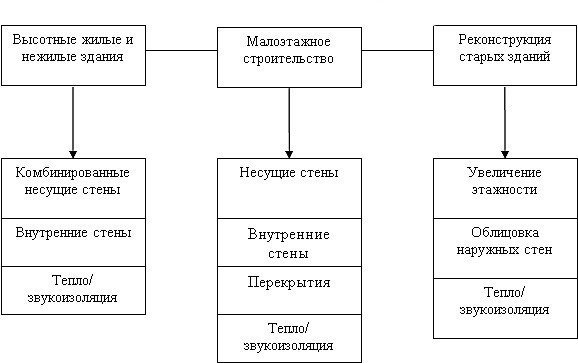

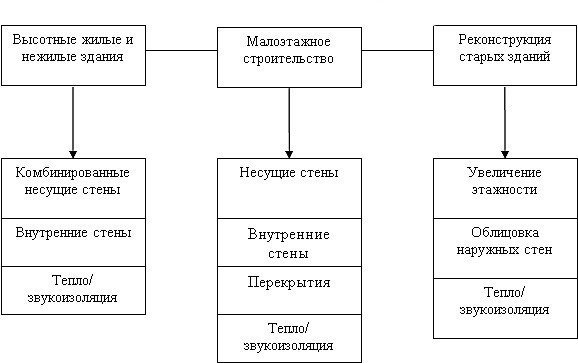

In what cases is it required to insulate aerated concrete?

When exactly should the aerated concrete wall be insulated? It is believed that if the blocks are 375 mm thick, then this is quite enough to keep the heat inside. For insulation, an outer cladding is sufficient; no additional work is required. In fact, everything is far from so simple. To avoid heat loss, it is best to use insulation. Work can be carried out both from the outside and from the inside.

Insulation is required in the following cases:

Scheme of wall insulation from aerated block.

- If aerated concrete blocks with a density from D500 are used for the construction of a house. This is a fairly high level of density, such blocks are used quite often in construction. Insulation is necessary for walls with a thickness of 300 mm.

- Insulation is required when, instead of a special glue, a cement mortar is used, which does not provide the necessary requirements for thermal insulation.

- If the seams are too thick, then thermal insulation work is not only recommended, but mandatory.

To insulate a house made of aerated concrete, materials such as:

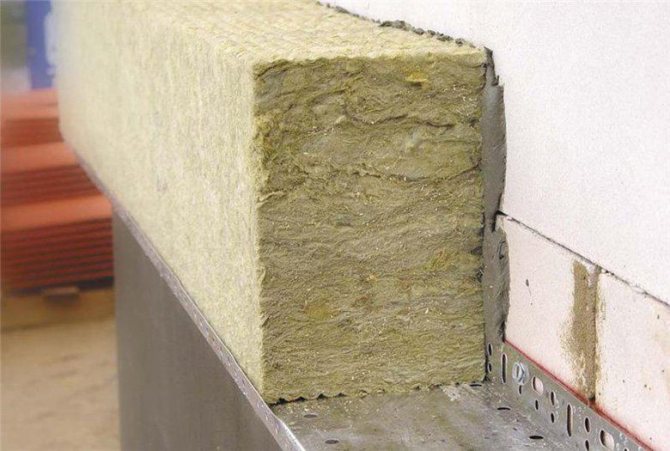

- Mineral wool is a material made from molten stone fibers. It is distinguished by its low weight, high quality insulation, simple installation. The cost of mineral wool is low, no experience is required for installation. First, the lathing is mounted, additionally the mineral wool is fixed with dowels. Surface

Insulation of aerated concrete walls outside and insideinsulation is closed with a waterproofing film.

- Styrofoam is also suitable as insulation. Such material can be used in the form of expanded polystyrene plates or polyurethane foam. In the first case, the material is laid on the wall surface as simply as possible, it is fastened using special dowels with hats in the form of an umbrella. After that, the surface is plastered. In the second case, it is necessary to use special equipment, since the material is applied under pressure in a liquid form. Such a coating has a low thickness with a high level of strength.

Types of plasters

There are several types of plaster that are suitable for the treatment of aerated concrete walls. There are certain requirements for the composition of the mixture for outdoor work.

