Heating with a stove on diesel fuel

The diesel stove is chosen for heating garages due to its small size and low energy consumption. For example, a stove with a capacity of 2.5 kW consumes no more than 0.2 liters of diesel fuel per hour. The weight of the stove usually does not exceed 10 kg, and the compactness of the device allows you to put the stove in any place convenient for a person.

There are several main types of diesel stoves:

- mini oven with wick;

- heat gun;

- direct combustion furnace;

- dropper stove;

- heated water oven.

Each of the ovens has its own characteristics.

Homemade stove on diesel fuel

Mini oven with wick

These heaters can be purchased at the store. The furnace design consists of two main parts - a fuel tank and an open tank. The vessels are interconnected, and the fuel supply is controlled by a special valve. Another indispensable element of a mini-oven is a wick, the tip of which is immersed in a container with fuel. The diesel fuel supply is regulated thanks to a special valve. After turning the valve, the valve opens between the communicating vessels, thereby impregnating the wick with a combustible mixture. In the same way, the device turns off, cutting off the fuel supply.

Such a furnace is fired manually. A match or a lighter is suitable for this. It is worth setting fire to the wick a couple of minutes after opening the valve. You must also wait 10 minutes for the oven to warm up. After that, the autonomous diesel oven will work independently. The diesel mini-oven turns off 5 minutes after you turn off the valve.

The power of the factory furnaces is from 1.8 to 5 kW. Some of them are equipped with a special metal grate on which you can heat something. For example, boil water. This design is suitable for those who spend a lot of time in the garage during the winter.

Do not forget that the diesel fuel stove has several significant drawbacks. First of all, it is a pungent unpleasant smell. It is best to light the wick outdoors. Diesel fuel vapors are toxic and carcinogenic; such a heater must not be used around the clock. Also, if you use the stove frequently, it is necessary to clean the burner on a regular basis. The wick needs to be replaced regularly.

Diesel Mini Oven with Industrial Wick

The simplest do-it-yourself stove

Solid fuel boilers for long burning, which were mentioned above, are difficult to do with your own hands according to the scheme. The drawings below will help the DIY master build the simplest heating device on his own. Equipment power - 35 kW, efficiency - up to 85%, burning time - 12 hours. Coal or fuel pellets are used as fuel. Loading with wood reduces the efficiency to 75%, the burning time is reduced to 8-10 hours.

A drawing of the furnace design will help you make it yourself

Homemade stove with wick

For the manufacture of a homemade stove on fuel, you must use only high quality materials. The furnace must be necessarily small in size, since the wick devices have a large heat release. If the device overheats, it could cause an explosion.

If possible, it is best to use a primus instead of a wick. Due to the low consumption of diesel fuel, it is safer. The primus should be made of asbestos cord. It must be rolled into a dead loop. The risers should be soldered into the fuel tank. The volume of the fuel tank must not exceed 0.7 liters.A small pallet must be soldered to the fuel pipes under the dead loop, which will be used for ignition. The principle of operation of a home-made stove is quite simple: diesel fuel is poured into the pallet and ignited, the primus heats up and the combustion process begins.

Heat gun

A heat gun is used to warm up large enough rooms, up to 20 m3. The cannon heats up the air by letting it through with a fan, thereby heating the process much faster than a device with a wick. The models are manufactured with power from 10 to 100 kW. This is a fireproof device that has emergency shutdown functions from the fuel supply.

A heat gun is a cylinder-shaped structure that consists of a fan, a fuel tank and a burner. To start the fan, such a device needs power supply.

There are two types of guns: direct and indirect heating. The direct heating device is suitable for heating air in open areas. For premises, you should purchase a heat gun only for indirect heating, the smoke from which is removed through the chimney.

Industrial Diesel Heat Gun

Diy heat gun

Despite the name, the heat gun can be made not only round, but also rectangular. To create the body of the unit, a metal pipe or galvanized iron sheet is suitable. Several containers need to be made. One will be used as a fuel tank, the other as a place for the combustion chamber and fan.

In order to heat the room as quickly as possible, it is advisable to use a sufficiently powerful fan. The air will circulate faster through the heat gun, thereby the room will heat up faster.

It is desirable to make the diesel tank from a material with low thermal conductivity. You can use ordinary metal, but then you should take care of thermal insulation. It is necessary to place the tank at the bottom of the structure, the distance to the top should be at least 15 cm.

The fan is installed on the back of the upper case. A metal tube extends from the fuel tank, which is connected to the fuel filter and a pump, which is connected to the combustion chamber through a nozzle. The front wall of the structure is closed with a mesh. It is also worth taking care of creating a smoke outlet.

The heat from a heat gun can reach 400 degrees, so you cannot be directly in front of the unit. It is best to use such a heater outdoors. If they heat the room, then you should take care of the smoke coming out of it.

