In this article, we will analyze in detail the installation of a warm floor for an ideal finish for a warm floor. Today, with all the richness of the choice of methods for building houses and the choice of building materials, a problem emerges: how can the beauty of the repair not be spoiled by the battery hanging on the wall?

Many have already realized that warm floors can help out in such a situation. That is why floor heating systems are gaining popularity today. It's beautiful, or rather, the underfloor heating system does not affect your interior in any way. Underfloor heating is economical. Heating costs are reduced by up to 50 percent. Warm floor is great. You can wear shorts and barefoot all year round.

About all the advantages of the underfloor heating system, you need to understand that everything must be done correctly. And it is wise to choose exactly the finishing coating for the warm floor. Since not all finishing coatings are suitable for installation over the underfloor heating system.

There are several types of basic flooring:

- Laminate and parquet boards, which have dimensions - 6-12 mm. The materials are laid on plywood or glue.

- Laminate flooring is another type of floor covering, the dimensions of which are 0.7-5mm in height. Does not require fixing, just lay on an adhesive base.

- Ceramic tiles are a type of coating that is used more in bathrooms. Product thickness - 5-12 mm. Fastened with glue.

- Carpet is a popular type of material where the pile thickness is 4 mm. The pile is made of fabric material, and the thickness of the main cover is 6mm.

- The parquet board has dimensions no more than 20 cm. The main boards fit well with glue.

Underfloor heating characteristics

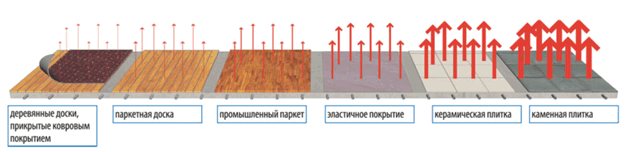

Since the underfloor heating system is a low-temperature heating system, it means that the finish coating must be able to quickly pass the low temperature through it. This is called heat transfer. Also, the finishing coating should be as natural as possible, which also affects heat transfer.

Another property that should have a final underfloor heating Is density. The denser the material, the better the thermal conductivity. This, of course, does not apply to artificial materials and materials of thermal insulation.

You can list the properties of the finishing material for underfloor heating systems for a long time. But for the first time, those three properties that I have listed above are enough to understand.

Now I want to analyze these main characteristics in detail and select the ideal coating for underfloor heating systems for them.

So, the first characteristic is good thermal conductivity. The best thermal conductivity will naturally be with the stone.

Now is the time to list those natural materials that we can use when finishing the final floor covering for underfloor heating systems.

Types of flooring and their thermal conductivity

In order for a warm floor in your home to please you, work for a long time and with maximum benefit, you need to choose the right floor covering. Finishing work in this case is of decisive importance, since mistakes made can negate all the advantages of a warm floor.

The materials for floor finishing produced today by manufacturers can be used as a covering for your warm floor. It doesn't really matter what material is used. Most floor coverings are practically compatible with heating. Differences can be in the structure of the base material and the thermal conductivity of the coating, which naturally affects the quality of the heating system.

Today the following types of floor coverings are used for the equipment of warm floors:

From natural raw materials:

- parquet board;

- industrial, technical parquet;

- laminate;

- wooden boards (oak, beech, ash);

- ceramic tile;

- porcelain stoneware;

Synthetic materials:

- linoleum.

All of the listed types of coatings and materials are available to the consumer. Only the price is different. In accordance with the physical properties and performance characteristics, the scope of application of each type is also determined. For living rooms, parquet, wood board and laminate flooring are perfect. For household premises, where there is high humidity and it is required to comply with sanitary standards, you can use linoleum, ceramic tiles and natural stone.

