Technical description

Getting acquainted with this product should start with its design features:

Structure

Thus, by turning the handle, we can set one of two positions:

- The ball is turned by the wall towards the passage, blocking it.

- The ball is turned with a hole towards the passage, opening it.

Dignity

The described device provides this type of shut-off valves with the following advantages:

- Simplicity and high speed of do-it-yourself use

... You just need to make a slight turn of the handle 90 degrees to stop the flow of water or resume it. - Small size and attractive appearance

... It looks quite aesthetically pleasing against the background of the rest of the plumbing system.

- Durability

... Unlike conical and cylindrical locking systems, the ball valve is not prone to such rapid wear.

Advice: it is recommended to install a coarse filter in front of the tap, which will prevent the appearance of scratches on the locking mechanism from grains of sand caught in the pipe. This will further extend the life of the product.

- Affordable price

... The simple design does not require an expensive manufacturing process. - High tightness rate

... The O-rings in combination with the ball itself seal the passage absolutely reliably.

Views

The products under consideration may differ in the size of the internal passage:

Repairs

How to disassemble a ball water valve in the event of a malfunction, which can be expressed by the appearance of a leak or squeaks in the area of the shut-off element?

The instruction is quite simple:

- We unscrew the nut fixing the handle and remove the handle.

- We remove the retaining ring from the stem, after which we take it out as well.

- We untwist the case with the keys.

- We inspect the ball, seat rings and sealing elements.

- If any defects are found on any part, we will replace it.

- We put the structure back, after having lubricated the moving components.

Choice

When buying a ball faucet, it is quite possible to purchase a low-quality fake.

First of all, you should understand that a quality product must be made of brass, so when choosing it, pay attention to the following signs:

- The weight. If the sample is light, then it is most likely made of cheap and silumin, which does not have a long service life and high strength.

- Ball mirror. If it is cloudy or dull, then this indicates either its poor-quality processing, or that it is made of steel, which is prone to corrosive processes. In any case, you should refuse to purchase.

- Cost. A crane that is too cheap is suspiciously cheap, then it is probably a fake, since the seller will never work at a loss.

- Defects. Do not be lazy and inspect the valve body for cracks, sagging and irregularities, they can tell a lot about the manufacturing level.

- Warranty card. The guarantee is provided only by well-known and proven manufacturers. If you have one, you can be sure that you are purchasing a quality product.

Pros of using a gas ball valve

A ball valve designed for underground installation is a device that is necessary to shut off the gas flow in pressure pipelines laid in trenches.

These devices are used in both industrial and domestic environments. Gas valves provide fast and complete shut-off of the flow of the working medium.Their widespread use is due to their reliability, durability, strength and relatively low cost.

If the gas valve breaks, then in the event of an emergency, the pipeline cannot be closed to isolate the damaged branch. It will not work and prevent the spread of gas

Ball valves are made of heavy-duty materials, resistant to corrosion, inert to aggressive media. In production, alloys are used that tolerate all kinds of mechanical damage without problems and deformations.

Products have high wear resistance regardless of operating conditions. Ball gas valves are capable of maintaining their technological properties for a thousand (or more) cycles without any malfunctions.

In this case, the temperature of the moving and the environment can be practically any. It was experimentally found that gas ball valves are capable of withstanding temperatures from -60 to +80 degrees. Most gas taps are able to last much longer than the manufacturer stated.

Ball valves are simple in design, so they do not require constant repair and maintenance, unlike complex systems

The closure of the gas ball valve is made in a spherical shape and has an opening through which gas passes through the pipes. The hole diameter is selected in accordance with the dimensions of the pipeline. Adjustment of the throughput of the line is provided due to the possibility of turning the locking mechanism around its axis.

In the working position, the lock is located perpendicular to the pipeline, and it can be easily closed by hand by turning the handle slightly. When rotated 90 degrees, the through hole side changes to a solid surface.

With a smaller turn, the pipe will be partially closed. But manufacturers do not recommend leaving the structure in a half-open state, because this contributes to increased abrasive wear of the device.

In intermediate positions, the O-rings can be completely damaged or partially deformed due to too high a flow velocity of the pumped medium. This in the future can lead to serious damage to the crane, its repair or replacement.

The body of the product is highly airtight. The use of metals and special alloys in the structure helps to reduce the weight of the structure. Such shut-off valves for gas pipelines can be easily installed in hard-to-reach places.