Do-it-yourself stove design

For independent design, it is necessary to have minimal knowledge in the field of thermodynamics (in order to understand how the formation and combustion of a combustible mixture of diesel fuel and oxygen is carried out), to be able to understand elementary drawings. It is desirable to have the simplest skills in the field of processing ferrous and non-ferrous metal (cutting, drilling and welding technology). If you don't have such experience, you can always turn to specialists.

A do-it-yourself diesel stove can be made in a garage, home workshop.

Construction from a conventional gas boiler

Elements of an old gas boiler can be used as a body. The boiler body must be cut into two halves. One will be the bottom of the stove, the other will be on top. The nozzles available in it must be expanded in order to ensure the free flow of diesel fuel into the mixing chamber and further into the combustion chamber.

Homemade stove from a gas boiler

The duct system can be converted into a chimney. It remains only to place the diesel fuel tank and the stove is ready.

Gas cylinder heater

An unused gas cylinder can be used as the body of the future stove. Before using it, you need to make sure that it is empty. In addition to the cylinder, you will need two pipes with a length of about 4 meters and an outer diameter of about 100 mm, a container for storing diesel fuel (on average from 10 to 15 liters), two copper pipes (for the production of a burner). The support should be made from steel corners with a 200mm shelf. In addition to the material, you will need tools: a drill and drills for metal, a grinder (grinder) with cut-off wheels, any welding machine.

Using a grinder, the cylinder is cut into two equal parts. The upper part will be the cover of the future stove, the lower one will function as a combustion chamber. For the stability of the entire structure, metal corners are welded from below, which are the legs of the future stove.

A hole is made in the upper half. An exhaust pipe will be installed in it. It must be welded securely. Make sure that it is located strictly vertically. A hole is made in the pipe. It functions as an air intake regulator.

Having departed from the pipe about 10 cm, make another hole up to 3 mm in size. There should be at least ten such holes. The latter should be at a distance from the welding point no more than 50 centimeters. In addition, a hole with diameters up to 8 centimeters is prepared in the upper part for pouring diesel fuel. A hole 5–8 cm in size is made in the upper part of the cylinder for filling the fuel.

Drip stove

They are quite economical and easy to manufacture. For example, to obtain a power of 10 kW, a diesel fuel consumption of only 0.6 liters per hour is required. By increasing the size of the structure, the heat transfer power can be increased to 20 kW.

The technology for manufacturing a dropper stove on diesel fuel does not present any particular technical difficulties. First, the dimensions of the future unit are calculated. The calculation is based on the following considerations. For heating a room with an area of 9 sq. m, there will be enough stove, the dimensions of which are equal to 30x30x45 cm. These dimensions allow you to calculate the volume of the stove itself. Most often, they use ready-made structures and not necessarily rectangular. For small stoves, the lower parts of fire extinguishers are used, for more powerful stoves, the bottom of metal barrels is used.

The supply of diesel fuel is organized using elements of a medical burner. The rubber hose present in it is fixed on a specially prepared copper tube. This tube is bent at right angles. Then it is fastened with a clamp or a specially prepared fastening. As a wick, you can use an improvised rag, which is pre-impregnated with diesel fuel.

Homemade stove dropper

The principle of operation of such a stove is to constantly wet the wick with diesel fuel, which flows by gravity through a hose and tube from a container with diesel fuel.

A door is made in the stove body, and a hole is made on top for a copper tube.

Steel sheet stove

It is shaped like two metal discs. There is a steel pipe between them. Several holes have been drilled in it. They are designed to supply external air from below and remove harmful combustion products.

Typically, such a unit has a fairly compact size. The specifics of the design make it safe enough. Another advantage of such stoves is their efficiency. This is due to the fact that the fuel mixture burns out completely and the most efficient heat transfer occurs.

For the manufacture of such a furnace, you will need sheet steel with a thickness of at least 5 mm, a steel pipe. It needs to be cut into two shorter pipes and two bends made. They must be made in such a way that it is possible to insert one into the other. After connecting these elements, a chimney design is obtained.I make two containers from steel. One, the lower one, serves as the firebox of the stove itself, the second upper one is the fuel tank. The size of the tank is determined by the manufacturer himself. Usually its volume does not exceed 12 liters. This is due to the convenience of pouring diesel fuel.

