Heating for the Russian climate is an indispensable attribute of any home. Previously, ovens were used for this, but they cannot provide a constant room temperature, unlike modern devices.

Therefore, in recent years, heating of a house with a solid fuel boiler has been increasingly used. This allows you to put firewood much less often and does not require heating early in the morning, since most devices are able to automatically maintain the required temperature. And how to properly heat a solid fuel boiler, we will consider further.

The heating device is warmth in the house

Many settlements have not yet been supplied with gas. Therefore, residents of such settlements have to look for an alternative to gas equipment. The best solution in this case is heating a country or private house with a solid fuel boiler.

It is gaining more and more popularity not only due to its ability to work on wood or coal, but also due to its complete autonomy.

Indeed, for a solid fuel boiler, neither gas nor electricity is needed. It can only work on wood, while maintaining a comfortable room temperature. However, such devices are produced in various modifications and in order to make the right choice, you need to at least briefly familiarize yourself with each of them.

Models

Consider the most popular models of solid fuel boilers Zota.

Zota carbon

Zota boiler carbon model

This model has been produced since 2013. The device is made of high quality steel and is used for heating both residential premises and industrial enterprises, the area of which reaches 600 m². The line includes 7 models of different sizes, the power of which varies from 15 to 60 kW.

Zota Carbon boilers have a unique design. Let's consider the key advantages of such devices:

- First of all, it is worth noting the firebox, the dimensions of which are very impressive. Fuel loading is from the top and air supply is adjustable. The boiler is very easy to replenish with a new portion of firewood, and its autonomous operation time increases to 11 hours.

- The body is made of steel, which is highly resistant to corrosion processes. Due to this, the cost is reduced, as well as the key disadvantage of steel boilers - the susceptibility to corrosion is reduced to nothing.

- The combustion chamber is designed in such a way that the fuel combustion process takes place at a specific place, which contributes to an increase in the duration of the boiler operation on one load. With the help of chamotte, you can burn out the exhaust gases, due to this, the heating unit becomes a coal-fired pyrolysis boiler.

Features of pyrolysis boilers for long burning are described here - The ash pan is located within a three-way heat exchanger, which contributes to an increase in heat removal and an increase in the efficiency of a solid fuel boiler, as well as an increase in its productivity.

- Thanks to the special design of the heat exchanger and the movable grate, the unit can be cleaned quickly and easily.

- You can install a heating element with a power of up to 9 kW with a control unit.

Key technical characteristics of Zota Carbon are presented in the table.

| power, kWt | 15 | 20 | 26 | 32 | 40 | 50 | 60 |

| Heated room area, m2 | 150 | 200 | 260 | 320 | 400 | 500 | 600 |

| Efficiency,% | 80 | ||||||

| Chimney section, mm | 150 | 180 | |||||

| Chimney height, m | 5 | 7 | 8 | 9 | 11 | 13 | 15 |

| Heat exchanger capacity, l | 48 | 55 | 66 | 78 | 93 | 102 | 121 |

Zota Mix

The main distinguishing feature of such devices is their versatility.Most of the boilers presented in this model range operate on wood and coal, but also in rare cases diesel, gas and electricity can be used for their operation. This flexibility is due to the special design, which makes it possible to mount different types of burners and operate with the same effect on different types of fuel.

Solid fuel boiler ZOTA MIX-40

What is the best coal for heating? The answer in this post

Pros:

- the heat exchanger is made in an X-shape, which contributes to a high heat removal and an increase in productivity;

- the water jacket is insulated, which also has a positive effect on the work efficiency. Thanks to its use, the amount of heat loss is reduced and the efficiency increases, in addition, fire safety is improved;

- the units are easy to clean and maintain, because unhindered access to the gas duct is provided and the ash drawer is spacious;

- the most suitable pressure for the heating system is 3 atm. In emergency situations, the device can withstand pressure surges up to 4 atm without the risk of explosive situations, as is the case with cast iron boilers;

- power can be adjusted by means of a built-in traction generator and a draft control damper in the chimney. Control and adjustment of temperature and pressure is carried out by means of a thermomanometer located in the front.

