Durability is one of the main requirements for building structures, for all that, it is determined by many indicators: quality, type of material chosen, construction technology, special constructive devices and many other factors.

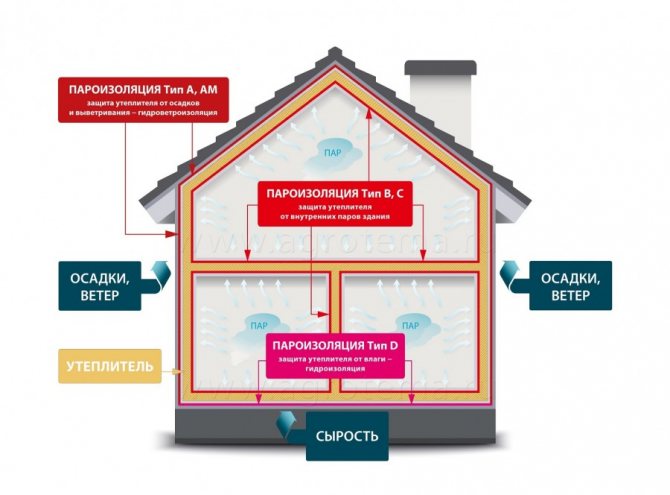

One of the important elements in the structure of almost any building is considered to be vapor barrier, being an element of protection, it is one of the technical tricks that determine the durability of the structure as a whole.

What it is, how is it done, about the features and implicit aspects of vapor barrier, will be discussed in this article.

Floor protection

In the case when the floor is installed directly on the ground, use a special anti-condensation film or sheets.

If there is a basement under the floor with high humidity, as well as in cases of possible sudden temperature changes, an aluminum-sprayed vapor barrier with special reflective membranes would be the best option.

What to buy a hydro-vapor barrier

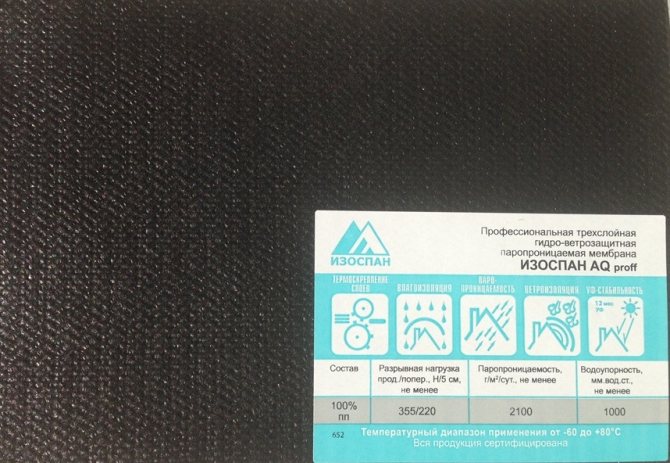

When buying, studying the advantages of hydro-vapor barrier, look at the following indicators:

- density - the higher it is, the stronger the film will be;

- vapor permeability - the higher the indicator, the better the film or membrane will remove vapor;

- water resistance - at a high rate, there will be higher resistance to moisture penetration;

- UV stability - the higher this indicator, the longer the film will preserve its properties when exposed to sunlight;

- mechanical tensile strength - the higher the indicator, the more resistant the film will be to mechanical damage during installation.

Roof protection

When choosing a vapor barrier for a roof, it is necessary to build on the type of roof. In this case, the thermal conductivity of the roofing material is of paramount importance.

Distinguish floorings with low thermal conductivity, in particular, they include:

- Roof tiles;

- Slate;

- Onduline and onduville coating;

- Bitumen compound coating.

For such a roof, a vapor barrier with diffusion membranes is used, while it is supplemented with a ventilation gap.

For roofs made of metal, profile iron and other types with heat-conducting coatings, vapor barrier is made on the basis of anti-condensate waterproofing. To screen condensate from the inside of the metal roof, use a film.

