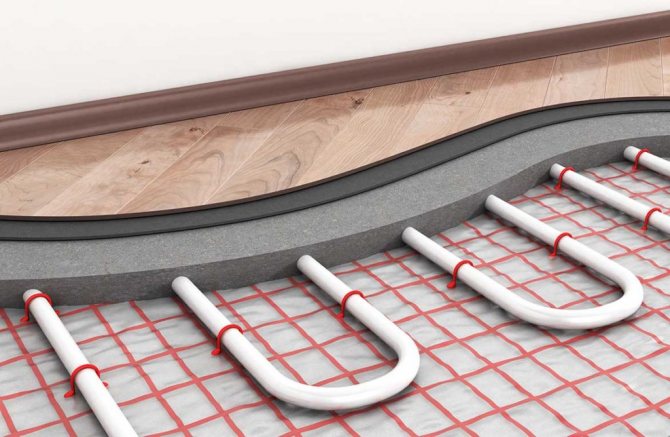

Heating based on underfloor heating is more energy efficient, does not affect the aesthetics of the room, and evenly heats the space. Since communications are embedded in concrete for decades, it is very important not to be mistaken with the choice of material. There are two types of pipes that experts recommend - metal-plastic and cross-linked polyethylene. Which pipes are better to use, you can decide only after studying their properties.

Criterias of choice

When choosing a material for the construction of communications, the decisive argument should not be considerations of economic benefits or the complexity of installation, but the compliance of the technical characteristics of the pipes with the expected operating conditions.

In the case of underfloor heating, the following requirements are imposed on pipe materials:

- Strength... According to the official requirements for pipes for underfloor heating, it is forbidden to use ferrous metal and seam pipes. Steel products without special anti-corrosion protection in a walled state will not last long. The joint is a "weak" point when the hydraulic pressure in the heating system increases. The use of such materials will lead to a rapid occurrence of an emergency, the elimination of which will require opening the concrete screed.

- Chemical inertness... For long-term operation without reducing the internal clearance, pipes with a perfectly smooth inner wall are required. The coolant contains salts of alkaline earth metals, which during long-term operation are deposited on the inner walls of most pipe materials.

- Resistance to mechanical stress without deformation... The minimum concrete screed exerts a pressure on the pipes equal to 10 kg of weight per sq. see Soft plastic pipes under this load will deform, and too hard plastic may burst.

- Resistance to high temperature and pressure of the medium in the heating system... The minimum required stability parameters are 95 degrees and 10 atm. respectively.

- High level of heat transfer... For efficient heating, it is important that communications are not a barrier between the coolant and the air.

- Lack of connections under the screed... Requires pipe materials that can be laid in one piece up to 120 m in length.

- Flexibility and resistance to fracture... When laying underfloor heating, it is important that the pipes are elastic enough to bend without damaging the walls and deforming the inner section at a minimum radius. Large pipe spacing causes cold segments.

We recommend that you familiarize yourself with: How to make and install a protective exhaust hood on a chimney

The choice of this or that material is also influenced by the type of heating in the house. If this is a central system, then the warm floor will be subjected to more serious loads than with an individual circuit.

Note! Those looking for the ideal floor heating device should consider using copper materials. Copper has a significantly greater margin of safety than is necessary in this case. There are two drawbacks - complicated installation and high price of copper pipes.

Reinforced plastic and cross-linked polyethylene are very close in terms of their technical and price characteristics. Comparison of their positive and negative sides will allow you to make the right choice in each case.

Manufacturers overview

When choosing pipes for underfloor heating, it is advisable to give preference to well-known manufacturers, whose products have already received a positive assessment from users.There is a wide range of cross-linked polypropylene pipes and structures using this material on the market. There are products of foreign companies, and there are also domestic products. To make it easier to make a choice, it is worth reviewing the manufacturers most in demand today. Leading positions are occupied by Rehau and Teplolux.

Rehau company

Today, Rehau warm floor is chosen by the majority of users. The range of models and standard sizes is wide enough. The company produces both universal and specialized pipes. Products of this famous brand make it possible to install the pipeline, regardless of the complexity of the configuration. Products are capable of functioning for a long time in high temperature conditions. High technical parameters, reliability and quality are the key to the success and popularity of the products of this manufacturer.

