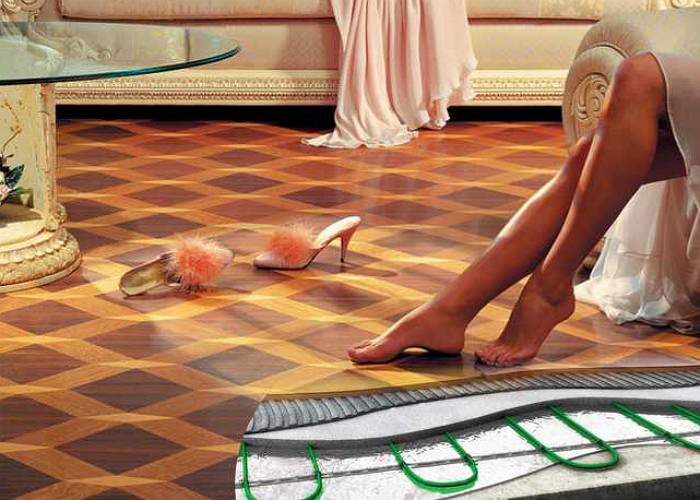

Is it possible to lay a warm floor under linoleum today raises a lot of controversy and questions. You can find a number of reviews and opinions that laying a warm floor under linoleum is impossible. However, there are several affirmative arguments and facts for all these opinions, which will be discussed in this article. We'll say right away that it is possible to put heating under this covering. The main condition is to choose the right linoleum for a warm floor. This is what this article will be about. You will also learn how to carry out installation work.

Is it possible to lay a warm floor under linoleum

You can lay a warm floor under linoleum. Moreover, there is a perfect technology for this. This is an infrared film field. If everything is clear with the choice of the heating element, then it is extremely important to learn the question concerning the linoleum itself. First of all, it should not be on a heat-insulating base. Otherwise, the heating efficiency will be reduced to almost zero. Moreover, it is extremely important to choose the right linoleum for its combination with a warm floor. Today there are many of its varieties, for example, PVC linoleum and the like. The market is filled with different types of linoleum.

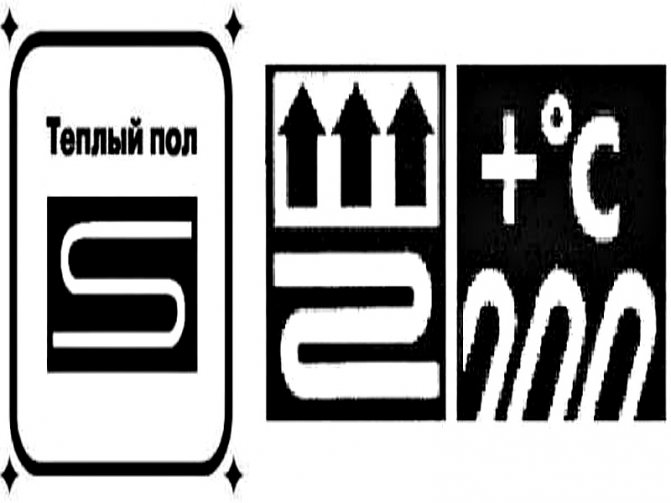

It is possible to lay linoleum on a warm floor only the one that is allowed for this by the manufacturer. On the packaging and in the technical passport for this material, the manufacturer must put a special sign indicating the admission of this product under linoleum. If you do not pay attention to this important point, then you can purchase an unsuitable linoleum. As a result, this will lead to the fact that, under the influence of high temperatures, it will begin to release formaldehyde into the air, a dangerous substance for people and pets. Moreover, the product will simply become elastic and break through.

Advice! When choosing linoleum, it is extremely important to pay attention to the safety class.

Moreover, a warm floor under linoleum is possible only if infrared heating is used as a heating element. This heating is the softest and most favorable. Now we will consider what kind of infrared heating is best to lay under this coating.

Types and features of linoleum

First, let's figure out the positive aspects of linoleum. Why do many people prefer to put it?

We recommend: How to install the warm floor on the boards?

Positive sides:

- it is convenient to clean rooms with linoleum;

- easy assembly and disassembly;

- resistant to pollution;

- long wear under the right operating conditions;

- repels water;

- certain species are resistant to high temperatures;

- affordable prices and a wide selection on the market;

- combined with other building materials;

Some people choose other coatings for the reasons that:

- color changes over time;

- the drawing is erased;

- does not withstand low temperatures;

- PVC linoleum has an unpleasant odor;

In order for the flooring to be of high quality and to serve for many years, it is necessary to understand its types and characteristics. Don't just be based on price.