In the event of any breakdown, the gas ball valve can be easily repaired using improvised means without damaging the rest of the system.

The use of quality gas ball valves is economically beneficial. These devices have a huge margin of safety and can function fully without needing to be replaced for many years.

This is especially true for ball valves from well-known and trusted manufacturers. At the same time, you can make sure of the quality of any crane by checking the certificates of conformity, which confirm the quality of the products.

The principle of operation of the ball valve

Ball valves are designed to completely shut off the working flow in the pipeline. They are not used to adjust it.

The operation of such a crane is based on a metal ball with a through hole.

When the hole is turned towards the pipe, the valve is open. If the ball is turned perpendicular to the pipe, then it is closed.

The shape of the hole in the ball can be in the form of a circle, rectangle, trapezoid, or oval. And its size depends on the type of pipes and the purpose of the crane.

The ball valve locking element can be placed, depending on the size and purpose of the valves, in two ways:

- installation of the ball on special supports is used in large cranes;

- for small devices, a floating ball is used.

Less often, the shut-off element (ball) is installed using additional seals. The operation of the ball valve is quite simple and is done by turning it 90 degrees.

Types of ball valves

Depending on the installation method, ball valves are of the following types.

Ball valve for coupling

used mainly in gas, heating and plumbing systems in residential and public buildings. Such devices are small in size, reliable and easy to use.

Ball-type coupling valves are used for installation in pipes with a diameter of up to 45 millimeters.

For large pipelines used flanged ball valves.

Flanged ball valves are installed on pipes with a diameter of more than 45 millimeters. When installed in such a crane, sealing gaskets are installed, with the help of which a high level of strength, reliability and tightness is achieved at the junction of the pipe with the crane.

Flange-type ball valves are resistant to heavy loads, high pressure of the working medium and are very durable. Such devices are widely used in gas pipelines and for systems for pumping petroleum products. They can be collapsible and with a monolithic body.

Ball valve

used in pipelines in the food and chemical industries and other industrial sectors.

The choke valve has a great advantage - a wide possibility of multiple dismantling.

Welded ball valve

differs from other similar elements in that it is installed in places where subsequent dismantling is not provided. Such a ball valve is assembled using a welding method by highly qualified specialists. Typically, a welded ball valve is used in construction work.

The combined ball valve differs from other devices in that it can be connected to pipes using various methods.

According to the number of connected branch pipes, ball valves are produced of the following types:

- pass-through devices, that is, one inlet and one outlet are connected;

- angle-type devices are installed if it is necessary to make a bend or turn of the pipeline on the crane;

- devices with more than three branch connections. The installation of such elements occurs in order to redirect or displace the flows of the pipeline working medium.

There is also a ball valve for underground installation. It has a high valve shaft which makes it suitable for use in underground pipelines. The axis with the ball valve handle is located above the ground surface, that is, such a device can be turned on and off remotely.

Ball valves advantages

The advantages of such devices are high reliability, usability and compact size. Such devices rarely break. Ease of use lies in the fact that you do not need to turn the valve for a long time to turn it on, but only by turning it 90 degrees, you can easily and quickly open or close the movement of the working flow moving through the pipeline. This is especially convenient in the event of various emergencies.

The ball valve has high strength and corrosion resistance compared to other shut-off devices. It is widely used in pipelines for the delivery of chemically aggressive substances.

Due to its excellent performance, repair and replacement of the ball valve is simple and convenient.

Benefits of using ball valves

Ball valves are very practical and compact devices, and are irreplaceable when it comes to the aesthetic component.They are easy to use - a simple turn of the tap handle 90 degrees will allow you to shut off the working medium supply almost instantly. This is important in the event of minor accidents - leaks in water pipes and leaks in gas pipelines.

These valves are resistant to corrosion and wear resistant. Perfectly adapted to the effects of aggressive environments. In addition, the repair of ball valves is quite simple, and in comparison with other types of valves, their purchase is quite cheap.

Ball valve installation

Before installing the ball valve, you must choose the right place so that there are no installation problems, and the movement of the pivot arm does not interfere with other devices. The pipe diameter must match the size of the valve.

The ball valve is available with two types of flanges: with external and internal thread or combined type.

Installation of ball valves in heating batteries or other household devices is carried out using various types of flanges.

