Features of kindling gas heating boilers

Each heater is equipped with automation. The ignition procedure depends on its design and features. Modern boilers are equipped with piezo ignition or automatic start-up. In villages it is rare, but there are still old KST boilers that are capable of operating on solid fuel and gas. During the conversion, the heating devices were equipped with primitive automation, where the ignition is ignited with matches.

The features of ignition depend on the automation of the gas boiler

Regardless of the model of the boiler and its automation, preparatory measures are carried out before ignition:

- Before the first start-up after the summer season, all units of the supply gas line, the automation are checked for gas leaks. Do this easily with soapy water. If gas is etched on the thread or connection, soap bubbles will appear.

- It is not superfluous to check the heating system itself for leaks. Make sure there is enough coolant. To do this, in a closed system, the pressure is checked on a pressure gauge. If the heating is gravity, make sure that the expansion tank is filled with water.

- After renovation, a lot of dust forms in the house. With the help of the draft, it partially enters the boiler furnace, settles on the burners. A similar situation is observed if the heating device in the country has stood idle for a long time. Before firing up, try to clean all burner assemblies with a vacuum cleaner or other devices.

- Immediately before starting the ignition, check the presence of traction. This can be done easily with a strip of paper. If it is pulled inside the firebox, then there is a draft.

After the preparatory measures, they proceed to the very process of firing up the boiler.

To properly ignite a gas appliance, you need to know the features of automation Important! When using a new gas boiler for the first time, carefully read the instructions from the manufacturer.

The ignition process begins with opening the gas supply valve to the boiler from the main line. If the heating is equipped with a circulation pump, it must be put into operation. Further actions depend on the features of the automation:

- Old KSTs with ancient automatics are ignited manually. First, a burning match or torch is introduced into the window, gas is supplied with a regulator. After lighting the igniter, give it a couple of minutes to warm up. The regulator lever is moved to the next position. The main burners are ignited.

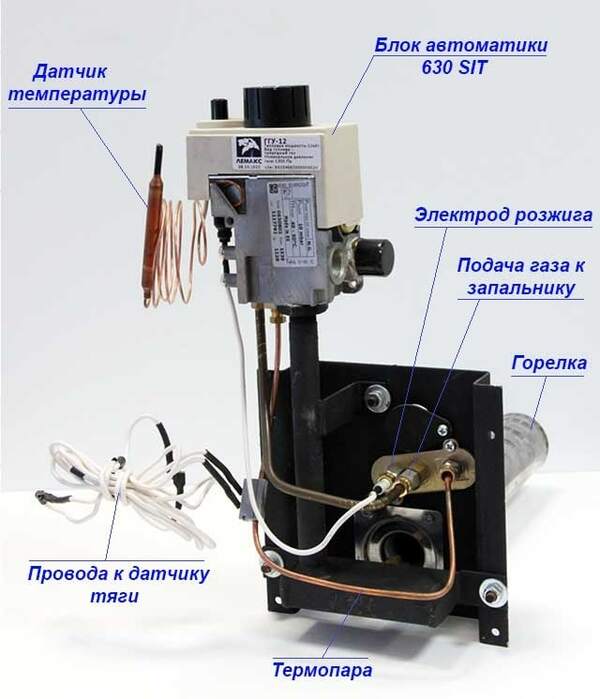

- Modern budget boilers are also started manually, but with the help of a piezoelectric element. Press the flame regulator with one hand. Continuing to hold it, the second hand press the button of the piezoelectric element. With each action, a click occurs, and a spark is formed on the electrodes near the igniter. The action continues until the flame appears. After the ignition of the igniter, the regulator is held for about 30 seconds to warm up the thermocouple. It can now be released and rotated to ignite the main burner.

- Expensive gas boilers are equipped with an electronic start. There are even models that are controlled by a remote control. The ignition of such devices is carried out with one click of the "Start" button. Then the automatics will do everything by itself. It is only important not to forget to connect the unit to the mains.

Only a specialist is trusted to set up automation

Each gas automation has its own characteristics. The regulators are marked with numbers, asterisks, circles.They indicate different positions at which a spark is supplied, the burner is ignited, and the temperature regime is set. All the nuances of a particular model are described in the manufacturer's instructions. It must be studied before starting the ignition.

Insufficient fuel pressure

One of the most common causes of burner damping in gas boilers is insufficient supply gas pressure. If the reason is related to malfunctions in the gas distribution network, then the only thing to do is to report the malfunctions to the gas service. But most often, the reasons are not in the gas distribution networks, but in the boiler itself or its piping.

