For the installation of expanded polystyrene plates (polystyrene) during thermal insulation work, it is necessary to purchase foam glue. Not only the service life of the structure, but also the effectiveness of future thermal insulation depends on the reliability of fixing the insulation to the finishing base. Therefore, the choice of glue and its further use must be approached with all responsibility.

Polyurethane Foam Adhesive

Solutions: how to glue the foam

Before you ask yourself what is the best way to glue your foam, you first need to understand the main criteria for your choice. Yes, foam, as a universal and specific material, can be glued with the simplest and most popular stabilizers, but the quality and durability of this method depends on the subsequent use. So, for example, if you are doing a complex and large craft using foam, or you are insulating an attic floor, temperature, humidity and other factors will play an important role, which can easily neutralize all your efforts and abilities of the means with which you glued.

Points to consider when choosing an adhesive:

- Your goals for the subsequent use of the bonded foam and its features, such as durability;

- The loads that the foam will be subjected to;

- The temperature that it will undergo;

- Room humidity.

In most cases, it is optimal to use ordinary PVA glue, but if it comes not to a simple structure, which is entrusted with serious construction or decorative purposes, it may not justify itself.

Adhesive requirements

In the selection process, first of all, buyers pay attention to the price of foam glue. Experienced installers give advice on selection. They argue that the presented tool must have a number of special qualities.

The glue should ensure perfect adhesion of the expanded polystyrene boards to the base. At the same time, the composition should not react to temperature changes, precipitation and other adverse environmental influences. The glue should not be toxic, so as not to harm the health of the master and the people living in the house. It is also important that the composition is applied to surfaces simply and evenly.

Not all manufacturers meet these requirements. Only proven well-known brands, constantly improving and controlling the properties of their products, can boast of similar characteristics of the glue.

Tips: how you can glue the foam together

Styrofoam can be glued using a wide variety of methods and materials. Many of these can be purchased at regular stationery stores, which can be used to process and join simple designs.

But if you need a serious fixation for a long time, your road lies in special construction stores, where you will need to carefully analyze the entire product range and choose the glue that suits your intentions.

The most common and simple way to create a full-fledged fixation is precisely glue of various strengths and purposes, although people sometimes use other means, such as polyurethane foam.

Foam bonding can be done using the following tools:

- Ordinary PVA glue - for simple structures and crafts, with a characteristic short-lived operation.

- Special Foam Adhesive for gluing together.You can find one in specialty hardware stores at a fairly low cost under the Styroglue configuration, but it is quite rare on the shelves, which is the difficulty in acquiring it.

- When insulating beam structures, it is quite possible to use polyurethane foam, however, all the individual characteristics of operation must be taken into account.

- Hot glue. It must be used with extreme caution and exclusively with a special glue gun.

- Spray glue, which can be used to glue different materials to each other, as well as foam elements.

Of course, this is not the whole list of possible means for gluing, because in the trade line you can often find special adhesives for gluing foam plastic to other surfaces - wood, metal, and so on. But for the purpose of gluing together, they are absolutely not suitable.

What are the types of polystyrene foam glue for indoor and outdoor use?

For the installation of extruded polystyrene foam outside buildings, a special cement-mineral adhesive mixture is used (for greater reliability, the slabs are additionally fixed with special umbrella dowels).

For internal work on the insulation of ceilings and walls, in most cases, compositions based on polymers and polyurethane are used.

Consider the characteristics of the most popular brands adhesives for expanded polystyrene boards.

- Penoplex FASTFIX glue is a special polyurethane glue designed for gluing thermal insulation boards made of extruded polystyrene foam to different types of substrates: concrete, stone, aerated concrete, metal, brick, ceramic and expanded clay concrete blocks, plaster, etc.

The adhesive is sold in 750 ml metal cans (like professional polyurethane foam).

The composition has high adhesion to most building materials, and a convenient form of release allows you to use a quick and convenient method of application using a special assembly gun.

Full hardening of the glue occurs after 24 hours, however, the glue layer sets in a few minutes.

Penoplex glue can be used to install thermal insulation on the outer walls, foundation and basement of a building, but more often this format is used for internal thermal insulation of premises, insulation of balconies of city apartments.

One 750 ml can is enough for gluing 6-10 square meters of boards.

