Traditional heating batteries are gradually becoming a thing of the past. And when choosing a heating system for a new city apartment or a country cottage, many prefer a warm floor. This design is more comfortable and invisible, in contrast to conventional radiators.

There are electric and water heated floors. Due to rising electricity prices, the latter option is most often set. But before you buy pipes for a warm water floor, you need to know which type to give preference to. This article will tell you which pipes are more suitable for the underfloor heating system.

Varieties of pipes depending on the material of manufacture

To understand which pipe to use for a warm water floor, you should consider the main varieties. This is how copper, metal-plastic, polypropylene and cross-linked polyethylene products are produced.

Copper pipes

The copper line is recognized as the best material for organizing water heating systems. It is copper pipes that are considered the most durable. But, besides this, this type of pipeline has a lot of other advantages.

Among the main advantages of this metal:

- High wear resistance. The material does not deteriorate under the influence of aggressive media.

- Excellent thermal conductivity.

- Flexibility. Typically, annealed copper tubing is used.

- Durability. Copper floor heating will last for decades.

The main disadvantage for users is that prices for copper floor heating pipes are very high. Although, given the long service life, the cost is quite justified. The disadvantages of highways made of this material include the fact that special equipment is needed for installation. Therefore, it is unlikely that you will be able to carry out the installation yourself. The work must be done by a professional.

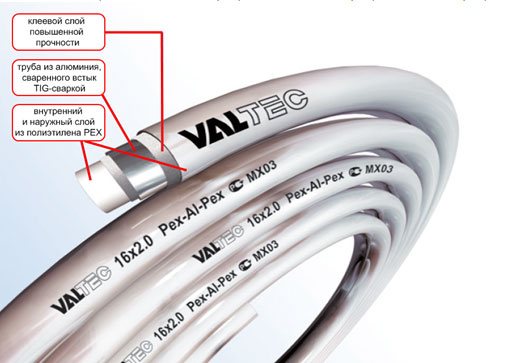

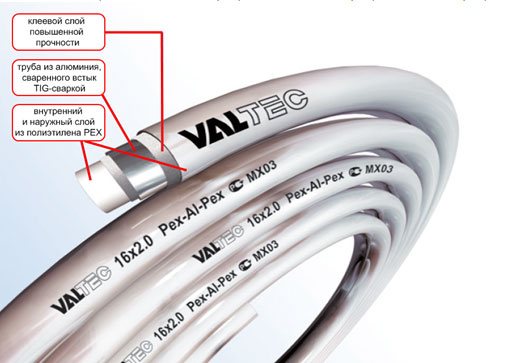

Reinforced-plastic pipes

The metal-plastic pipe for underfloor heating, consisting of two layers of polymer with an aluminum interlayer, is also very popular. Pipes made of such material are most popular with owners due to their affordable cost, as well as a number of other advantages.

The product has the following advantages:

- Good thermal conductivity. This is achieved through an aluminum interlayer.

- The structure is reliably protected from various kinds of damage thanks to polymer layers.

- Availability. It should be noted that the price of a metal-plastic pipe for a warm floor is quite acceptable.

- Installation is simple enough. The pipeline bends well. Therefore, it is very convenient to use this material in the system of water floors.

- The coefficient of casting expansion of metal-plastic is low. And this prevents wear of the line, the destruction of the screed.

Of course, in comparison with traditional plastic or copper counterparts, metal-plastic pipes have better characteristics. Therefore, many sellers, when asked by the client, which is the best pipe for a warm water floor, answer that it is made of metal-plastic. But here it is important to remember that the operational parameters of these products strongly depend on how high-quality adhesive component was used. Manufacturers, on the other hand, often try to save money on the adhesive composition.

Polypropylene pipes

Polypropylene pipes are cheap. But they are rarely used for floor heating equipment. In terms of thermal conductivity, the product is similar to metal-plastic lines. But it has poor elasticity. Such pipes can be bent no more than 8 radii. And for the heat supply system, this is a significant drawback.

XLPE pipes

A cross-linked polyethylene pipe for underfloor heating, which has a number of positive characteristics, has proven itself quite well. For example, the product is highly durable, does not wear out, is not afraid of scratches, does not crack, and is resistant to temperature extremes. Of course, the quality depends a lot on the degree and method of stitching.

Good cross-linking density of polymer lines ranges from 65 to 80%. The higher the density of the product, the higher the quality and durability. Accordingly, the price of a cross-linked polyethylene pipe for a warm floor will also be higher. Oxygen bed pipes are an excellent choice.