- The material must be permeable and at the same time its coefficient must be higher than that of the treated surface - aerated concrete or a sealant.

- The plaster must be frost and temperature resistant.

- To prevent cracking, the applied layer must be elastic.

- The plaster must have strong adhesion properties with aerated concrete.

Calculation of the "dew point" for the walls of your cottage

On the Internet, you can find the relevant online calculators for building envelope heating technology. We recommend the following:

An example of calculation by reference: Region: Yekaterinburg, Sverdlovsk region; Premises: Residential; Construction type: Wall; Construction layers: Autoclaved aerated concrete D400, 400 mm thick (one layer, without finishing and insulation)

It is enough to select a region and enter information about the structure of the walls (in layers). Next, open the "Moisture accumulation" tab. If it appears that "The enclosing structure meets the standards for waterlogging" - that's it, the calculation is over!

Please note: when calculating the "dew point", the average temperature for the heating period is considered. In the Sverdlovsk region, it is about -7 ° С.If within a few days the temperature drops to -35 ° C, so much steam will not have time to pass through the wall, which will fill all the pores, the moisture will turn into ice, and the ice will "break" the material. Especially if the walls are made of Twinblock - its frost resistance (F) is 100 cycles.

The lower the temperature, the lower the humidity both outdoors and indoors. Thus, the likelihood of steam turning into water is low.

Summary: The dewpoint in the wall itself is not as dangerous as we are often frightened. Risks arise only from the accumulation of moisture in the walls during the heating period in general.

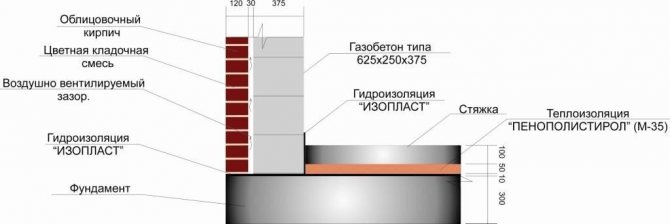

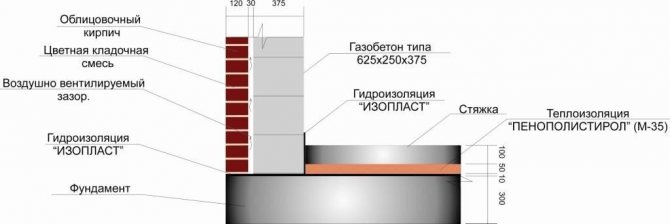

Two common ways to insulate outside

Builders often offer one of two methods of insulation: a plastering system, also called the "wet method", and a ventilated facade, also known as a dry method of insulation.

Wet facade

The plaster insulation system is as follows:

- outer wall;

- insulation;

- adhesive mixture with embedded alkali-resistant plastic mesh;

- facade finishing.

The method is good for independent execution, since it does not require a frame device and a high qualification of the performer, however, such insulation can only be carried out at positive air temperatures.

Ventilated facade

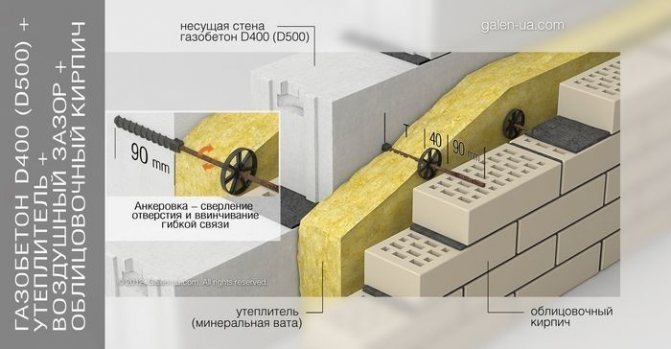

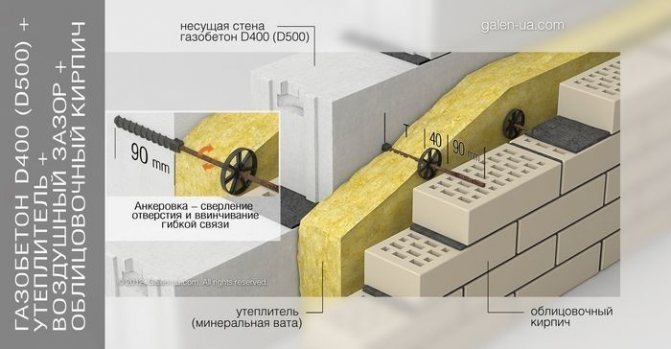

A ventilated facade is considered by professionals to be more reliable, giving more opportunities for home decoration. The insulation scheme is as follows:

- outer wall;

- supporting frame;

- insulation;

- wind and moisture protection membrane;

- ventilated gap not less than 40 mm;

- hinged facade.

To perform thermal insulation using this method, it will be necessary to build a frame with an accurate alignment of the facade surface, otherwise irregularities will be visible on the facade.

The ventilated facade gives more opportunities for outdoor decoration, work can be performed even at temperatures below minus 7 ° C, however, the contractor is required to have skills in using a construction tool.

Types of materials for insulation

Insulation of an aerated concrete house is performed by the following types of insulating compounds:

- mineral wool;

- penoplex;

- Styrofoam;

- polyurethane foam;

- vermiculite, etc.

Materials differ in technical characteristics (weight, density, composition), installation technique and cost.

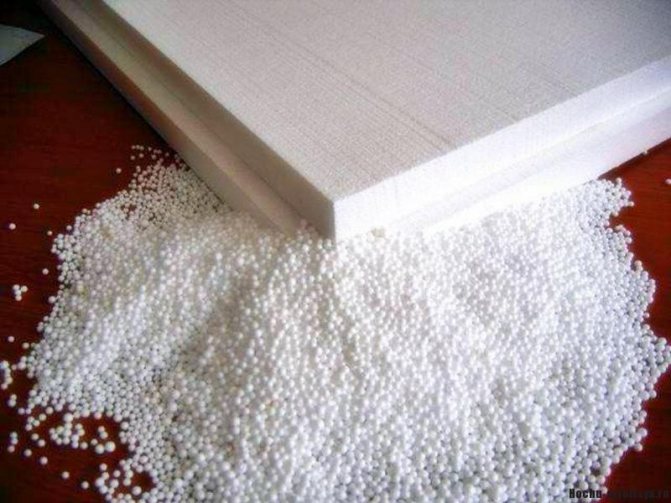

Styrofoam

Polyfoam is lightweight, easy to prepare and install. On the inside, the blocks consist of voids filled with gas bubbles that are formed during the manufacture of the composition. Polyfoam is suitable for the construction of residential and industrial buildings. The advantage of the material lies in its low cost, in the possibility of independent work.

Insulation of walls made of aerated concrete with foam is carried out subject to multilayer installation. Internal walls are finished with compounds with high thermal conductivity and high heat capacity. Polyfoam does not have the ability to pass steam, is suitable for internal work and is not used for external insulation.

Experts do not recommend using the material in regions with high humidity to prevent the appearance of rot and destruction of buildings.

In southern regions with dry air, foam can be used to insulate houses after preparing the wall panels. You will need to equip a ventilation system to prevent the formation of condensation on the walls. When designing a building, you need to take into account the large thickness of the foam blocks. The internal usable area of the building finished with expanded polystyrene will be reduced.

Advantage of finishing material:

- aesthetics;

- high degree of heat retention in the room;

- light load on wall panels and foundations;

- high sound insulation;

- resistance to biological organisms (mold, fungus);

- prevention of temperature fluctuations in the room.

Sequence of work

Installation of polystyrene is carried out on a special adhesive composition, similar to the solution for installing tiles. A layer of glue is applied to the wall, then an insulator plate is tightly applied to it and fixed with dowels with wide washers (fungi).

The installation of the material is done as tightly as possible, without gaps or gaps, which should be immediately filled with polyurethane foam, thin strips of polystyrene or the same glue on which the sheets are attached. After the entire area of the wall is covered with foam, a reinforcing fiberglass mesh is attached to its surface with brackets and a layer of plaster is applied.