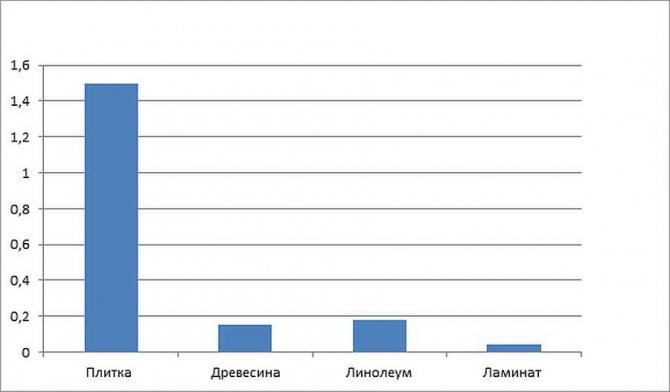

Different areas of use and operating conditions determine the effectiveness of underfloor heating. However, the decisive factor for the operation of the "warm floor" heating system is the thermal conductivity of the materials. The figure shows the thermal conductivity of all floor coverings used today in everyday life, which can be used in combination with hot water floors.

Ceramic tile. Natural and artificial stone coverings

In terms of thermal conductivity, one of the first places is occupied by ceramic tiles and other coatings made of natural or artificial stone. An example of the high efficiency of such floor coverings is the concrete screed itself. Yes, the concrete floor will have to be heated for a long time, but then, the concrete will perfectly keep the heat, giving off part of it inside the heated room. The same principle applies to ceramic tiles.

For reference: Warm ceramic tiles are ideal floor coverings for bathrooms, saunas and baths. In rooms with high humidity, tiled floors not only create additional comfort and coziness, but also perform an important sanitary function. The quick drying of the floor surface prevents the formation of mold and other pathogens.

It is important to take into account not only the good thermal conductivity of ceramic tiles and porcelain stoneware, but also their high heat capacity. For normal heating, you need a powerful boiler and a specific layout for the water circuit. Correctly selected step of laying the underfloor heating pipe will ensure uniform and stable heating of the entire surface of the concrete-ceramic floor.

Laminate and wood flooring

The most popular floor covering for living quarters is laminate. Today this material is very popular. The high aesthetic characteristics of the laminate, its practicality in use and the simple method of installation are captivating. Moreover, laminate is much cheaper than parquet board, although outwardly it is not much inferior to the original wooden covering.

Thanks to the manufacturing technology, the laminate has a dense structure, which naturally has a positive effect on the thermal conductivity of the material. Laminate flooring looks great and harmonious in living spaces and, if properly installed, can satisfy you in all aspects.

Important! Laminate flooring should only be laid on dry concrete screed. Otherwise, the lower surface of the material will absorb the remaining moisture, which will ultimately lead to disastrous results. As the tiles dry, the laminate tiles will begin to change their physical properties and shape. The coating will begin to "walk", creak and deform.

For laminate flooring, the permissible temperature for underfloor heating is 270C. This temperature is very comfortable for the human foot and has a positive effect on the condition of the floor covering.

Using underfloor heating in combination with a wooden board is not the best option. Natural wood has a low thermal conductivity, so the efficiency of a water floor in such a room will be extremely low.Under the influence of heat, the boards dry out faster, which naturally affects the strength of the floor and its aesthetic characteristics. The behavior of parquet in combination with warm floors can be summarized in a similar way. Expensive and luxurious appearance, which gives parquet to the interior decoration of the premises, will become an obstacle to the normal heating of the interior space.

Synthetic materials

Linoleum, familiar to us all, does not behave in the best way together with water floors. In practice, it has been noticed more than once. Different types of linoleum behave differently in combination with a heating floor, although some types cope with the tasks. What kind? Linoleum without insulation, on a smooth base has the necessary thermal conductivity, is resistant to heating and retains its shape for a long time.

On a note: use linoleum without felt insulation and foamed PVC. For a warm floor covered with thin linoleum, the optimum heating temperature is no more than 270C. Otherwise, under the influence of high temperature, linoleum can change color, become excessively soft and lose its shape.

It is strongly not recommended to use vinyl or PVC tiles for covering warm floors. These materials have a high coefficient of thermal linear expansion (CTE), which negatively affects their behavior at the time of heating. Remember the option with polymer pipes used in the communication system.

The most unsuitable material for water-heated floors, carpet. The material completely extinguishes the heat coming from below, interfering with the main action of the heating system.

Warm floor coverings made of natural materials

Such coatings include marble, granite, porcelain stoneware, ceramic tiles, tiles and so on. That is, any material with similar properties and characteristics will do.

