Tile adhesive for underfloor heating selection criteria

All layers of flooring in contact with the heating system provide heat conduction and are subject to significant temperature fluctuations. The laws of physics always work, which means that materials, including tile glue, increase in volume when heated, and in the process of cooling they acquire the same size. Therefore, after gaining final hardness, its composition should retain plasticity, easily tolerating temperature changes.

Standard mortars used for tiling are designed to securely hold and hold the weight of the ceramic. When operated with a floor heating system, they quickly lose their qualities, dry out and crack. As a result, the tiles can come off or, with strong adhesion, crack after the adhesive layer. By purchasing a special tile adhesive for warm floors and porcelain stoneware, you will save yourself from such a nuisance and keep the original look of the repair.

photo from ardano.ru

Adhesive solutions that will be laid on the underfloor heating system must strictly comply with the following quality characteristics:

- Resistance to temperature extremes. Despite the fact that the heating of the warm floor does not exceed 40С, high-quality glue can withstand the operating range from -30 to + 100⁰С.

- The adhesion provided by the finished compound should be 0.8-1 MPa, which guarantees a sufficient level of adhesion for floor coverings.

- Compatibility with the base material is a very important point, since even well-known brands of glue may not stick without taking this factor into account.

- Ease of use - ready-made mixtures are more convenient, but due to their high cost, they are rarely used. Dry glue is used most often, although it requires preliminary mixing.

- Price segment. Famous brands of building mixtures are reasonably expensive and provide guaranteed quality, but an unknown product at an attractive price can fail. We will dwell on proven brands and their characteristics below.

- The composition should contain aluminant cement, which is responsible for the stability of the hardened layer to mechanical stress and the maximum strength of the coating.

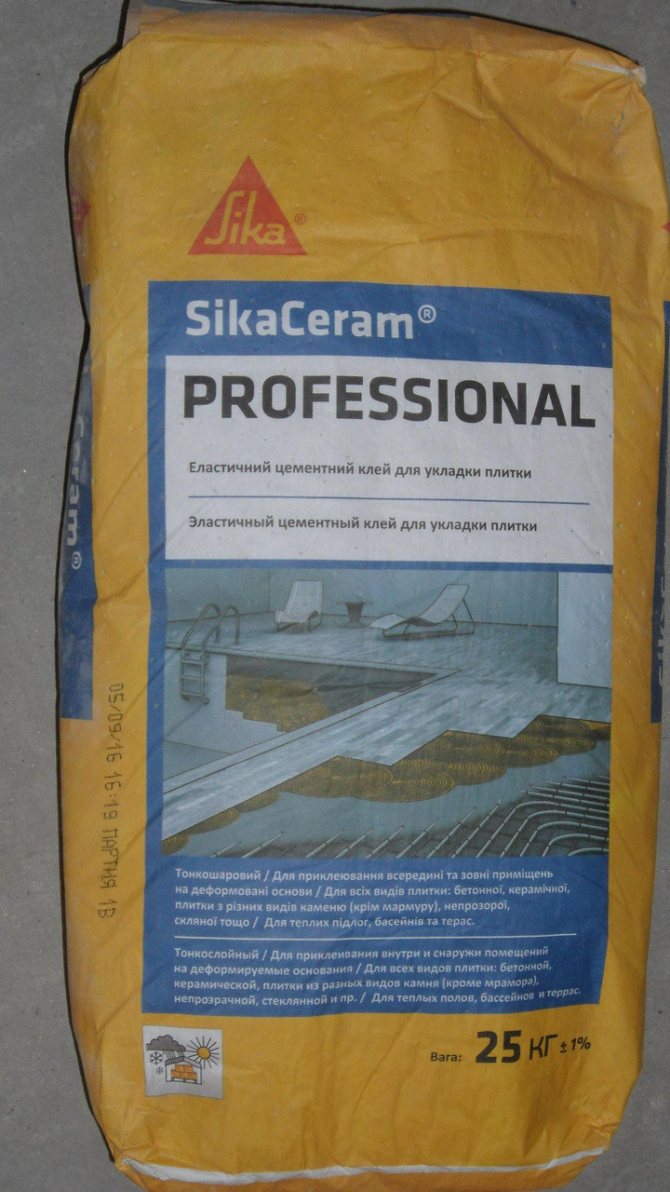

If you don't want to delve into all the subtleties and details, just take the glue for underfloor heating under the tiles with the appropriate marking or inscription on the package. If such designations are indicated by a well-known manufacturer, their product is likely to meet all operational requirements.