You can use another type of installation, when a frame (crate) is pre-installed on the wall, in the slots of which pieces of insulation are tightly installed. Then sheathing is installed on the frame strips - lining, wall panels, sheet materials, etc. This method allows you to perform work faster and not get involved with "wet" solutions.

Penoplex

Thermal insulation of aerated concrete walls can be performed using foam. Extruded polystyrene foam is manufactured at elevated temperature and high pressure. It is necessary to take into account the high cost of the material.

Composition advantages:

- small thickness;

- high vapor barrier characteristics;

- the incombustibility of the composition allows you to prevent the development of a fire.

Sequence of work

Penoplex is installed using the same technology as the installation of foam... The only caveat in this matter is preference for "wet" finish, since the material is sufficiently rigid and capable of providing a solid and reliable support plane for the plaster.

Recommended choose material with corrugated surface, the plaster holds better on it, does not peel off over time and allows you to drill holes for brackets for hanging furniture or appliances. The dry method of installation is also used, although there is no reason to create a full-fledged lathing in this case - it is quite possible to get by with the installation of vertical or horizontal strips at a distance convenient for installing the cladding.

Mineral wool

Mineral wool is produced in the form of slabs or sold in rolls. The raw materials are fire resistant, have vapor permeable properties, high noise insulation characteristics, are made from environmentally friendly raw materials and are safe to use.

The period of operation of the composition is high, cotton wool is resistant to fungus and mold. When fixing, it is required to provide waterproofing, because the composition is permeable to moisture and can form condensation. When decorating a building from the outside with mineral wool, it is prohibited to use acrylic plaster, which will increase the formation of condensation.

According to GOST standards, the class of mineral wool includes 3 types of compositions:

- glass fiber;

- slag fibers;

- stone wool.

Materials differ in structure (thickness and length of fibers), resistance to stress, parameters of thermal conductivity and resistance to moisture, fire resistance.

Glass wool consists of long fibers up to 15-50 mm with a thickness of 5-15 microns. The material is elastic, durable, however, it requires compliance with safety standards during work and the use of protective clothing (gloves, glasses, respirator). The thermal conductivity of the material is 0.03-0.052 W / (mK). The permitted heating temperature is limited to + 450 ° C. The material has an average level of hygroscopicity.

Slag wool is made from the remains of blast-furnace production (slag). Its fibers are 16 mm long and 4-12 microns thick. The material has residual acidity and can negatively affect the metal in case of high humidity in the room.

Slag wool is distinguished by good moisture absorption, therefore it is used for interior work and is not suitable for decorating facade structures, water supply systems of a building. The material is fragile. The heating temperature is limited to + 300 ° C, the thermal conductivity is from 0.46 to 0.48 W / (mK).

Stone wool is similar in technical characteristics to slag wool, but it is not brittle and does not damage the surface. Cotton wool is easy to use and does not require complex protection during repairs. Mineral raw materials from mining rocks have a permitted heating rate up to + 600 ° С. The thermal conductivity of the composition reaches 0.077-0.12 W / (mK). Index of hygroscopicity of the composition of the average level.

Sequence of work

For installing mineral wool first, the crate is mounted with the thickness of the strips equal or slightly exceeding the thickness of the insulator. The step of the lathing is taken equal to the width of the roll or slab of mineral wool, so that it does not have to be adjusted to fit the frame nests. The material fits snugly between the slats, no gaps or crevices are allowed... If they do appear, they should be filled with polyurethane foam, for which the cylinder must be kept close at hand.

Over the installed mineral wool with horizontal stripes a vapor barrier membrane is laid... First, the lower strip is laid, fixed to the crate with a stapler, then the next one is overlapped by 10-15 cm - and so on to the very top. All joints must be additionally connected with special tape.

On top of the membrane in the transverse direction, the strips of the second layer of the frame are installed - counter bars... They are at least 4 cm thick (the minimum ventilation gap), after which the sheathing is installed on them.

Polyurethane foam

You can insulate a house from aerated concrete with polyurethane foam. The composition is applied to the panels using special high pressure spray equipment. Foam polyurethane can be used to cover an uneven surface, irregularities and cracks are filled with the compound, after which an even seamless coating is formed.

