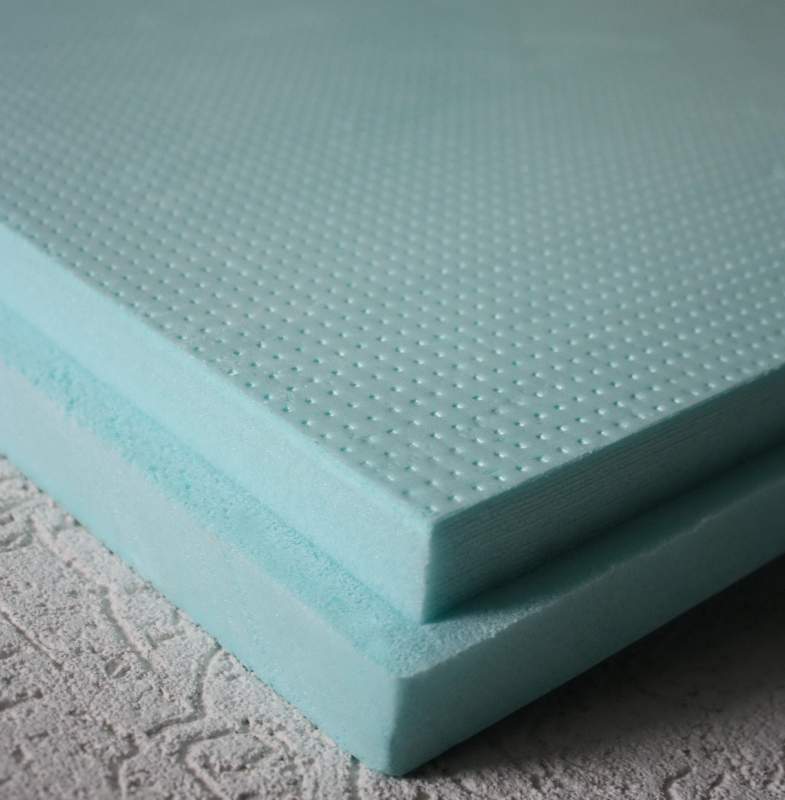

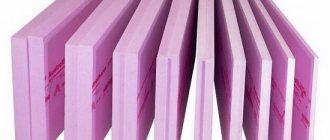

Extruded polystyrene foam is a synthetic plate heat-insulating material. It is produced by foaming the polymer composition during the extrusion process.

Foam boards are about 95% (MISSING) free from air, which makes the material lightweight and easy to cut and otherwise machine. Expanded polystyrene ...

2

Properties and characteristics - why is the composition better than a liquid solution?