Factors influencing the choice of adhesive

Regardless of the design features of the "warm floor" system, before laying the tiles, the floor plane is leveled to the parameters regulated by building codes (2 mm of a difference in elevation should be distributed over a maximum of 2 m2). That is, before gluing the tiles, it is imperative to level them with a cement or polymer screed. When choosing a tile adhesive for a warm floor, you must pay attention to the base materials listed by the manufacturer that are compatible with this adhesive composition.

You can learn more about how to lay ceramic tiles yourself from the article:.

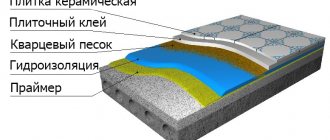

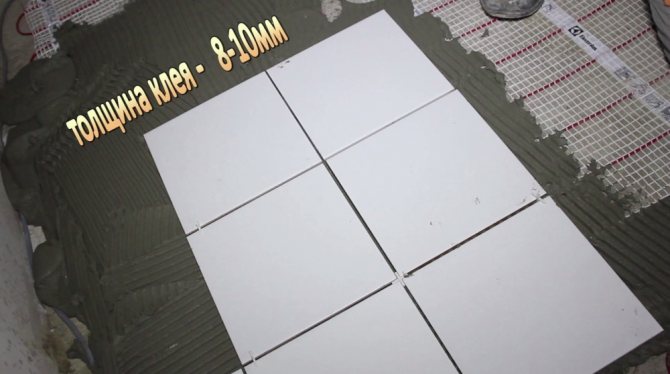

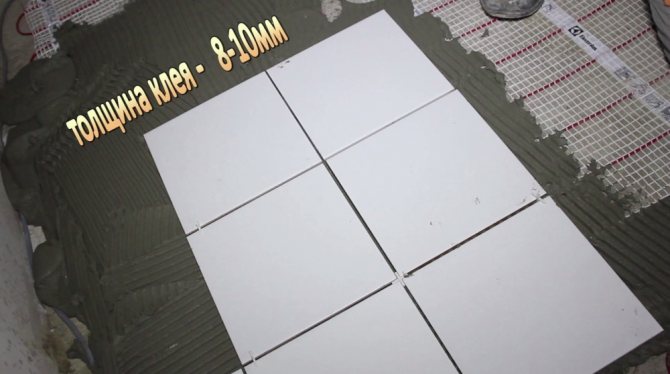

Diagram of the device for underfloor heating with tiles (top to bottom): top layer - floor covering; then elastic glue; leveling screed, in which the heating system is located; galvanized mesh; insulation

Attention.The device of the infrared film floor, regardless of which factory it is produced, is not made directly into the screed; glue must not be applied to the surface of the film heating system. The alkaline environment of the components of the adhesive composition causes the destruction of the structural bonds of the film floor and damage to the heating system. Therefore, leveling sheets of DSP or glass-magnetic material are laid on top of the film, after which a screed is applied or a layer of glue is applied.

It is possible to level the floor with heating equipment for the installation of tiles using isolon or drywall, but this option will significantly reduce the distance between the ceiling surface and the floor plane.

The best tile adhesive for outdoor use

For exterior decoration, special types of glue are chosen that are designed for aggressive factors - temperature, precipitation, mechanical damage - and provide greater adhesion to the surface.

Vitonit Ultra Fix Winter

The name itself speaks of the properties of frost resistance. Vitonite is attached to concrete, drywall and all its derivatives; bricks, screeds, plasters and putties with any composition. It is allowed to carry out facade activities at -10 ° C, without connecting heat guns.

Vitonit Ultra Fix Winter

Suitable for surfaces that experience high loads: stairs, terraces, ramps, balconies. During work, the temperature of the surface and material must be at least 0 ° C. Windy weather will reduce the activity of adhesive properties, you will have to move faster. Irregularities and indentations within 1.5 cm can be leveled with the mortar itself. A 25 kg bag will take about 7 liters of liquid within the range of + 7 ° ... + 20 ° C. Mixing is carried out with a drill with a nozzle, at a speed of no more than 600 rpm. After finishing mixing, leave to rest for 10 minutes and repeat the action. Working properties are maintained for 120 minutes. Do not add water again after mixing.

after 48 hours of drying

Layer thickness, mm

Paper bag, 25

The cost is 690 rubles.

- wide range of applications;

- elasticity;

- resistance to vibrations and loads;

cannot be used on gypsum plaster.

Bergauf granit

Working with large tiles does not require additional fasteners. In addition to finishing facades of plinths and balconies, it is used for underfloor heating systems, in rooms with a humidity level above normal and in swimming pools.

You can change the position of the plates within 25 minutes after application. The pot life of the solution is 180 min. The cladding must have a temperature not lower than 5 ° C and not higher than 25 ° C.

Layer thickness, mm

1.8 after full adhesion

Operating temperature, ° С

The cost is 520 rubles.

suitable for bathrooms, swimming pools.