Source: SpetsOtoplenie.ru

Polyethylene pipes

Cross-linked polyethylene is a modern high-tech chemical product. Crosslinking of the polymer occurs at the molecular level. Conventional polyethylene is a long, linear chain of molecules. Modern technologies allow chemists to bind these molecules together with strong additional chemical bonds. Just as a strong fabric is formed from threads, a three-dimensional web of cross-linked polyethylene is formed from linear molecules.

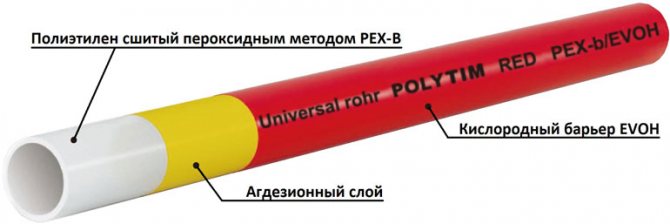

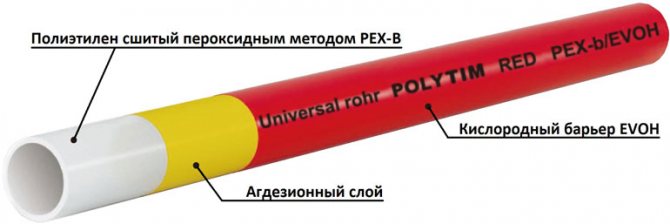

There are several technologies for the production of cross-linked polyethylene. They differ in their cost, the percentage of connected linear molecules at the exit and marking. For underfloor heating, pipes with a crosslinking percentage of at least 65% are required.

PEX-a pipes have up to 85% crosslinked molecules. The manufacturing process is quite expensive, but guarantees high quality material. The technology for the production of PEX-b pipes is cheaper, but the output gives only 65% of the connected molecules.

Note! Pipes marked PEX-c for floor insulation are not reliable enough.

The best properties of polyethylene pipes:

- High elasticity - allows you to lay pipes as close to each other as possible without damage.

- Small coefficient of expansion. XLPE does not “walk” under concrete when the temperature changes. Resistance to mechanical influences from outside and outside. The material does not deform under the concrete screed and does not burst when freezing with water.

- The ability to return to its original form. This guarantees tightness when using fittings and does not deform in bending.

- Inert to chemical and biological influences. Pipes do not rot and are not destroyed by an aggressive environment.

- Compliance with the technical characteristics of the material to the operating conditions. Cross-linked polyethylene can withstand water heating up to 90 degrees (recommended temperature 80) and pressure up to 8 atm.

We recommend that you familiarize yourself with: Using PVC-U pipes in pressure systems

There are few disadvantages of cross-linked polyethylene and they are associated with installation. The high elasticity of the material in bending requires the pipelayers to rigidly fix the pipes during installation. The second point is the need to preserve the external protective coating. This complicates the work somewhat in comparison with metal-plastic.

XLPE pipes

XLPE pipes - REX pipes... REX stands for Crosslinked Polyethylene. This flexible, durable material is becoming an increasingly popular material. To give the polyethylene strength and resistance to temperature influences, it is subjected to high pressure processing. This leads to education additional molecular bonds... This processing method is called * crosslinked *, which is why polyethylene is called crosslinked polyethylene.

Due to the three-dimensional molecular bond in the structure of polyethylene, there are a number of advantages over traditional metal pipes.Three-dimensional molecular bond increases the resistance of pipes to thermal deformation, abrasion, scratches, shrinkage, cracks due to internal stress.

When choosing REX pipes, you should pay attention to degree of crosslinking... The standard requires a certain degree of crosslinking, not less than 65%, ranging from 65% to 80%. The stitching method affects the durability and performance as well as the cost of the pipes.

Exists three ways obtaining crosslinked polyethylene, affecting the degree of crosslinking.

- Pyroxide (REX - a) - pyroxides are introduced into polyethylene. The degree of crosslinking is up to 85%.