Porcelain stoneware floor

Therefore, warm under the tiles is the most ideal and compromise option. Also, tiles or natural stone have additional advantages. This coating transfers heat quickly. Many people are familiar with this feeling of filling the whole body with warmth when you stand with your bare feet on marble with a warm floor system.

A fine finish of natural stone or tiles is easy to clean. He took a rag, brushed off the dust and that's it. It is very comfortable and looks beautiful and rich.

Tile floor

There is also such an important property of the floor heating as density. If we take, for example, natural dense marble and ordinary clay tiles, then the thermal conductivity of marble will be better.

The same applies, for example, to coatings such as parquet and laminate. If the parquet is made of dense types of wood, such as elm, then its thermal conductivity is lower.

At the same time, laminate is an artificially made material using natural materials. Consequently, the thermal conductivity of the parquet is better.

Now let's summarize a little. If you plan to install underfloor heating systems in your home, be it electric or water, then make sure that the finishing coating is made of natural stone, ceramic tiles or tiles to the maximum.

Infrared equipment

This type of underfloor heating is radically different from the water subspecies. Installation takes no more than one day. Moreover, most of the time is devoted to the competent distribution of zones that require increased attention.

The rest is done in a few hours. Simplicity of design does not mean availability of materials. Only suitable for IR heating:

- linoleum;

- carpet;

- tree;

- laminate;

- tile;

- parquet.

Of course, each has its own advantages. We all have something in common. Versatility due to the original production of quality materials with high thermal conductivity. The temperature of the warm floor rarely even reaches 21 degrees Celsius.

Usually everyone sets the standard 20. Correct setting will exclude heat loss. The insulating layer prevents moisture from entering, directs the radiation flow straight up.

Rapid warming up / cooling down implies temperature differences. Therefore, the material must initially be resistant to such things.

The room must be carefully insulated with appropriate substances. Then it heats up effectively by eliminating losses.

Of all the available coatings, only ceramic tiles are demanding to install. Preference should be given to models with self-adjusting rods.

Such mats are used even in places of high humidity. Some are successfully combined with porcelain stoneware. But you have to think about the heat-reflecting substrate. The total thickness of the warm floor remains at the level of 2-6 cm.

Features of soft flooring, laminate, parquet

An infrared warm floor, unlike a water one, is quickly repaired. Installation of a non-hard final coating excludes serious fixation. The only difficulty will be to ensure the required rigidity. The parameter is achieved by installing a protective layer. Even plywood or chipboard is suitable.

Then children / adults can even jump without fear of breaking the structure. After all, the material itself has some rigidity. And do not forget about the presence of a waterproofing layer. Hard polyethylene will eliminate even the smallest moisture from the carbon heater.

We recommend: Do you need a mixer for an underfloor heating?

The permissible thickness is 5-8 mm. This is quite sufficient with adequate protection. The mechanical impact is also extinguished by a special stacking device. That is, nothing is attached to the panels themselves. The additional layer has pivot points at the desired intervals.

Nuances are taken into account even at the planning stage. They are marked on the graph for the concentration of heat in specific places.

Laminate

It is a type of wood-based panel with fibers, which is distinguished by its high density. The main layer is a decorative protective film.

Before starting the calculations, all the details are clarified. In addition to the main coating material, cement mortar is considered, as well as insulation.

If the area of the room is 50 m², then the thickness of the insulation, laminate and mortar is 4/1 / 0.2 cm.

The layers under the pipes will also be of three types: concrete and two insulation. The thickness of the elements under the pipe is 22, 2 and 4 cm.

After choosing the average temperature of the heating medium, for example 40 ° C, the upward flow values will be 72 W / m², and the maximum floor temperature will be 26 ° C. These calculations allow you to determine which coating is best suited.

Linoleum is a tribute to the past!

Linoleum has long been used as a flooring material. As for its compatibility with warm floors, it is important to take into account the low coefficient of thermal conductivity. Therefore, in this version, it is used less often than the above technologies.