- not suitable for transparent tiles;

- application with a thick layer is difficult;

- shrinkage is present.

Ceresit CM 117

The scope of application of this frost-resistant glue extends to fixing all types of tiles of natural and artificial type. The mixture is used on non-deformable substrates in any pre-treatment. Before starting installation, it is required to clean the surface from dust, bitumen, grease and dirt.

A solution is prepared in a ratio of 1: 3. The water is clean, warm + 5 ° C… 20 ° C. The work surface and air must have a minimum temperature of + 6 ° C. If you are installing over underfloor heating, you will have to turn off the system 48 hours before starting. And it is worth turning it on after three days.

Layer thickness, mm

1.8 after full adhesion

Operating temperature, ° С

Paper bag, 25

- suitable for clinker, porcelain stoneware;

- can be placed in pools;

- not stable in air;

- high price tag.

Types of adhesive bases by composition

Tile adhesive mixtures can vary in their composition. Among the most common types, there are one-component, two-component and cement bases.The first of them are quite convenient to use, since they are sold in plastic buckets in a ready-made pasty state. They are made on the basis of artificial resins, acrylics and various modifiers. The mixtures differ in their average setting time, therefore they make it possible to change the position of the tiles within 20 minutes after laying.

Rapid-hardening two-component (reactive) mixtures are mixed from various components before starting the facing work. They are composed of epoxy resin and polyurethane. They withstand temperature extremes and are distinguished by fairly high elasticity and adhesion rates. Due to this, the tile covering is securely attached to all types of bases.

Cement-based fine glue remains the most popular option, despite the availability of more modern and advanced mixes. It is made from Portland cement with the addition of fine river sand and plasticizers. The popularity of the composition lies in the affordable price and ease of making the adhesive mixture. It is the options for this glue from various manufacturers that are worth considering for purchase if you are planning to lay tiles yourself.

Features of tile adhesive

All layers of the pie of water and electric underfloor heating are constantly exposed to temperature changes, the adhesive composition cracks, and tiles or porcelain stoneware can peel off. To avoid this, it is necessary to use a special adhesive composition, which contains additional compounds that improve plasticity and heat resistance. The working temperature range of such glue is from - 30 to + 70 ° C. Adhesive for warm floors can be:

- One-component (dispersive), which is produced in the form of an acrylic mixture with artificial resins and modifiers contained in it. Suitable for laying ceramic tiles or porcelain stoneware on cable and other types of warm floors. It is evenly distributed over the grid over the heating elements, it has good adhesion (adhesion to the surface) and hardens within 20 minutes - this allows you to adjust the location of the tiles.

- Fast hardening multicomponent. It contains polyurethane and epoxy resins. The two basic ingredients are diluted with water before installation. It tolerates temperature changes well.

- Universal. It contains cement containing fine river sand and modifying compounds. It is sold as a dry mixture that is diluted with water.

Advice! You can fix the tiles with glue only after the concrete screed is completely dry. Drying takes about 28 days.

Ceresit CM 11 tile adhesive

When choosing a specific brand of adhesive for underfloor heating systems for ceramic tiles, you should focus on the following requirements:

- Temperature exposure within the range from - 30 to + 70 ° C;

- High degree of elasticity and ease of application;

- Good adhesion even when applied in a thin layer;

- Frost resistance;

- Moisture resistance;

- Specific gravity;

- The hardening time of the composition after laying the tile covering;

- Consumption per 1 sq. m.

Basic questions before buying

To choose the right tool, first you need to understand:

- whether it will be exposed to temperature extremes;

- located outside or inside the premises;

- whether the level of humidity is high, especially when it comes to a pool, steam room or sauna.

Based on the above, all types of tile adhesive are divided into:

- waterproof;

- heat resistant;

- for interior work;

- the facade of the basement;

- universal - suitable for both indoor and outdoor use.

When choosing which tile adhesive is better, you need to focus on its main indicators:

- plasticity - the composition should not spread and not flake off either during operation or after drying;

- elasticity - even in a residential building there is a temperature drop, respectively, an already dried composition must withstand deformation loads;

- slow drying - this is necessary for the possibility of adjustments and other actions during laying;

- fast setting - for heavy tiles, for wall and ceiling work.

We study the composition of the types of adhesive mixtures

photo from geomedia.com.ua

The shelves of building supermarkets offer a large number of different mixtures, but you will have to choose from only three basic types. Based on the main component, tile adhesive for underfloor heating is classified as follows:

- One-component polymer compounds are produced in the form of pasty solutions, packaged in plastic buckets. They are made on the basis of artificial resins with the addition of modifying components. After laying the tiles, you will have 20 minutes before the initial setting of the mortar to correct defects, which is very convenient for DIYers who do not have sufficient skills.