- Silane (REX - b) - organosilanides are added to polyethylene. The degree of crosslinking is not less than 65%.

- Radiation (REX - c) - the degree of crosslinking is 60%.

If the degree of crosslinking is 0%, then the pipes become too brittle and prone to cracking. Too little stitching can have equally serious consequences.

Pros of REX pipes

REX pipes have a number of advantages:

- low noise level pipes due to their flexibility and ability to absorb pressure surges;

- ease;

- convenience in the installation;

- possess * shape memory *, can easily restore their original shape;

- corrosion resistance;

- strength, the operation is designed for a period of at least 50 years;

- sustainability to freeze in cold weather;

- flexibility;

- minimum probability * explosions * after defrosting the system;

- withstand high temperature and pressure drops.

XLPE pipes affordable... REX pipes are installed using specialized fittings. This can significantly reduce hydraulic losses in the pipeline. The lifespan of the underfloor heating system is increased as fewer fittings are used on fractures, which reduces the risk of leaks and costly repairs in the future.

Cons of XLPE pipes

The disadvantages include the following:

- negative impact direct sunlight;

- REX pipes, unlike metal-plastic pipes, do not have an aluminum layer, therefore, with them harder to work, since more movements are required to fix the pipe and keep its shape;

- the anti-diffusion protection is on the outside of the pipe as long as the pipe is handled carefully so that there are no problems with installation. If the installation rules are not followed, you can damage anti-diffusion protection... This is also one of the reasons why, regardless of the type of pipe used, the installation must be carried out by experienced certified technicians.

When comparing metal-plastic pipes and pipes made of cross-linked polyethylene (REX), it can be seen that these types of pipes have many of the same characteristics, such as anti-oxygen barrier, corrosion resistance, flexibility, strength, durability, ease of installation. But there are also some differences.

Metal-plastic pipes heat up faster, have greater thermal conductivity, and are easier to install. But the cost of XLPE pipes is lowerthan metal-plastic. But REX pipes have a greater heat transfer, so the underfloor heating system becomes more economical, which allows pipes to be laid with a large gap during installation. This contributes to less power consumption for heating the area of the room. Installation of REX pipes should be done more carefully.so as not to damage the pipes and not to disturb the diffusion protection.

In any case, these two types of pipes are high quality and reliable, meet modern technical requirements, and are ideal for underfloor heating.

Source: teplo.guru

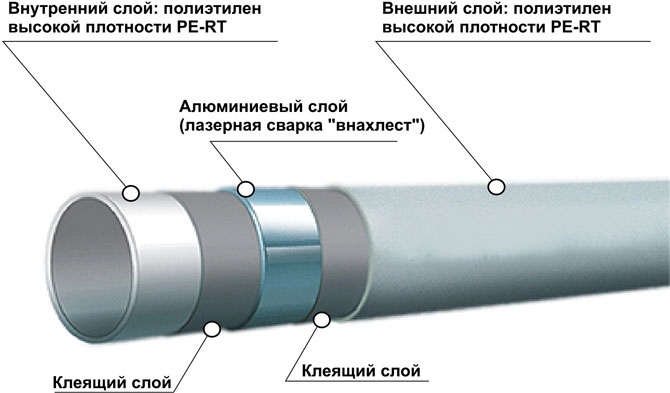

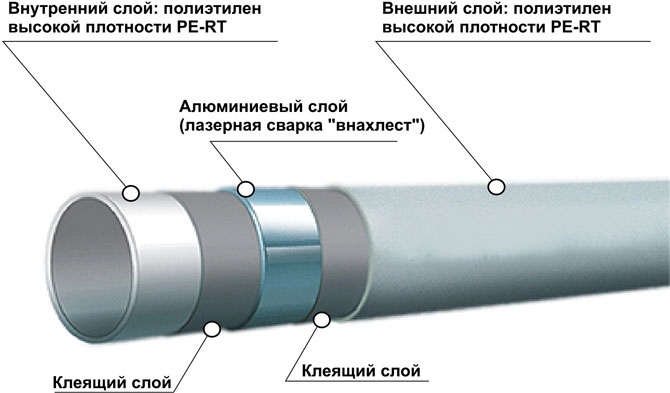

Reinforced plastic tubular products for floor insulation

Reinforced-plastic pipes were originally designed for the construction of closed floor insulation systems. These materials have a complex, multi-layer structure, where aluminum foil is the supporting element.The addition of metal to XLPE eliminates its disadvantages, but adds its own characteristics that should be taken into account during installation.

