibility, environmental friendliness.

To insulate the walls of the bath, a frame is built from the inside

The "suitability" of thermal insulation for a bath is largely determined by the material from which it is built. There are options, of course, there are, but still, the vast majority of baths in Russia have been built from time immemorial from time to time, since it is not a problem for our places.

Types of insulation and its application

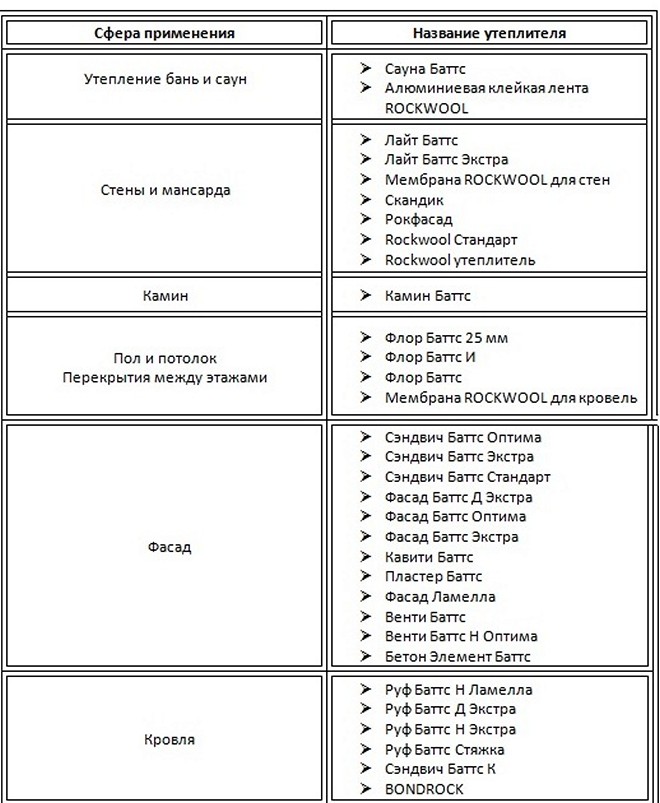

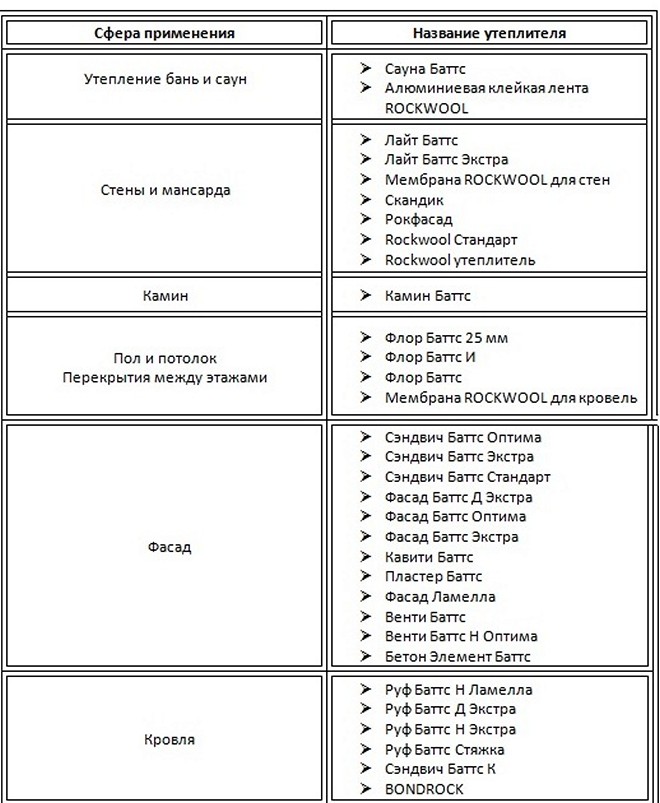

Rockwool manufactures a wide range of insulation products. So, each of the heaters can be applied to different parts of a house or apartment, and all products can be divided into blocks, taking into account the scope of its use:

This is not a complete list of manufactured stone wool for thermal insulation of premises. Among other things, there are special membranes, aluminum tapes, vapor barrier plates, which are also aimed at retaining heat. Also, some types can be used in different areas. For example, Light Butts, Light Butts Extra, Scandic, Floor Butts can be used to insulate balconies and loggias, as well as for floors and storey ceilings. And, for example, Light Butts is perfectly practiced as a second thermal layer for steam rooms.