- Fast hardening two-component mixture. Since such a solution gains primary hardness very quickly, the glue is mixed strictly before use. Excellent plasticity and adhesion properties guarantee reliable fixation and resistance to temperature changes, even when tiling difficult substrates.

- Finely dispersed cement-based mixtures. Despite the variety of polymer types, a simple and affordable cement glue remains a popular option. Thanks to modifying additives, it does an excellent job of its functions. Another plus is the ability to prepare a well-dosed portion, which is convenient to work out in one go.

It is the addition of plasticizers to all types of heat-resistant formulations that ensures the preservation of elasticity and constancy of adhesion during expansion and contraction. At the same time, fixing qualities are not as important for floor tiles as for wall cladding, because here the force of gravity works for you. Therefore, glue for porcelain stoneware on a warm floor can be taken without taking into account the severity of the material.

Varieties of adhesive solutions and their features

For arranging warm substrates, tile adhesives intended for such work are used. And yet, with what glue to glue the tiles on the warm floor, because there are several types of products on the market? Consider these types:

- One-component - pasty mixture. The material is easy to work with: no need to waste time on cooking. Components - acrylic, modifiers, artificial resins. The adhesive hardens within 20 minutes, which is enough for laying and adjusting the installed tiles.

- Two-component - fast hardening (“reactive”), usually containing epoxy resin and polyurethane filler. The solution is mixed immediately before finishing work. Withstands high temperatures, has good adhesion and elasticity. Due to these properties, the tile covering is strong and durable, in comparison with similar materials.

- Finely dispersed cement-based. The main components are Portland cement, river fine sand and modifying plasticizers. Mixes with the highest quality aluminate (alumina) cement create strong adhesion of the finish to the rough surface. For the layer of glue to be strong, you should follow the instructions for cooking.

When looking for tile adhesive on your own, you should carefully study the properties, technical characteristics and scope. All the necessary information about the material is placed on the packaging. In addition to the standard description, there may be graphic symbols.

Criteria for choosing an adhesive for tiles for underfloor heating

When choosing an adhesive for installing tiles, it is imperative to take into account the type of facing material. A good adhesive resists slipping of large tiles and very heavy elements.On the tile, porcelain stoneware, marble, there should be no stains and efflorescence during the operation of the warm floor.

If the product is to be used in the bathroom, it must be resistant to high humidity and contain antifungal components.

For outdoor work, special compounds for anti-icing systems are used, which additionally have frost resistance. If it is necessary to level the base, self-leveling mixtures with heat-resistant properties, sufficient elasticity are used. Also, when buying glue, it is worth considering the manufacturer's rating and purchasing only a proven brand that boasts excellent quality.

Why you need a special tile adhesive for underfloor heating and how to choose it

The peculiarity of tiles as flooring is their high thermal conductivity. This means that the coating quickly gives off heat, and itself will always remain cold. This quality plays an important role when facing fireplaces, stoves and other heating objects, since all the heat is transferred to the room, and the surface does not heat up much, therefore, the risk of getting burned is reduced. But when it comes to flooring, this feature turns into a disadvantage, since walking on cold tiles is completely unpleasant.

Laying tiles on tile adhesive

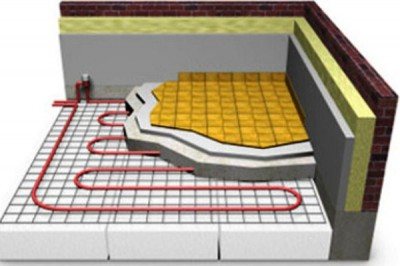

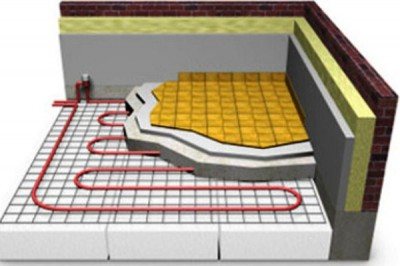

That is why heating systems are most often installed under the tiled floor - underfloor heating with different heating elements:

Cross-section of cable electric underfloor heating

Laying scheme for layers for electric underfloor heating under tiles

Laying water underfloor heating under tiles

When the issue of thermal conductivity is resolved, the next problem arises - a tile solution. The fact is that the traditional cement mixture has a different linear expansion than that of porcelain stoneware, so you can often observe cracks on the tile, its peeling, falling off and other unpleasant things. To solve this problem, manufacturers began to add special components to traditional mixtures - plasticizers, which harden the glue and bring its linear expansion to a tile indicator.