In this case, the direction of installation of the valve should be observed, on the body of which there is a special arrow indicating the direction of the water flow.

It is necessary to connect the tap when using a special tape or tow in order to prevent water leaks during operation. The tape must be wound in the direction of the tap, otherwise a reliable connection may not work.

The construction of a water supply or heating system both in a private house and in an apartment is impossible without the use of valves. One of the most widely used elements of plumbing systems is a brass ball valve. It can be used in various sections of pipelines.

Design features of ball valves

Although the installation of ball valves has been used for a long time, however, their widespread use began only with the advent of modern materials (fluoroplastic, artificial rubber and other synthetic substances) capable of providing reliable sealing and practically avoiding wear of working elements, which, in conjunction with high-quality lubricants, significantly reduce friction also makes it easier to operate even large ball valves.

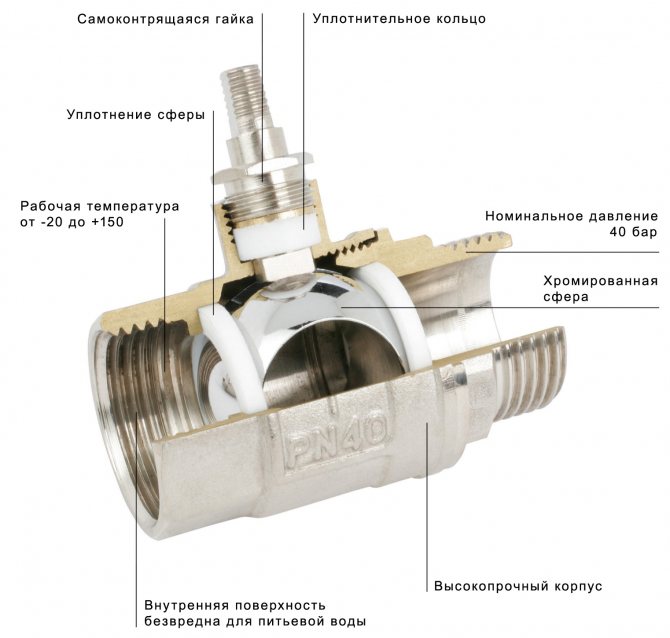

The device of modern ball valves is quite simple and consists of the following elements.

Namely:

- shutter - a part in motion in the form of a metal ball with a through cylindrical hole in the center to ensure the passage of the transported medium;

- hulls;

- sealing rod;

- control knobs;

- body nut;

- Teflon sealing seats;

- rubber stem seal;

- adjusting nut;

- sealing washer.

The opening in the valve is equal to the inside diameter of the connected pipe, which is why these valves are called full bore. When the valve is fully opened, there are practically no hydraulic losses in the flow circulation when passing through the valve and the valve as a whole, which reduces the wear of pipes and the locking mechanism several times in comparison with previous types of locking devices. By turning the valve handle 90 degrees, the work flow will be completely shut off.

General principles for the construction of a water supply system

Of course, the construction of plumbing systems is a matter that is best undertaken by professionals. No wonder in any construction university there is a faculty, which is called "Water supply and sewerage". But at the same time, with the minimum necessary knowledge, you can easily create an internal sewer system and supply it with all the necessary devices yourself. In addition, knowledge in the field of design and construction of a water supply system will help you not to make mistakes when controlling work performed by third-party organizations or craftsmen.

So, in order to build a water supply system with your own hands, you need to carry out work in the following stages.

We draw up a diagram and plan of the future water supply system

The initial stage of any construction work is drawing up a plan.

The best option would be to draw up a plan of engineering communications either in a specialized computer program or on a regular sheet of graph paper. As a rule, water supply communications pass along the walls of the room, and in some cases they are laid in grooves - niches hollowed out in the wall.

At this stage, you will be able to calculate the required number of water supply pipes and related fittings.

An important role in planning the water supply system is played by the calculation of the required number of valves. As a rule, modern water pipes are built from metal-plastic pipes. They are lightweight and easy to install. On such pipes, it is recommended to install classic shut-off ball valves made of brass or their alloys. Such a material of manufacture is absolutely neutral and does not enter into chemical reactions with flowing water. As a result, the water does not receive additional impurities, and the brass of the ball valves does not oxidize when the liquid passes.

Ball valve device

Shutoff and distribution water supply valves based on balls were invented about a century ago and during this time they have become very widespread. Such devices can currently be used both in industrial enterprises and in private households.