To understand how a reinforced plastic pipe works, you need to understand its structure. The material is a "sandwich" of two layers of polyethylene, interlaced with metal. The bonding agent is a special glue that is applied to the metal foil on both sides.

Aluminum inclusion adds metal-plastic to all the advantages of polyethylene pipes:

- resistance to water hammer;

- higher operating parameters - pressure up to 10 atm, temperature up to 95-100 degrees (recommended 93);

- faster and more efficient heating of the room;

- the ability to maintain the shape of a bend without fixing, which simplifies installation.

When choosing high-quality pipes, you will not encounter any drawbacks. Poor-quality metal-plastic can create problems already during installation. Poor glue base leads to pipe delamination, and thin foil will quickly break at fracture.

Note! Installation of a reinforced-plastic floor is carried out at a distance of 35 cm. Closer laying will lead to deformation of the pipe at the bend.

Reinforced plastic or cross-linked polypropylene

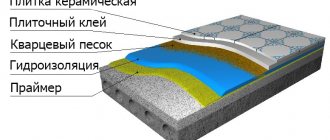

Pipes are an important component of a warm floor. And the efficiency and durability of the entire system depends on their quality, reliability and technical characteristics. Copper and steel corrugated pipes are quite expensive. But the price of cross-linked polypropylene for underfloor heating and metal-plastic pipes is much more affordable. At the same time, the operating parameters of the products are excellent. Which explains the popularity of these materials.

But what to choose: cross-linked polyethylene or metal-plastic for underfloor heating, which product is better? This remains to be understood. As far as cost is concerned, there isn't much of a difference between the two designs. Having found material at a favorable price, in both cases, you can save a lot. Therefore, it is necessary to pay attention precisely to the operational characteristics and installation features.

So, if installation of complex diameters is to be done, then it is better to opt for metal-plastic. XLPE behaves slightly worse. If the room is small in area, it is supposed to implement a complex scheme for laying the heated floor system; it is also worth giving preference to metal-plastic structures. In all other cases, experts recommend buying cross-linked polypropylene for underfloor heating, as it is a more practical and reliable option.

The main characteristics of XLPE products are:

- mechanical strength;

- high impact strength;

- resistance to corrosion processes;

- high elasticity;

- heat resistance;

- the ability to absorb vibration and noise.

It is important to take special care when installing a cross-linked polypropylene underfloor heating. Indeed, in places of bending, the pipe does not retain its shape very well.

Many experts consider cross-linked polypropylene lines to be much more reliable than multilayer metal-plastic counterparts.

It is also noted that, for example, the Pex pipe for a warm floor perfectly tolerates freezing, does not burst. The combustion temperature of the material is +400 degrees. When burning, the product does not emit toxic substances. In favor of the underfloor heating made of polypropylene, it is also said that during welding, all pipe joints become monolithic. In addition, the cost of fittings and pipes is low. Therefore, most consumers believe that buying cross-linked polyethylene for underfloor heating is the most suitable option.

What to choose

The answer to this question depends on the criteria that will be prioritized for the host:

- Based on the technical characteristics, we can conclude that it is better to use metal-plastic products for floor insulation in an apartment building - they are more resistant to operation in harsh conditions of pressure and temperature differences.

- With self-installation, it is also better to pay a little more for metal-plastic, but to make it easier for yourself to install.

- Crosslinked polyethylene will serve faithfully in an individual home. Even if you forget to drain the water and the system freezes, there will be no trouble, the quality of the pipes will not suffer.

- A limited budget with professional skills will also allow you to choose more economical polyethylene.

We recommend that you familiarize yourself with: How and why is the production of PU foam insulation carried out?

Both materials are guaranteed to last at least 50 years, withstand well the average operating parameters of the heating system on the water circuit, and do not differ critically in cost.