Review of the best brands of tile adhesive

In order to determine whether the glue for a warm floor is of high quality, you need to pay attention to its main characteristics:

Tile adhesive consumption table

- firstly, heat resistance - the composition must withstand heating up to 100 ° C;

- secondly, the number of temperature change cycles (100–150 is considered optimal);

- thirdly, for what type of tile is the glue intended (mainly porcelain stoneware is laid on the floor);

- fourthly, for what type of base (floor screed) the composition is intended.

Based on such requirements, it is possible to distinguish tile adhesive for underfloor heating of the following brands:

Types of tile adhesives for warm floors

Characteristics of Eunice tile adhesive

Warm floor in a layer of tile adhesive

Tile adhesive Eunice Granite

Unis tile adhesive plus

Unis glue Belfix

The universal and most popular is Unis Plus floor heating glue. It is designed for all types of tiles, porcelain stoneware, stone and other natural or artificial materials. Specifications:

- permissible load - 100 kg / m 2;

Characteristics of Yunis Plus tile adhesive

Ceresit

One of the most popular brands of dry building mixtures. The following compositions are suitable for porcelain stoneware:

Ceresit tile adhesive

- Ceresit CM14 Extra;

- Ceresit CM16 Flex;

- Ceresit CM17;

- Ceresit CM.

Ceresit CM14 Extra is considered optimal in the price / quality ratio - it is a universal mixture, suitable for all types of tiles and porcelain stoneware, can be laid on cement and concrete screeds.

However, the manufacturer limits the tile size to 45 * 45 cm, for large squares, Ceresit CM117 should be used.

Technical characteristics of Ceresit CM14 Extra:

Terms of use Ceresit CM 14

Bergauf

Tile adhesive for all substrates Bergauf

The most common, universal composition is Bergauf Keramik Pro. It is intended for porcelain stoneware tiles, no more than 900 cm 2 in size, it is distinguished by high elasticity, frost resistance, moisture resistance, and also the absence of tile slipping after laying. Specifications:

Keramik Pro features

- load - up to 100 kg / m 2;

- adhesion to the base - 0.5 MPa;

- temperature for work - from +5 to +25 o С;

- frost resistance - more than 100 cycles;

- optimal layer thickness - up to 10 mm;

Tile grouting Bergauf

Which adhesive for underfloor heating is better

H2_2

When choosing an adhesive for laying tiles, you need to pay attention to the special marking on the packaging, which allows the mixture to be combined with a warm floor. The following brands have proven themselves most well:

Adhesive for tiles for warm floors EuniceCeresit CM11 is ideal for laying ceramic tiles and porcelain stoneware over underfloor heating systems. The composition contains M500 aluminate cement, thanks to which the coating is able to withstand intense mechanical stress. Suitable for installing large tiles. In addition, the presented tile adhesive for underfloor heating has high elasticity, water resistance and prevents the formation of voids under the tile or porcelain stoneware coating. Ceresit CM11 is suitable for rooms with high humidity, and thanks to the CC83 modifier included in the composition, the glue can be applied in a thin layer, which saves on costs.

- Eunice. Differs in high adhesion - 1.25 MPa and is easily applied to the heating mat of an electric warm floor. It can be used for laying ceramic tiles with dimensions up to 60 × 60 cm. Due to the inclusion of white clay, Eunice glue has high strength and resistance to high temperatures. Fully hardens within 3 hours. Surface application can be carried out at temperatures from 5 to + 30 ° C. The adhesive consumption is 4 kg / m2 with a layer thickness of 1.5 cm.

- Prospectors. Freezes within 25 minutes, has a low cost compared to analogues. When a layer is applied over the screed, the adhesion performance is significantly enhanced.

- Knauf. An economical adhesive that combines well with thin-layer veneers with minimal consumption. Knauf Fliesen is suitable for all types of underfloor heating systems, can be used for fixing tiles in rooms with a high moisture content, withstands temperatures up to 80 ° C. The adhesion index is up to 0.5 MPa. Dries completely after 2 days.

Technology for laying tiles on a warm floor

According to building codes, the degree of difference or slope of the base for laying tiles should not exceed 2 mm for every 2 m of the screed. If self-leveling mixtures are used, then the drop can be completely avoided.

The process of laying tiles on a warm floor:

The process of laying tiles on a warm floor

- Surface preparation: cleaning of debris, foreign objects.

- For better adhesion, a primer can be used, especially if the substrate is concrete. The primer dries for 4 hours.

- Preparation of the solution. According to the instructions: add water and mix thoroughly. Then let the solution brew (up to 5 minutes to complete all chemical reactions) and mix again.

- Please note that the package will indicate the "pot life" of the solution, usually 3 hours;

Installation of electric underfloor heating under ceramic tiles

Throughout the laying of tiles, it is necessary to control the horizontalness of the coating using a building level, and in order to have perfect seams, use calibration crosses.

