Today we will talk with you about induction heating. Many are trying to present induction boilers as something innovative, which supposedly will save our money and ensure the existence of our heating system. And what is it really?

In fact, induction boilers are very expensive, large-sized, inconvenient to use and not endowed with a sufficient number of properties and qualities that are necessary for the normal operation of a modern electric heating boiler.

Those people who invent these boilers and try to sell them to you do not tell the consumer anything about these aspects of their products, but expose only positive qualities to the light. Here we will display all the pros and cons of induction heating at home.

What do induction heating manufacturers say?

Most often, manufacturers of induction heating boilers are compared with traditional ones, and traditional ones are 99% of all electric boilers on the market.

Boilers are always compared according to the following scheme: the imaginary flaws of the heating elements and the positive qualities of induction heating of the house are highlighted.

For example, such indicators:

- There are a lot of heating elements;

- That one or even several heating elements can allegedly fail;

- It is said that the boiler may lose its working capacity;

- They pay special attention to scale, which can appear as a deposit right on the very surface of the heating elements;

- The complexity and bulkiness of the design is due to a sufficiently large number of electrical contacts;

- The creators of induction boilers claim that their boilers last longer due to the fact that they can soften the water;

- Absolutely unfounded and unfounded assertion that periodic replacement of gaskets, heating elements and risers is required.

Principle of operation

A simple example of this is a coil that is wound around a dielectric tube. Inside you need to install a steel core. The electric coil will heat the metal bar.

All that remains is to connect it to the coolant line, and such an "induction boiler" will begin to supply heat.

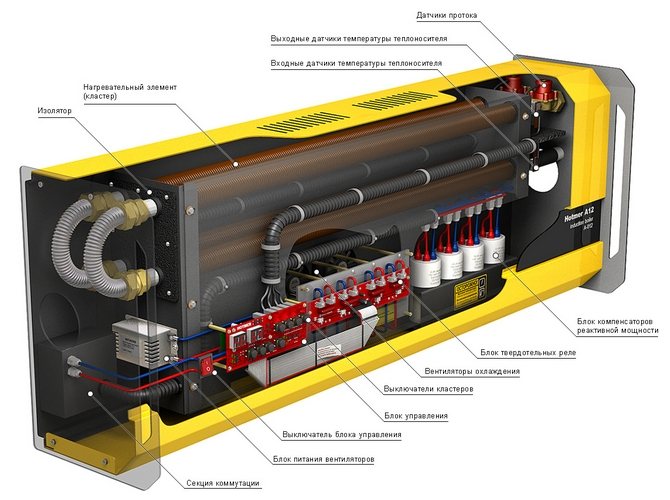

Hotmer induction boiler device

Induction boilers for heating a private house are great. The boiler functions by using a coil on the principle of an induction cooker. The inductive coil generates a magnetic field.

Heat moves from the heater to the liquid heat carrier through the labyrinth of metal tubes without leakage.

The strength of the current affects the change in the strength of the magnetic field in the device. This is how the house is heated.

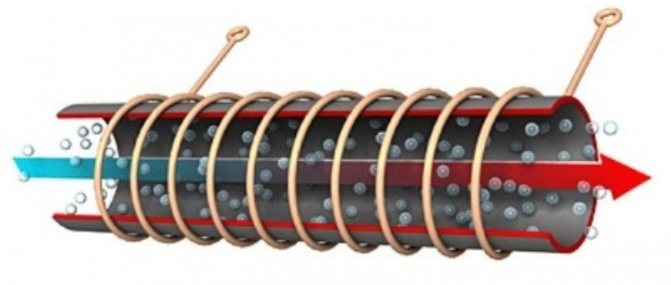

After being placed inside the coil of the core, Foucault eddy currents appear, which affect the electrical resistance of the metal. The temperature rises on the surface of the tube system.

Criticism of the wrong heating boilers

It is indicated that there are no heating elements in a high-quality induction heating boiler. Of course, this is not the case, because without a heating element we would have nothing to heat the water with, that is, it is always there in any boiler!

In the overwhelming majority of installed electric boilers, the heating element does not fail almost the entire service life of the boiler.

If the heating element still fails, then we can easily change it, since it is under the flange or on the thread. If suddenly, for no reason at all, the unit breaks down during induction heating, then it is almost impossible to replace it.

Now about the scale... It exists in a kettle, but in home heating systems it does not exist, because there water does not boil at all, deposits are present always and everywhere, in any systems: on gas, diesel, wood-burning, electric, heating, electronic, induction boilers. It doesn't matter which boiler. Sediments will always be present as these are deposits that are always present in the water. This is not a disadvantage or an advantage, but a reality.

About electrical contacts. Manufacturers write that there are no electrical contacts in an induction heating boiler. But in fact, electrical contacts are always and everywhere. And if we talk about heating boilers, then electrical contacts, terminal blocks. absent there for many years. There are electrical contacts under the screw connections that do not require tightening, and there are spring clips that are not worth servicing either.