Expensive material, in turn, can be bad when installed in the wrong conditions, just as cheap material can be good when used correctly.

Although in some cases it is better to overpay a little for quality than to ignore important characteristics, choosing cheaper and more affordable material.

Linoleum is divided into 3 classes at the place of operation:

- domestic.Withstands a small load, suitable for installation in residential premises;

- semi-commercial. Used in medium-duty commercial buildings;

- commercial. The most durable and thickest type of linoleum, is used in public institutions with a large flow of people;

With the classes sorted out. Now let's move on to the 5 main subspecies of linoleum:

- natural. Possesses increased fire resistance and resistance to electricity due to organic components in the composition. Eco-friendly and safe for both people and pets. Long-lasting and wear-resistant type of linoleum. Among the minuses - fragility during transportation, flooring requires a flat surface, unstable to moisture, expensive price;

- linoleum-PVC. Poorly tolerates high temperatures, deforms over time, flammable, unstable to substances with a caustic chemical composition, has an unpleasant odor. The material is definitely not suitable for a warm floor;

- alkyd (glyphthalic) linoleum. Fabric backed coating with added natural ingredients, which has increased the cost in the market. The products are endowed with increased thermal insulation and various designs. Cons - does not withstand temperature jumps, deforms over time, it is not recommended to transport in the cold season;

- nitrolinoleum (colloxylin). Single layer nitrocellulose based material. The small thickness has both pros and cons. The first includes light weight, flexibility, plasticity. The second - poorly insulates noise, heat, installation requires a completely flat floor, supports combustion, ignites without problems;

- rubber. Two-layer rubber-based coating. Ductility and moisture retention are guaranteed, and the rubber coating adds anti-slip properties. Antistatic, resistant to temperature extremes. Found application in public buildings, medical institutions, sports facilities.

We recommend: Features of the system "combined heating: warm floor and radiators"

The above types and their characteristics will help you make the right choice, based not only on the price, but also on the most important qualities of the material. It would also be a crime not to touch on the types of floor heating because in order to choose the perfect combination, you need to know the characteristics of both.

Which is the best IR heating

Making a warm floor for linoleum with your own hands is possible using infrared heating. There are two types of it: film and rod. Which one is the best to stack? Let's consider their features:

- If we talk about the budget option, then this is a film infrared heat-insulated floor. This heating element is best combined with such a coating. Thanks to the installation of a thermostat, you can set the most comfortable temperature, which will allow you not to spoil the linoleum. The heating process is carried out by radiation of an infrared beam.

- As for the IR rod heating, a composite material is used here. Flexible rods are built into thermocouples with busbars. They also radiate infrared heat. In contrast to the film floor, the rod has the advantage of using a self-regulating cable. That is, it regulates the floor heating temperature by itself.

Benefits of underfloor heating

Is it possible to lay linoleum on a warm floor system? The answer is definitely yes! The main thing is to take into account the peculiarities of this coating and choose the right equipment. We will talk about this in detail in this article, supplementing the instructions with photos and video materials.

There are no hopeless situations, especially if you study the numerous reviews. Underfloor heating under linoleum can be made using an electric heating system in the form of a film. What are its advantages?

- Installation on a wooden base and on a concrete floor;

- Ease of installation;

- Relatively low power consumption;

- Possibility of laying under linoleum.

Is thermal insulation needed

Installation of a warm floor under linoleum raises another question, which is associated with the installation of an insulating layer. Of course, you can't do without it. Thermal insulation is even needed if the warm floor is installed on a wooden floor. Wood can take up some of the heat energy, which will reduce the efficiency of the entire system.

The thickness of the thermal insulation layer must be at least 3 mm. There must be a layer of reflective film on top of the thermal insulation. It is good if the insulation immediately has a reflective layer. In this case, all heat energy will be directed up the room. As a result, the efficiency of the warm floor will be at a high level.

Important! When installing thermal insulation, it is unacceptable to leave any joints and gaps. The insulation is connected to each other with adhesive tape.

The easiest way

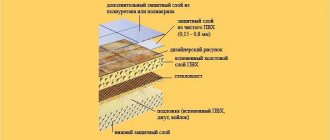

A thick backed material is suitable for lining a concrete base.

If you want to cover the concrete base of the floor, which is characterized by its cold surface in the shortest possible time, the best option would be to use linoleum with glued insulation.

This coating consists of 2 layers. Upper, decorative, made of high quality PVC coating, lower - heat-insulating lining.