Also noteworthy is the pe rt pipe for underfloor heating systems, which has increased heat resistance, has an oxygen barrier made of ethylene vinyl alcohol. The product is characterized by a high level of protection against mechanical damage.

Types of pipes for a water-heated floor

Pipes for underfloor heating can be divided into two groups:

- Metallic.

- Polymeric.

The second group also includes pipes with a metal screen.

Metal pipes

Copper pipes... This is the most expensive but also the most proven type of pipe. They have a number of undeniable advantages:

- Excellent ductility.

- Highest thermal conductivity.

- Inertia.

From these data follows the ability to tolerate freezing, lay with a small bend radius (from 4 ᴓ pipes), and most importantly, the ability to use pipes with a smaller diameter. After all, copper has the highest thermal conductivity. The only drawback of copper pipes is the price. 1 r.m. pipe ᴓ 12 mm, costs about 200 rubles. There is a variant of using a copper pipe in a polyethylene sheath. Its price is 12-15% lower. Additionally, when using such pipes, protection against stray currents is required. But if everything is done correctly, then your grandchildren will walk on this warm floor in old age.

Corrugated stainless steel. These pipes appeared on the market relatively recently, about 10 years ago, and have very little distribution. But nevertheless, they have earned a decent reputation for themselves. They also have high thermal conductivity and unique flexibility (bending from 3 ᴓ pipe). And what is important, there are no fakes on the market yet, because the process of their manufacture is too complicated. Their cost is almost two times lower than that of copper pipes. A high-quality corrugated pipe for underfloor heating made of stainless steel from the leader of this market segment "KOFULSO" will cost 80-85 r / m. at ᴓ15 mm. If you do not take into account the relatively high price, then their only drawback is the need to arrange protection of the water floor heating circuit from electrochemical corrosion.

Polymer pipes

Due to the fact that the coolant in the underfloor heating circuit should not be heated above 30 ° C, we will not pay attention to the operating temperature range.

Polypropylene pipes... There are three modifications available:

A. PPH = homopolymer;

B. PPB - block copolymer;

B. PPRC is a polymer of propylene and ethylene.

Only PPRC pipes with continuous aluminum foil reinforcement are suitable for a high-quality water-heated floor system. And here are the reasons. Continuous reinforcement eliminates gas permeability. And this is a very important parameter. Basically, perforated reinforcement was introduced by Turkish manufacturers to facilitate the welding process. And fiberglass reinforcement does not in any way affect the gas permeability parameter. Particularly attractive in PPRC pipes is the affordable price ≈ 50r / m (ᴓ20 mm). Although it is higher than PPH and PPB pipes.

But propylene pipes have a huge disadvantage - elasticity. It is possible to bend these pipes only on special equipment, while the bending radius is 8 ᴓ of the pipe. Also, polypropylene pipes have very low thermal conductivity. That is, the transfer of heat from the coolant to the screed will be extremely slow, which will increase the inertia of the system.

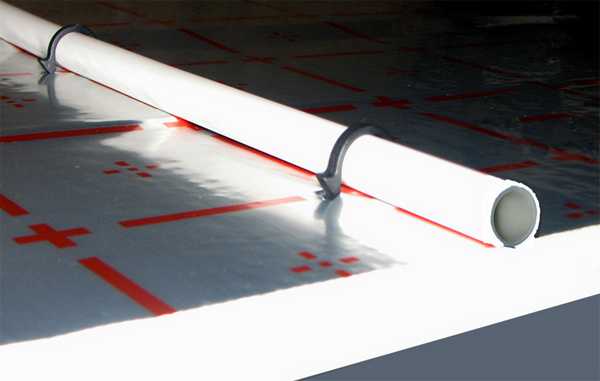

Reinforced-plastic pipes

For the price, they are the most affordable.And according to the guaranteed service life, the most short-lived. Quite comfortable when you take into account ease of installation, low oxygen permeability, small bending radius (6 ᴓ pipes). But all this applies to branded metal-plastic pipes. And the market is now just replete with fakes. Here are a few points to look out for when buying:

- The inner and outer layers of the polymer are of the same thickness;

- The armature is located strictly in the center;

- The foil is butt-welded!

- Clear and legible inscription on the pipe indicating the batch number, manufacturer;

- Buy goods in reputable stores;

- Ask for a quality certificate for this particular batch of pipes.

IMPORTANT: These requirements apply to all plastic pipes.