It is profitable to use linoleum for underfloor heating only when it is made of natural materials. If you heat the artificial linoleum material for a long time, then it will release harmful substances into the air.

Carpet

This is a type of floor covering that differs from other types in its softness. It is sold in rolls, where a drawing or a beautiful ornament may be present on each version.

The difference between installing carpet and laminate is already noticeable at first when it comes to changes above the pipe. In this case, only the flooring and cement mortar remain. Thickness - 4 and 1 cm.

The layers under the pipes remain unchanged because they are not affected by changes in the coating. The thickness of the concrete and two insulation materials is 22, 2 and 4 cm.

When calculating, set the same temperature as in the first option (40 ° C). After calculation, the upward flow has noticeably decreased - 60.1 W / m², and the maximum room temperature is 25 ° С.

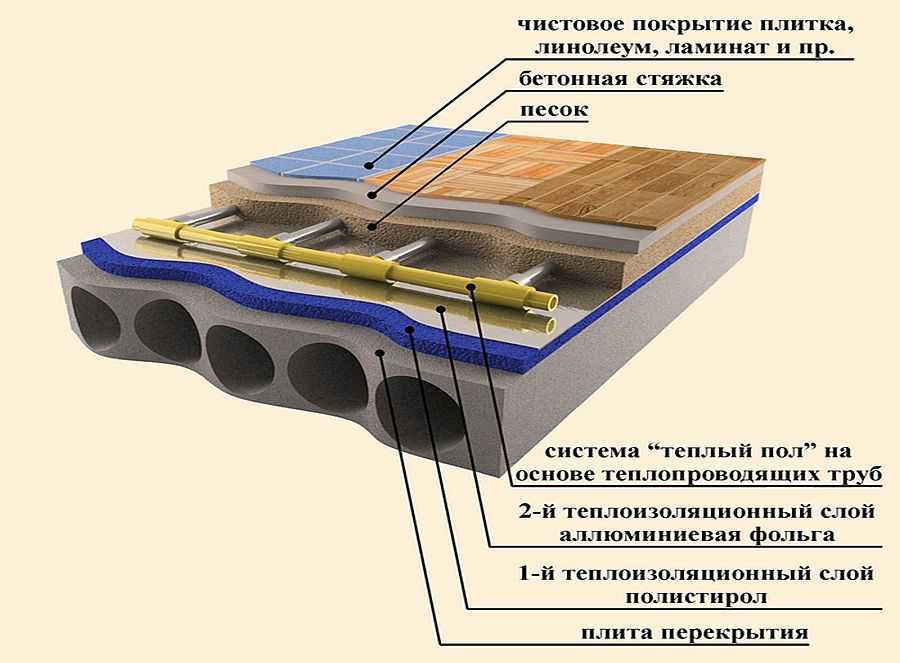

Features of a warm water floor

Underfloor heating (TP) on a water basis is a coil - a special design of pipes, the ends of which are supplied to the heating and hot water supply system. If we briefly describe the installation process, then the coil tubes are laid on the required floor area and poured with a cement screed or filled with special dry mixtures.

Further, in the usual order, the final finishing of the room is carried out, including the laying of flooring, for example, tiles, suitable in technical parameters for a device for a warm water floor and satisfying the wishes of household members.

The features of a water-based underfloor heating include:

- ease of installation - a plumber with average knowledge and little work experience can handle it, or the apartment owner himself, if he understands plumbing;

- no space restrictions - TP can be laid in almost any configuration, while making it double-circuit or more (this will require a plumbing comb);

- freedom in choosing a connection method - TP can be supplied to central heating pipes, to a common riser with hot water supply, to a gas or electric boiler;

- low cost of resources in comparison with electric TP or by blowing hot air from the ventilation;

- versatility - TP can be installed in almost any type of premises:

- safety and ease of use - just turn the tap and fill the coil with hot water, the floor will quickly warm up.