Spraying of raw materials is possible in hard-to-reach places. The advantage of polyurethane foam is good adhesion to the surface, there is no need to build a frame to insulate the facade.

When choosing polyurethane foam as thermal insulation, it is required to select materials for the interior decoration of the building that prevent the penetration of steam. Vinyl wallpaper materials, alkyd dyes, cement chip plaster, ceramic tiles, etc. are optimal as a composition for decoration.

Sequence of work

Before applying, you should prepare the surface... Remove all brackets, clean off layers, remove loose or peeled parts. The material can lie on damp (not wet) surfaces, but if there is ice on them, then it should be removed.

Installation of the lathing is performed only to create a supporting structure for the subsequent installation of the cladding, therefore, all requirements for it are due to the type and size of the outer coating.

For applying polyurethane foam special equipment is used... Usually, for this, specialists are invited with the necessary technique, experience and skills for such work. Self-application is not recommended, since it is necessary to know exactly the degree of expansion of the foam in order to ensure the correct consumption of material and create a layer of insulation of the required thickness.

Reinforcement of aerated concrete

Reinforcement scheme for aerated concrete walls.

A house built from this material, like any other structure, is constantly subjected to deforming loads.

Uneven shrinkage, soil deposition, temperature fluctuations and strong gusts of wind can lead to the appearance of hairline cracks, which do not affect the quality of the load-bearing walls, but worsen their appearance.

The reinforcement design should be prepared taking into account the basic requirements. For example, the structure of long load-bearing walls, which is constantly exposed to wind loads, which can lead to the formation of a crack on the wall, needs additional reinforcement.

The reinforcement should be laid in the armored belts specially designed for this, located on the surface of the bearing walls.

Expansion seams

Expansion joints, like reinforcement, protect the surface of the load-bearing walls from cracks. Places for such seams should be selected individually.

As a rule, such seams are arranged in places where there is a change in the height or thickness of the bearing walls, between the warm and cold surface of the walls, at the intersection of sufficiently long bearing walls, etc.

Expansion joints must be sealed with polyethylene or mineral wool. From the inside, such seams must be treated with a sealant (vapor-proof), and from the outside - with a weather-resistant sealant.

Next, the roof is erected. To do this, you should make its frame and lay the roof on it. But that's another story.

Fixing parts

The most convenient method of fastening parts is to lay the reinforcement during the construction of the walls. If the reinforcement was laid, then windows, doors, brackets and other elements are attached to the walls with special nails or dowels.

When drilling holes in aerated concrete masonry, it is not recommended to use a drill (percussion), otherwise, at best, cracks will appear.

It is imperative to insulate such a house. Insulation is carried out with mineral wool, followed by wet plastering.

What insulation is best for aerated concrete walls?

Cellular concretes differ from conventional grades in their porosity, hygroscopicity and high vapor permeability. Since it is necessary to follow the rule that requires increasing the degree of vapor permeability in the direction from the inside to the outside, it is possible to determine the best option for a heat insulator only knowing which side the installation will be made from.

If installation is planned outside, then the best option is stone (basalt) mineral wool, which has indicators that meet all the requirements.

For indoor installation, the best option is the minimum (ideally zero) degree of permeability to water vapor. In this case, both polystyrene and penoplex are suitable.

A good option would be polyurethane foam, although it is more difficult with it in living quarters - decorative finishing after spraying is more labor intensivethan when using other materials, it is easier to use penoplex.

Floor arrangement schemes on the ground in a house, basement, garage or bathhouse

In houses without basements, the floor of the first floor can be made according to two schemes:

- based on the ground - with a screed on the ground or on logs;

- with support on the walls - like a ceiling over a ventilated underground.

Which of the two options would be better and easier?

In houses without a basement, ground flooring is a popular solution for all rooms on the ground floor.

Ground floors are cheap, simple and lightweight; it is also beneficial to arrange in a basement, garage, bathhouse and other utility rooms. A simple design, the use of modern materials, the placement of a heating circuit in the floor (warm floor), make such floors

comfortable and attractive in value.

In winter, the backfill under the floor always has a positive temperature. For this reason, the soil at the base of the foundation freezes less - the risk of frost heaving of the soil is reduced. In addition, the thickness of the floor insulation on the ground may be less than that of the floor above the ventilated underground.

