The laying of fireplaces and stoves has a number of features, because the structure will be constantly exposed to high-temperature exposure. In this regard, for the process, you need to choose a special glue for stoves and fireplaces, it will help preserve the structure, and will not collapse, crack in such conditions. More details about what properties a high-quality refractory glue should have, what types exist, will be described later.

Heat-resistant glue for stoves and fireplaces

For laying work, tilers use a special glue for laying ovens based on clay, however, for facing work, the solution is inconvenient, it spreads over the surface, and the hardening process takes longer. Therefore, for this purpose, furnace adhesives with a different composition were created. They are a viscous substance that ensures fast and reliable fixation of the veneer. It can be sold ready-made, or in the form of a dry mixture, which requires dilution before use.

The first option has several drawbacks: you need to work with it quickly, otherwise it will dry out, and its price is also higher.

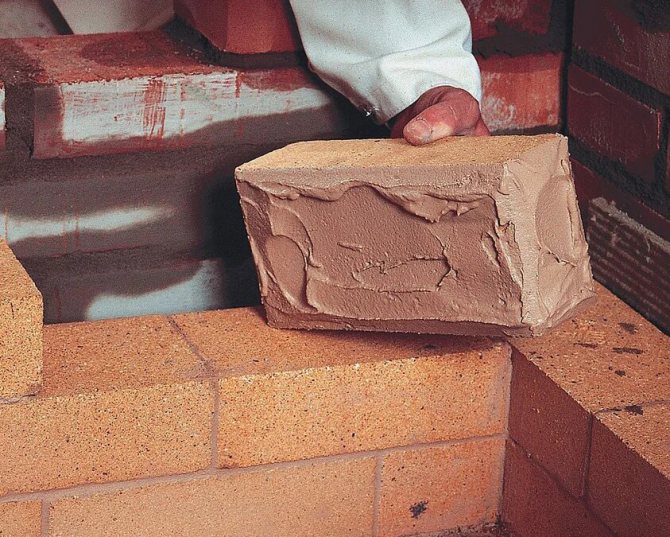

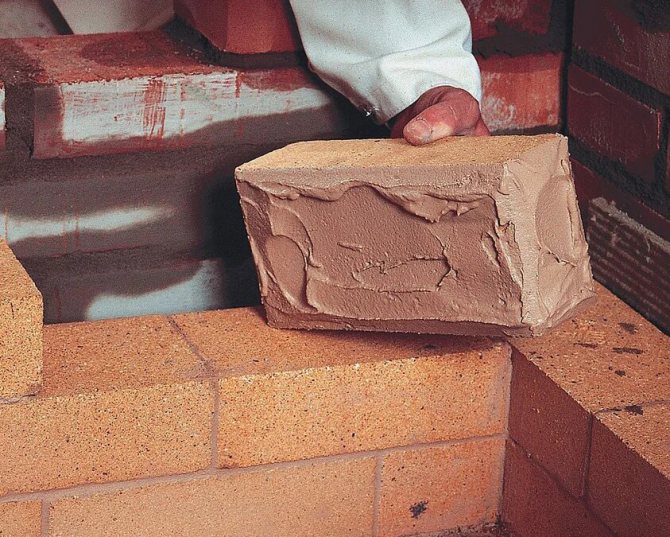

For laying work, tilers use a special glue for laying ovens, based on clay.

What components should be included

Manufacturers are trying to create heat-resistant tile adhesive for ovens with universal properties, but more attention is paid to improving a number of properties necessary for these structures:

- Heat resistant resistance;

- Water resistance;

- Plastic structure;

- Heat exchange capacity;

- Linear expansion;

- Environmental friendliness.

To obtain these characteristics, various fillers are added to the main elements. These include:

- Cement mixture;

- Sand;

- Fireclay fibers;

- Mineral supplements;

- Synthetic elements.

Manufacturers try to create heat-resistant tile adhesive for ovens with universal properties.

