Design features and main characteristics

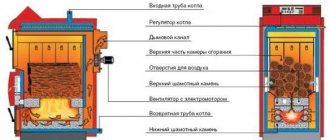

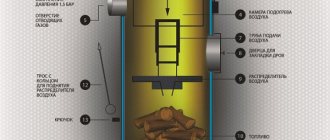

Like most solid fuel models, the Don 16 boiler is a steel device with a water jacket. Its main part is the firebox. Manufacturers deliberately went on to increase its size in order for it to hold more fuel, thereby providing a longer burning time. The fuel chamber is made of a special alloy, which makes it resistant to corrosion.

Photo 1: Steel universal solid fuel boiler Don 16

The second significant part of the Don 16 hot water boiler is the heat exchanger. Its task is to provide maximum heat removal and transfer it to the coolant. To ensure maximum heat removal, the design of the heat exchanger is made in such a way that the smoke tubes pass through it. For even better heat transfer, turbolizers are installed inside them. The heated coolant is fed through the upper branch pipe to the heating system. The return of water to the solid fuel boiler occurs through the return pipe. The coolant temperature is controlled by a thermal sensor.

Photo 2: Ash pan of the Don 16 boiler of the old modification

In Don 16 double-circuit boilers, a coil is installed inside the heat exchanger, around the smoke tubes. Due to its proximity to the heat source, the water in it heats up quickly, providing the owner of the house with hot water for sanitary needs without interruption. The flow rate is regulated by a valve or mixer.

On the front panel there are skimming and loading doors. They are used for loading and removing ash, as well as cleaning internal surfaces. Adjustment of the thrust, and hence the intensity of combustion, occurs with the help of the gate handle.

Photo 3: Gas burner for a solid fuel boiler with a water circuit Don 16

In addition to the 16 kW universal boiler, 30 kW models are also available. Also in the line there are devices capable of operating only on solid fuels. Here are some of the technical characteristics that the manufacturer gives on the official website:

ModelKS-TG-16 / 20SKS-TG-30 / 40S

| Power (coal / gas), kW | 16/20 | 30/40 |

| Room area (coal / gas), m2 | 160/200 | 300/400 |

| Efficiency (coal / gas),% | 86/90 | 86/90 |

| Gas consumption, m³ / h | 1,3 | 2,5 |

| Price, rub | 19 800 | 45 000 |

To ensure gas operation, the skewer door and grate are dismantled, and a gas burner controlled by automatic equipment is mounted in the lower opening of the front panel. The upper part of the firebox is closed with a fire plate tight to the front wall.

Attention: The installation of gas equipment should not be done by hand. Connecting on your own may be insecure. These works should be entrusted to professionals, especially since any gas equipment requires approval and registration.

Photo 4: Heating boiler Don 16 with a pellet burner

Installation recommendations

Installation of solid fuel units does not imply obtaining special permits. At the same time, this does not mean that the owner should not monitor the quality of construction work and comply with fire regulations.

Expert advice:

- The installation of the boiler should be carried out on a flat concrete base, making an indent from the wall at least 0.5 meters.

- When installing the boiler on a wooden floor, under it and half a meter in front of its front wall, a sheet of asbestos cardboard or felt soaked in a solution of clay is laid on the floor, and steel sheets are laid on top of it.

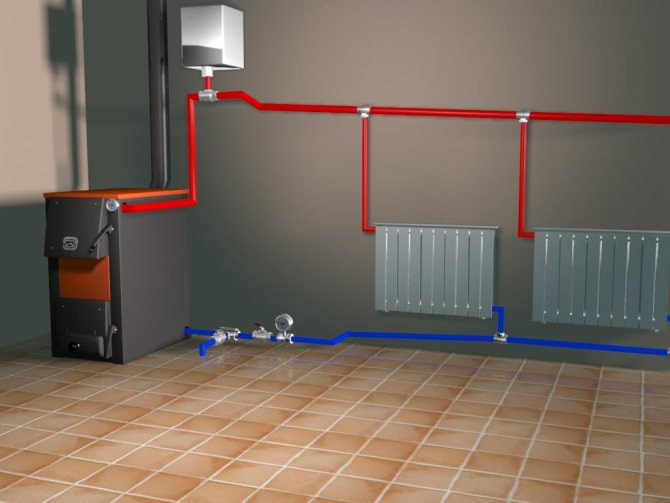

- For normal circulation of liquid in the system, the boiler must be installed in such a way that its lower branch pipe is lower in level compared to the outputs from the heating batteries.