Technical characteristics of Zota Mix boilers.

| power, kWt | 20 | 31,5 | 40 | 50 |

| Room area, m2 | 200 | 315 | 400 | 500 |

| Efficiency,% | 80 | |||

| Furnace volume, l | 35 | 45 | 63 | 79 |

| Heat exchanger capacity, l | 50 | 70 | 120 | 140 |

| Chimney diameter, mm | 150 | 180 | ||

| Chimney height, m | 6 | 7 | 8 | 9 |

The solid fuel boiler Zota Mix has won the love and trust of users and they leave a lot of positive feedback about these heating devices.

Topol M

This model is an improved modification of household solid fuel units with low power ratings of the Poplar series.

Of course, such devices are produced in a new design, but besides this there are their other advantages:

- the boiler body is insulated with cardboard or balsat, due to this, heat losses are reduced and the efficiency of work is increased;

- an auxiliary horizontal heat exchanger is located inside the firebox, due to which the unit becomes three-way;

- you can open the door of the firebox both horizontally and vertically; firewood is easily loaded with the help of a skewer door, the length of which reaches 58 cm;

- the ash pan is equipped with a flap, the degree of opening of which can be adjusted either mechanically or by means of an automatic traction regulator;

- in the area where the scraper door is located, you can mount a heating element and a gas burner.

Characteristics of Zota Poplar M

| power, kWt | 14 | 20 | 30 |

| Heated room area, m2 | 140 | 200 | 300 |

| Efficiency,% | 80 | ||

| Furnace capacity, l | 36 | 46 | 53 |

| Heat exchanger volume, l | 46 | 54 | 64 |

| Chimney diameter, mm | 150 | ||

| Chimney height, m | 6 | 7 | 9 |

The solid fuel boiler Zota Topol M will be an excellent solution for those who wish to purchase a small, versatile unit with high performance. Due to their high efficiency rates, reasonable cost and ease of use, these units have gained wide popularity in the domestic market.

Household boiler with stove Zota Master

Zota Master is a high-quality, compact heating boiler, which is characterized by high efficiency. Its main feature is the presence of a hob, which makes it possible to use the unit not only for heating, but also for cooking. In addition, a number of other advantages stand out:

- high performance is due to high-quality thermal insulation and the design of the heat exchanger, which provides good heat dissipation;

- the volume of the combustion chamber allows you to heat the boiler with wood;

- in the public domain there is such an option as a mechanical traction regulator, which allows you to transfer the action of the device to automatic mode;

- a unit with a power of 32 kW can be equipped with a heating element or a gas burner.

Read about the features of solid fuel boilers with a stove here

Due to the high quality assembly, the unit has a large heat removal area and good thermal insulation. Zota Master boilers are becoming modern solid fuel long-burning units, which, moreover, please with their "pleasant" price.

Technical characteristics of Zota Master

| power, kWt | 12 | 18 | 20 | 25 | 32 |

| The area of the heated room. m² | 120 | 180 | 200 | 250 | 320 |

| Efficiency,% | 75 | 73 | 75 | 73 | 73 |

| Loading chamber volume, l | 32 | 38 | 40 | 52 | 61 |

| Chimney section, mm | 150 | ||||

| Chimney height, m | 5 | 5 | 5 | 6 | 7 |

Zota Haze M

Zota Smoke AOTV-12 M

The solid fuel boiler Dymok M is a budget heating device that is highly reliable and is in great demand among users. To date, there are already 4 versions of this series on the market, each of which is more and more improved.

Main advantages:

- The firebox is very spacious, so you can safely load long logs into it.

- The loading and ash doors have high-quality thermal insulation. Due to this, the boiler is characterized by a higher gas density, which leads to a decrease in heat loss and an increase in productivity.

- You can install heating elements on all standard sizes.

- Models with low power indicators have a hob.

Technical characteristics of the Zota Dymok M series

| Model | AOTV-12M | AOTV-18M | AOTV-20M | AOTV-25M |

| power, kWt | 12 | 18 | 20 | 25 |

| Heated room area, m2 | 120 | 180 | 200 | 250 |

| Efficiency,% | 70 | |||

| Loading chamber volume, l | 34 | 60 | 70 | 80 |

| Chimney section, mm | 150 | |||

| Chimney height, m | 5 | 5 | 5 | 6 |

Types of solid fuel boilers

All equipment of this class can be divided into 2 groups:

- Automatic fuel supply

- Manual loading

The first include pellet boilers. In them, the role of fuel is played by granules, they are loaded into special bunkers and from there they enter the furnace. Such devices have a high efficiency and can work in automatic mode for weeks, without human participation in the process.