Fire retardant adhesive for fireplace cladding

When coating is required, it is best to use a dedicated wall adhesive. Due to the presence of minerals, maximum astringency is achieved.

Heat-resistant mastic for facing stoves and fireplaces

In addition, not only glue, but also a solution based on talcochlorite can boast of heat resistance for a fireplace. It consists of stone (the so-called soap component) and magnesite and chlorite. When interacting with liquid glass, the tile serves for a long time, even with mechanical damage.

By the way, the difference between the adhesive for tiles of the second category is that it is able to transfer heat well, that is, the heat energy will not go away "on itself" and, accordingly, the room warms up much faster.

High temperature resistant adhesives

Varieties of oven adhesives are distinguished according to two main criteria: by purpose, at what stage the composition is applied; according to the form of release, the choice is determined by the conditions and volume of work, the experience of the master.

By appointment

You can always find universal remedies on sale, but you can get a more reliable and high-quality effect by choosing a composition for a specific purpose and conditions.

An important guideline is the type of material that will be glued. Adhesive for metal will not work so well with glass. Heat-resistant glue for a fireplace has its own characteristics and in other situations it can affect the quality.

An important guideline is the type of material that will be glued.

By release form

When an inexperienced stove-maker is going to work, it is better for him to choose ready-made types of adhesives, it will be easier for him to work with them. After all, you do not have to dilute the composition with water, of course, manufacturers attach instructions for preparation, but the process can still cause difficulties.

It is important to take into account that ready-made mixtures cannot be stored for a long time, they can solidify during laying, so you need to work with them faster. You should not buy any type of adhesives in large quantities, the shelf life of the formulations does not exceed 1 year.

Dry mix is usually used when working with uneven surfaces. During production, the mixture is subjected to heat treatment, changing its structure.

The disadvantages are: the need to have a number of skills, the narrowness of the scope of use.

Ready-made adhesives on the market are presented in large quantities, they differ from each other in purpose. Therefore, a suitable solution can be selected for each purpose. It is more convenient to work with them, they are often produced in tubes.

Dry mixes are usually used when work is carried out on an uneven surface.

What the main parameters say

Many novice craftsmen mistakenly believe that indicators such as heat resistance, thermal strength, heat resistance and fire resistance are synonymous with one parameter. Then, in the case of using a universal tool, in which all these characteristics are expressed to a high degree, they may simply be lucky and the hot melt glue will cope with all the functions. Professional craftsmen distinguish between these terms and manipulate these parameters, choosing the composition for various types of work.

- Heat-resistant glue is capable of maintaining technical properties for several hours at temperatures above 140 ° C.

- A heat-resistant material must retain its qualities for a long time.

- The heat-resistant material increases the temperature bar of the heat-resistant adhesive by 10 times.

- Heat resistance - the ability to maintain qualities during prolonged exposure to temperatures above 1000 ° C degrees.

- The fire retardant composition is in direct contact (open contact) with the flame itself for several hours.

- The refractory adhesive is adapted to lasting contact with fire.

Good to know: How a fireplace door is made, how to do it yourself

In the event that only certain characteristics are pronounced in the adhesive composition, then such a material is suitable for performing a narrow interval of work.

Mix under the brand name Terracotta

Heat-resistant and refractory mixtures are used when laying fireclay bricks in the firebox itself. They form a strong mortar that, when dry, has high adhesion and withstands critical temperatures without cracking. Heat-resistant compounds are often used for laying stoves in places of heat exchange or in the labyrinths of a brick chimney.

From inexperienced craftsmen, offers are often received to use heat-resistant glue in all types of work, since it has the highest performance. Such a thought can be formulated from a misunderstanding of the basic processes that occur in a stove or fireplace during their operation.