- The connection to pipes can be made both on threads and on welds.

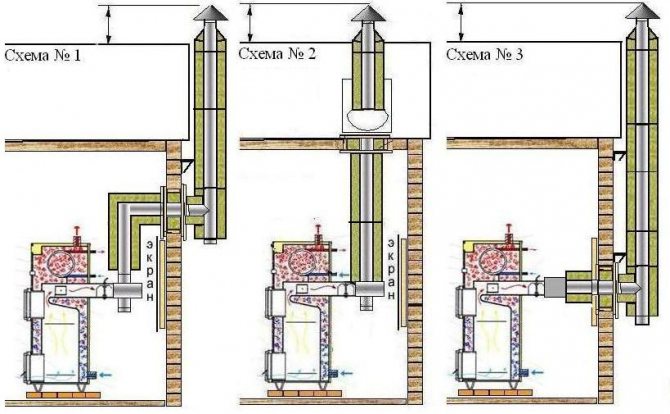

Do not forget about the features of the installation of chimney ducts:

- chimneys are double-circuit, with thermal insulation between the structures. Thus, no water vapor is generated;

- for the construction of a chimney, asbestos-cement pipes are often taken;

- the diameter of the chimney must be the same as the diameter of the outlet of the boiler equipment;

- the chimney must be brought out above the roof level, read the rules of SNiP;

- the chimney must be flat, without ledges.

How it works ↑

The scheme of functioning is simple. The elements that make up an ordinary Don 16 boiler are few, they are simple: a firebox with a water jacket, temperature sensors, a pipe system supplemented with turbulators. When fuel is burned, the water cavity heats the injected water, the convection amplifiers send the liquid into the general circuit through the upper branch pipe, it is replaced by cold flows supplied by the lower one. The meter monitors, corrects the temperature.

Although the devices are manufactured on a single basis, they have a slightly different structure. The difference lies in the details. What they promise advantages in each case, the letters that make up the brand name will help to understand. There are nine letters: 1). "K" is the boiler. 2). "T" - solid fuel. 3). "G" - gas. four). "M" is modified. five). "C" - with a steel heat exchanger. 6). "Ch" - with cast iron. 7). "B" - with a water coil. 8). "R" - with draft regulator. nine). "TG" is universal.

Brief operating instructions ↑

one). Fill the system with fresh water in small portions (maximum 8 l / min.) Until liquid comes out of the overflow pipe of the expansion tank. 2). Proceed to kindling, focusing on the nature of the feeding substances: I. Ignition of TT: a). open the plug of the primary air, bring the folded newspaper to the gap between it and the sanding valve, make sure that there is traction (the pages will press down); b). fill the receiving chamber with wood evenly to half, set it on fire, pour small (up to 25-30 cm) pieces of coal on top upon ignition; at). put no more than 5-6 kg of fuel at a time, spend about an hour on loading the bunker; then set the gate so that the thrust is stable. II. Starting the gas burner: a). ventilate for 5-10 minutes. the combustion block by closing the main tap; b). check the pulling force by bringing a sheet of paper closer to the viewing window; at). open the air supply gate, light a fire. 3). Close the doors; later adjust the temperature with mixer or coil valve.

Recommendations for use

For stable and high-quality operation of the system, the following several points must be taken into account:

- The units must be used in open systems (with an expansion vessel). In addition, you should not allow the liquid in the tank to sink to the bottom.

- If water hammer occurs in the system (knocks are heard), it is necessary to immediately turn off the boiler, add liquid to the system and start the device again.

- When the system is operating, it is required to monitor the heating of water, its maximum heating should be 95 ° C.

- Remember that when a solid fuel unit is operating, it is prohibited to use only a water heater with the heating turned off.

- When in winter it is necessary to stop the boiler for longer than a day, then it is worth draining the liquid from the pipes in order to exclude the failure of the system.