Errors when laying tiles on a heated floor

To improve the quality of the finished coating, you need to follow the advice of specialists and eliminate common mistakes.

Expansion joints

The joints compensate for the linear expansion of the subfloor during heating and cooling.The grout shrinks under the influence of physical factors, and the tiles in the area of the damper joint (between the wall and the floor) can separate, because the fluctuations are sometimes up to several millimeters. Even the most elastic material is not able to smooth out such a flaw, so tilers use special techniques.

To seal the damper joint, you can use a special tile layout so that only the edges fall on the joint, but this negatively affects the overall layout of the coating. It is also possible to seal the joints only with silicone sealant, but it often differs in color from the main grout. It is better to smear part of the tile with glue directly above the damper joint, and treat the rest of the material with a sealant, as a result, the correct layout of the plates will not be disturbed.

Wrong choice of glue

Manufacturers also produce so-called "universal" adhesives that can be used on most substrates: from concrete, OSB boards to drywall and underfloor heating. Most often, the adhesion of such compositions is lower than that of specialized mixtures that are designed for a specific building material. It is better to choose a really suitable glue, which is especially important when laying smooth porcelain stoneware.

Defective tiles

In stores, tile marriage is rare, but sometimes you can get into it. Usually there are deviations in shape, thickness of porcelain stoneware. Finding trouble before gluing the boards will allow you to immediately correct the situation by increasing the thickness of the adhesive and applying the correct layout. If the tile is curved, it is best not to use it at all. Elements of non-standard size are most reliably glued with a herringbone layout.

Dry glue remains in the open bag

All tile adhesives are quite hygroscopic, but they can be stored even open for 14-20 days. To do this, remove air from the bag as thoroughly as possible, wrap the package with a plastic bag in several layers. Store the bag in a room with low humidity and temperature. After 1-2 months, the glue will still have to be thrown away if it remains unclaimed.

The glue on the ridges is dry

Do not lay the tiles on dried glue that is not able to provide a sufficient level of adhesion. You just need to take a notched trowel, run it over the glue a couple of times and apply a little fresh product. Excess should be removed from the tile.

Stepping on uncured glue

Walking on an incompletely dried surface must not be allowed. If this happens, you should remove the tiles from the floor surface. To avoid damage to neighboring elements, you need to put an OSB-slab or board on the floor, which will increase the area of the stop and help prevent further displacement of the slabs. After that it is necessary to remove the displaced element, clean it from the glue and repeat the installation again.

Rules for choosing tile adhesive for underfloor heating: manufacturer rating

The tiled surface is always cold, even at elevated temperatures in the room. To create a comfortable touch to the tiled floor and improve the quality of heating, a "warm floor" system has been created. But for laying tiles on this system, you need a special tile adhesive for warm floors. It has the appropriate composition and application technology.

Characteristics of adhesives

Before buying, you need to carefully read the data on the packaging of this or that product. The glue must necessarily correspond to a number of characteristics, otherwise it will not be suitable for underfloor heating systems:

- resistance to temperature extremes (not less than -30 ... + 100 degrees), including up to critical temperatures;

- adhesion from 0.5-1 MPa;

- compatibility with coating and base material;

- high elasticity;

- ease of application.

Criteria for choosing an adhesive for tiles for underfloor heating

In order for the adhesive for tiles on heated floors to ensure the strength and durability of the connection, it must be selected according to certain criteria:

- Resistant to temperature changes.The materials from which the heating system is arranged periodically experience a decrease, an increase in heat. The same happens with the adhesive layer. Therefore, the adhesive layer must be flexible, withstand jumps up to 90 degrees.

- Increased adhesion.

- Compatibility with the laying material and the surface to be covered. Detailed information can be found on the packaging.

- Ease of use. It is easier to work with ready-made compositions. But this is not a very economical option. Dry mixes are cheaper, it is possible to prepare a solution of the required amount.

- Tile adhesive is bought only by a proven, well-known TM. Cheap options from unknown manufacturers may not show the declared properties, which is fraught with an impact on repairs. In addition, such compositions are inconvenient to work with.

- On the top of the package there should be an inscription that the glue is intended for the "warm floor" construction.

- The composition is well studied. It is great if it includes an aluminate type of cement. It provides great resistance to all types of stress.

Varieties of glue according to the basic composition

Different TM glue contains different base components. This breaks down the masses into varieties:

- Ready-made one-component glue mixture. Convenient to use, as the consistency is pasty. Such masses contain resins of artificial origin, acrylic additives, modifiers. This type does not have a quick setting, there is time for adjustment (up to 20 minutes).

- Two-component fast-setting adhesive. The solution is prepared only before the actual application. The base is epoxy resin with polyurethane components. Such masses are resistant to temperature extremes, have high adhesion and flexibility. It is used for difficult substrates.