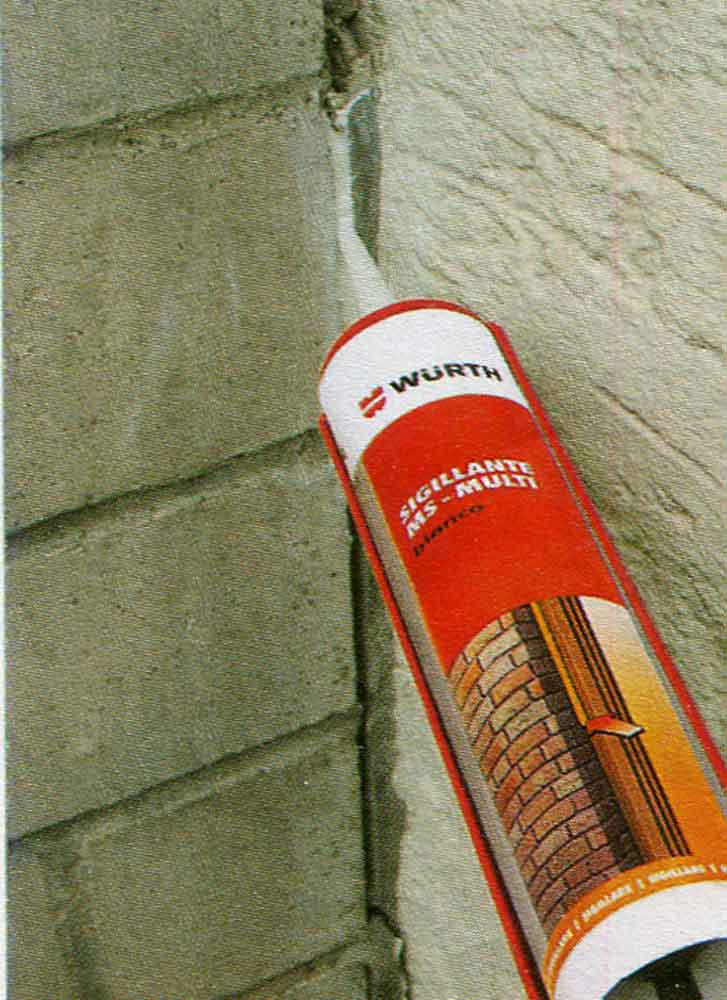

Polyurethane foam is the only adhesive for the installation of foam. It reliably adheres extruded polystyrene foam to any surface. Before the advent of this composition, it was believed that this material is not suitable for adhesive installation. True, craftsmen came up with technologies for gluing foam to the walls, but they had to install it only at their own peril and risk. Foam glue is recommended for the installation of this insulation by the manufacturers themselves, for this it was developed.

The possibility of reliable adhesion of foam is associated with the ability of liquid polyurethane foam to adhere well to any surfaces, including the smoothest ones. In addition, thanks to the additives, the composition has high technical characteristics:

| Specifications | Value |

| Adhesion to concrete, MPa | 0,3 |

| Adhesion to expanded polystyrene, MPa | 0,1 |

| Application temperature, ° С | -10 +40 |

| Thermal conductivity coefficient, W / mK | 0,040 |

| Consumption of one cylinder, m2 | 10 |

| Setting time at a temperature of +20 ° C, h | 2 |

The table shows that the adhesive foam has not only good adhesion, but also a number of other advantages, such as:

- Low thermal conductivity - due to this quality, the composition is used to insulate the seams. Thus, you can get rid of not only cold bridges, but also glue the expanded polystyrene together. This reduces the likelihood of cracking in the plaster.

- High speed of solidification - already two hours after the installation of the plates, you can proceed to the next stages of work - grouting and reinforcement.

- The ability to carry out installation at low temperatures. But not all types of glue have this property. Therefore, before buying a composition for the winter, carefully read the instructions.

Foam glue has other advantages:

- Increases the speed of work - unlike a cement-based mixture, the foam does not need to be dissolved with water and brought to a homogeneous consistency with a mixer. It is applied simply and quickly. Therefore, the process of fixing the plates to the wall is performed five times faster than in the case of using a liquid solution..

- It is lightweight - as a result, material transportation is simplified and the load on the foundation is reduced. If the slurry increases the weight of the board by ~ 3 kg, foam has practically no effect on this indicator.

Therefore, it makes sense to use such glue not only for penoplex, but also for ordinary foam, especially if you need to perform installation work quickly. True, its big drawback is its high cost.

The foam can be used as a supplement to liquid adhesives, for thermal insulation and for gluing seams.

general information

Saving resources is always important, especially when the cold season comes. Thinking about alternative ways of storing thermal energy, many decide to insulate themselves with heat-insulating plates. Not so long ago, an interesting type of insulation appeared on the market - expanded polystyrene, which is a modernized version of the foam that is familiar to us. With a more efficient heat transfer coefficient, it is used for external cladding, in foundations, in the construction of roofs and ceilings.Expanded polystyrene (PPS) is a material for insulating facades. It is a polymer that is blown up / filled with gas. Has a closed granule structure. Almost one hundred percent content of gases in the composition gives it impeccable heat-insulating and sound-absorbing properties. Choosing an adhesive for expanded polystyrene is not such an easy task as it might seem at first glance. The vending product may have contraindications and incompatibility in use. The main thing is that the glue does not contain substances that can dissolve the PPS structure:

- xylene

- acetone

- toluene

- drying oil

- formaldehyde

- epoxy resin

- polyester resin

- gasoline-kerosene-containing substances

If you are convinced that the composition of the glue does not threaten the integrity of the expanded polystyrene, you can buy it.

Bitumen based adhesive

Bituminous adhesive does not need to be heated before application

Bituminous glue is a plaster and glue mixture in which bitumen is used as a binder. It goes well with expanded polystyrene and adheres well to the glued surface. Bituminous adhesive is flexible and does not require preheating before use.