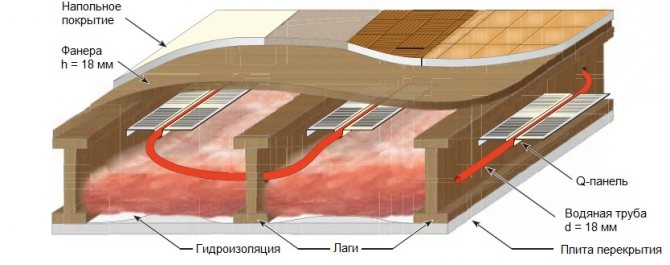

Parquet board

This type of flooring is made from different types of trees. Depending on the type of manufacture, it differs in different types. According to the established generally accepted rules, it is necessary to install additional insulation under this coating. Therefore, there are now three layers on top of the underfloor heating pipe, together with insulation, mortar and the main parquet, 4, 2 and 0.2 cm thick.

The layers under the pipe do not change (concrete and two insulation materials).

Parquet boards, like carpet, differ from laminate in their less effective thermal conductivity. Therefore, when the temperature is set to 40 ° C, the upward flow is 59.6, and the floor temperature is 25.6.

Wood products

If you do decide to lay boards, parquet or parquet on a warm floor, choose the densest wood. Even if it is a layer of only 3-4 mm of coverage, as in a parquet board. The less loose the wood is, the better it will transfer heat. You should not choose "capricious" varieties: they will crack or bend. For laying on a warm floor, "stable" species are more suitable: walnut, ash, oak.

Parquet or floor board can also be laid on a warm floor. But you need to choose non-capricious dense rocks.

For laying parquet on a warm floor, there are a couple of practical tips from practitioners:

- The boards should be small. Only in this case, the cracks inevitably appearing when the wood dries will be invisible.

- It is better to use a contactless installation method, rather than the traditional one on plywood. This makes cracking and warping less noticeable.

- If, nevertheless, it was decided to lay the parquet on plywood, then on the warm floor you need to glue small boards no more than 50 * 50 mm with one-component glue (the underfloor heating screed should be perfectly even). After the glue dries, this "mosaic" is sanded, and parquet is laid on top.

Boards on a warm floor can be used, but the best option in this case is a film infrared floor of increased power. This is if you put the floorboards on the logs: you will not achieve the adhesion of the heating element, but the high radiation power will warm up the solid wood well. Moreover, if you have a choice, buy a carbon film with a continuous spray, and not a striped one: in order to avoid warping of the material, its uniform heating is necessary, and a continuous coating copes with this better. The requirements for wood are similar: the hardest, non-capricious species that you will find.There is one more nuance: a massive board on a warm floor should be made from a very dry material of chamber drying (humidity not higher than 8%). This will minimize possible warpage or cracking.

Parquet or floorboard is not the best option, but possible

You can use a cable or water-heated floor under the board, but all this is very difficult: it gives uneven heating and the cracking will be more intense. To make it less noticeable, you can make a chamfer on the board - it makes the cracks almost invisible, but such a floor is much more difficult to clean.

Ceramic tile

This is a type of plate that is made of baked clay, which takes different shapes. Flat and rectangular views are popular. With the help of these squares, patterns are created on the flooring. This material does not require additional insulation, therefore, only mortar and tiles are used, in a thickness ratio of 4 to 0.8 cm, where the coating belongs to a lesser value.

The layers located under the underfloor heating pipe do not change, there remains concrete and two insulation (22, 2, 4 cm). If you set the average temperature of the heat carrier to 40 ° C, then the air flow will increase significantly to 107 W / m². The maximum room temperature rises to 29 ° C.

Choice of laminate

Not every type of laminate is suitable for laying on a heated floor heating. The coating that is produced for a traditional floor has a low thermal conductivity and is not suitable for our purposes. And we need those collections that are specially made thinner and denser for better heat conduction. They are marked accordingly: there is a pictogram on the packaging or in the accompanying documents, which indicates the suitability for laying on a warm floor. Moreover, a laminate for a water-heated floor is unsuitable for electric heating and vice versa. In order to be able to distinguish the system with which the laminate is "friendly", they use graphic images of water or an electricity icon, sometimes the chemical formula of water H2O is put on the coating for water systems, or the word "water" is written in English or German. ) and wasser (German). If there is no indication of the environment, but there is a sign of suitability for underfloor heating, then the coating is universal.