- Cement masses. The basis is Portland cement with fine-grained river sand. Plasticizers are used as additives. This type is universal. It is convenient to use, as you can prepare the right amount of solution.

Popular brands of tile adhesives and their manufacturers

When buying a well-known TM of adhesive mixtures, it is worth paying attention to the "warm floor" construction:

- Litokol Litoflex K80 is produced on a cement base with the addition of synthetic resins. Pros of use: flexibility of the layer, increased adhesion, hydrophobicity, does not contain toxic compounds. The downside is the high price. Country of origin Italy.

- Bergauf Keramik PRO is prepared on a cement-sand base. The seam is elastic, moisture resistant, capable of holding large tiles. Withstands temperature drops in the range of -50 - +70 degrees. Application in a thick layer is provided. Time for correction is up to 20 minutes. Exporting country Germany.

- UNIS Plus includes mineral additives to the main component - cement. Refers to over-setting mixtures, which involve the laying of heavy boards. The ready-made solution can be used within three hours, the correction time is 20 minutes. Today there are many fakes of this TM, so you need to buy only from trusted suppliers, in specialized stores. Produced in Russia.

- Ceresit CM 17 Super Flex is a cement-sandy main component of Ceresit for underfloor heating. Suitable for application on complex substrates that are subject to stress, deformation, vibration processes. Such properties are available thanks to the fibers included in the composition. Provides strength, durability to the connection. Country of origin Germany, produced in Russia.

- Knauf is a cement compound. Convenient to use, does not slip, easy mixing. Does not contain toxic compounds, safe for the body, the environment. Manufactured in Germany.

- The leader is mastic with synthetic, mineral compounds. Waterproof, withstands high temperatures, works with difficult surfaces. Produced in Russia.

- Mapei Kerabond T is intended for the installation of heavy mosaic tiles on underfloor heating systems. There are white gray cement masses on sale. Provides reliable fastening, moisture resistance. Correction time 45 minutes, working up to 8 hours. Not applicable on surfaces subject to deformation. Country of origin - Italy.

- Ceresit SM-14 Extra. It is used for laying porcelain stoneware on a warm floor. Resistant to increased moisture. Provides adhesion to concrete, cement surfaces and waterproofing. The works are carried out indoors, outdoors.

All of these mixtures have proven themselves in the market. They have only good reviews from buyers, craftsmen.

Characteristics of the adhesive solution

The base of the tile adhesive can be cement. It is diluted with water in certain proportions; they are indicated on the package. The mixture is prepared immediately before application to the substrate.

Thin-layer glue is used for tiles. It is laid with a depth of 1-2 cm. The mixture quickly sets and dries. The disadvantage is the hygroscopicity of the cement surface.

Manufacturers offer polymer mixes for tile laying. The basis is acrylic, latex, polyvinyl acetate. The mixture is water-dispersive, one-component. It is sold ready-made, in plastic buckets. There may be liquid on top of the paste.

The solution must be thoroughly mixed before use. It hardens on contact with moisture in the air. The material is used for rooms of any humidity. The surface repels moisture, withstands high mechanical stress; suitable for both ceramic tiles and porcelain stoneware.

Polyurethane two-component mixtures are used as an adhesive solution. They are composed of polyester and a hardener. To prepare the solution, the components are mixed.

The solution based on polyurethane has high plasticity, resistance to mechanical stress, to temperature changes. It is used for the installation of tiles indoors and outdoors.

Not all types of adhesive mixtures can be designed for laying tiles on "warm floors". For underfloor heating, choose a material with certain characteristics.

- Concrete screed or adhesive coating constantly withstands temperatures of 30-50 ° C. All elements of the "warm floor" expand, so the tile mix must have high elasticity; not to deform or collapse when the temperature changes.

- Condensation may form on the surface of the screed or adhesive coating under the influence of heating elements. A material that is hygroscopic for a warm floor is not suitable. It will quickly collapse and lose its ability to hold the floor cladding. Moisture resistant solutions are preferable.

- The surface must have good adhesion. The optimal indicator is 1 MPa; the characteristic is indicated on the package.

- Tile adhesive for underfloor heating must withstand high temperatures. The manufacturer provides for a reserve up to 95 ° C.

- On the package there are pictograms: "snake" with upward arrows; it means that the material can be used for laying tiles on heated floors.

- Choose solutions that indicate "elastic glue" or "warm floor".

- When choosing a solution, the adjustment time is taken into account. For beginners in the construction business, choose a material with an adjustment period of up to 20 minutes. This time is allotted in order to correct the thickness of the adhesive surface or the location of the tile.