What can lead to attenuation?

If the gas boiler often goes out, then perhaps this is due to the following factors:

- Gas meter jammed. A meter is installed on the gas supply pipe. It happens that the device starts to pass gas worse. To check the health of the meter, you need to see how it works. If the readings change smoothly at the gas flow rate, then the meter is in good working order. If the readings change abruptly, or the device begins to emit an unusual noise, then the reason for the poor operation of the boiler is obvious. To fix the problem, you must contact the gas service. The specialist will replace the meter and the unit will stop damping.

Advice! It is strictly forbidden to try to repair the gas meter yourself. If gas service workers see that the consumer has interfered with the operation of the device, then the homeowner will be issued a fine and obliged to replace the meter, of course, at their own expense.

- The sensor that controls the burner is out of order. This may be a temperature sensor that, during normal operation, turns off the burner when the coolant heats up to a certain level. Or a sensor that analyzes the gas content in the air. This appliance shuts off the gas supply when the gas concentration in the room air rises. Diagnostics of operation and replacement (if necessary) of sensors should be carried out by a specialist.

- Poor connection quality. If the connections in the gas supply line are not tight enough, this will lead to the formation of leaks. As a result, the gas enters the furnace at a reduced pressure. In order to locate the leak, it is necessary to treat the joints with soapy water. If gas leaks, the liquid will begin to foam. Identified leaks will need to be sealed to eliminate leaks.

The reasons why the gas boiler goes out

There are many reasons for the extinction of a flame in a firebox. They are different for each type of boiler. This is due to the fact that gas heating appliances of different models differ in the principle of operation.

Atmospheric boilers

Atmospheric boilers are considered to be the simplest in functionality. Combustion in the furnace is supported by natural air exchange - draft. If it disappears, the burner in the gas boiler goes out, and with it the igniter. Other reasons for the extinguishing of the flame can be malfunctions with the automation.

Clogged working units

Gas is supplied to the igniter and burners through the nozzles of the nozzles. They are also called nozzles. Gas burners have a fine mesh filter at the inlet. If these elements are contaminated, the igniter will not ignite at start-up or the burners will often go out.

When the nozzles, mesh filters are clogged, the boiler does not ignite or goes out

A simple dust blockage is blown out with a vacuum cleaner, hairdryer or compressor. If the burners continue to go out, they will have to be removed and cleaned from burning. When the igniter does not fire at all, the jet is probably boiling. The nozzle is removed, carefully cleaned of burning. After cleaning, the jet should freely enter its nest.

Attention! It is prohibited to enlarge the size of the nozzle orifice.

Failure of thermocouples and other electrical problems

A thermocouple monitors the control of the flame in the firebox of a gas boiler.The node is connected to an electrical circuit, where there is an electromagnet, connecting contacts. If one of the units fails, the AOGV gas boiler goes out when fired up.

The thermocouple monitors the presence of a flame in the furnace

If the thermocouple fails, a signal is sent to the solenoid valve that there is no flame. The assembly shuts off the gas supply. The same happens when the solenoid valve fails. Even with a working thermocouple, the unit will not leak gas. If a breakdown occurs in a working boiler, it immediately goes out. When the thermocouple or valve is generally inoperative, the heater cannot be ignited.

A similar situation applies to contacts. They oxidize over time. The problem is easy to calculate when the gas in the boiler goes out often and for no apparent reason. Poor current flows through oxidized contacts. The circuit is periodically broken, the solenoid valve shuts off the gas supply, and the boiler goes out.

The failure of each unit can be found by dialing a multimeter. Oxidized contacts are cleaned. The thermocouple and solenoid valve cannot be repaired. They only change.

Important! A faulty thermocouple is often mistaken for incorrect alignment. The sensing element of the assembly must be permanently located in the combustion area of the pilot. If the flame does not hit it, the boiler goes out.