It is better to refuse from the floor on the ground if it is required to backfill with soil to a too high height, more than 0.6-1 m.In this case, the costs of backfilling and compaction of the soil may be too high.

The floor on the ground is not suitable for buildings on a pile or columnar foundation with a grillage, which is located above the ground.

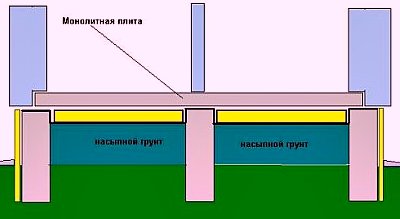

Three schematic diagrams of flooring on the ground

In the first option

concrete monolithic reinforced floor slab rests on load-bearing walls,

Fig. 1

.

|

| Fig. 1. Monolithic overlap on the ground (suspended floor) |

After the concrete has hardened, the entire load is transferred to the walls. In this variant a monolithic reinforced concrete floor slab plays the role of a floor slab and must be calculated for the standard load of the floors, have appropriate strength and reinforcement.

Insulation from the inside

If, taking into account all the advantages and disadvantages, you decide to insulate the building from the inside, it is important to remember the following nuances:

- Frequent replacement of the insulation layer is inevitable. This is due to the fact that condensation forms on the surface of the walls made of aerated concrete, which gradually destroys the wall and the thermal insulation layer.

- For high-quality insulation, you also need to install a waterproofing layer. We also need a ventilated layer to maintain the desired microclimate in the building.

But nevertheless, the internal insulation of the walls of the house is undoubtedly easier than the external one. Even if the building has many floors, it will be quite easy to use insulation. Moreover, it is not that expensive.

It is possible to insulate aerated concrete walls from the inside using the following materials:

Tile

Thermal insulation of aerated concrete with tiles inside.

Fired clay slabs that are square in shape. This material is often used for wall and floor cladding. Also great for insulation. It should be remembered that the installation of tiles minimizes the permeability of steam into the walls. But since the walls should "breathe" at least a little, it is recommended to lay tiles only in bathrooms, kitchens, and internal partitions between two rooms. You can also lay out colorful mosaics from the tile. They are best done in small rooms. It makes no sense to lay tiles on huge walls.

Drywall

The material is very practical and comfortable. It can be used both to decorate the walls of a building inside and for ceilings. For these criteria, it is divided into two types: for walls, the ideal thickness of drywall should be 12 millimeters, and for ceilings - 9 millimeters.

Drywall is still divided into other types. So you need to decide for what purposes you will use it in order to choose the one you need:

- Alignment and insulation of walls with drywall. It is best suited for rooms with high humidity, for example, a bathroom, a toilet.

- Flame retardant. Ideal for rooms where fire is more likely - boiler room, emergency exit, kitchen.

- Classical. Suitable for ordinary rooms and rooms. It is important to remember that it does not have moisture-resistant and fire-resistant properties.

- Combined. The best type of drywall, as it combines properties against moisture and fire.

This material is fastened quite simply - with self-tapping screws. Their length must be at least 25 millimeters.

Brick

The method of brick insulation will depend on the size of the room, but if you do everything right, the walls will be very strengthened and will serve you for several decades. Although brick, as a rule, is used to decorate the outer walls of a house, it is also excellent for internal insulation of aerated concrete walls.

How to choose the thickness of the insulation?

The thickness of the insulation depends on the climate in which the owner of the house lives. But still, you should not use plates from two to four centimeters, since they are not particularly useful. The thicker the insulation layer on the walls, the less you will have to spend on heating in the future. In addition, by choosing a thinner insulation, you will not save much.

A thinner layer will not contribute to better insulation, and is acceptable only for interior decoration.Then it is better not to take up the area of the room with a bulky ten-centimeter layer.

Features of the arrangement

First you need to dig a hole for the foundation. Next, a uniform slab is taken, on which there are no cracks, which makes up a single whole with the formwork, and is laid under the entire area of the future house. In the process of laying, it is necessary to apply at least 2 layers of reinforcing mesh.