Felt also serves as a floor leveler

The first layer is usually no more than 2 mm in thickness and is very elastic. In addition, it has a long service life and ease of maintenance.

The inner layer, made of felt or a bundle no more than 5 mm thick, serves not only to insulate the cold base, but also plays the role of an excellent leveler for small flaws in the plane.

The disadvantage is the lack of the ability to glue such a coating without violating the heat-insulating properties.

Underfloor heating installation technology

The principle of installing underfloor heating under linoleum is reduced to several successive stages. You can do all the work with your own hands and without the involvement of specialists:

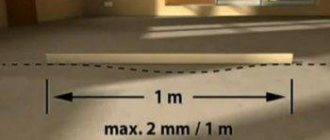

- First of all, the preparation of the base is carried out. You need to make sure that it is perfectly even. Among other things, the floor surface must be completely free of construction debris and dust. It is very good if you have a construction vacuum cleaner. They can be trained well. If the rough coating has obvious irregularities, then it is necessary to fill the screed. For this, you can use self-leveling mixtures.

- When everything is ready, the waterproofing layer is laid. Ordinary polyethylene can be used as waterproofing.

- A roll of thermal insulation is rolled out on top of the waterproofing. It is connected to each other with scotch tape.

- The next step is the installation of the infrared heating floor. The mats are laid out over the entire area of the heated surface. Please note that cutting the heating foil can only be done in the indicated places. In this case, the cut is necessarily insulated with bitumen insulation.

- The film is connected using special clamps. They are mounted on copper strips. The film is connected in parallel.

- When laying the film, it is unacceptable to overlap it. When doing this, make sure that the copper busbars are pointing upwards.

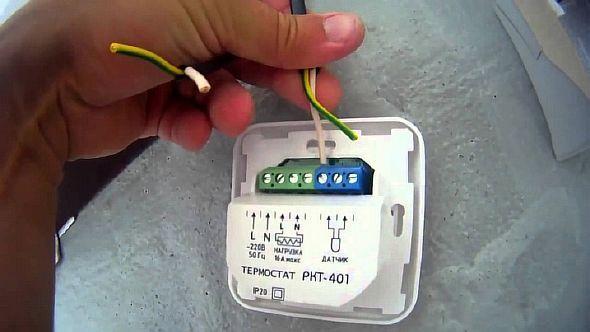

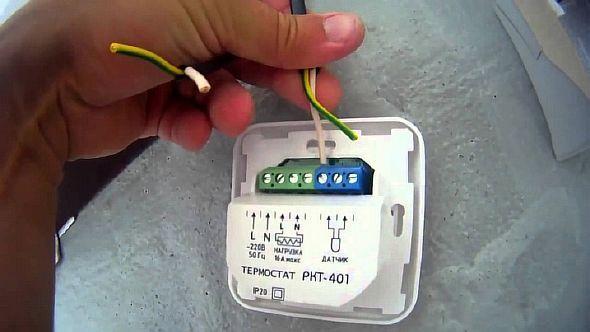

- The wire from the film is directed to the thermostat. The thermostat connection is carried out according to the scheme indicated on the reverse side of the thermostat.

- A temperature sensor is placed directly next to the heating element. Its installation must be carried out in a special corrugation. Due to this, if it fails, the sensor will be easy to change.

- As for the connection of the thermostat to the electrical network, it is best for this to draw a separate line to the electrical panel and install an individual RCD.

Before laying the finishing flooring material, it is necessary to carry out a test run of the warm floor. To do this, turn on the heating for 20 minutes. You need to make sure that all areas of the floor are heated. Also make sure that all connections to the films are properly insulated with bitumen insulation. If you find any malfunctions, then be sure to eliminate them. Failure to do so may result in a short circuit.

If everything is working properly, then you can start laying linoleum. Please note that PVC linoleum or some other of its kind is a relatively soft coating. It is very easy to pierce it with a sharp object, heel, etc. Therefore, before laying it, be sure to put plywood or other sheet material on the floor. Before that, lay polyethylene on top of the foil, which will exclude accidental damage to the heating element.

Advice! It is recommended to stick the infrared film to the base with tape. This will keep the heating circuit in place when installing the topcoat.

So, having laid plywood or other sheet material, you can start laying linoleum on the floor. The process of laying linoleum on a warm floor is no different from simple laying. Spread it all over the floor and leave it on the floor for about a day. During this time, he will acquire the required room temperature and straighten out. Then its flooring is carried out.