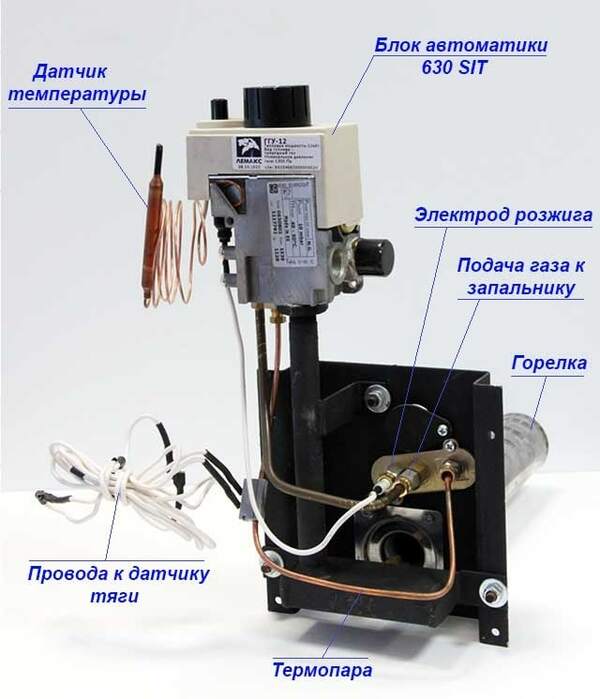

Traction problem

Most often, atmospheric boilers go out due to a draft problem. Its complete absence indicates that the furnace or chimney is clogged with soot. There is only one way out, to start a thorough cleaning.

You can check the presence of traction with a burning match brought to the viewing window

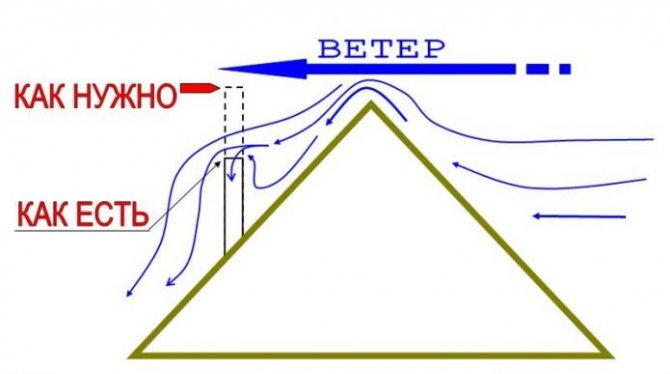

There is such a thing as reverse thrust. When it appears, the gas boiler instantly goes out. There is a strong smell of carbon monoxide in the room. Back draft is when air movement does not traditionally take place from the firebox through the chimney to the street, but in the opposite direction.

If the boiler goes out for no reason, check the draft first. The gas supply from the main line is shut off with a tap. A burning match is brought to the viewing window. If the flame draws into the furnace, the draft is all right. The gas appliance goes out for another reason. In the absence of traction, the flame will burn evenly near the window without hesitation. If the flame deviates from the viewing window towards the room, then this is a clear sign of back draft, due to which the boiler burner goes out.

Advice! The presence of traction can be checked with a thin strip of paper.

Back draft is caused by wind blowing through an incorrectly installed chimney

Back draft arises from blowing wind into the chimney. Carbon monoxide returns through the pipe to the boiler furnace, gas contamination occurs, and the burner goes out. The problem is solved by lengthening or shortening the chimney, installing a cap that protects from wind and precipitation.

Lack of oxygen

Combustion is supported by oxygen. If it is not enough inside the firebox, the wick of the gas boiler burns, and the burner goes out during operation.

Combustion inside the furnace maintains oxygen

Lack of oxygen occurs for several reasons:

- a room with a gas appliance is hermetically closed by doors, double-glazed windows are installed that do not allow air to pass through;

- boiler room planning errors;

- next to the boiler there is a gas stove with a powerful hood;

- improper arrangement of forced ventilation in the house.

It is easy to restore oxygen access by simply opening a window or door. In the boiler room, a special window is installed on the lower part of the wall for air flow.

Gas pressure drop

Each gas appliance is designed for a specific gas pressure. If the parameter in the line does not correspond to the required standards, the burner goes out.

The presence of a pressure gauge will allow you to constantly monitor the pressure change in the gas line

A decrease in pressure usually occurs with the beginning of the heating season, when gas is consumed en masse. Over the course of service, the parameter is restored by the adjustment method. If the pressure drop has occurred due to a gas leak at the boiler units, it is immediately turned off and specialists are called in, without waiting for the boiler to go out.