- the optimal thickness of the slab (reinforced concrete) used for the foundation of low-rise buildings from blocks (aerated concrete) is 400 mm, 300 mm of which is above ground level, and 100 mm, respectively, below. Then drainage is arranged around the foundation and laid on a footing (a thin layer of concrete at the very base of the foundation) a pair of layers of waterproofing;

- then it is necessary to reinforce and fill the foundation slab. The frame should be created in the form of a solid structure that captures the blind area. The distance between the reinforcing bars should be no more than 300 mm;

- in order to avoid swelling of the walls and to prevent cracks from forming, the formwork must be rigidly fixed with leveling beams, tie bolts, and also jacks. To prevent concrete leakage, you need to attach polyethylene or roofing felt to the inner section of the formwork.

Aerated concrete threshold construction scheme.

Concreting is required to be done in layers of no more than 150 mm. The concrete should be leveled with a shovel and compacted with a bayonet. In order for the solution to fill all the voids, the formwork must be tapped from the outside.

The dismantling of the formwork must be carried out after the concrete has hardened, otherwise cracks may form. All cavities that have formed between the surfaces of the walls of the pit and the foundation must be covered with soil.

Do you need waterproofing and vapor barrier for the facade for aerated concrete?

Waterproofing and vapor barrier of aerated concrete walls necessary only for insulation from the insidewhen you need a reliable multi-stage cutoff of material from the steam contained in the indoor air of living quarters. In this case, no precaution will become unnecessary, except for the situation when liquid polyurethane foam is used. It itself is an excellent vapor-waterproofing agent; the use of additional layers is useless or even harmful.

If the insulation is done outside, no cut-off layers are needed between the wall and the insulation. There are exceptions here - it is allowed to install an insulating membrane between the wall and the mineral wool, if there is a real danger of it getting wet. In this case, there should not be any impregnations or primers, otherwise the steam will be locked in the wall and the result of insulation will be a slow destruction of the walls of the house.

Service life and other advantages of insulation

Life time mineral wool thermal insulation is 25 to 40 years old. Other advantages of this insulation include:

- environmental friendliness - in this case it is not relevant, because the insulation is outside and inside the "pie" of the wall;

- incombustibility, the material does not support combustion;

- absence smoke formation under the influence of open fire;

- low hydrophobicity, does not absorb moisture, but lets it out;

- low deformation, over time the insulation does not lose its shape;

- biological and chemical resistance, inertness.

The characteristics and quality of mineral wool depends largely on the manufacturer. Considered good mineral wool «TechnoNIKOL"," Rockwool "," Park "," Ursa ".

Pros and cons

Among the advantages of aerated concrete it should be noted:

- The density of the material, which varies in the range of 400-1200 kg / cubic meter. The use of elements for the construction of walls, which have a relatively low specific weight, makes it possible to increase the speed of wall construction several times.

- Moisture resistance. It is due to the porosity of the material.At a relative humidity of 60%, this parameter of the wall block remains at a level of approximately 5%. If the relative humidity of the air fluctuates between 90-95%, then a similar indicator of the material remains about 6-8%.

- The level of frost resistance of this material allows it to withstand more than 200 thawing and freezing cycles. This advantage allows the use of wall blocks for the construction of buildings in the most severe conditions.

- Increased resistance to biological influences frees structures (enclosing) from auxiliary antiseptic treatment. No accumulation of various fungi, bacteria or mold was observed inside the material.

- The increased fire resistance of the material characterizes the material in that aerated concrete is resistant not only to extremely high temperatures, but also does not burn.

- Such wall material is quite durable. Its service life is calculated for more than 100 years.

- Aerated concrete is very environmentally friendly. According to this parameter, the material is ahead of only natural material - wood.

Scheme of aerated concrete wall with insulation.

Like any other material for construction, aerated concrete also has disadvantages, which manufacturers try to tactfully keep silent about. Among them:

Since this material for the construction of walls is porous (i.e. breathable), then after a while of its use this leads to the accumulation of moisture in the pores, which is a prerequisite for decompaction, which at some point will lead to the destruction of the structure.

It is quite simple to deal with this drawback. It is imperative to provide for a fairly high level of waterproofing of the building;

Cracks can form on the material over time.