- Before starting the ignition of the unit, it is required to ventilate the combustion chamber for ten minutes.

How to calculate the volume of an expansion tank

If you are thinking about organizing a heating system in the house, but you do not want to waste a lot of time, money and effort in boiler equipment, then you should consider the Don solid fuel boiler. It is a reliable and efficient device that is popular with consumers and is gaining more and more positive reviews.Thanks to a large model range, you can choose the most suitable option for heating equipment.

Advantages and Disadvantages ↑

Steel heating boilers "DON" are designed for heating rooms up to 400-500 sq. M.

Consumers appreciate the compliance of the equipment with domestic conditions of use (strong and long frosts, hard water), the energy independence of its mechanisms. Previously, consumer interest was aroused by good technical characteristics of the rulers, now the stability of demand is supported by such qualities as:

- excellent thermal insulation and high safety (attached by an 8mm casing);

- an impressive period of independent combustion with low fuel consumption (the presence of a lined chamber makes the Don 16 boiler capable of operating on one tab for up to 8 hours);

- durability (due to the construction of the case from 3 mm steel);

- maintainability (parts are replaced).

Solid fuel boiler Don 16 - design, installation, reviews

Introduction

When planning a heating system in a private house, owners often try to find a universal solution that allows you to easily switch from solid fuel to gas. On the Russian market, there are models of heating devices capable of solving this problem. One of these devices is the Don 16 solid fuel boiler. In this article we will tell you about the features of its design, advantages and disadvantages, and also give the opinions of users.

So what exactly is this model? The Don 16 boiler is a steel household solid fuel boiler with a water circuit, designed for heating houses or other small premises and for organizing hot water supply. Firewood or coal can be used as fuel, as well as with minor modifications - pellets or gas. Let's take a close look at its design and find out what makes it possible to achieve such versatility.

Design features and main characteristics

Like most solid fuel models, the Don 16 boiler is a steel device with a water jacket. Its main part is the firebox. Manufacturers deliberately went on to increase its size in order for it to hold more fuel, thereby providing a longer burning time. The fuel chamber is made of a special alloy, which makes it resistant to corrosion.

Photo 1: Steel universal solid fuel boiler Don 16

The second significant part of the Don 16 hot water boiler is the heat exchanger. Its task is to provide maximum heat removal and transfer it to the coolant. To ensure maximum heat removal, the design of the heat exchanger is made in such a way that the smoke tubes pass through it. For even better heat transfer, turbolizers are installed inside them. The heated coolant is fed through the upper branch pipe to the heating system. The return of water to the solid fuel boiler occurs through the return pipe. The coolant temperature is controlled by a thermal sensor.

Photo 2: Ash pan of the Don 16 boiler of the old modification

In Don 16 double-circuit boilers, a coil is installed inside the heat exchanger, around the smoke tubes. Due to its proximity to the heat source, the water in it heats up quickly, providing the owner of the house with hot water for sanitary needs without interruption. The flow rate is regulated by a valve or mixer.

Reviews ↑

At the professional forum, the installer Melky writes that in the villages of his area they order exclusively such solid fuel boilers, everyone is happy. In response, Fox criticizes the KS-T-16R model. He is angry that he is on duty at the stove in winter, throwing up firewood every 3 hours, struggling with the tricks of the traction regulator, suffering from the cold. Nikola SD tells him: problems are created by an ill-conceived principle of operation, which requires the ignition of all loaded fuel at once. Combustion is uneven, adjusting the damper does not help here. It is especially difficult to achieve the required performance in the off-season.

Price ↑

Multi-fuel hot water systems are considered versatile products. The cost of the units is: 4-7 thousand rubles. (budget options), 10-35 thousand rubles. (available), 35-70 thousand rubles. (premium). According to the specified gradation, the Don 16 boilers belong to middle class goods, which is confirmed by the following figures:

- KS-T-16 models: 12-14.5 thousand rubles;

- versions of the KS-T-16R: 15-16 thousand rubles;

- systems KS-TG-16: 16.5-17 thousand rubles.