What pipes are used for underfloor heating? Why choose metal-plastic and polypropylene more often?

The pipeline is the main working part of the heating system "warm water floors", therefore, what kind of consumable will be used, i.e. which pipe will go into operation, the main attention is paid during installation. The quality of consumables and high technological characteristics of the pipe are important for the construction of underfloor heating. Due to the rapid growth in the popularity of hot water heating, technology for the production of equipment and consumables for heating have stepped forward.

The following types of pipes are presented on the market of thermal and heating equipment:

- metal-plastic;

- polypropylene;

- copper;

- corrugated pipes made of steel;

- Consumables made of cross-linked polyethylene.

Any of the voiced options copes well with the tasks assigned to it. The only point that distinguishes all options from each other is cost and performance. We will talk about copper pipes and a corrugated channel for the water circuit another time. These materials are not popular at the household level due to their high cost.

Now let's consider another question. Which is better for your floor, metal-reinforced plastic or polypropylene? What is the difference between these most common materials?

Metal-plastic is one of those materials with which you can work with any qualification. Pipelines made of metal-plastic pipes are quite easy to install, repair or replace damaged sections.

On a note: Reinforced-plastic pipes are very convenient for laying water lines in autonomous heating systems. The radiator heating method is mainly mounted using metal-plastic pipelines.

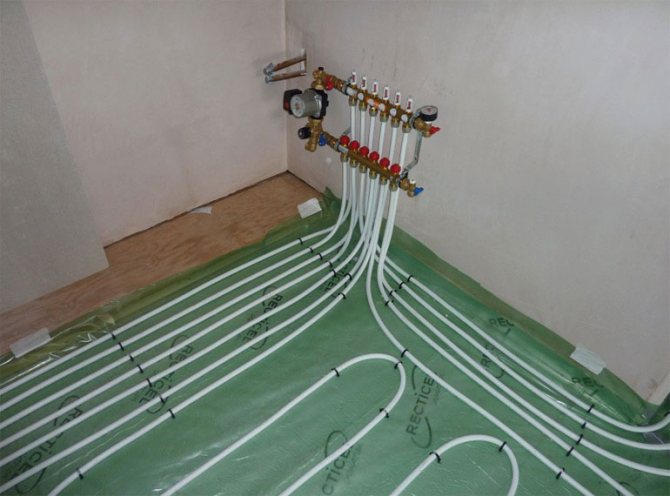

Correctly laid water circuit makes the floor made of reinforced-plastic pipes reliable, practical and durable. Particularly captivating is the fact that the water heating circuits made of solid metal-plastic are durable and airtight, and have a high degree of reliability. The lines are connected to the manifold manifold using fittings, which most often have a metal base. Docking of fragments of a metal-plastic pipe with adapters is carried out by means of a threaded connection.

For reference: According to experts, if you do not apply certain skills and dexterity, threaded joints in contact with metal-plastic pipes can leak.

A metal-plastic water floor pipe, connected using press fittings, is more reliable. As a result of crimping, a strong and sealed connection is created.

Polypropylene pipes are also connected using fittings. The difference is that joining is carried out by heating the pipe edge with special equipment. By means of a soldering iron, polypropylene is tightly connected to the fitting, making the connection monolithic and reliable.

In order to make a choice in favor of metal-plastic or to give preference to polypropylene materials, it is necessary to answer the question. What is better than polyethylene or metal-plastic, how practical are the products during the operation of warm water floors, and what will be the cost of installing a heating water circuit? Costs are often a defining issue. The difficulties of installation will become known already in the process. The design features of both materials play an important role in terms of choice. What is the difference between consumables?

Both options are perfect for water supply and hot water heating systems. Due to the low cost of materials, it is possible to lay fairly long pipelines, providing water supply and heat supply to the entire house. For underfloor heating, the use of metal-plastic pipes is associated with a certain risk. Laying the channel of the heating circuit in a concrete screed or under a tile, in the event of a leak, the repair work will be quite large-scale and difficult. Polypropylene pipes are more reliable in this aspect. Considering the coefficient of warm expansion, correctly laid polypropylene heating circuits will last a long time.

Crimp method

The crimp connection does not require the purchase of separate tools. Use fittings, press collar, and wrench.