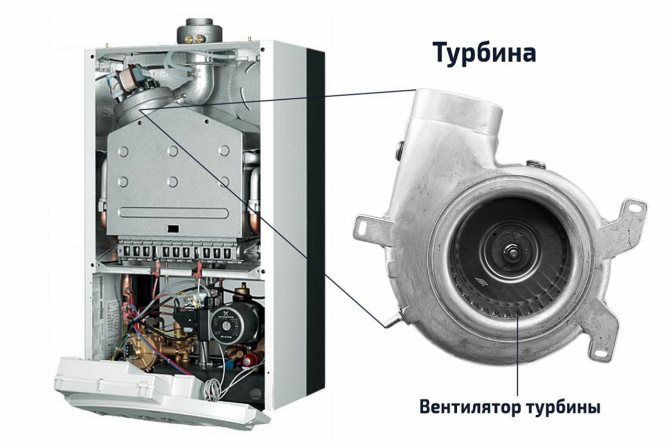

Turbocharged boilers

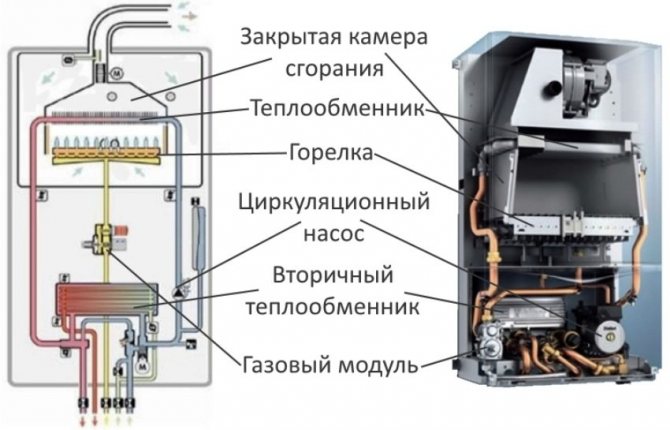

A feature of turbocharged gas appliances is the presence of a closed combustion chamber. Forced draft is provided by a fan. The reasons why a floor or wall gas boiler goes out are the same as for atmospheric counterparts, but attention needs to be paid to two more points.

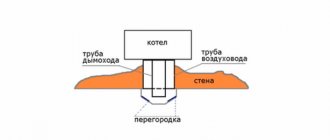

Chimney outlet icing

During operation of the gas appliance, condensation forms in the coaxial chimney due to the temperature difference. In winter, with severe frosts, it turns into ice growths. The same situation occurs when, to protect against precipitation, the chimney of a gas appliance is equipped from a coaxial pipe or a cornice-type head. The ice closes the channels, the draft disappears, the burner of the heater goes out.

Ice build-up forms on a non-insulated coaxial chimney

The problem is solved by insulating the chimney section protruding outside the building. Ice build-up is thawed with a hairdryer, a construction burner or hot water. It is undesirable to break the ice. The pipe could be damaged.

Failure of the turbine

The advantage of turbine devices is the constant thrust provided by the turbocharging. The exhaust fan is responsible for the removal of combustion products. If the unit fails, the thrust disappears. The burner, together with the igniter, instantly goes out.

When the turbine is not working, the burner with the igniter will instantly go out

A working turbine can be heard over a uniform hum. A change in sound or complete silence indicates a problem. To repair the unit, they call specialists or make its replacement.

Double-circuit boilers

A feature of double-circuit gas appliances is the presence of an additional circuit built into the main heat exchanger. It serves to provide hot water supply to one taps.

Boilers are capable of going out from all of the above reasons, as well as when the protection against water overheating is triggered. The second problem occurs in two cases:

- cold and hot streams of water mixed;

- the reducer diaphragm is worn out.

The second problem is clear. The membrane needs to be replaced. As for mixing streams, the manufacturer in the instructions notifies that you cannot open the taps of cold and hot water at the same time. If the cold flow is higher, hot water remains in the heat exchanger. To prevent it from bursting by pressure, the protective system shuts off the gas, the burner goes out.

Volatile electronic boilers

Modern volatile boilers are crammed with electronics. The units are sensitive to voltage surges, incorrect phase and zero connections. The gas appliance goes out if at least one node in the system is out of order.

Electronic volatile boilers are sensitive to power surges

The burner can go out due to improper draft, wear of the ionization electrode, stopping of the circulation pump. All malfunctions are recorded by sensors, transmit information to the electronic unit, which in turn displays the error code on the display. Most breakdowns can only be eliminated by specialists.

Incorrect location of the gas boiler in the room

The location of the gas boiler in the room also plays an important role. In some cases, such situations were observed when, for example, the boiler is in the kitchen, which in turn is located somewhere on the second or third floor of the building and this kitchen has a balcony.

So what's going on? People open the balcony door, the draft in the chimney is excellent and ... What happens? At first we had some kind of air flow from the corridor or from neighboring rooms when opening the kitchen door and the draft was more or less stable. And then, with a sharp opening of the balcony, what happens? A huge amount of fresh cold air enters the kitchen and a very sharp strong draft is formed in the chimney.