Due to the content of bitumen in the glue, the surface pasted over with extruded polystyrene foam, provided that the glue is carefully applied to the surface of the materials, has high waterproofing qualities.

This makes it possible to use this technology when insulating foundations, floors of the first floor with polyurethane materials, when installing floors on the ground and in other cases when extruded polystyrene foam is used in structures exposed to moisture.

For high-quality adhesion of the surfaces to be glued, attention must be paid to the application of the adhesive to the surface of the materials. It is spread in a small, even layer using a comb trowel.

This will allow not only to firmly connect the materials used, but also to ensure the creation of a high-quality waterproofing layer between them. After that, you need to create a certain pressure on the materials to be glued for half an hour. This can be accomplished using spacers, clamps, or other available methods.

The preparation of bitumen-based glue does not require much effort and is carried out in a matter of minutes using an electric drill with a nozzle in the volumes necessary for high-quality work.

The best styrofoam adhesive for outdoor use

The main requirements for the composition for outdoor use are resistance to low and high temperatures, quick adhesion to the surface, reliable fixation of the glued surfaces and ease of use.

Knauf Klebenspachtel

Knauf Klebeshpachtel is a mineral-cement composition for gluing thermal insulation boards, laying a fiberglass reinforcing mesh. Can be used alone as plaster. For outdoor use. High adhesion to most surfaces. A bag of powder is diluted in 8 liters of water. Layer no more than 5 mm.

The best glue for expanded polystyrene for interior use

It is clear that a different adhesive composition is used for external and internal work, but in both cases there should be a low thermal conductivity. It is not enough to glue the insulation, you also need to provide thermal insulation for the whole house.

TechnoNIKOL Professional

Foam adhesive for expanded polystyrene is used for fixing boards and filling gaps. It is used for decoration of interior partitions, insulation of walls, balconies, plinths and foundations. Moisture resistant, not prone to fungus. Mounted on: porous surfaces, mineral, cement and wood substrates, OSB boards.

Polyurethane foam TechnoNIKOL Professional

Depends on the type of work (sealing, thermal insulation) 750 - 10-12

Drying time, h

Adhesion to concrete MPa

Temperature for installation work

The plasticity of the foam (detachment) is maintained for 15 minutes. The foam adheres well to most building materials, with the exception of PTFE, silicone and polyethylene.

Ceresit Express CT 84

Bonds expanded polystyrene, as well as extruded type on: concrete, plaster, wood, OSB, mosaic cladding and mineral substrates. Excellent adhesive properties. You can start work even if the base temperature is -10ºC.

Ceresit Express CT 84

Drying time, h

Adhesion to concrete, MPa

Temperature for installation work

The peel-off time to correct the position of the panels is 10 minutes. To improve adhesion to concrete, moisten with water before applying the foam. We must not forget that the foam, although it sticks, is still a beacon. That is, you need to drown the insulation plate to the desired level, and as the glue dries, dowel it. Dowels are driven into the T-joint. The price of a cylinder is 700 rubles.

Penoplex Fastfix

Designed for mounting extruded and foamed EPS to various surfaces: concrete, brick, aerated concrete, ceramics, etc. It is also used for thermal insulation of the basement, balcony, rooms, foundation and roof - in general, it gives good results during external and internal work. Suitable for almost all common surfaces.

Drying time, h

Adhesion to concrete, MPa

Temperature for installation work

Light blue foam. It is applied to the sheet in vertical stripes with a step of 5 cm, after which they wait 5-7 minutes, then they are glued. Be sure to carry out the dowel plug. Not allowed with foil coatings, with compositions containing: bitumen, polyethylene, silicone and Teflon.

Varieties of foam glue

To find out which glue is best for foam, you need to consider all the options. Then, after analyzing, comparing their advantages and disadvantages, we can draw a conclusion. So, let's start with the first type - dry glue mixture.