Regarding the service life of the heating element and the numbers arguing this period. It is not clear where these figures are taken from and how they are confirmed. In addition, here the authors confuse water supply and heating systems. The heating system does not have as many impurities as there are in the water supply system. Water softening in the carrier of the heating system is not required.

It should be noted that in an induction heating boiler, the replacement of units is practically not possible at all, because everything is in a sealed flask and it must be cut in order to pull something out of there.

Advantages and disadvantages of an induction boiler

Induction boilers have the following advantages:

- High efficiency;

- Lack of consumable items, design reliability;

- Small overall dimensions;

- Ease of installation and operation;

- High heating rate;

Induction-type boilers have an efficiency of up to 99%, which exceeds the efficiency of heating elements and electrode units. The boiler efficiency of 20 - 30%, declared by the manufacturers, contradicts the principles of the law of conservation of energy.

But some savings can still be achieved due to the absence of scale. The fact is that the core, when exposed to electromagnetic induction, not only heats up, but also acquires stable microvibration. The formation of deposits and scale in such conditions is practically impossible.

In heating elements and electrode boilers, the formation of scale is a stable constant process. Lime deposits have a certain thermal resistance and reduce the heat transfer coefficient from the heating element to the heating medium. Scale 0.5 mm thick impairs heat transfer by 8 - 10%. In induction boilers, there is no such obstacle and electrical energy is consumed more rationally.

The presence of the vibration phenomenon also allows the use of water in the heating system, even with a high content of hardness salts. In general, untreated water, antifreeze, even oil can be used as a coolant during the operation of inductor boilers - that is, there are no chemical composition requirements that are inherent in other electric boilers.

Induction boilers do not have high-wearing elements (heating elements, electrodes) in their design. The service life of the equipment is declared at 25 years (with a 2-year warranty). Regular replacement of heating elements is not required - this reduces equipment operating costs.

Household boilers have small dimensions (the height does not exceed 1 meter) and can be located in any room. Installation of the product does not require obtaining any permits; installation can be done independently. A prerequisite for installation is the grounding of the device to prevent electric shock.

The independent manufacture of an induction-type boiler should be said separately. The implementation of this task is possible with a welding machine and certain skills.But a prerequisite is knowledge of electrical equipment and devices, because any complex equipment requires a serious security, control and management system. Self-assembly of the control unit and security systems is not for everyone.

Induction boilers can be called multifunctional. They can be used not only for heating, but also for the production of hot water in instantaneous water heater mode.

Induction boilers practically do not have any serious drawbacks. It can only be noted that, according to user reviews, there are complaints about the noise of the product during operation. This is caused by the presence of vibration. In principle, this negative factor can be eliminated - the boiler should be fastened with shock-absorbing inserts (made of rubber, etc.), which will prevent the transmission of vibration to building structures.

It can also be noted that an uncontrolled coolant leak is a serious hazard. If the flow control system fails, the equipment will be destroyed and become non-repairable. And another significant drawback inherent in all electrical heating equipment is the very high cost of electrical energy.

Induction heating boilers are high-quality and efficient equipment from a technical point of view. By their design, they are more perfect than heating elements and electrode electric boilers. In the absence of energy sources other than electricity, equipment of this type may eventually become more popular for heating private houses and summer cottages.

(, 2 today)

We recommend reading:

Autonomous water heating of a private house

Cascade connection of boilers

Replacing the toilet yourself

Replacing the heating radiator in the apartment

Electric boiler for heating a private house

Water supply device for a private house from a well

We reveal the main myth of induction heating

Recently, they have already stopped saying that the efficiency at induction heating higher than the efficiency of a heating boiler 2-3 times. But the supporters of the induction boiler argue that the heating boiler quickly loses its properties and goes out of service, because scale builds up on it!

It is said that the power of the heating boiler decreases by 15-20% during the year. Is it really?

Yes, deposits are not really present, but the heating system and the water supply system should never be confused. For example, scale actually forms in the water supply system, just like it forms in the kettle that we see in the kitchen every morning. This never interferes with our work, we know, and there is no doubt that water boils in a kettle anyway.

On the contrary, in the heating system known to us, impurities rarely enter the water. The deposition layer is very thin and does not pose any significant obstacle to heat transfer.

If the energy has gone somewhere from the network, it does not completely disappear anywhere. It turns into absolute heat and the heat carrier is heated, which, in turn, heats up with exactly the same efficiency as it was heated before and how it will always be heated. If it were not so, the ten would have burst with surplus energy.

As soon as scale appears, heat exchange takes place at a higher temperature. There can be no talk of any decrease in efficiency, no matter what temperature is in the heating element.

The cost and maintenance of induction heating boilers

Induction heating boilers are 2 times more expensive than heating boilers. Despite the fact that they are qualitatively lower, as we saw from a critical analysis of their so-called "advantages".

They also weigh 2 times more than heating boilers, have large bulky dimensions, and all the electronic filling is outside. While in heating boilers, it is hidden in the boiler itself.And here there is an additional box, which sometimes there is nowhere to place, especially when it comes to a very small room for a boiler room.