The amount of air increases and hot air begins to go into the chimney with an even greater speed. Thus, the wick literally starts to hesitate, to walk. That is, it can simply either be blown off, or, if there are bad contacts of the safety circuit, or worn out sensors. This can also cause your boiler to go out.

It should be noted that the above reasons are the most common problems. There may be special cases when the cause of the fading and blowing out of the gas boiler can only be determined by a specialist as a result of a thorough examination.

Only one thing is important - observe the safety rules for gas supply and comply with the standards prescribed there.

What to do if the gas boiler goes out

When the flame goes out, do not panic. The first step is to shut off the gas supply from the main with a tap at the inlet. The room is ventilated, since the smell of fumes or pure gas is not always felt by the smell.

The next step is to try to establish the cause. The traction problem is solved independently. Examine the chimney. If necessary, clean it from soot, ice.

To clean it from burning or replace the thermocouple, the unit is removed from the boiler

If the device goes out due to minor faults, you can fix them yourself. To replace the thermocouple, remove the igniter assembly from the boiler, unscrew the cap nuts with a wrench.

When there is a power surge in electronic heating devices, fuses often burn

Even a volatile gas appliance can be repaired on your own. If it does not turn on, the fuses may have overheated from a power surge. It is necessary to get to the main unit and replace the failed elements.

All other malfunctions of complex units, gas equipment are trusted by specialists. Mistakes made will lead not only to more serious breakdowns, but also dangerous to life, since the gas is explosive.

The video tells why the igniter on the gas boiler does not ignite or go out:

Attenuation problems associated with the boiler itself

Malfunctions of various kinds can also occur in the boiler itself and cause the device to turn off or dim.

Problems can be expressed by the following symptoms:

1. The gas burner does not start or burns very weakly. The origin of the problem may lie in the clogged nozzles. In case of unsatisfactory operation of the nozzles, the burner may start to smoke. You can clean the gas boiler yourself using a thin wire or a soft brush.

2. The burner goes out after a short time. This can be caused by contamination of the ionization electrode, a gap violation, or a disconnected lead wire that causes the unit to howl and hum. This type of breakdown is completely removable.

3. Flame separation. With this malfunction, it is necessary to adjust the gas pressure in the pilot. Excessive ventilation can also be the cause.

4. Extraneous noise in the device and unreasonable shutdown. This may indicate a breakdown of the internal fan or pump, as well as the failure of the thermostat.

An excellent choice for protecting a gas boiler from voltage surges in the house will be the purchase of an uninterruptible power supply. More details:

Professional advice

In order for the burner or wick not to go out unreasonably, the gas equipment needs care. Experts advise to periodically carry out a routine inspection, wash the units to search for gas leaks.Chimneys and firebox are optimally cleaned every six months.

Correct burner operation is indicated by a blue flame

If the device, which is under warranty, breaks down, it is impossible to carry out independent work. It is optimal to contact the service department. The same goes for electronic boilers. Complex automation cannot be repaired without special devices and tools, as well as experience.

The main malfunctions of gas boilers Lemax

The most common malfunctions include:

- Leak of gas. Open windows immediately, shut off the gas supply, turn off the boiler and call the gas service workers.

- The color of the flame is reddish, the tongues are elongated and smoky. Poor draft or burner clogging. Clean the chimney and burner, correct the position of the pipe.

- Spontaneous shutdown of the main burner. Chimney or thermostat problems.

- There is no water circulation. If there is a pump, the reason lies in it. If natural circulation is used, it is necessary to correct the configuration of the pipelines, giving them the correct slope.

- Shutdown of the boiler. Usually occurs due to a gas supply cutoff.

The list of possible malfunctions can be continued for a long time, but there is no point in this, since each situation requires separate consideration.

How to turn on (light up)

The Lemax boiler is started up after filling the system with the required volume of water (12-14 liters for each kW of power) and connecting the gas pipeline.

Procedure:

- Open the lid, providing yourself with access to the regulator and the piezo ignition button.

- Turn the regulator counterclockwise, which will move the boiler to the “on” position.

- Sink the regulator all the way down and hold it in this position while pressing the piezo ignition button.

- After the flame appears on the pilot burner, the button can be released, but the regulator must be held for another minute.

IMPORTANT!

If the attempt to ignite the boiler was unsuccessful, it can be repeated only after 1 minute, not earlier.