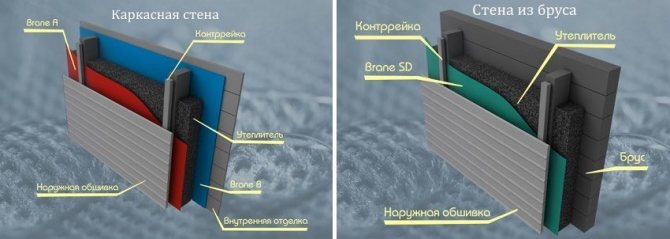

Features of the installation of vapor barrier for the walls of a wooden house

Vapor barrier is an important stage in house insulation work. The technology of its installation depends on whether we are talking about external or internal insulation of the house, which, in turn, depends on the condition of the building, the type of logs, etc. So, if it is necessary to insulate an old wooden house and improve its appearance, the insulation is mounted outside. If the house is new or the stage of external finishing is completed, the house is insulated from the inside.

Vapor barrier complements the properties of the insulation and extends the service life of the entire structure

Installation of vapor barrier for external insulation of a wooden house

When laying the vapor barrier on the outer wall of a house made of round logs, it is possible not to leave ventilation gaps. Their role is to fill the voids at the junction of the logs themselves. If the house is erected from a smooth square or rectangular bar, then it is impossible to lay the vapor barrier layer directly on the tree.This will disrupt the steam circulation. On the logs, it is necessary to fill rails with a thickness of 2.5 cm in 1 m increments. And only after that it is possible to lay the vapor barrier material, fixing it with a construction stapler.

Protective film prevents water vapor from entering the insulation

Then the crate is installed, on which the thermal insulation is laid, the waterproofing film is pulled on top, and finally, they proceed to the external finishing.

This option allows you to maintain a special indoor climate due to the fact that the tree inside the house is not hidden under the decoration. It is suitable not only for log houses, but also for frame houses, it is quite simple, which allows you to carry out vapor barrier of walls outside a wooden house with your own hands.

If the membrane is installed correctly, moisture leaves the room and does not penetrate back

However, there are also certain disadvantages. The wood must dry completely, which can take more than one year. Therefore, this option is not very suitable for new buildings. In addition, the joints must be treated with a sealant, the grooves must be drilled on both sides, and only water-repellent materials can be used as insulation. The service life of such a structure does not differ in durability.

Installation of vapor barrier for internal insulation of a wooden house

There is also a way to install a vapor barrier for the walls of a wooden house from the inside. For this, the walls are thoroughly cleaned and treated with an antiseptic composition. A crate of slats is installed on top. Insulation is laid between the slats, and a vapor barrier layer is mounted on top of it. It is fastened with staples or nails with wide heads.

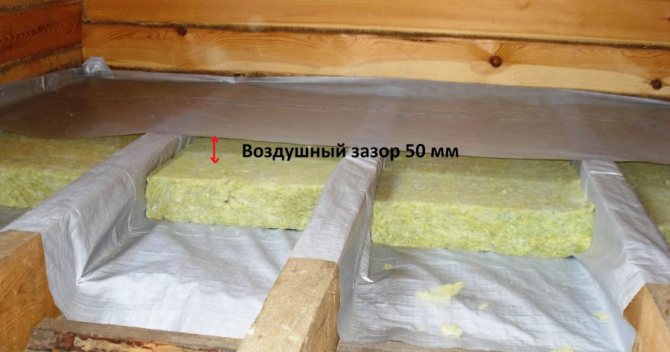

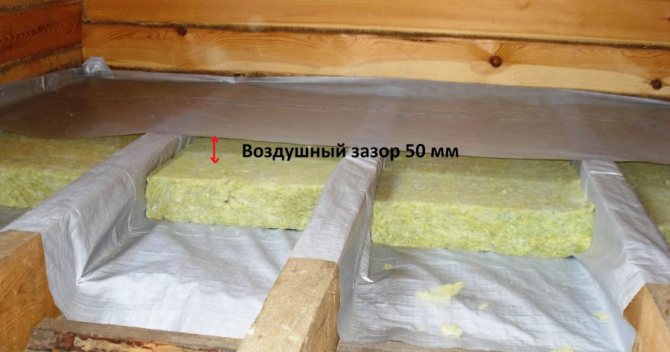

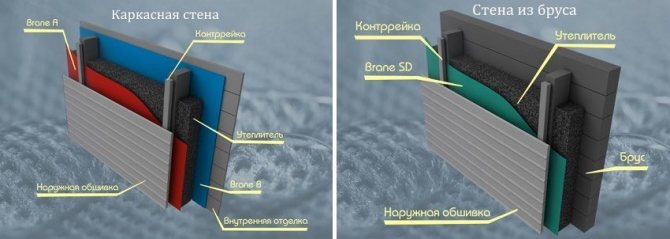

Examples of arranging a vapor barrier for a frame wall and a wall from a bar

If a diffusion membrane is used as a vapor barrier, it is laid directly on the insulation. Otherwise, it is necessary to leave a distance of about 5 cm between the thermal insulation and the vapor barrier. The film must be well stretched, otherwise its protective properties will decrease. The cladding is attached to the vapor barrier, and the finishing interior is already applied to it. The distance between the sheathing and the film should not be less than 3 cm, otherwise free circulation will be impaired and the moisture accumulated on the film will not evaporate.