Polyethylene pipes

For the organization of warm water floors, only two types of polyethylene pipes are suitable:

- PERT;

- PEX.

These pipes are made from the same monomer, ethylene, but with a different approach. In the manufacture of PERT pipes, during the polymerization process, microscopic fractions of saturated hydrocarbons with the number of carbon atoms from 7 to 10 are added to the reaction mass. This leads to the formation of cross-links between the layers of oligomers.

The same effect can be achieved in an already finished product if it is irradiated with a powerful flow of electrons (PEXc) or treat with chemicals at elevated pressure (PEXa, PEXb, PEXd). With this approach, PEX pipes are obtained. The subscripts indicate the different reagents used to form additional bonds.

In terms of their properties, these pipes are approximately equivalent, but the advantage is still for PERT. After all, its properties are innate, not acquired. Guaranteed service life from 80 years. They are not afraid of freezing, chemically inert, and relatively easy to weld. Their only drawback is their rather high elasticity. Therefore, they require a secure fit when laying on the floor. Price for 1 running meter of pipe ᴓ 20 mm: PEXc - 70 rubles, and PERT - 85 rubles.

Important: when choosing polyethylene pipes for a water-heated floor, pay attention to the presence of the marking "EVOH" (oxygen-tight membrane).

Existing nuances when choosing a product

So, the main line for organizing the heat supply system can be used of different types. But how to choose pipes for underfloor heating, which ones are best suited? The answer depends a lot on the consumer's budget. And also from the forecasts of living in a particular house.

If the building is reliable and no move is planned in the coming decades, it is advisable to stay with copper pipes.

Yes, they are expensive. But having laid such communications, you can forget about the need for repairs, replacement of system parts. If the budget is small, then you can buy a pipe for a warm floor made of metal-plastic. For the installation of such products, special equipment is not required. And the consumption of materials is minimal. The choice also depends on the type of coolant used. So, if antifreeze is supposed to be used, it is better to purchase pipes made of cross-linked polyethylene or polyethylene of a heat-resistant class. These options are highly resistant to the influence of aggressive environments.

Below are tips on how to choose a pipe for a warm floor so that your purchase in the future does not disappoint:

- Preference should be given to options with the maximum level of heat transfer. This indicator affects how well the apartment will be heated.

- Strength is also important. The higher it is, the more pressure the pipe can withstand. Strength also affects the ability of the product to work properly at high temperatures.

- It is necessary to pay attention to the minimum radius along which the pipeline can be bent without damaging it. The good flexibility of the product makes the installation process much easier.

- The pipe must have a low coefficient of expansion.Quality depends on it.

- It is important that the product is environmentally friendly and does not emit toxic substances. And also had a long service life. The pipe is filled with a screed. And it will be very expensive to replace it. Yes, and troublesome. Therefore, durability is a very important parameter.

Of course, it is up to the consumer to decide which pipe to choose for a warm floor. But, taking into account the above recommendations, it will be much easier to choose a high-quality and durable product.

Selection options

Pipes for a water-heated floor used to create a system must meet certain characteristics. Without taking them into account, installation is difficult, and the system may not meet expectations. The choice of a pipe for a warm floor is carried out after determining the power of the system. This is necessary in order to navigate in the diameter, which correlates with the flow rate of the coolant through the system.

When choosing a pipe for a water-heated floor, the following parameters are used:

- Materialfrom which the pipelines are made. The physical and mechanical characteristics of the system, installation features and the possibility of application in specific conditions depend on it.

- Diameter... The speed of movement of the coolant depends on it, as well as the hydraulic resistance, which directly affects the choice of the pump. The diameter of the pipe for underfloor heating, which is most often used in practice, is 16, 20, 25, 32 mm. In most cases, 16 or 20 mm is sufficient.

- Heating agent operating temperature... This parameter is important not only for heat engineering calculations, but also for determining the suitability of the pipe. Each type of pipeline has operating and short-term maximum temperatures at which its characteristics do not change.

- Maximum pressure... Since underfloor heating is used not only in private houses, but also in multi-storey buildings, in some cases high pressure is required for work. Typically, in private houses, pipelines are designed for pressures up to 6 bar, and in multi-storey ones up to 10 bar. In addition to the material itself, the pressure depends on the wall thickness - 2.0, 3.0, 3.5 mm.

If most of the described characteristics depend on the parameters and features of the system, then the choice of a specific material is more influenced by the preference of the installers or the customer, as well as the price factor.

How much will it cost to buy pipes?