- variations KS-TVm-16: 17.5-20.5 thousand rubles;

- schemes TGVm-16: 21-23 thousand rubles.

How to choose

Thermal power. Choosing it, you need to know not only the area that is supposed to be heated. If the device is chosen for heating a private house, you must also take into account what material it is built from and how insulated.

In apartments, the location is important - central or corner. In the latter, it is always colder, therefore, the power must be chosen with a margin.

The approximate power of the device is determined by the ratio - 1000 W for every 10 squares of area. And for every cubic meter - 40-60 watts. But it is recommended to take boilers with a heating capacity margin of 30% for cold houses and apartments. Firstly, there will be no problems with heating in the most severe frosts, and secondly, the equipment will not work for wear and tear and will last longer.

Dependence on power grids. This parameter is more important for reliability and stability than for economy. If electricity consumption is provided in boilers, for example, for ignition, then it is insignificant.

The number of contours. The choice of this parameter determines the capabilities and cost of the heater. Single-circuit ones are chosen for heating, double-circuit ones, in addition to heating rooms, can heat water for domestic use.

Installation method. Wall-mounted or floor-mounted. The choice depends on the area of the room. Wall-mounted versions are more compact.

Heat exchanger material - steel or cast iron. Cast iron is more reliable, they are not afraid of corrosion.

Combustion chamber type. It is more convenient with a closed firebox: they are safer, do not waste the internal air of the premises, they are preferred today by the owners of houses and apartments that are not equipped with traditional chimneys.

How much do they cost

Equipment from domestic brands is a priori cheaper than imported ones, and products are no exception.

The price of Don boilers depends on the model and its capacity. An inexpensive single-circuit apparatus KS-T-16, designed for heating 160 m², costs about 17,000 rubles. The cost of a powerful double-circuit device designed for heating 300 m² is 37,000 rubles.

Types of boilers Don

- The single-circuit boiler is represented by the Don KS T 16 and Don KS T 16 RT models. The latter is equipped with a draft regulator. In their work, the boilers use solid fuel, have a high efficiency, and are made of high quality steel. Models of this series are durable, reliable and safe to use. The large volume of the chamber avoids additional fuel loading.

- The double-circuit boiler Don KS makes it possible to heat the room and provide it with hot water. TGV 16–20 boilers operate on solid fuels and natural gas. It is possible to replace the coil, which contributes to the durability of the circuit.

Solid fuel boilers Don in the price segment are economical. If cast-iron sections of the heat exchanger are installed in them, they will have a significant effect on the thermal stability and corrosion resistance of the equipment, increasing its service life. Solid fuel boilers can be sold with electric heaters on request or as a set. Such shades allow you to increase the heating time of the room.

Minuses

The main disadvantage of all solid fuel units is the impossibility of complete automation of the process. To ensure optimal operation of the heating system, you will need to constantly throw logs into the combustion chamber, as well as clean the equipment, removing combustion products.

Devices for servicing boiler equipment (scoop, poker, etc.) are usually not included in the standard set, they will need to be purchased separately.

It is worth saying that the Don solid fuel boiler cools down for a long time.This is inconvenient when repair work is urgently needed. After stopping the operation of the unit, you will have to wait a long time until all parts become cold.

Solid fuel boiler Don KS-T 30 RT

Specifications ↑

These products of the Rostov association are presented in five varieties. Without a pre-installed gas burner, only Don KS-T-16 boilers go, taking only firewood. The rest of the solutions (T-R, TG, TVm, TGVm) are equipped with the circuits necessary for the transition. General properties:

- power (kW): 16;

- Efficiency on solid fuel / gas (%): 75/82;

- gas consumption (m3 / h): 2;

- weight (kg): 139-154;

- length / width / height (mm): 700/470/1030;

- heated area (m2): 160.

Only one unit in the range is equipped with a traction control for easy operation. In improved solutions, the disadvantages associated with its absence are compensated for by the worthy adaptability of gas burner systems, good performance of the DHW circuit. The modest design of the classic is due to the desire for ease of use.