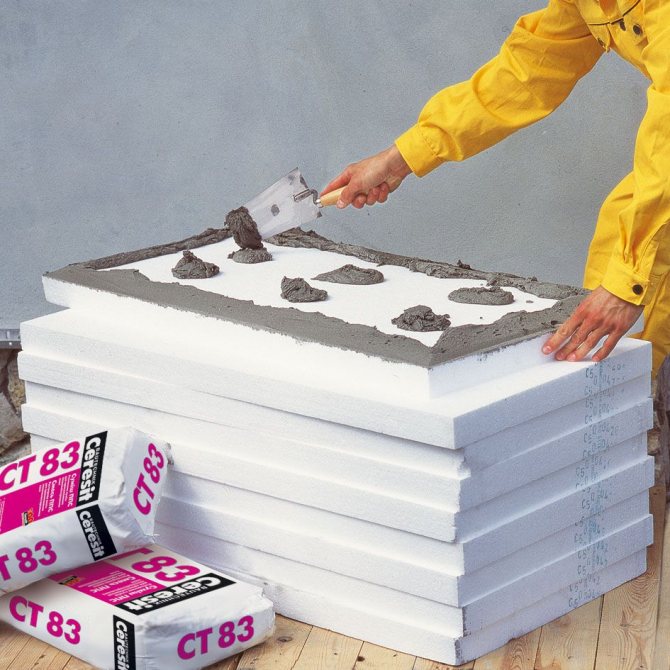

Dry adhesive mixtures

These dry mixes can be used for indoor and outdoor work. They are usually sold in 25 kg bags. As with all dry building mixtures, the glue must be prepared. How? This will require a mixer and water. According to the instructions on the package, the mixture is combined with water and mixed. She's ready to go.

Dry foam adhesive is divided into two groups:

- adhesive composition for foam, which must be applied to the surface of the sheet and glued to the wall;

- reinforcing composition that is already applied to the glued foam on top of the reinforced mesh. This protects the foam from damage.

Note! When buying, it is recommended to immediately buy a couple of mixtures, glue and reinforcing composition to it.

The following are the benefits of dry mixes:

- Acceptable cost in the region of 200-400 rubles per bag of 25 kg.

- Low consumption, approx. 6 kg per 1 m2.

- Good grip.

However, such compositions have their own significant disadvantages:

- preparation of the composition requires human participation. Before work, you need to mess around with cooking;

- foam glue cannot be used on concrete walls and metal surfaces;

- additional fixation by means of dowels has to be performed only a day after the moment of gluing.

This option cannot be called the best. He's good, but not perfect. Foam glue is a completely different matter.

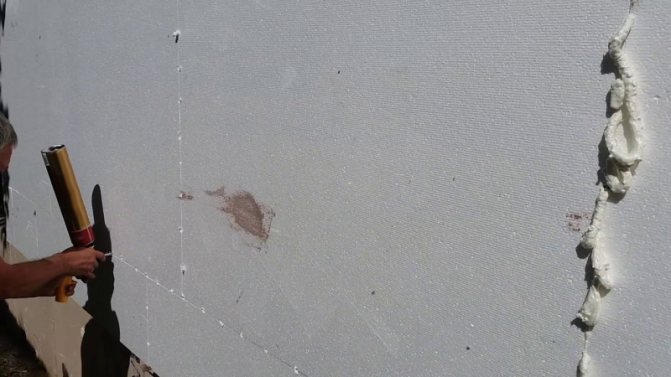

Polyurethane compound

This is the second kind of materials. It is also called polyurethane foam adhesive. What is its peculiarity? As stated by most builders, this is one of the best options for fixing Styrofoam. This is a kind of polyurethane foam that is applied to the sheet before gluing (wet method). The glue can be used for interior and exterior work. Unlike the previous version, it is suitable for any surface, be it concrete, metal, wood or plaster.

The glue is based on polyurethane with additives. Due to its composition, the glue copes with its task perfectly and firmly glues the foam sheet. It does not affect the material in any way, does not harm it and changes its properties. Foam adhesive foam has the following advantages:

- It's pretty easy to work with. The composition is sold ready-made in special containers (bottle), as seen in the photo below. Application is very simple and fast. Moreover, it can be stored for a long time. But the prepared dry mixture should be used up quickly. The leftovers can no longer be used.

- The material has excellent adhesion to any surface. The gluing quality is at the highest level. In addition, you can fix the sheet with dowels 2-3 hours after gluing, because the glue sets pretty quickly.

- The consumption of the adhesive is also small. Just one can of foam will be enough to treat a surface of 10 m2.

- In addition, one cannot fail to note the moisture resistance that polystyrene foam has. It is several times better than that of dry adhesives.