For many users who are planning to buy a pipe for a warm water floor - the price is a decisive factor in the purchase. But here it is important not to chase cheap models from unknown companies.

Prices for pipes for heating systems depend on the production technology, material used, product diameter, country of origin, brand.

And really high-quality communications are unlikely to have a low cost. The product is not purchased for a year or two. And frequent repairs will be very expensive for the owner of the house. Indeed, in addition to buying and replacing individual parts of the system, you will also have to dismantle the floor covering. Therefore, deciding which pipes are better for a warm floor - the price should be of secondary importance.

On average, communications for a warm floor cost at least 70-80 rubles per square meter. Copper models are considered the most expensive. So the price of a copper pipe for a warm floor is from 500 rubles per meter. Therefore, copper communications are used extremely rarely, in cases where it is necessary to create a high temperature or high pressure in the circuit.

What pipe diameter to use for a warm water floor.

Almost always, before starting the installation of a warm water floor, the question arises about the diameter of the pipes that need to be used.

Table of pipe diameters for underfloor heating

For laying a warm floor, pipes with a diameter of 16 and 20 mm are used.

Almost always, the circuit is laid with pipes of 16 mm.

Pipe diameter 20 mm. it is necessary to lay in areas over 100-120 mm.

Pipes with a diameter of 20 mm. used in cases where the warm floor will be the main source of heat.

Review of popular manufacturers

Today the heating equipment market offers various types of pipes from different manufacturers. Let's consider the most popular options in more detail.

Valtek

VALTEC multilayer metal-plastic pipes are very popular. The product is made on the basis of cross-linked polyethylene technology. The material is highly resistant to mechanical damage and has high temperature resistance. The degree of hydraulic resistance is quite low. Pipes are not subject to corrosion. Electrically inert. Service life exceeds 50 years. The price of the product is about 60 rubles per meter.

Rehau

Rehau is one of the leading companies in the market for the production of pipelines for water-type systems. The company uses cross-linked polyethylene and polypropylene as a material. The pipe for underfloor heating Rehau has high quality standards and unique properties. The product is highly durable, absolutely safe. Also characterized by resistance to temperature fluctuations. After deformation, the product is able to restore its original shape and all parameters. Resistance to corrosion and scale can also be attributed to the list of advantages inherent in pipes of this manufacturer.

In addition, the price of Rehau pipes for underfloor heating is quite acceptable for most consumer groups - about 90 rubles per meter. Of course, it all depends on the diameter, wall thickness. So a product with a diameter of 20 and a wall thickness of 2 mm will cost the buyer about 110 rubles per meter. But the Rehau 16 pipe for a warm floor will already cost a little cheaper: about 75 rubles per meter.

Giacomini

The pipes of the Italian company Giacomini are also quite popular. Products are manufactured from cross-linked polyethylene. The pipes are characterized by excellent flexibility. And thanks to the smooth inner surface, the likelihood of scale or build-up is minimized. The communications of this brand are quite durable: subject to proper installation, they can last more than half a century. In addition, the price of a tube for a warm water floor is very affordable: only 45 rubles per meter.

Of course, there are many more affordable Chinese-made models on the market. But it's better not to buy them. Products of little-known companies are also not worth choosing. The first criterion when choosing should be quality.

How to calculate the flow rate of a pipe?

On average, the consumption of a floor heating pipe per 1 m2 is 5 running meters of the product. This method is considered the easiest. Knowing the area of the apartment, you can simply calculate the required number of pipes. You can determine the required number of pipes for underfloor heating equipment using a special formula. To do this, you need to know the laying step and the area of the room. The area should be divided by the laying step and multiplied by the pipe stock per bends (1.1). Also, when calculating, it is important not to forget to add the number of meters from the floor to the collector and back.

If there will be dimensional equipment, furniture in the room, then it is impossible to lay pipes under these objects. As a result, the area will shrink. Also, about 20 cm should be retreated from the walls. All this must be taken into account when calculating the total area of the warm floor.

Thus, there are three types of pipes that can be used when organizing a water-type floor heating system. The best option, of course, is considered to be copper communications. But their cost is extremely high. Therefore, if it is not planned to create high pressure, high temperature in the circuit, it is recommended to use metal-plastic products or pipes made of cross-linked polypropylene.

Having decided on the material of the pipes, you should calculate the required amount of the product. This is quite simple to do, because there is a special formula.You can install communications for the underfloor heating system yourself. The main thing is to have skills, experience and clearly follow the instructions.