The latter, depending on the design features, are divided into 3 types:

- Classic

- Pyrolysis

- Long burning

They can use firewood and wood waste as fuel.

A traditional or solid fuel boiler for wood has been produced for a very long time, and structurally has practically not changed. In it, the combustion chamber is located at the bottom and is considered the hottest part of it. Most often it is made of cast iron or steel. However, such heating of a wooden house with a solid fuel boiler is rarely used, since it requires frequent maintenance.

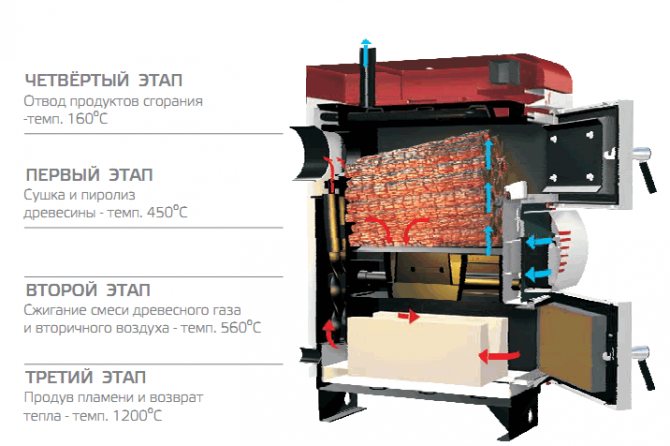

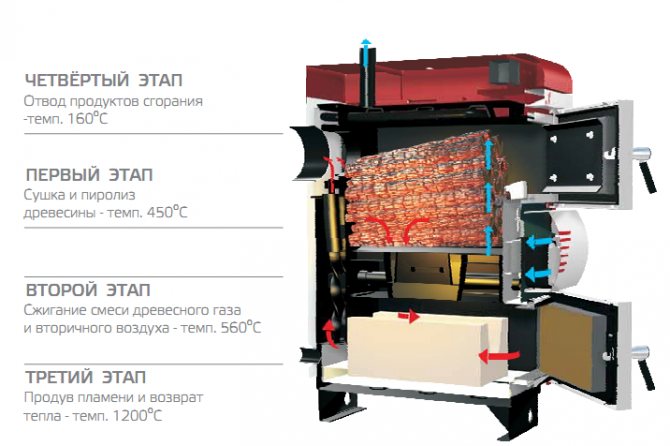

Pyrolysis machines are a new step in the solid fuel environment. Their work is based on the principle of decomposition of wood into solid residues and gases and combustion of the latter. The advantages of this device include high efficiency, minimal ash and soot formation. Among the disadvantages is the need to burn dry firewood with a moisture content of no more than 20%.

Long burning - their principle of operation was developed in Russia and has no analogues in the world yet. It is a new generation boiler not only structurally, but also in terms of operation. Its main advantage is its simplicity of design and the ability to service it once a day when operating on natural moisture fuel. A solid fuel wood-fired boiler has the most accurate power control and can produce a given amount of heat.

Additional abilities

These solid fuel boilers for long burning "Zota" can be supplemented with a block heating element, the power of which varies from 3 to 9 kW.The equipment is supplied with a thermomanometer with a convenient scale, which is located on the front of the device. The equipment is capable of operating at a high pressure of 3 atmospheres, which is why the unit copes well with the conditions of closed systems. The ash pan is located on a water-cooled surface. According to users, this improves the gas tightness, as a result of which the efficiency and duration of combustion increase. The equipment has a locking loading door.

Heating system with solid fuel apparatus

The use of devices of this type, although in demand, is not as popular as gas. This is due to the need to constantly add fuel for solid fuel boilers and monitor the operation of the device. However, there are several ways to simplify the operation of a solid fuel boiler:

- Automatic fuel loading

- Turning on the device together with the electrical

- Automation of water supply

The first is easily done by connecting pellet equipment to the heating system. In it, the fuel supply is carried out automatically and human participation in this process is not required. Such heating of a private house with a solid fuel boiler is permissible even in the case of non-permanent residence in it.

The second method is considered the cheapest in terms of labor costs and the most popular. Two devices are connected in parallel to the primary ring of the system. In this case, the electric only maintains the minimum water temperature. And the main source of heat is solid fuel.