As you can see, it is not for nothing that this glue is considered one of the best for foam. However, like any material, it has several drawbacks. The first is that for application you will have to buy a special assembly gun. Its cost ranges from 400-2.5 thousand rubles. This makes the work more expensive. But, on the other hand, it is this gun that makes the installation process so simple and convenient. In addition, the pistol will remain with you and can be used if needed.

Recommended: How oh, "moment" from the hands, how to stick fingers?

Advice! In order not to spend extra money, you can borrow an assembly gun from friends to stick the foam sheets.

The second caveat concerns the price. The minimum price is approximately 500 rubles. This figure may increase depending on the manufacturer.

Liquid Nails

The last type of foam glue is liquid nails. They are used for small surfaces. They cannot be considered a full-fledged competitor for the first two types. When choosing a glue, it is important to pay attention to the composition. It should not contain solvents.

It is impossible to call them a strong and reliable composition. That is why they are combined with another adhesive (dry mix, foam for polystyrene) to glue the foam. There is a little trick on how to improve the quality of fixation. To do this, you need to apply the adhesive composition in a dotted manner. The proportions are as follows: on 1/3 of the surface of the foam, liquid nails are applied, and on 2/3 of the adhesive composition from a dry mixture.

In this way, good results can be achieved. Thanks to liquid nails, the sheet will quickly fix on the surface, without any supports, and due to the dry mixture, a reliable fixation will be provided. Given that liquid nails cost from 150 to 300 rubles, such a combination is quite justified.

Pros of liquid nails:

- Acceptable cost.

- Fast setting.

- In combination with other adhesives, it provides secure adhesion.

- It is easy to apply.

Minuses:

- as is the case with polyurethane glue, you will need to buy an assembly gun to work;

- poor adhesion to the surface;

- not suitable for some surfaces.

If you make an unbiased analysis, it becomes clear that it is the polyurethane foam composition that is considered the best adhesive for foam. In the second place, you can put dry mixes, and in the last place, liquid nails.

How to properly glue expanded polystyrene

Before proceeding with the installation of PPS plates, it is required to assess the quality of the surface.

If there are drops and irregularities

You will need to use a primer and putty the existing flaws. Make sure that the composition of the putty mixture will not interfere with the adhesive.

Cleansing of previous layers is required

Oil based paints, mildew, rust, salt and grease deposits all reduce the adhesive properties of the surface.

Experts advise to conduct a test to check the adhesion of the working surface. We'll have to sacrifice one slab, cutting it into 10x10 cm cubes, and glue them in various places where thermal insulation is planned. Tear them off after 72 hours - if the base of the cube, together with the glue, remains in place, and only pieces of expanded polystyrene come off, you can start the installation in full.

After you have eliminated all sorts of shortcomings and conducted the test, and everything you need has already been purchased, you can start.

How to choose foam adhesive for fixing expanded polystyrene boards

Like any building material, polyurethane foam has a number of characteristics, which determine the quality of the product. All the main points will definitely be indicated on the label. So, what you should look for when buying:

It is very easy to distinguish household polyurethane foam from professional one. It is enough to look at the balloon - if a nozzle in the form of a thin plastic tube is attached to it, then it is intended for household needs.

However, it is impossible to say unequivocally that only beginners use such foam, and professionals necessarily use a nozzle in the form of a pistol. Let's consider the main differences that will help you decide and choose the right type.

How long does the glue dry

The drying process of cement-polymer mixtures is inferior in speed to polyurethane foams. Complete curing of the layer takes up to 3 days, while the foam cures in 48 hours.

VIDEO: TOP-10 home insulation mistakes

TECHNONICOL GLUE-FOAM is intended for fixing panels of extruded polystyrene foam and expanded polystyrene to the base when installing thermal insulation of external and internal walls of a building, roofs, basements, foundations, floors in both new and reconstructed buildings.

Also TECHNONICOL GLUE-FOAM is used for:

- Temporary fixing of XPS and EPS boards to vertical surfaces inside premises when insulating walls, interior partitions, balconies and loggias

- Temporary fixing of XPS and EPS boards to vertical surfaces when insulating facades

- Temporary fixing of XPS and EPS boards to vertical surfaces when insulating plinths and foundations

- Sealing gaps between insulation boards

- Bonding XPS and Styrofoam to various materials

TECHNONICOL GLUE-FOAM for expanded polystyrene

possesses good resistance to moisture, mold, aging, high adhesion to concrete, cement plasters and other mineral substrates, as well as to wood, chipboards, OSB boards, etc.