- The hardening time of the mixture is determined by its pot life. The longer this period, the longer it can be used. If the material has a pot life of 2.5 hours, then it must be consumed within this time. Otherwise, the mixture will harden, it will be impossible to use it.

We recommend: What is a mobile floor heating?

Craftsmen prefer to choose inexpensive cement-based mixtures, but they add plasticizers, fiber from polypropylene fiber or from metal threads. These substances increase the elasticity, strength of the adhesive surface, and increase its thermal conductivity.

Among the plasticizers, experts distinguish the CemThermo solution. It is produced in 1 liter plastic bottles. This means is enough for the preparation of concrete 1 m3.

The plasticizer is added to the screed solution or tile adhesive. When using moisture-repellent impregnations, you can reduce the hygroscopicity of the mixture.

Technology for laying tiles on a warm floor

Floor installation work is easier if the heating elements are laid on mats. With this method, it is not necessary to make a surface screed. When the inflow raw materials are laid on the mats, additional rigidity is given with glue, while the cable is hidden.

If the installation of the tile takes place on a concrete base, then high-quality cement should be used for pouring, but a self-leveling mixture is better. At the same time, the flatness of the plane is observed, since when laying the tiles, a difference of more than 2 mm by 2 meters is not allowed.

The tiles are installed on a completely dry screed (1–8 weeks).

- The tile is laid on a surface free of dirt and dust.

- The glue is applied with a special notched trowel, leveled, grooves are formed.

- The tiles are laid according to a pre-selected pattern.

- The correction is made within 10-15 minutes.

The adhesive mass is not applied immediately to a large area of the floor.

The tiles should not be stacked end-to-end, as the floor deformation or the influence of the heating system will cause cracks on its surface.

It is also necessary to observe the interval between laying tiles, grouting, commissioning. Trowelling works are carried out one day after the floor is tiled, and the floor is put into operation in 7–30 days.

We recommend a video on the topic:

How are the tiles laid?

Prepare the surface for the adhesive solution. It should be flat. Differences of 1 mm per 1 m are allowed. The mixture is diluted in small portions in order to use it quickly, avoiding hardening in the container.

We recommend: How does a flow meter for an underfloor heating collector work?

It is easier to stir the solution with a drill with a special nozzle. The mortar is laid on a concrete screed or on floor heating elements.

- A damper tape is reinforced along the lower perimeter of the walls. It has an adhesive surface. The tape is pressed against the wall.

- The concrete screed is treated with impregnation to increase adhesion.

- Dilute tile adhesive and apply to a small area of concrete.

- Layer thickness 1-3 cm.

- Align the glue surface with the rule. They pass along it with a comb. The optimum tine height is 5 mm.

- Tiles are laid on the solution. perform surface corrections.

- Calibration elements in the form of small crosses are installed between the tiles.

- Take out another area for laying tiles.

- After a day, the calibration elements are removed, the seams are rubbed. For grouting, mixtures are used, which include plasticizers.

If the underfloor heating is equipped with cable or rod mats, an impregnation for increasing adhesion is used before the installation of electric heating elements. Tile adhesive is applied to the mats.

The optimum surface thickness is 2-3 cm. Use a notched trowel carefully so as not to damage the cable or carbon rod. The height of the teeth should not exceed 3 mm.

For facing a warm floor with tiles, choose solutions or mixtures with certain characteristics, the main of which are elasticity, resistance to high temperatures, moisture resistance. Choose a material intended for cladding hot surfaces. If necessary, use plasticizers.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled.Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- How to make underfloor heating from central heating?

- How to choose a thermostatic valve for underfloor heating?

- How to install a warm floor in the country?

- How to make a solution for underfloor heating screed?

- How to install cable underfloor heating?

- Do you need a mixer for an underfloor heating?

General tips for using glue

When working with tile adhesive for underfloor heating, it is worth considering the tips for its use:

- Material consumption. The average mass consumption is indicated on the packaging. But these data are calculated in compliance with the preliminary leveling of the surface and only for a certain layer thickness. Correction of consumption is carried out with changes in layer thickness, if the adhesive serves as a leveling base. Also, this figure depends on the skill of the stacker.

- If the tiles are laid on mats of the thermal system, then the composition of the adhesive raw material must be taken into account, since the chemical components of the solution can destroy the mesh. Therefore, a preliminary protective coating is applied.

- Only high-quality material is used, its production time and the integrity of the original packaging are checked.

- When working, optimal conditions must be created. The laying temperature should be within 20 degrees. Then increased adhesion and gradual drying of the layer will be ensured.

- Heating starts after the glue is completely dry. The specific period is indicated on the package. Do not turn on the maximum temperature for the first time. The build-up should be carried out several days in advance. If this rule is observed, deformation of the adhesive layer is excluded.