Sources of

- https://kotlydlyadoma.ru/kotel-don-16-na-tverdom-toplive.html

- https://TeploLiVam.ru/otoplenie/kotly/kotel-don-16.html

- https://restart24.ru/otoplenie/kotel-don-16-tehnicheskie-harakteristiki-2.html

- https://nasos-kotel.ru/don-ks-tv-m-1620-tv-s-gaz-kotel/

- https://www.teplomatica.ru/kotly/tverdotoplivnye/don-konord-tve.html

[collapse]

Model overview

Let's describe the best models.

CS 16

Of all the models presented by domestic manufacturers, one of the most popular is Don KS 16. Its main advantages are excellent technical characteristics, convenient operation and economical consumption of energy resources.

Having domestic assembly and components, it is ready to work in the most difficult climatic conditions. It is the climate of Russia that does not allow many European analogues to compete with domestic developments. This line includes modifications that differ in the number of contours and a number of smaller differences.

Key technical parameters:

| Heating area, m2 | 160 |

| Natural gas consumption, m³ / h | 2,0 |

| Thermal power, kW | 16 |

| Efficiency,% | 90 |

| Weight, kg | 139 |

| Dimensions (HxWxD), mm | 1030x470x700 |

| Cost, rub. | 22 000 |

KS-T-11

Steel. Non-volatile. For small objects. Operates on gas or solid fuel - the burner is changed.

Installed automation. Thanks to the Honeywell regulator, energy consumption is reduced by 30%. The material of the furnace is corrosion-resistant carbon steel. Adapted to hard water.

| Heating area, m2 | 110 |

| Natural gas consumption, m³ / h | 2,0 |

| Thermal power, kW | 11 |

| Efficiency,% | 80 |

| Weight, kg | 65 |

| Dimensions (HxWxD), mm | 680x470x580 |

| Cost, rub. | 12 500 |

- Outdoor installation.

- Steel heat exchanger.

- Combustion products outlet - chimney.

Don Eco

An economical version, the main difference of which is its compactness. The small apparatus contains reliable Italian automation and an efficient heat exchanger. It features stable burner operation and high heat transfer.

The boilers are designed for heating small areas, it is allowed to use it with a flow-through water heater ("DON" or "KONORD"). In tandem with a water heater, this model will provide a small house with warmth and hot water.

For example, we give the technical characteristics and design features of Don Eco KS-G-12S:

| Heating area, m2 | 120 |

| Natural gas consumption, m³ / h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 90 |

| Weight, kg | 34,3 |

| Dimensions (HxWxD), mm | 650x230x573 |

| Cost, rub. | 13 500 |

- Heating system pressure (min / max) - 0.1 / 1.2 bar.

- The heat carrier is water.

- One circuit.

- Outdoor execution.

- Open firebox.

- Steel heat exchanger.

- Discharge of gases - through a vertical chimney.

- Body color - white.

- The warranty is 2 years.

DonStail

New gas equipment from - models with increased performance DonStail. Powerful heaters with a strict and stylish design. White color and decorative perforation on the case create a feeling of lightness, the device harmoniously fits into the modern interior.

Thanks to the special design of the heat exchanger and the Sit automation and the Polidoro burner, these modifications have high efficiency, low energy consumption and are completely safe.

Characteristics of the single-circuit version of DonStail KS-G-12 S:

| Heating area, m2 | 120 |

| Natural gas consumption, m³ / h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 92 |

| Weight, kg | 73 |

| Dimensions (HxWxD), mm | 835х343х515 |

| Cost, rub. | 18 000 |

- Outdoor execution.

- Open firebox.

- Steel heat exchanger.

- White color.

- The warranty is 3 years.

- Piezo ignition.

Powerful boilers "Don"

For heating large cottages, industrial and warehouse buildings, high-power devices are used:

- 40 kW. The efficiency is 76%. Heats a room up to 400 m². Weight - 290 kg. Dimensions are small - 700x850x1430 mm.

- At 50 kW. Consumption 3 m³ / h. Provides heat to cottages up to 50 m². The efficiency is 85%. Dimensions - 850x700x1430 mm.

- For 100 kW. The most powerful option is 1000 m². The efficiency is 87%. Weight - 560 kg. Dimensions - 1280x900x1090 mm. An ideal solution for large country houses and non-residential premises.