The consumption of glue-foam is:

For 750ml cylinder - 10-12m2

For a 400ml cylinder - 2-4m2.

The consumption of FOAM GLUE is determined from the weight of the binder. So, in a large container, the binder content is

260gr. Taking into account the degree of evacuation of the binder from the cylinder, which is at least 85%, the consumption for cylinders of different capacities is not a multiple of the volume of the cylinder.

It is used at temperatures from 0 ° C to + 35 ° C.

Plaster and adhesive mixture

Such mixtures are suitable for gluing PPP to gypsum plasterboard, brick, concrete, cinder block substrates. They need to be bred by ourselves, since they are realized in the form of a dry mass. The composition includes mineral components, plasticizers, Portland cement, a number of auxiliary additives. The mixtures are suitable for outdoor use and indoor decoration, they will hide all the unevenness of the base. The downside is the need for preliminary deep priming of the surface.

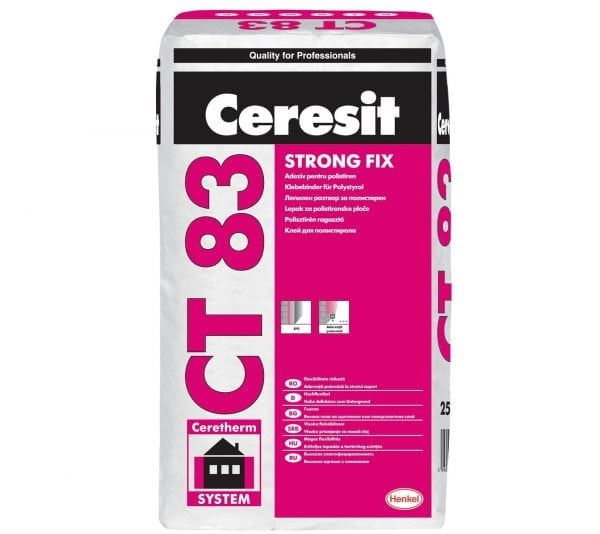

Ceresit CT-83

"Ceresit ST-83" is widely used for pasting the facades of buildings. It has excellent frost resistance, adheres well to wood, concrete, plaster, brick. After drying, ST-83 is breathable. Consumption per 1 sq. m is small, because it is enough to apply a mass of 1 cm thick (this is done with a notched trowel).

The company also produces high-quality Ceresit CT 85 glue, which is considered universal.High strength and ductility are due to the polymers included in the composition. But this tool costs an order of magnitude more expensive than the previous one, so builders prefer ST-83. Both materials are applied in intermittent stripes, slightly receding from the edge for better air release.

Bergauf ISOFIX

Bergauf Isofix glue is a mixture of minerals, fillers, cement, sand, plasticizers, special additives. It is used for any premises and for outdoor use. Average consumption - up to 5.5 kg / sq. m, a thin layer (3 mm) is required. After dilution, the mixture is viable for 1.5 hours, it is possible to change the position of the slab on the wall within 25 minutes. The glue is sold in bags of 25 kg, it can glue extruded polystyrene foam with all types of surfaces.

We recommend: Primer for walls under wallpaper: choose which primer is best for walls under wallpaper

Mounting method:

- Place the TECHNONICOL Glue-Foam cylinder for expanded polystyrene with the valve upwards on a flat surface, remove the protective cap from the valve and carefully align the cylinder valve with the landing bridge of the assembly gun. After placing the can on the gun, shake the can vigorously 20 times.

- Before starting the installation of polystyrene or XPS boards on the surface, the starter fixing profile must be fixed on which the first row of boards will rest.

- TECHNONICOL GLUE-FOAM for expanded polystyrene is applied with an assembly gun in the position of the balloon upward, keeping the distance between the gun and the plate for the correct application of the glue.

- TECHNONICOL GLUE-FOAM for expanded polystyrene should be applied along the perimeter with an indent of about 2 cm from the edge of the board in strips about 3 cm wide and in one strip through the center of the board at an equal distance from its long sides. After applying TECHNONICOL FOAM ADHESIVE for expanded polystyrene to the board, wait at least 5 minutes for the foam to fully expand, and then fix the thermal insulation board on a vertical surface.