Underfloor heating cable systems

Coiled heating cable is supplied in polyethylene packaging or in a cardboard box. A distinction is made between shielded and unshielded cables, as well as single-core and two-core.

For the installation of underfloor heating systems, shielded cables are purchased. The following specifications are indicated on the heating cable packaging:

- power;

- length of cable;

- operating voltage, etc.

Based on the quadrature of the room, a cable of the required length and power is selected. The thickness of the electrical cable is 5-6 mm, so it is laid in the thickness of the concrete screed.

A reinforcing mesh is first laid on the leveled concrete floor, a cable is laid on it, fixed, and poured with a layer of concrete mixture.

The screed is leveled, dries, after which the linoleum or other floor covering chosen by the owner of the house is made.

The scope of delivery of the heating cable in the box includes installation instructions, corrugated tube, mounting tape with folding eyelets

Subtleties of heating cable installation

On the wall, at some distance from the floor (at least 30 cm), a place is selected for fixing the thermostat. This place should not be obstructed by furniture and other bulky items that make it difficult to approach the installed device.

A round hole is drilled in the wall, the diameter of which is calculated taking into account the dimensions of the thermostat. Two grooves are drilled from the round hole, into which the corrugated tubes will be embedded.

A sensor for controlling the temperature of the warm floor will be inserted into one of them, and the mounting ends of the cable heating section will be inserted into the other. Power is supplied to the installation site of the thermostat, while taking into account that the cross-section of the conductor of the power line must correspond to the current strength of the warm floor.

Debris is removed from the concrete floor with a brush or vacuum cleaner. The base base is treated with a primer, which increases the quality of its adhesion to the cement-sand screed laid during the installation of the underfloor heating.

Then mark the floor, indicating the areas on which the heating cable will not be laid.There is no need to install underfloor heating under plumbing fixtures, permanently standing furniture, household appliances, etc.

In addition, the cable is laid at a distance of at least:

- 5 cm from the walls of the room;

- 10 cm from other heating devices and devices.

The next step is to install thermal insulation throughout the room, if there is a cold room under the ceiling. Otherwise, it is enough to install thin thermal insulation only in the places where the heating cable is laid.

The sheets of rolled thermal insulation are attached to the concrete floor and to each other with foil tape.

After that, they proceed to the layout of the mounting tapes with hooks, necessary for quick fixing of the heating cable, rolled out with a snake with a step between the loops, calculated by the formula: the area of the concrete floor increased by 100 times, on which the cable system will be laid, divided by the cable length, taken in meters ...

The minimum laying step size is 8 cm. It is impossible to place the cable coils closer to each other.

The heating cable is laid in parallel loops, each of which is attached to a mounting tape laid at a distance of half a meter from each other

Laying of the cable underfloor heating should be started with connecting the mounting (“cold”) end of the heating section to the thermostat and fixing it on a tape with easily bendable loops and hooks.

From this place, they begin to lay out the section throughout the room, while the cable is laid evenly, avoiding intersections. The calculated laying step must be strictly observed.

The bends of the heating cable loops should be smooth and rounded. The presence of kinks and tension in the electric cable is not allowed. Couplings, like end couplings, must be located on the floor. Fix the position of the heating cable throughout the installation on mounting tapes.

The mounting ends of the cable heating section are led out to the thermostat and connected to it in accordance with the diagram indicated on the rear panel of the device.

Insert the temperature sensor into the corrugated plastic tube. Fix the tube itself exactly in the middle between the two turns of the cable. For fastening, use the same mounting tape to which you tie the tube.

Close the end of the corrugated tube with a special cap or wrap it with electrical tape so that the concrete solution does not get inside. The sensor should be located at a distance of 55-65 cm from the wall.

Bring the corrugated tube with the wire from the temperature sensor to the mounting box of the thermostat and connect it to the jacks indicated on the device connection diagram.

If necessary, the sensor can be easily changed without opening the floor by inserting a new element into the tube. After installing the sensor, the grooves are rubbed with cement mortar.

To test the functionality of the underfloor heating cable system, set the temperature on the thermostat to 26 degrees, and apply the mains voltage for one minute.

This time is enough to understand whether the cable is warming up or not. Disconnect the power supply. Sketch the layout of the underfloor heating cable, indicating on it the location of the main elements (sensor, couplings, etc.).

It remains to fill in a cement-sand screed or self-leveling self-leveling floor. To do this, dilute the solution in accordance with the instructions, apply it carefully to the cable system of the warm floor, allow time for complete drying and hardening, and then lay the linoleum on a substrate or without it.