Wet Facade Walls

This method of insulating facades is the most common and has its own advantages:

- maximum heat savings;

- reduction of financial costs.

A variant of the "wet" method of insulation

So, after all the preparations for the facade, a basement profile is installed, which serves to balance the load distribution from the insulation. Next, the installation of the Rockwool Butts thermal insulation layer is carried out:

- Along the edges of the insulation, at a distance of 3-4 cm, an adhesive mortar is applied in a wide strip.

- Then it is pressed tightly against the wall, but the excess glue is removed immediately. The second layer of insulation is pressed against the first with the same effort.

- Move from the basement profile - up.

- After 2-3 days, when the glue solution is completely dry, the insulation is additionally fixed with dowels. The length of the fasteners must match - in addition to the rock wool layer, they must fit into the wall.

After all the fortifications are completed, a reinforcing layer is installed:

- building glue is applied to the insulation layer, in which the fiberglass mesh is recessed;

- the same adhesive is applied over the mesh.

It should be remembered that the total layer should not be more than 6-7 mm. After the glue is completely dry, plaster is applied on top for external use.

Two-layer masonry

Layout of two-layer brickwork with insulation inside

Warming with a pre-given method is the easiest way to insulate a room using Scandic or Light Butts slabs. In this case, the insulation is mounted between two rows of masonry. For example, a wall is built using bricks (silicate, ceramic). Further, stone wool is fixed to it using the same method as with the wet facade technology. And then another layer of wall masonry is erected. It can also be made of bricks or other building materials - foam block, slag concrete and others. Rockwool Venti Butts are often used to insulate suspended systems with an air gap.

Frame walls

Rockwool Light Butts is the ideal insulation for frame walls

Any house consists of two walls - internal and external.In this method, both are insulated. For this, the ideal choice would be Rockwool Caviti Butts or Rockwood Facade Butts:

- outside the facade of the house is sheathed with wood planks;

- a waterproofing membrane is strengthened on them, which protects the insulation from moisture, also from the outside;

- from the inside of the house, Rockwool is installed in the frame racks for the walls;

- all gaps and voids are filled with polyurethane foam;

- the inner walls should be covered with a vapor barrier membrane and wood-based panels should be reinforced over it.

Walls from the inside

Insulation of the wall of the house from the inside with Rockwool insulation

Not all insulation materials are suitable for interior decoration, as some have very low environmental performance. So, the insulation must meet the following requirements:

- durability;

- high fire safety;

- low heat loss;

- complete environmental friendliness.

All these requirements are met:

- Rockwool Light Butts Extra;

- Light Butts Scandic XL.

Work from the inside takes place in several stages:

- To prevent the appearance of mold and mildew, the surface is treated with a deep-penetrating primer.

- The crate is installed in the form of a metal frame or wooden bars.

- Insulation is laid;

- The waterproofing or vapor barrier membrane is stretched.

- Drywall is attached.

Screed floors

Insulation of the floor under the screed with Rockwool insulation

Thermal insulation wool is laid on the floor slabs. For greater efficiency of heat preservation, it is recommended to lay in several layers in a checkerboard pattern, i.e. when the edge of the top plate is in the middle of the bottom. As soon as the insulation is tightly mounted, they begin to level the floor - with cement mortar or using wood planks. This is followed by laying the flooring - linoleum, parquet, laminate, wood.

The most popular floor insulation materials are:

- Floor Butts 25 mm;

- Flor Butts I;

- Flor Butts.

Floor on logs

Thermal insulation of the floor along the logs

At the first stage, a Rockwool membrane is installed on the floor, intended for waterproofing. Its joints must be glued with tape. Then lag bars are laid, in the intervals of which thermal insulation is laid. It is recommended to strengthen the vapor barrier membrane from above and only then the floor covering is laid.