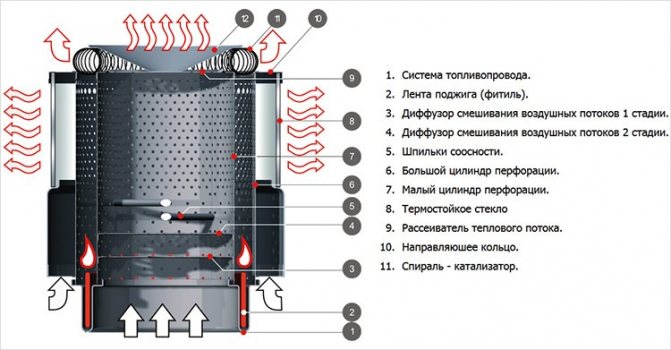

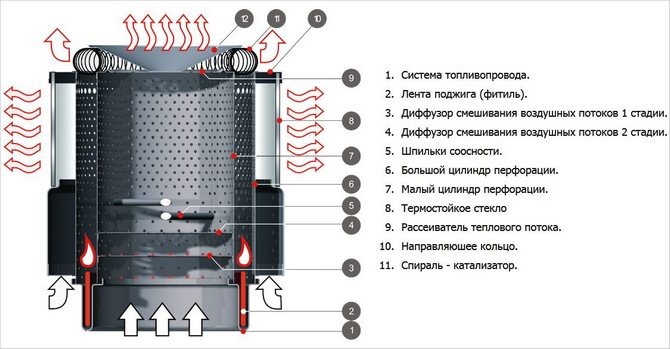

The location of the tank above the level of the combustion chamber is based on the principle of diesel fuel supply. It flows by gravity. In a special chamber, diesel fuel is mixed with air and heats up. Thus, a combustible mixture is formed. Further, the combustible mixture enters the combustion chamber. In it, during combustion, the spiral heats up. This coil acts as a heating element. With proper operation, it heats up to a temperature of about 800 ° C.

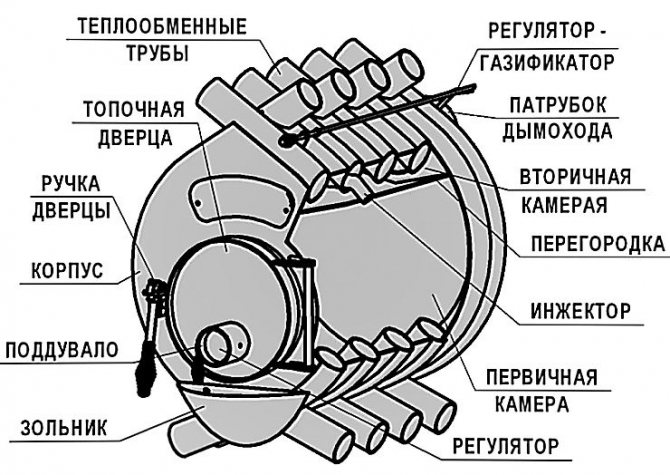

Direct combustion furnace

A direct combustion stove can be made by yourself. Such a unit will work due to the natural draft of air.

To create a direct combustion furnace, only three structural elements are needed - two metal tanks and a pipe. The containers can be either square or cylindrical.

The lower tank serves as a container for diesel fuel. It is necessary to attach several legs to it for the stability of the structure. The tank is no more than half filled with liquid fuel. A small hole with a flap must be made on the cover, through which it will be possible to regulate the air supply.

A pipe must be connected to the lower tank. This is the so-called afterburner. In it, the remaining fuel is mixed with secondary air.

The pipe is connected to the upper tank. The container must be equipped with a partition inside, behind which a hole will be made for the smoke to escape.

The disadvantage of such a furnace is its high fuel consumption. An hour of heating can take up to 2 liters of diesel fuel. Like any home-made heater, a direct combustion stove can ignite, so it must not be left unattended.

Disadvantages of modern devices

Note that all the excitement around the new cooking device is gradually dying down and the novelty, at best, quietly and silently serves its owners. More often, the perpetrators have to sink into oblivion, as a certain disappointment sets in. The hostess in the kitchen needs an assistant for convenient quick preparation of delicious food, which would also be useful.

With the advent of microwave ovens on the market, all manufacturers, suppliers and retailers unanimously reiterate that this is the oven of the future. Cooking food through exposure to high frequency waves is a guarantee of a healthy lifestyle.

However, it turned out that the microwave is useful for quick heating, and even then, not in every case. It is quite expensive to cook in it, since the device consumes a lot of electricity, and the requirements for dishes, which are often prohibitively expensive, completely discourage people from enjoying such a blessing of civilization. Now this stove has changed its status from the category "Super Prize Pole of Miracles" to the category of "suitcase without a handle".

A new round in the development of devices with intelligent cooking was marked by the advent of the multicooker. This story looks just ridiculous, the housewives were promised a super device that can cook any dish from ingredients, and in the end they got the same saucepan in which they need to put cooked, peeled chopped vegetables. Naturally, no one expected a miracle.

A modern take on an old friend

We must pay tribute to the developers, the lack of food contact with the heating element could not fail to impress the housewives, but the accompanying work on the care of the device makes it easier for many to prepare dinner in the traditional way than to clean, wash and dry the elements of the multicooker later.

Good to know: How to build a brick stove with your own hands