Some of the contact surfaces (fireplace walls and their cladding) have different expansion coefficients. Only an elastic material, which is not a heat-resistant adhesive, can act as a connecting link. After drying, heat-resistant mixtures are able to deform without destruction under the influence of external forces. Such glue is suitable for facing the fireplace frame, as a tile mortar or in places where the temperature does not exceed 140 ° C degrees.

How to choose the right one, the most important criteria

To make the right choice of fireplace glue, you need to consider some criteria. These include:

- The location of the stove, whether it will be on the street or in the house. The threshold for maintaining temperatures can reach +1200 degrees, but the minimum temperatures that the solution can withstand may differ, therefore, if the structure is to stand on the street, then the presence of frost-resistant properties of the composition is required;

- You should carefully read the instructions to buy exactly the heat-resistant look;

- One glue cannot be used for different types of materials, it is worth knowing in advance which facing material will be used;

- The application of the adhesive solution should be carried out in a thin layer, therefore, if the surface has strong irregularities, then the choice should fall on compositions with high viscosity indicators;

- It is worth paying attention to the indicator of moisture and vapor permeability, they are most important for stoves in saunas;

- The safety of the formulations for human health is important, the level of toxicity of solutions must be taken into account, toxic substances can be released under the influence of high temperatures, therefore, on the packaging you need to read about the environmental friendliness of the solution.

You should carefully read the instructions in order to buy exactly the heat-resistant look.

How to do masonry correctly

Working with heat-resistant glue, especially when it comes to masonry, requires some nuances. They help to do the job efficiently and reliably. If you do the laying yourself, without the help of professionals, pay attention to the following nuances.

Operating procedure

Correct construction of the workflow - 80% of success. When carrying out finishing work on a fireplace or stove, follow the instructions below:

- Prepare your work surface by removing dirt and other components.

- The working surface is treated with a layer of primer several hours before the start of work, if it has increased absorbent properties.

- Follow the instructions for making the adhesive if you are working with dry mix. Deviation from the standards specified by the manufacturer will greatly affect the quality of the final product.

- We apply the finished solution to the work surface with a spatula.

- As soon as the solution is evenly distributed over the surface, we lay the tiles.

- Correction of the position of the tiles is possible within 2-3 minutes after laying. After that, it should not be touched for 2 days.

Note! The thickness of the screed on which the tiles are laid should not exceed 1 centimeter.

Storage and safety rules

Store the adhesive under the following conditions:

- humidity - up to 60%;

- ambient temperature - 1-30 o;

- shelf life - 12 months from the date of production.

Preparation of the composition at home

To prepare a composition that can cope with fixing tiled materials on the stove with a thickness not exceeding the thickness of the tile, you should prepare:

- 1 part cement;

- 1 part clay;

- 3 pieces of sand;

- Edible salt 1 glass.

Clay must be refractory, in order to test its stability, you need:

- Twist the material with your hands into a rope.

- Wrap it around the object in the shape of a cylinder.

- Next, they look at the appearance of cracks in the material, if they appear only in the upper layer, then sand should be added. Normally, the cracks should be distributed over the entire surface of the bundle evenly, while their depth should not exceed a third or a quarter of the mass, if the flaws are thicker, then a grease must be used.

The clay must be refractory.

To prepare the grease, the following steps are carried out:

- Finely ground clay is poured into the container.

- Add water, mix the components well.

- Waiting for the appearance of a precipitate.

- Half of the liquid is drained off the sediment.

- Next, the mixture should be infused, the fat is ready.

First, sand, clay, cement are mixed, then water is added. It must be added gradually, checking the resulting viscosity. Then salt is added.Mix everything again thoroughly.

First, sand, clay, cement are mixed, then water is added.

Heat-resistant glue for stoves and fireplaces must withstand special operating conditions, therefore special requirements are imposed on it. You need to choose the composition, carefully studying the instructions. For beginners, it is preferable to stop the choice on ready-made solutions.