A pipe cutter is needed to remove uneven edges. To increase the inner diameter of the pipe, calibration with a countersink is intended. How to make a crimp connection?

- The edges of the pipes must be straight. To do this, measure 2-3 cm from the end of the product, set a mark. A correct chamfer is formed at this mark with a pipe cutter; remove part of the contour.

- The fittings are chosen depending on the size of the contour diameter, but the connecting elements have round rubber inserts-seals. To prevent their deformation, it is necessary to slightly increase the diameter of the pipe. To do this, use a countersink calibration. The tool is inserted inside the contour, rotary movements are performed. Chips are removed from the inner surface. This increases the diameter.

- A crimp ring is put on the pipe.

- Insert the fitting.

- Press the ring onto the fitting. Tighten the crimp nut by hand. In the future, 2 keys are used. One is for holding the fitting, the other for tightening the compression nut.

- Check the assembly of metal-plastic pipes.

We recommend: How to lay underfloor heating on the ground?

This connection method is used most often. Installation is quick, no expensive equipment is required. The crimp nut securely holds the reinforced plastic circuit.

Press crimping with electric crimping machine

In order to connect individual sections of the line using a press crimp, an electric crimper is used. The kit includes nozzles with holes that correspond to a certain diameter of the pipe for "warm floor". Crimping is carried out as follows:

- carry out preparatory work: form a chamfer and increase the diameter of the product by means of calibration with a countersink;

- install the fitting;

- a pressing ring is put on one end;

- a nozzle is attached to the tool; it is made in the form of forceps; they are disconnected, a pipe is inserted;

- connect the tool to the electrical network;

- connect the tongs; a click will be heard;

- hold them in place for 2-3 seconds;

- disconnect the tongs, check the crimping site.

Installation is fast. The line connects reliably, withstands the high pressure of the coolant, there are no leaks. The disadvantage is the use of expensive equipment. AT

the place of the electric pressurizer can be operated with a hydraulic tool. It costs less, but physical effort is required for crimping.

Press crimping with hydraulic device

The hydraulic pressure tester is a pliers.They are equipped with nozzles for pipes of a certain diameter; they are in the shape of a semicircle; use nozzles in pairs.

The size of the diameter is indicated on the surface of the product. One semicircle is located on the body of the forceps, the other on the head. The nozzle is inserted into the grooves until it clicks.

- Preparatory work is carried out: they form a chamfer and increase the diameter.

- Put on the crimping nut, insert the fitting. The fitting has holes. They determine the correct location of the pipe.

- Place the junction on the body of the forceps, close the head.

- Increase the handles of the crimper. This will increase the stress during crimping. The handles are at an angle of 1800.

- Connect the handles. This will compress the forceps. The fitting and the ring are connected.

- The handles are bred to open the head of the device. To open the head, you need to hit it with your palm.

- Remove the pipe, test the connecting unit.

If there is a rupture of the line, then the space on the floor is freed from the screed, the circuit is opened. The inner and outer walls are washed. Make sure that debris does not get inside the pipeline.

The connection of individual sections of the contour is carried out. It is recommended to close the node with pipe insulation. The material will protect the fittings from oxidative processes. The line is poured with a building mixture for a "warm floor".

Manual hydraulic press Viar

The joints are installed closer to the border of the water circuit so that they can be easily reached; do not open the entire "warm floor". Fittings are protected with plastic or insulation. The contour diagram is transferred to a sheet of paper in order to further determine where the nodes of the trunk connection are.

We recommend: How to check the warm floor?

Reinforced-plastic pipes for "warm floors" are a good alternative to polyethylene products. When using the line, it is necessary to monitor the heating mode.

Avoid high pressure in the water circuit over 10 bar, liquid temperature over 90 ° C. "Warm floor" is connected to the boiler, to the collector or to the radiator.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- How to choose a wire for a warm floor?

- How to connect a warm water floor in a house from a gas boiler?

- What is the layout of the underfloor heating mixing unit?

- How is the installation of an infrared underfloor heating carried out?

- How is the warm floor installed on the balcony?

- How is the underfloor heating connected?