Flat roof

Expanding a flat roof with Rockwool Roof insulation

Insulation of a flat roof should be carried out only from the outside. Initially, Rockwool slabs are laid on the base - Roof Butts, Bondrock, Butts K. Sandwich. Then the cement screed is poured and the roofing material itself is laid.

Mansards and roofs with rockwool slabs

The attic is insulated only from the inside. So, the insulation is inserted between the rafters and covered with drywall or thin sheathing board. In this case, it is advisable to lay the insulation in several layers.

Pitched roof structures and attics

Insulation of the roof over the mansandra

These works are carried out only after the roofing has been installed. This will prevent the insulation from getting wet in case of rain or snow. The inner side of the counter battens is sheathed with a ROCKWOOL hydro-windproof roofing membrane. Further, the finished frame of the attic or pitched roof structure is filled with insulation. Then it is covered with a vapor barrier membrane and reinforced with a construction stapler. To create an air gap, a crate is installed in the form of drywall, sheathing board or wood-based panels.

Baths or saunas

Insulation for baths and saunas Rockwool

Rockwool produces special materials for thermal insulation of baths and saunas, which have high properties for keeping warm in steam rooms. They effectively store heat, which helps save on electricity or wood. Of particular importance is the aluminum coating on one side of the Butts insulation, which significantly increases the vapor barrier properties.

The insulation is installed in two layers from the inside of the room with the aluminum side inward in a checkerboard pattern, that is, in staggered fashion. This provides excellent thermal protection. For greater efficiency, the joints are glued with 100 or 50 mm Rockwool aluminum adhesive tape. Next, a crate is installed, which provides an air gap between the insulation and the external finish. The slabs themselves are mounted against the frame racks. The most common types of insulation for steam rooms are Rockwool Sauna Butts and the second layer of Rockwool Light Butts Scandic 100 and 50 mm.

Insulation ISOVER Sauna ↑

This is a modern technological thermal insulation based on fiberglass with one-sided foil. For added strength, the polished aluminum foil is reinforced with a fine mesh to reduce the risk of tearing. The standard isover sauna is produced in the form of mats. Widely applicable for insulation of walls, floors on logs and ceilings (floors) structures with high humidity.

Soda, sand, limestone and a certain amount of binders are used in the production of isover for the bath.

Thanks to the foil layer, Isover Sauna provides thermal protection, reflecting about 95% of the heat back into the room. The rest of the heat is retained by mineral glass wool. Isover Sauna slabs have a low coefficient of thermal conductivity - 0.041 W / m · K, which is achieved by a large number of air voids between the fibers. Its density is 30 kg / m3.

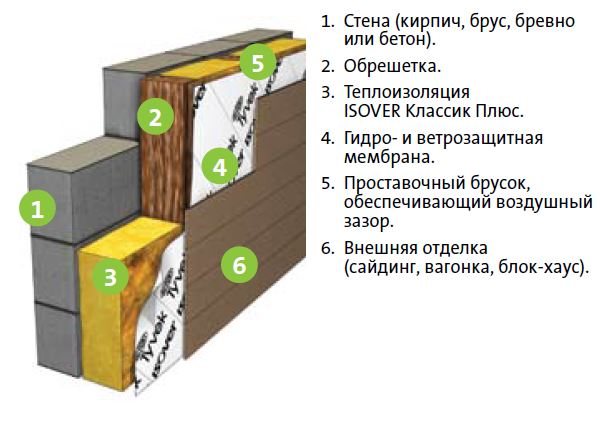

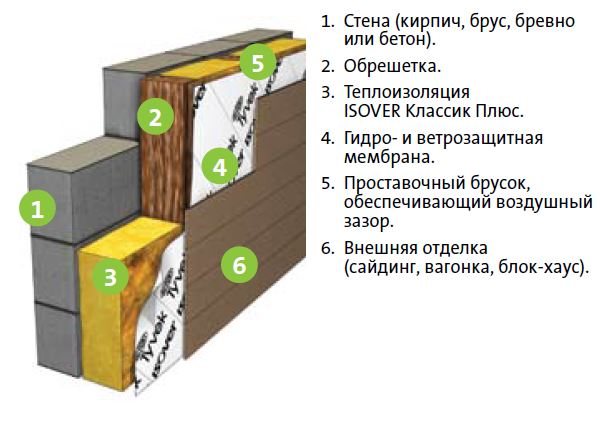

The scheme of insulating the walls of the bath from the outside with plates Isover Classic Plus