The main field of application of ball valves is the complete shut-off of the water supply system. Therefore, they are installed at offsets from the main water supply canals or in places where temporary dismantling of hydraulic devices is possible.

The most obvious locations for ball valves are:

- the place of connection of the flexible toilet bowl in the bathroom;

- the place of connection of the outlet to the dishwasher or to the washing machine;

- the place of connection of the heating boiler;

- also, shut-off valves with ball valves can be installed on the heating system at the connection points of the "bypass" - a bypass path that is installed next to the water pump;

- in addition, ball valves are also installed in conventional water taps, which are located on sinks and bathrooms.

The water distribution valve with a ball mechanism for water withdrawal has a body and a rotatable distribution element in its design. The design of the spout of the faucet (its body) usually differs significantly depending on the preferences of the manufacturer, but the ball element is the same for all modifications.

In such taps, the distributing element has a cavity inside, at the opposite ends of the hollow ball there are holes: two on one side and one on the other. Hot and cold water flows through two holes, flows mix in the ball cavity and water of the desired temperature is supplied to the spout.

A hollow ball is also used in shut-off valves, only on both sides it has one hole. The cross-section of the holes in the ball is usually equal to the internal cross-section of the pipeline, therefore such valves are called full bore. In the normal, open position of the tap, the hole in the ball leaves the water passage completely open, and when the ball is turned 90 degrees, the water flow is completely blocked.

Why are ball valves widespread?

Ball valves and ball valves have become very popular due to a combination of several factors:

- long term of trouble-free operation;

- excellent tightness - the outer part of the valve body is a single whole;

- attractive appearance;

- ease of installation - it is enough to fix only the inlet and outlet pipes on the thread.

Attention! Despite all the visible advantages of ball valves, they are not recommended to be installed on pipeline systems, in the flow of which there is a large amount of debris or impurities. The ball device fits quite tightly to the PTFE pads inside the body and damage to their articulation can cause inadequate operation of the device.

What are ball valves made of?

All ball valves produced by modern industry can be divided into three large groups according to the materials of their manufacture:

- steel - most often carbon steel with alloying additions is used, resistant to corrosion;

- copper-based alloys, in particular brass. The use of such alloys on copper pipelines prevents the appearance of electrochemical corrosion;

- plastic materials - the wide development of polymers has led to the fact that in their qualities they began to closely approach metals.

Shut-off valves made of plastic

For the manufacture of valves from polymeric materials, polyethylene or polypropylene is used. Such a material is absolutely immune to corrosion, both chemical and electrochemical. Such cranes are usually installed on systems designed to move corrosive liquids.

A significant disadvantage of plastic as a material for the manufacture of valves is the impossibility of using it in hot water supply and heating systems - hot water has a destructive effect on plastic.

Shut-off valves made of steel

Ball valves are used in industrial pipelines. They are widely used when transporting liquids heated to high temperatures and even steam. Also, the use of steel ball valves is allowed in pipelines where the liquid moves under pressure.

Brass ball valves

The most common ball valves for domestic use are made of brass, a copper-based alloy. There are two main methods of making brass ball valves: they are molded into molds or forged using mechanical presses. Forged crane bodies are considered more durable and reliable. The reason for this: with this technology, no air cavities are formed in the alloy mass.

The composition of the brass alloy includes substances with different electrochemical potentials. Therefore, to prevent chemical corrosion, products are electroplated by applying a thin protective layer to them.

Attention! The use of ball valves with a working mechanism based on brass is not allowed in pipelines where the temperature of the working environment should not exceed 150 degrees. Too hot liquid forms the smallest cavities in brass, which leads to a significant increase in its brittleness.

Fitting the mixer to the sink

Let's get down to the practical part.

Now let's talk about how to install a faucet in the kitchen.

For convenience, we have compiled step-by-step instructions:

- We turn off the water supply, take the mixer out of the box, read the manufacturer's instructions and attach the gander to the body... On the reverse side, we screw the flexible hoses into the corresponding holes;

We assemble the device and connect flexible hoses.

- We put a rubber O-ring on the hoses and insert it into the groove on the base of the mixer, where it will adhere to the sink;

Insert the O-ring.

- We stretch the hoses into the hole in the sink body and put the tap in the installation position, closing the hole in the sink with its base... We take a threaded pin (there can be 2 of them) and screw it into the hole on the base of the mixer;

We screw in the fixing pin.