Aerated concrete blocks can be classified according to the following principles:

By the type of binder:

- lime binder;

- cement;

- slag;

- mixed (cement + slag or lime);

- ash.

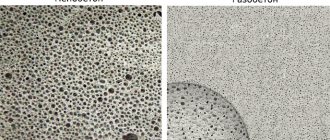

By the principle of hardening:

- non-autoclave;

- autoclave.

By appointment:

- thermal insulation (200-500 kg / m3);

- structural (1000-1200 kg / m3);

- structural and thermal insulation (500-1000 kg / m3).

Scheme of the production of aerated concrete blocks.

Having stopped their own choice on aerated concrete blocks as the main building material. it is necessary to first decide on the project of the building, its design and, of course, the layout.

In the project, it is required to designate all the main structural units in the house: the foundation, the roof rafter structure, the calculation of the roof surface, the number of floors with cuts, both window and door openings, indicating their reinforcements by means of jumpers.

It is recommended in advance to think over the finishing of the building made of aerated concrete. From this material, you can cut out various arches with your own hands, give rounded shapes to columns and openings.

Due to its absorbent surface, this material perfectly binds to various textured and figured plasters. That is why almost all design ideas in terms of construction and finishing of aerated concrete building are feasible.

Final points and recommendations

Gas silicate blocks are an excellent masonry material, however, it should be purchased from trusted manufacturers, with a certificate of conformity, so as not to waste money on low-quality handicraft material.

When performing work, it should be remembered that this material has low mechanical and impact strength, the use of a percussion punch tool is unacceptable.

Since the blocks have high moisture absorption, it is advisable to hydrophobize them with a special primer before gluing the insulation.

Finally - recommendations for those who build from aerated concrete:

- The most economical, quick-to-manufacture and comfortable-to-live construction of external walls is made of aerated concrete blocks of density D400 (D400).In our region, such blocks are produced only under the Twinblock trademark; - Build a house for permanent residence, - Twinblock D400 with a thickness of 400 mm will suit you; - Build a house for seasonal living, - Twinblock D400 with a thickness of 300 mm is optimal for you;

- Aerated concrete blocks cannot be placed on ordinary cement mortar. Only for special glue - mineral or polyurethane. Seam thickness - no more than 3 mm;

- Carefully control the quality of filling the seams (especially vertical ones) in order to prevent "wasteland";

- Do not use metal products that "pierce" a significant part of the wall thickness. For example, metal dowel nails for attaching insulation;

- Do not use PSBs foam and EPSP extruded polystyrene foam as insulation for external walls. For external walls made of aerated concrete of density D400 of sufficient thickness, insulation is not required at all;

- Use adhesives, plaster mixes and paints with a high vapor transmission value for exterior wall decoration;

If you follow these recommendations, you can not be afraid of the negative consequences associated with the "dew point". Its appearance is a natural physical process. The main thing is to take this factor into account when choosing a wall structure and observe the technology during construction!

Preparatory work

In order to build a house from aerated concrete blocks, a number of preparatory work should be carried out.

Reinforcement scheme for aerated concrete masonry.

- To begin with, it is necessary to transport aerated concrete to the construction site on special pallets, fixing it with shrink film. In order to prevent shifting, the pallets should be secured with straps. This must be done to avoid the possibility of damaging the blocks for the construction of the walls of the building.

- It is advisable to carry out work related to laying the material at an air temperature of +5 - +25 degrees Celsius. If the temperature is above the limit (+25 degrees Celsius), then the surface of aerated concrete blocks will have to be constantly moistened.

- In the cold period, for laying aerated concrete walls, it is necessary to use glue, which contains a special additive. This will allow construction work to be carried out at temperatures down to -15 degrees Celsius.

It is extremely important to provide lighting to the work site before starting work, prepare a place where the material will be placed, and bring equipment, inventory and tools to the site. It is advisable to bring the material to the construction site at least a week before the start of construction.

It is imperative to perform geodetic preparation and break the axes on the ground, indicate the absolute zero indicator of the horizon. You should also make the arrangement of the foundation under the surface of the walls and the indispensable waterproofing.