The last method involves turning on the accumulator tank. It accumulates the coolant prepared by the boiler during the day, with the aim of its further consumption at night, when there is no manual fuel loading. Such a system can be automated.

Each of the schemes has the right to exist and the choice of the optimal one depends on various factors.

Reviews of boilers from the Topol-M series

The solid fuel boiler "Zota Topol" has a more insulated and gas-tight body. The water jacket under the decorative cladding is protected in the form of basalt cardboard, which reduces heat loss. The combustion door opens horizontally, it is equipped with a blower flap, which can be adjusted using a screw or a mechanical thermostat. This, according to buyers, increases the gas tightness of the device, allowing more precise control of the oxygen supply. As a result, the combustion cycle can be extended from 10 to 12 hours. The solid fuel boiler "Zota Topol-M" has a redesigned combustion chamber. A three-way gas flue is added to the horizontally oriented heat exchanger. This increases the heat transfer area and greatly improves the heat transfer efficiency. The damper is removable for cleaning the heat exchanger. There is a hatch on the flue, with the help of which, as customers mention, it is easy to remove soot.

Having examined the top panel, you will notice that there is a thermometer in this part of the boiler, it determines the temperature of the water supply. As an alternative to firewood and coal, you can use electric heating, from which Topol-M will work. This possibility is provided thanks to the built-in heating element block with an external control panel. It is possible to install a gas burner instead of a bore door. The presence of the latter creates additional convenience for loading fuel. The depth of the furnace can vary from 38 to 58 cm. According to buyers, the boiler has an additional ash door, with which you can remove ash, and do it at any time in the furnace. To make the use of the boiler more comfortable, ergonomic handles are installed on each door.

Kinds of kindling

Most of the devices of this type operate on various types of fuel:

- Firewood

- Peat briquettes

- Granules

- Anthracite

- Cox

- Brown coal

Moreover, their calorie content is different, and the effective operation of the device depends on it. Therefore, those who purchase such a boiler should take into account that when burning less high-calorie fuel, the power drop can be up to 30% (at permissible humidity) and even more at natural humidity.

There is one more nuance. Usually, the manufacturer indicates the best way to heat a solid fuel boiler and which fuel should be taken as the main one. It is advisable to comply with these requirements in order to achieve maximum efficiency and to make heating a country house with a solid fuel boiler as convenient as possible.

For example, when recommending to heat with brown coal, it should be used as the main one, and fine-grained fractions should be added only to the hot layer and in small portions.

Briquettes - can be peat, straw or wood. It is ideal to use only those produced by pressing. Briquettes disintegrating into sawdust may only be used together with firewood or brown coal, so as not to damage the boiler.

Pellets can also be made from straw or wood waste. They are pressed, like briquettes, and are most often used in special solid fuel boilers.

The consumption of firewood in a solid fuel boiler will be minimal if they are dry, only then it is possible to achieve maximum power from the boiler and extend its service life. Otherwise, the useful energy content of wood will be significantly lower.

Reviews of boilers series "Zota Mix"

One of the most popular among the described manufacturer is the solid fuel boiler "Zota Mix". It has an x-shaped heat exchanger design, with the help of which it was possible to achieve maximum heat transfer area. This indicates a better heat transfer and an increase in efficiency. Users note that heat loss is reduced due to the quality of the thermal insulation used. The boiler becomes less fire hazardous. The outer casing, which covers the insulation, is covered with powder paint, which, as the owners of such equipment emphasize, is characterized by increased wear resistance. The manufacturer has taken care of the convenience of cleaning the equipment; for this, there is a removable door on the front panel that provides access to the entrance. In order to get rid of combustion products, an ash box is provided, it is located behind the ash pan door.

Experts recommend

The operation of a solid fuel boiler will be effective only if the correct fuel is selected for it, as well as regular maintenance of the device. And in order to determine for yourself how to heat a solid fuel boiler, and to achieve maximum efficiency, professionals advise:

- When striking wood, a large amount of smoke is emitted, therefore it is recommended to place larger logs at the edges, and small kindling in the middle

- The use of peat in densely populated areas is not recommended due to the release of large particles into the atmosphere and the release of a sour odor

- For the complete combustion of anthracite, a massive hearth is required, therefore, when it is used, when extracting the ash, larger fragments are sifted out and reused