The composition of the facing adhesive

Adhesive for self-lining stoves and fireplaces, as a rule, regardless of the manufacturer, consists of the same list of components. So:

- Sand.

- Cement.

- Natural ingredients.

- Synthetic additives.

- The so-called chamotte fibers.

Heat-resistant glue has its own purpose, depending on the components. So:

- Strength is provided by a cement mixture.

- Mineral (natural) substances are responsible for elasticity.

- Heat resistance is supported by fireclay fibers.

- Water resistance is provided by "synthetics".

It should be understood that an increase in a certain component will certainly increase its influence, but at the same time it will reduce other characteristics.

Therefore, in fact, there are two main types of glue, which subdivide it not only in composition, but also in scope. So:

- For finishing works.

- For masonry, including for the formation of the bottom chord of the base.

Technology for gluing and fixing tiles

It is important not only to choose heat resistant tile adhesive, but also apply the purchased composition over certain technology and at the same time follow some rules. Then the structure will serve for a long time. But before you start masonry, you should know these rules. This work can be done by hand, thus reducing the cost of the entire structure. To do this, you should stock up on patience and some knowledge.

Surface preparation

Apply heat-resistant tile adhesive for fireplaces only on a properly prepared surface. The service life of the structure will also depend on this. So, before doing the masonry:

- We clean the surface from all irregularities. For this, you can use a trowel. If there is a frozen solution that is difficult to remove, then a grinder with a circle should be used. With their help, all irregularities can be eliminated.

- Now we need to deepen the seams by one cm. This will help the glue penetrate better. You can do this work with a grinder with a circle.

Attention! If the structure has been painted, then remove the paint before applying the heat resistant tile adhesive. If this cannot be done efficiently, then a mesh will have to be applied to the plane to improve the bonding of surfaces, which will solve the issue of a strong connection.

- If you decide to use a mesh, then it is best to attach to the tabs in the seams. If they are missing, then you will have to drive nails into the seam to help hold the mesh. They should be taken at least 100 mm and put washers under the head before attaching the mesh. If instead of nails you decide to use screws, then holes should be made in the masonry before joining.

- After fixing the mesh, apply a layer of putty to the surface and make it perfectly flat.

- If your surface is flat enough, then you can not fix the mesh, but do the cladding directly on the surface. Just before fastening, you need to prime the surface with a primer. Apply preferably a deep penetration fluid. It is possible to glue the tiles only after the plane has completely dried.

Mix selection

To select a high-quality adhesive material that would meet all the requirements and standards, some features of each type of mixture for cladding heating devices or their masonry should be taken into account.

High-temperature tile adhesive is selected based on the place where the stove or fireplace is planned to be laid.The requirements for masonry material will differ depending on whether the indicated place is chosen - indoors or outside.

Thus, if internal work can be performed using almost any mixture for masonry, due to the fact that heat and high-temperature compositions are operated at 1200 ° C, then external repairs should be carried out, taking into account the restrictions on the lower temperature range of the adhesive.

Heat-resistant glue for fireplaces and stoves when installing a heating device on the street must be resistant to low temperature degrees and their sharp drops. Therefore, it is worth carefully studying the manufacturer's instructions.

The choice of the composition should be made, taking into account what specific material will be used to finish the heating device, since heat-resistant tile adhesive for stoves, based on the brand, is intended for the most part for use with certain materials.

It is worth not forgetting about the material for manufacturing the construction of the heating device, since the possibility of the presence of restrictions on the use of any group of materials for decoration depends on this, which is not combined with the present base.

Heat-resistant tile adhesive is applied in thin layers only. Because of this, it is first necessary to take into account the surface area (height differences to the plane). If they are small, you should prefer a thicker glue, this will make it possible to quickly remove such irregularities.

It is worth remembering about the vapor and water permeability of the walls. When choosing a heat-resistant glue for a bath, it is very important to meet these requirements for the stove.

You can read about high temperature sealant for stoves and fireplaces here.