Look for pictogram icons when choosing a floor covering for underfloor heating.

What if there are no icons? You can, based on the technical characteristics, independently determine whether this coating is suitable. According to the recommendations of European building associations, laminate flooring is suitable for laying on underfloor heating, the total coefficient of thermal resistance of which does not exceed 0.15 kW / m2. Moreover, this is the total value for both the coating itself and the substrate. Therefore, the substrate for the laminate on the warm floor is selected from synthetic materials - they retain heat less than cork (popular for ordinary floors).

Pay attention to the formaldehyde content. It is, of course, standardized and tracked, denoted E0-E3. Under normal conditions, any grade up to E3 is safe, but only E1 or E0 are suitable for underfloor heating.

In order for the laminate on a warm floor to be safe, it must have an emission class of phenol-formaldehyde resins not higher than E1

Practitioners advise to select also the thickness of the laminate - it should be in the region of 8-10 mm. Then the coating will be quite reliable, and the heat will pass well. There are also different types of laminate connections - glue or thorn-groove type. Some people prefer glue, because they believe that the coating turns out to be more monolithic and does not form gaps in it. But the Click-type locking system (there is also a Lock) turns out to be no less reliable, and such a coating is laid faster and it is also more maintainable, which is important.

You also need to choose a laminate in terms of strength and abrasion resistance. Judging by the reviews, it is better to take class 32 and 33 or higher - traces of furniture, which necessarily appear on a less durable coating, do not remain on it. How strength and abrasion resistance are indicated, how to select a laminate based on these characteristics in different rooms - see the video.

Linoleum

This type of coating is made of polymer materials. In this case, no insulation is installed above the pipes of the warm floor, but only the cement-concrete mixture and the main coating, in a ratio of 4 to 0.2 cm.

For layers under the pipe, reinforced concrete and expanded polystyrene (22, 2 and 4 cm) are used.

When the temperature of the heating medium is set at 40 ° C, the heat flux also increases to 102. The maximum floor temperature is 29.2. This is a significantly increased value than in previous versions, except for ceramic tiles.

If we compare all coatings with each other, then at the same temperature in all rooms, the upward heat flux will be lower for parquet boards and carpet, which is explained by the poor thermal conductivity of these carriers. Linoleum and ceramic tiles have the highest flux and good thermal conductivity.

If the floor temperature is taken into account, the rating will remain unchanged. Parquet and carpet are heated up to 25 ° С, and linoleum and tiles up to 29 ° С.

The golden mean of this rating is laminate. The flow and temperature of the floor are closer in values to parquet and laminate (73 W / m² and 26.8 ° C. In general, it is most often used with a combination of water floor heating.

Opposite values are obtained for heat loss, when carriers with better thermal conductivity lose more heat than less conductive coatings.

Unfortunately, linoleum and tiles heat the floor above the allowed limit (26 ° C), so a larger installation step can be taken to eliminate this problem. Also, for this it is not necessary to set huge temperatures of the coolant, it is enough to reduce the values and the norms will be met.

The best coating option for an underfloor heating system is linoleum and tiles. After all, they are the most effective material, because the energy expended for heating will be much less if you lower the temperature and bring the values back to normal.

Such conclusions help to save more on electricity if you install linoleum and tiles.

Preferences given

It is always best to start the choice between floor heating systems by studying the water type. He shows one of the longest paths. But it implies great opportunities.

Not to mention the simplicity of design, long service life, a huge number of methods used, and a variety of materials for the final coating.

Installation in buildings / apartments with neighbors from below will become a challenge. Even one incorrectly positioned element will lead to flooding.

Electrical options have their own advantages. But they are used according to a certain algorithm. If in the case of the cable there is still a concrete screed, then the IR radiation does not have such protection.

But it heats up / cools down quickly. Easy to repair. Of course, it is better to give preference based on personal interests.

- Similar posts

- How is xl pipe underfloor heating installed?

- How to install a water-heated floor?

- How are PEX pipes for underfloor heating connected?

- Do you need a mixer for an underfloor heating?

- How to install Energy underfloor heating?

- How to install an electric underfloor heating under the tiles?