50 mm insulation

50mm Rockwool mineral wool has a permanent binder among the ingredients. The material is used for thermal insulation of pipes, roofs and walls. It can become part of construction and engineering industrial buildings, office premises and residential buildings. Insulation can be used for interior slabs. A truly exclusive product is Sandik slabs, which are produced specifically for private housing construction. At the final stage, the canvases are compressed, which saves space during transportation. The material is compressed by 60%.

The thermal conductivity of Rockwool mineral wool is quite low. The edges of such products can spring, so installation is quick and easy. Water absorption by volume is 1.5%.

Evgeny Filimonov

Ask a Question

Transportation of the material is carried out in a vacuum package, so the consumer does not have to transport air anymore.

You will only transport material.

It should be laid horizontally and covered vehicles are recommended for transportation. The described material is manufactured in a standard size, which is 800 × 600 mm. As an example of a 50mm slab, you can also consider Light Butts, which is specifically designed for lightweight roofing and lightweight structures.

Reviews about cotton wool "Rockwool Light Butts"

On sale today you can find hydrophobized lightweight insulation boards, which are made on the basis of basalt rocks. This product is unique, and it is intended for private housing construction. The main feature is the revolutionary quality of the fibers, which allow the plates to be compressed up to 70%.

Engineers worked for a long time to create this material, in the end they managed to obtain a structure that is capable of maintaining outstanding performance in all respects. In addition, the material has excellent recoverability. Mineral wool "Rockwool Light Butts" has, according to consumers, many other advantages, among them the ability to compressibility should be highlighted.

The material is springy, thanks to which the installation is facilitated, which is true in conjunction with a metal or wooden frame.The springy edge, according to users, is located on the long side, while the edge width is 50 mm. By looking at the end of the slab, you can see the flexed edge that is marked.

Installation Izospan V - instructions and important tips for use

Vapor barrier marked B is considered to be very popular when installing the roof, as well as walls. This vapor barrier material consists of rough and smooth layers. It extends the operating time of various buildings and perfectly preserves their heat-insulating characteristics, does not allow crumbling insulation particles to penetrate into the building's elements, and prevents the development of corrosion in the building frame.

Instructions for use Izospan B requires the installation of films on the rough sheathing or on the inside of the insulation material used.

Membranes are most often fastened with galvanized nails; it is also allowed to use a construction stapler.

On sloping roofs and walls, Izospan is mounted with horizontal panels from bottom to top. They are overlapped (do not forget about the mandatory overlap of the sheets by the required amount). If the structure is finished with plasterboard products, the film is fixed with galvanized profiles. But when using decorative panels, plywood, lining as finishing materials, it is recommended to fasten Izospan with wooden antiseptic slats with dimensions of 50x30 mm.

When a room is vaporized from the inside, the finishing must be attached to galvanized metal profiles or a frame made of strips. In this case, a gap (ventilation) of about 30-50 mm should be maintained. Experts, in addition, advise to interconnect Izospan sheets and additionally attach them to penetrating (roof antennas, ventilation and chimneys) and enclosing (floors, walls) structures. For these purposes, it is best to use the Izospan SL tape connector.

When equipping basement and attic floors with any insulating materials, Izospan under the B brand should be placed on a black ceiling or floor between beams or logs. In this case, the rough side of the films must be located outward. It is recommended to fasten the vapor barrier with wooden slats and a stapler. The scheme of work is as follows:

- lay out (as tightly as possible) the insulation between the beams or logs;

- roll the top layer of the film across the lags (beams);

- fix the vapor barrier.