Underfloor heating is ready to work.

Linoleum selection

Let's say a few more words about choosing linoleum for an infrared warm floor. First of all, there should be absolutely no harmful substances in the composition of this coating. Therefore, it is best to purchase natural linoleum, which is based on exclusively natural ingredients.According to a number of reviews, some types of linoleum do not withstand constant exposure to temperature. Because of this, the coating may wrinkle, as well as the formation of accordions that will no longer straighten out. This is due to several factors.

For example, when laying linoleum on a rod infrared floor, the temperature level will be automatically adjusted. You will not need to worry about adjustments. With regard to film heating, then it is necessary to set restrictions. For this purpose, a thermostat must be installed. So, it is unacceptable to heat linoleum more than 30 degrees Celsius.

Advice! As practice shows, it is best to warm up linoleum to a temperature of 27 degrees Celsius. This temperature will be sufficient to achieve the most comfortable operating temperature for the coating.

Plus, the flooring itself must be heat-resistant. For this, it should not be too thin or thick. Its thickness should be medium. Ideally, use a commercial grade that is equipped with a protective coating.

As mentioned at the beginning of this article, when choosing, be sure to pay attention to the designations from the manufacturer. The label must have a sign that allows linoleum to be heated. Only in this case it will last a long time and, plus everything, will not have a negative effect on health.

How to choose linoleum for underfloor heating?

Despite the apparent similarity, the linoleum on the market has different characteristics. It may differ in thickness, composition, structure, and in the presence of a reinforced base, the material from which it is made can also be different.

When choosing a floor covering, you should familiarize yourself with the information that is encrypted on the manufacturer's label. It contains data on the composition of the product, on the admissibility of its heating and the near-limit temperature. Linoleum must have:

- high thermal conductivity;

- good resistance to fading;

- resistance to deformation.

The main types of linoleum:

- Alkyd-type linoleum - definitely not suitable for installation on a warm floor. The product is equipped with a glyphthal polymer base. This species does not conduct heat well and can change its size over time.

- Colloxylin linoleum, which has a nitrocellulose base, is also not recommended for heated systems, as it has increased flammability. Even though it contains fire retardant boric acid, which partially reduces the risk of fire.

- Rubber - not recommended for heated floors. It has heat insulating properties, in addition, when heated, its structure changes, and destruction.

- The PVC model is the most ideal type for installation over a warm floor, it is durable and hygienic and environmentally friendly for use. The natural look - marmolium, is more expensive, as it consists of safe components: jute fabric, dye of natural origin, etc. The basic rule for use is that PVC heating temperature is permissible up to 30 degrees, and products from natural raw materials - up to 27.

Choosing PVC for underfloor heating, experts advise not to stop at the household type, but to purchase a commercial or semi-commercial model - they are more durable.

In this case, a heat-insulating substrate is not required, since it will reduce the efficiency of the system. In general, it is recommended to lay the product without a backing or with a small fabric backing.

Vinyl linoleum laid on the underfloor heating cable can immediately emit an unpleasant odor, but it will pass after a while.

Important! When buying a material, you need to pay attention to the manufacturer's markings, it speaks of the possibility of using it together with a warm floor.

Tips & Tricks

When choosing a heating method, it is extremely important to understand several important nuances.First of all, whether such heating will be primary or additional. When combining linoleum with infrared floor heating, it is allowed only as an additional source of heat. After all, you will not be able to warm up the coating to the required temperature, without damaging the material.

It will also be useful to look at a number of reviews that are left on the forums by those who use a similar heating system. In this way, you can learn from consumers. Well, the most important requirement is compliance with the sequence of installation work. This is the only way you can achieve a positive result.

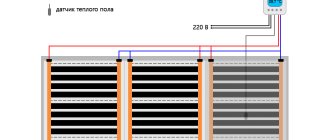

We make an infrared warm floor on concrete

Infrared film is the most suitable option for installation under linoleum. The main condition is a perfectly flat concrete base so as not to damage the film.

For your information! For the infrared film floor to work efficiently, it is necessary that the heat transfer process is one-sided. This is possible with different thermal conductivity of the materials located on both sides of the heating elements. The layer on top should have a higher heat capacity than the bottom one. If this condition is met, the efficiency of the infrared film will be 97%.

Having decided to put a heated film system on the concrete floor under the linoleum, you need to stock up on the right amount of film and additional material that will be needed in the process of constructing a warm cake.