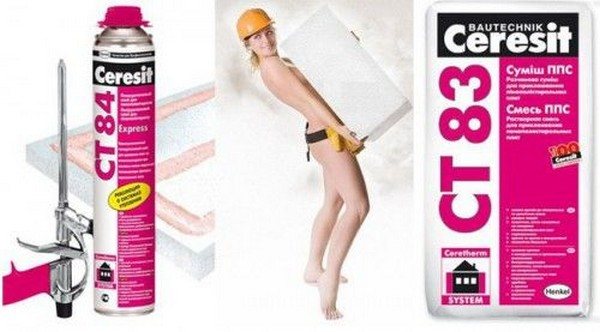

- Glue-foam TechnoNIKOL for expanded polystyrene is a modern adhesive based on polyurethane, intended for the installation of thermal insulation boards in the process of insulating facades and internal walls of buildings.

The glue is sold in 750 ml metal cans. The foam is also suitable for sealing gaps between installed insulation boards. The composition is resistant to moisture, mold, aging.

Possesses high adhesion to concrete surfaces, cement and gypsum plasters, wood, OSB-boards, etc.

One 750 ml can is enough for gluing 10-12 square meters of boards.

- Adhesive for expanded polystyrene Ceresit CT 83 (Ceresit 83) is a universal cement-mineral adhesive mixture for mounting expanded polystyrene boards to various substrates when performing external work on wall insulation.

You can work at temperatures from zero degrees, has high adhesion to concrete, brick, aerated concrete, ceramic and expanded clay concrete blocks.

To prepare the glue, it is enough to pour the mixture into water and mix thoroughly. The average consumption of dry mix is 5 kg per square meter.

- Adhesive for Bitumast expanded polystyrene boards based on modified bitumen is a ready-to-use adhesive for mounting insulation boards to substrates made of brick, concrete, metal, wood and other building materials.

With the help of bitumast, insulation boards can be glued. The absence of toxic components in the composition allows it to be used for carrying out not only external, but also internal work.

The average consumption of glue is about 0.5 liters per square meter. Working temperature - not lower than +5 degrees.

What glue to glue the foam together

So, let's define a specific list of the most suitable adhesives for processing and bonding foam. Of course, they will be specialized substances for such a specific material as polystyrene, or its closest relatives - extruded polystyrene foam, which is also quite common in household use.

The main qualities and features of special glue Styroglue for working with foam:

- It is made taking into account all the features of the non-standard constitution of the foam - its porosity and foam-like behavior.

- The best option would be to use a spray adhesive, because it penetrates even better into the complex structure of the foam and forms a kind of sticky film. But here we can highlight a feature - the obligatory use of gloves, because it easily gets on everything that is nearby and it is not easy to wash it.

- It is more durable and dries faster than many other adhesives when used as intended.

It is quite appropriate to use glue sprays or guns, but when using them, there are several features that are extremely important to consider so as not to harm the structure of the foam (in more detail - below).

Bonding Styrofoam to Styrofoam:

What matters is how to glue the foam to the foam... To do this, you can use:

liquid foam;- concrete contact anhydrous mixtures;

- liquid nails;

- silicone sealants;

- special glue-foam;

- compositions for tiles.

Liquid foam is a sticky substance that is created when there is no glue in the house. Can be used in case of sudden crack formation in the roofing material. The product must be dissolved and thereby glue is obtained..

How to glue polystyrene correctly

The basic instructions for gluing polystyrene foam are simple, and the results are often not long in coming. However, there are some peculiarities that depend on your goals, the specifics of the glue and the raw materials themselves.

Styrofoam gluing instructions:

- Prepare everything you need for work - gluing material, glue, preferably rubber gloves. If the work takes place with large structures - small weighting materials to press and better fix the raw material.

- Depending on the glue used, apply it with a brush (if we are talking about ordinary liquid glue), with a gun in several strips, or spray it onto the surface. If the target is not strong and clear fixation, it can be applied pointwise, along the edges and several points in the center.

- Attach polystyrene (expanded polystyrene) to each other and, if the situation so requires, press down with weighting materials. Leave everything for a certain time with glue and material dimensions (from 20 minutes to several hours).

- Use the result as intended, removing the weighting agents and checking the quality of the work done.

Features are the use of specific tools and methods. For example, some adhesives foam when they are on paralon for a long time or polystyrene foam - for this you have to remove the remnants from time to time with a sponge or rag.

There are also rules for gluing large or slightly damaged areas - before the procedure, they must be thoroughly cleaned of dust and, if possible, treated with sandpaper to make the surface smoother, less porous and thereby increase the level of stabilization and fixation.

It is important to monitor the temperature level when using hot glue.If the temperature is too high, the glue easily corrodes the entire surface, making subsequent gluing almost impossible.