In buildings with an outer layer of insulation, the described vapor barrier material is installed with the rough side inward on the inner surface of the structure. If you are installing Izospan on block or brick walls, be sure to use the tape marked SL. And then fix the film with profiles (galvanized) or wood counter-rails, intended for the installation of internal cladding.

Vapor barrier rockwool which side to lay - rockwool waterproofing

Supply of building materials

working hours: Mon-Fri from 9-00 to 18-00

in Russia for free

Categories

Brands

You may need

- In the basket:

- the main

- Catalog

- Insulation materials

- Vapor barrier for roofs, walls, ceilings

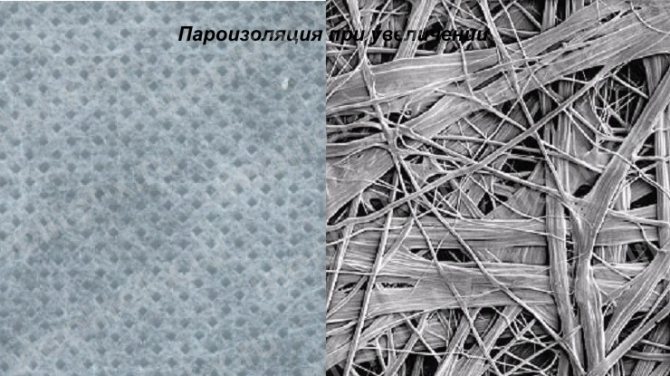

"ROCKWOOL® vapor barrier for roofs, walls, ceilings" - a two-layer material of non-woven polypropylene fabric laminated with a layer of hot melt polypropylene and / or polyethylene

The material has a two-layer structure: one side is smooth, the other - with a rough surface to retain condensate drops and their subsequent evaporation.

APPLICATION

It is used in frame structures for insulation of pitched roofs, walls and ceilings, as well as for internal insulation.

Installed on the warm side of the insulation with a smooth surface to it.

It is recommended to leave an air gap of at least 1 cm between the vapor barrier and the interior decoration.

"ROCKWOOL® vapor barrier for roofs, walls, ceilings" allows to reduce heat loss, provides a comfortable humidity regime for rooms and extends the service life of the entire structure.

SPECIFICATIONS

| Water resistance, mm of water Art., not less | 1000 |

| Water vapor permeability, g / (m2 * 24 hours), not less | 19 |

| Resistance to vapor permeation, m2 * h * Pa / mg, not less | 7,0 |

Packaging

"ROCKWOOL® vapor barrier for roofs, walls, ceilings" is rolled up and packed in plastic wrap.

Two types of packaging are produced - a roll with a total area of 70 m2 and 30 m2

Roll length - 43.75 m or 18.75 m, respectively.

Roll width - 1.60 m

INSTALLATION

INSULATION OF THE ATTIC

- Internal cladding;

- Air gap (

FRAME WALLS

- Internal cladding;

- Counter grill;

- Air gap (

Rockwool vapor barrier is a competitor to Izospan

Also, products under the ROCKWOOL brand can be used to protect building elements from moisture and condensation. This material is suitable for vapor barrier walls, roofs and ceilings. It is a material with two layers:

- Polypropylene non-woven fabric.

- A layer of laminated material made from polyethylene or polypropylene by hot melt method.

Rockwool also has two sides - rough and smooth. The first of them ensures high-quality retention of condensate and guarantees its rapid evaporation. This two-layer material limits the volume of water vapor passing through the structure to be protected. Due to this, their durability increases, and an ideal humidity regime is always present in the premises.

Rockwool vapor barrier features:

- water resistance - 1000 mm of water. Art .;

- density (surface) - 67–74 g / m2;

- the value of vapor permeability per day is not higher than 19 g / m2.

Rockwool is sold in rolls, designed for structures of 70 or 30 square meters. The roll width is standard and is 160 cm. Installation of the ROCKWOOL vapor barrier is carried out according to the same standards as Izospan.