Depending on the area of the room, the number of underfloor heating packages is purchased, which include: the thermal film itself, electrical wiring, bitumen insulation, a set of clamps and instructions for installing the structure.

In addition, for arranging a film underfloor heating, you will need:

- polyethylene film;

- heat-reflecting coating;

- scotch tape, knife, screwdriver, scissors;

- thermostat.

When installing an infrared system on a concrete base, it is necessary to choose the right linoleum. It should be made from natural raw materials, durable, waterproof, not static and not emitting toxic substances when heated. IR foil is not compatible with products with synthetic base.

The sequence of installation of an infrared floor under linoleum.

Step-by-step installation of a warm infrared floor is as follows:

- Preparation of the concrete base. The surface is checked for cracks and irregularities. If differences are detected, the base is poured with a small layer of self-regulating mixture.

- Determination of the location of the film and the enclosure. For this, markings are made on the floor, while it should be remembered that you cannot place the film under heavy furniture.

- Coating of a heat-reflecting layer. It can be used as a heat reflector - izolon or other product with a foil layer on a lavsan base. The material is spread on a concrete floor and fixed with double-sided tape, which also connects the sheets to each other. A product with a heat-reflecting layer must cover the entire area of the room, otherwise the heat will go in vain.

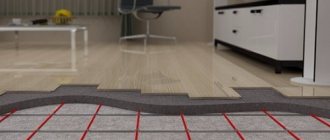

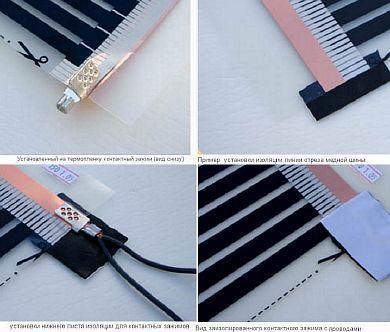

- Thermal film laying. The film, pre-cut into strips of the desired size, is laid down with copper plates. The tire cut points should be insulated with bitumen, it is sold in a set with underfloor heating. This must be done without fail, the silver contacts must be well insulated along the entire cut, and where the clamps will be installed for future fixing of the wires.

The recommended distance of the foil from the walls is 200 mm, the distance between the strips is 30 - 50 mm, it is impossible to overlap. And as far as possible, place the contacts closer to the wall where the thermostat will be mounted.

- Fixing the thermal film. The laid strips of film are attached to the heat-reflecting layer with adhesive tape. The strips are also fixed to each other, which will prevent their displacement in the future, when mounting the cake.

- Installation of contact clips.Clips are mounted at the junction of the copper bus and electrical wires. They should be positioned so that one side is inside the film and the other is outside. Then, the contact is tightly compressed with pliers.

- Thermal film connection. To connect the system, you need to put a bare wire or several wires into the clip, it depends on the design of the terminals. The contact is compressed to fix the wire in the clip. After that, all contacts are isolated. One layer of bitumen insulator is applied on top and the other on the bottom of the connection section. In addition, it is necessary to tightly glue the strips of insulation together.

Important! Silver contacts must be reliably insulated throughout the cut-off point, and in the wire-to-copper busbar connections.

- Connecting the thermostat. The temperature device is often sold together with a thermostat. The device is installed under a thermal film, it is fixed with an insulator to the graphite strip of the heating element. To make the floor surface even, a special recess is made in the heat reflector layer for the sensor, wire and clamps. After laying the wires in the prepared grooves, they are fixed with tape.

On the planned section of the wall, a panel for the thermostat is mounted. Wires are connected to it, in accordance with the diagram and instructions that are applied by the manufacturer to the heated floor.

After that, the system is tested. The temperature should not exceed 27 degrees. The heating of each strip is checked separately.

- Laying a protective layer under linoleum. Since linoleum is considered a fairly tough coating, it is necessary to install an additional protective layer for the heating elements. A polyethylene film is spread on the heating cake, on top of which a protective material is laid, for example, plywood sheets 0.8 cm thick. They are screwed to the main floor carefully so as not to damage the film. For this purpose, there are special gaps between the heating elements or along the edges of the film. The standard distance between fasteners is 150 mm. Also, a gap (0.1 mm) should be left between the walls and the plywood, which will be filled with a sealant with moisture resistant qualities. When it is dry, the dust is removed from it with a vacuum cleaner, and the plywood is treated with a primer.

- Installation of flooring. Linoleum is rolled onto plywood and left to age for several days. After that, the skirting boards are installed.

For your information! To make the strips of thermal film smaller, you need to lay them along the room.