Varieties of adhesives for installing foam

Many argue that polystyrene foam boards can be mounted on almost any glue used in construction. To some extent, we can agree with this statement, since reliable adhesion of the foam to the finishing surface can be achieved using a putty, drywall glue, ceramic tiles, etc.

However, these mixtures do not take into account the porous structure and low moisture absorption of polystyrene foam, which leads to an increase in the drying time of the glue and a shift in the preset position of the sheets. Therefore, when decorating walls, floors or ceilings, it is recommended to use adhesives made directly for the selected material.

When choosing an adhesive for extruded polystyrene foam or foam, it is necessary to take into account both the quality of the finishing surface and the operating conditions of the insulation boards.

Dry Blend Foam Adhesive

All mixtures used for the installation of polystyrene can be conditionally divided into 2 groups:

- dry mixes;

- polyurethane compounds.

These substances differ from each other not only in appearance and preparation method, but also in application technology. Therefore, we will consider both options in more detail.

Dry mixes for polystyrene foam installation

Today, dry adhesives are the best option in terms of price and quality for many construction activities. Precisely calculated proportions of all components of such mixtures allow to achieve reliable fixation of insulation boards without violating their technical characteristics.

Dry compositions can be used both for internal work and for external (facade glue). In this case, in the second case, special additives are used that increase the resistance of the material to low temperatures and high humidity. For what work this or that composition is intended, it is indicated on the packaging.

Dry construction foam adhesive

In most cases, dry mixes are sold in 25 kg paper bags. Before buying such glue, you must familiarize yourself with the date of its manufacture. This is due to the fact that the shelf life of powders is no more than 1 year.

All adhesive mixtures for foam plastic are divided into universal and separate use. Universal glue can not only fix expanded polystyrene plates, but also reinforce them with a mesh. The second group is used for a specific type of work (for example, with one composition only the installation of foam can be performed, and the other - reinforcement). Universal glue has average characteristics and is considered an economy option. If you want to get a really high-quality installation of polystyrene, then you should give preference to highly specialized formulations.

Polyurethane foam adhesive

Dry mixes are indispensable in cases where it is required not only to insulate any surface, but also to level it at the same time.

With their help, you can level the bases with height differences up to 60 mm. Another advantage of such compositions is their relatively low cost, which is especially important when carrying out repair work with a limited budget.

Dry glue has not only advantages, but also disadvantages, among which should be highlighted:

- large weight, which limits its use in high-altitude work;

- dustiness when preparing the solution;

- long setting time (at least 2 days).

Foam Adhesive Foam

Unlike dry mixes, polyurethane glue (foam glue for polystyrene) does not have such disadvantages, therefore it is often used when working at height, as well as when it is necessary to shorten the installation time of insulation.

The use of polyurethane foam in cylinders allows you to solve the following tasks:

- reduce the time of installation work up to 4 times;

- improve the adhesion of the foam to the finishing base;

- to exclude improper preparation of the mixture with your own hands, since polyurethane glue is supplied to the markets in a ready-made form;

- fill the assembly seams with high quality, thereby minimizing heat loss through the insulated surface;

- to glue foam at low temperatures.

A typical instruction for the use of polyurethane glue is as follows:

- Preparation of the base. Before installing the foam, the finishing surface must be leveled (height differences no more than 10 mm) and cleaned of debris.

- Base primer. The use of a primer increases the adhesion of the adhesive, thereby increasing the bond strength.

- Applying the mixture to the foam. Adhesive foam is applied to the boards along the entire perimeter with an indent from the edge of about 20 mm, as well as in the center.

- Bonding foam to the base. The glue-treated board is applied to the finishing surface and fixed on it with little effort. In this case, the position of the plate can be changed within 20 minutes after its installation.

The setting time of the foam is about 2 hours. After this time has elapsed, you can start finishing the insulation with the selected material.

Foam glue

Outdoor adhesive for expanded polystyrene can be made in the form of foam. It is created on a polyurethane base. Such a composition is sold in cylinders. Glue in this category has many advantages.

The polyurethane compound is easy to apply to polystyrene foam sheets. It dries quickly, thus avoiding the use of special props. The expense of funds is the most economical. He is not afraid of adverse environmental influences. The mass does not spread on the surface.

The quality of installation when using glue-foam increases significantly. The composition gains full strength within 2 hours. Other types of installers take up to 6 hours to dry completely. One can of foam equals 25 kg of dry cement mortar.