Vapor barrier parameters

In addition to knowing the types and materials of vapor and condensate protection systems, it is important to know and understand what vapor barrier characteristics exist and how they affect the choice. Let's list the main ones:

The most important parameter is vapor permeability. In general, this indicator determines the overall ability of the protection to effectively shield the space from steam. The vapor permeability index is measured in grams per square meter per day. The lower this coefficient is, the higher the quality of the barrier will be.

Durability. It would be unnecessary to explain the meaning of this parameter. Note that it is from the mechanical strength of the material, heat resistance, the ability to stretch and resistance to tearing.

The highest durability is possessed by a vapor barrier made of artificial materials with a protective coating.

Cost. This parameter depends on the quality of the vapor barrier material and its mechanical properties, as well as on the geometric dimensions, and therefore it is necessary to correctly approach the assessment of the area and analyze how and how much material is required.

It is important to remember that a well-planned system of protection of building structures from various mechanical, weather and other conditions will guarantee its durability, and therefore it is necessary to approach these issues with due attention.

How to install a vapor barrier on walls and roofs

When installing building structures, for example, compound walls, it is necessary to take into account the peculiarities of the actual passage of steam through all elements. Otherwise, a situation may arise when the steam that has passed through several layers does not have time to overcome the next obstacle due to the obstacle that has arisen, and the next party props it from behind.

In such a place, steam will accumulate, its saturation will increase. At some point, at a certain temperature, it will reach a critical state and condensate will form at the border of the problem layers with the release of water.

In our example, we encountered a “dew point” formed inside a compound wall in front of the last exit layer, when an obstacle appeared in the steam route, restricting its exit and leading to the formation of condensation.

In practice, a similar situation often occurs when, from the outside of the building, its owner sheathes the walls with material with impaired steam conductivity: impregnated plywood, DSP, OSB, and there is no vapor barrier inside the wall or it is of very low quality.

As a result, it turns out that moisture is collected on the inner side of the outer skin due to condensation, and the adjacent layer of insulation - mineral wool or foam becomes constantly wet and ceases to fulfill its intended purpose. A dew point has formed on their surface.

The solution to such a technical issue can be accomplished in one of two ways:

- on the basis of theoretical knowledge and practical experiments, select building materials for each layer so that they exclude the formation of condensation in the overall structure of the wall and do not create obstacles for the passage of steam to the street;

- inside the rooms of the building, mount a vapor barrier and ensure its maximum tightness.

The first method requires high qualifications of workers and high-quality installation work, and the second is much simpler and consists in the fact that steam from living quarters is simply not passed into the walls and roof, but is removed through the ventilation system.

A layer of airtight vapor barrier mounted on the side of the room guarantees the absence of condensation inside the walls and roof.

This is the path taken by construction companies in Western countries, using one of two materials:

- aluminum foil;

- ordinary plastic film 200 microns thick.

Foil has the best vapor barrier properties, but it is more difficult to install. Therefore, polyethylene is preferred.

The vapor barrier layer must be completely sealed. Since the sheets of film need to be connected, builders use mainly two methods:

- installation of overlapping layers with overlap;

- gluing joints with special tape.

The first method is widely promoted on the Russian Internet. It's easier to do. But it does not provide complete tightness and steam can pass through the small cracks that have arisen and form condensation right inside the walls, which is very bad.

For this reason, you should use adhesive tape, seal all joints with it, seal openings for electrical wiring, pipelines and all household communications. Only then will the vapor barrier work effectively, blocking the ingress of steam into the wall materials.

A poorly executed vapor barrier causes the formation of a wet wall or roof, creating excessive moisture with all the negative consequences. You can still put up with it if the building is used for living during the summer cottage, and in winter it is idle without heating.

When people live in such a house all year round, the likelihood of condensation in the walls and the occurrence of dampness is very high. The amount of accumulated moisture can be measured in liters.