- Place the panel with TECHNONICOL FOAM ADHESIVE for expanded polystyrene to the wall and press lightly. Fix the board until the glue sets. Plates should be fastened close to each other with a gap in the seams. The gap between the plates should not exceed 2 mm.

- The panels can be adjusted within 5-20 minutes after their installation, depending on environmental conditions.

- To prevent the formation of cold bridges, larger gaps between the boards must be tightly filled with scraps of expanded polystyrene and TECHNONICOL FOAM ADHESIVE for XPS.

- Cut off excess foam after drying with a knife and sand with a trowel.

| Indicator name | Unit measurements | Value |

| The degree of evacuation of the contents from the package, not less | % | 94 |

| Polymerization start time, no more | min | 10 |

| Curing time at 20 ° С and relative humidity more than 50%, h, no more | h | 2 |

| Full curing time, no more | h | 24 |

| Density after curing | g / cm3 | 25 |

| Thermal conductivity | W / mK | 0,035 |

| Adhesion strength (adhesion) to a concrete surface, not less | MPa | 0,15 |

| Adhesion strength (adhesion) with expanded polystyrene, not less | MPa | 0,07 |

Polyurethane foam as glue?

Greetings! Dear experts, tell me - is it possible to "glue" 50mm polystyrene plates onto bare concrete on polyurethane foam? Polyfoam itself is very good. It weighs a little, it is necessary to sheathe a loggia for insulation, as far as I noticed the foam "grasps" wet and clean concrete very well .. it seems like a logical way out, but I understand little about construction matters.

Easy. Is it difficult to check for yourself?

Only today I did it, only on a curved ceiling. Installation foam glues everything except perhaps glass and cellophane. The smaller the gap, the stronger the gluing, but this is not relevant for foam plastic. But if there are built-in lamps in the suspended ceiling, the foam can leak.

Recently, the balcony was insulated, a special foam was used: expanded polystyrene (Sturodur), it is specially designed for insulation. And for gluing they used a special glue-cement for insulation Ceresit CT85, and Polimin P22. But you can just glue it with cement.

Generally, polyurethane foam melts polystyrene, but not so that criminal. There may also be problems with different thicknesses of the foam layer. Better to put on glue.

problemnet wrote: polyurethane foam melts polystyrene

It is there. But this is the key to the strength of the connection.

2 Problems 2Mals Glued EPS on polyurethane foam, did not notice melting. Maybe you had winter foam?

Foam - cheap (if I remember correctly - repair +), foam - which is cheaper (well, the task was "budget", hence the materials). The foam penetration layer in the PP was up to 5 mm. But, again, I repeat, it was very beneficial.

2robot himself insulated his loggia in this way. glued 50mm foam on a concrete slab.

to check, I cut off a piece of foam 20x5 cm, nipped the foam there and glued it to the inner side of the plate after a day, my sister (21 years old) could not tear it off, I tore it off with great effort.

and now the subtleties:

- buy a pistol: the dosage is accurate, rational use, grease secondary expansion of the foam, large balloons with foam (take a balloon for a pistol and an ordinary one, which is heavier?), an order of magnitude more convenient to work, foam can remain in the pistol for about a month. shorter than balloons in 20 it will pay off. a nuance when buying a pistol, take the trigger, you should hear the sound of outgoing air (such a puff), which will indicate the tightness of the pistol, if there is no such thing, take another (maybe another company).

- Apply foam to the foam using a dotted method (or serpentine), over the entire area, so that these points do not intersect when flattened. then attach the foam to the base and press it to the base with medium force vibrating movements, then tear it off (yes, just tear it off), apply more foam on the foam (somewhere in half less) wait about 2-4 minutes and press it again with the same movements, and so on hold for a few minutes (2-4). which will give tearing - it will dry a little the layer of foam on the base and the foam, thereby improving its adhesive ability. as you glue the next sheets, keep an eye on the old ones, they may slightly (5mm) move away with the same vibrating movements, return them back.

- apply foam equally to all foam sheets so that there are no uneven joints,

- the joints of the polystyrene mezhin malfunction and from the wall I further frothed too slightly.

- Well, then the usual technology, mesh foam glue.