In induction boilers there is no automatic power selection, that is, only a heating element boiler can choose itself at what power it needs to work at the moment.

With induction heating at home, there will be constant voltage surges and overloads, and in heating boilers, the relay works very quietly. And you can only notice it as quiet clicks, being next to a working boiler.

Even in induction boilers, thermal protection for overheating and freezing is completely absent, which is available in heating boilers.

There are no low water pressure sensors in induction heating boilers. There is no error indication that allows you to accurately establish the malfunction due to which it got up (the corresponding indicator will blink on the display of the heating boiler).

But the most important thing that induction boilers do not have is the ability to connect a boiler!

Varieties of induction boilers

There are two of them. The main difference between them is that different purities of current are used for heating.

Induction boilers SAV

These devices use conventional alternating electric current, which is known to have a frequency of 50 Hz. Various types of such boilers can be designed for a voltage of 220 volts or 380 volts.

For example, we will give the characteristics of one of the models. If the power is 2.5 kW, then the heating power will be 2100 kcal per hour. This is enough to heat a room with an area of 30 - 40 square meters. The cost of such boilers will be approximately 30 thousand rubles.

WIN boilers

These boilers use high frequency alternating current. In order to obtain it, an appropriate converter is used. As a result, we get a more efficient heating of the coolant. In such boilers, the inner part is made of a special electromagnetic alloy. During operation, a magnetization reversal occurs, as a result of which a strong heating of the coolant occurs.

Thus, heating in boilers of this type occurs not only due to the heating of the pipes through which the coolant moves, but also due to the heating of the ferromagnetic parts of the body and the mechanism. A typical 3 kW boiler of this type emits 2500 kcal per hour. The whole system, together with the pump and the automation necessary for operation, will make from 33 to 35 thousand rubles.

If you have a country house, then induction boilers for heating it will be the best option. Only this type of heating systems will be effective when operating in automatic mode. The temperature in the house will be maintained without any intervention from you.

To buy or not to buy an induction heating boiler?

Of course, you yourself must make a decision for yourself which boiler you should buy: a high-quality heating element or still a more bulky, less efficient and expensive induction boiler.

But you must consider the following: an induction boiler is not a unit for heating systems, especially if they are individual and do not require large capacities. Of course, it is impossible to do without induction heating in some industrial areas of technical production, but this applies to production tasks.

Still, there is nothing to drag a complex, heavy and expensive unit into your house. You can get by with a more elegant solution - a heating boiler.

Manufacturers of induction heating boilers deliberately give incomplete information about their products, which misleads those who make a choice in the direction of one or another boiler. It is important here to tell the truth and show your product from all angles so that people know what they are buying.

The device and principle of operation of an induction boiler

An induction boiler consists of the main elements:

- Housings;

- Induction coil;

- Core.

The principle of operation of induction units is extremely simple: passing through the coil, an electric current generates a strong electromagnetic field. In accordance with the Joule-Lenz law, under the influence of electromagnetic waves, the tubular core is intensely heated, giving off thermal energy to the coolant circulating inside it.

The performance of such systems is evidenced by the fact that, since the 30s of the twentieth century, the principle of electromagnetic heating has been successfully used in metal-melting furnaces.

Expert review of an induction heating boiler

One of the leading Russian experts in the field of boiler installation and maintenance in Russia Vladimir Sukhorukov in one of his YouTube programs "Induction boiler - a big misunderstanding", released on December 12, 2020, he proved in detail and in detail that induction heating boilers are inferior to traditional heating boilers.

Vladimir Sukhorukov did not find any reason for using an induction boiler in a boiler room. Moreover, he strongly advises not to buy induction boilers under any circumstances when there are high-quality heating boilers that work stably and smoothly.

Perhaps you need to heed the advice of an expert.

Operating principle

First, let's talk about the general principle of operation of such heaters. As you know, when a direct current circuit is turned on or off, an electromagnetic field is formed, which, in turn, creates a current in the conductors located in it in a certain way. This action heats up the conductor on which it acts.

If we now imagine the action of an ordinary alternating current having a frequency 50 Hz, then we will see that the action of the field will lead to an even greater heating of the metal core. It is clear that, in some cases, a high-frequency electric current can be applied, which is even more capable of producing heat.

This idea was used to create induction heating boilers. Now let's dwell on how exactly they are arranged.

The entire device is housed inside a metal casing.

The heating element is a seamless metal tube that is located inside it. They are located inside the coil, which is placed inside a closed housing. An alternating electric current is passed through it, as a result of which the metal pipes are heated and, accordingly, the liquid that flows through them.

For this, ordinary water or other specialized types of liquids can be executed. Usually, in order to circulate the liquid, a pump is used that drives water through pipes.

An important feature of this type of heating is the presence of microvibration, which plays an important role in preventing the formation of scale in the pipes. In addition to water, antifreeze or, for example, machine oil can also be used as a heat carrier.