- Install the gasket, then take the mounting bracket, put it on the pin and tighten with a nut... It should be tightened so that the tap is firmly attached to the washbasin and does not stagger, but you should not overtighten either;

We tighten the bracket with a nut.

- If the sink is not installed, we install it... Then we wind the FUM tape on the couplings of the water pipes and wind the ends of the flexible hoses. Tighten with an adjustable wrench.

We connect water pipes.

- We connect the sewer, turn on the water supply and check the operation of the tap.

We check the operation of the device.

Important! Do not mix up the hot and cold water hoses when installing. They must be connected in accordance with the markings on the thumbs of the device.

Installation of ball valves

The technology for assembling ball valves will differ depending on the material of manufacture of the pipelines. So, polypropylene pipes are connected to each other using a special heating device. Copper pipes are connected by soldering, and steel pipes are installed either by welding or using threaded connectors.

Be sure to seal the connections when installing the crane. To do this, you can use both traditional linseed tow, and more modern elements - fum tape or sealant.

After installing the tap, in the water supply or heating system, the tightness of the connection is checked. Run water into the system and place a piece of toilet paper or paper napkin under the mounted tap. If there is even the slightest leak in the connection, you will immediately see drops of moisture on the paper.

As you can see, the selection and installation of a ball valve in the water supply can be done independently. When choosing a ball valve, pay special attention to its characteristics and appearance, and during installation, ensure complete tightness of the connection, then the valve will serve you for many years.

You can get acquainted with the brass ball valves, the features of their selection and installation in more detail in the training video.

Video - Brass ball valve

Add to bookmarks

Depending on the purpose and diameter of pipelines, as well as the operating environment, valves are made of cast iron, brass, bronze, steel, titanium, polyethylene. Brass ball valves are compact, convenient and aesthetic, therefore they have received well-deserved recognition from consumers and are presented in a wide range on the market. They are installed mainly on in-house water supply and heating networks. But not all products that enter the markets can be considered of high quality.

The products of Italian firms are recognized as the highest quality shut-off valves for in-house wiring. The quality of Polish, Turkish and Chinese firms is much lower. Valves made in Italy are usually hot-pressed, which ensures the uniformity of the structure of the product, and therefore increases its reliability. Chinese and Turkish products are usually made by casting. The accuracy of execution, as well as the quality of the seals that ensure the tightness of the valves, in the products of Italian firms is much higher.

Types of materials for ball valves: (cast iron, brass, bronze, steel, titanium, polyethylene).

From brass and bronze, shut-off and control valves with a nominal bore of DN less than 50 mm are usually used for pipelines, including low-pressure gas pipelines at temperatures below 150 ° C.

But more expensive and reliable ones are made of stainless steel. For pipelines operating under shock loading conditions, the standards recommend the use of cast iron shut-off valves.

Recently, polyethylene taps have become widespread. The polyethylene gas faucet has no metal parts. It is much lighter than similar metal products, simple and reliable in handling, besides, its strength and resistance to mechanical stress can be well characterized.A gas ball valve is an economically viable option for most types of pipelines. The use of polyethylene shut-off valves on gas pipelines simplifies network maintenance. Installation of polyethylene valves is carried out by butt welding or equipped with couplings with embedded heaters. This enables fast and reliable welding.

In accordance with GOST 4666-75, all valves must have a distinctive color. The body and covers are painted in a color corresponding to a specific metal. Cast iron products are painted black, carbon steel - gray, corrosion-resistant steel - blue; alloy steel - blue.

The fastening parts to the pipeline are welded joints, flanges, couplings and pins. For pipes with a nominal bore up to 4-45 mm, it is advisable to use a coupling fastening of a ball valve. Flanged ball valves are used for installation in pipes with a diameter of more than 45-50 mm. The flange connections of the ball valve with the pipe can withstand significant loads. They have a high tightness due to the use of modern gaskets.

According to the requirements of GOST R 52760-2007, the marking of shut-off and control valves must be made on the body or on the nameplate securely attached to the product.

Product marking must contain the following information:

nominal diameter DN (nominal size), nominal pressure PN, body material, manufacturer's trademark; an arrow indicating the direction of flow of liquid or air; maximum temperature or range of permissible temperatures, operating or design pressure, year of manufacture.

How to choose a ball valve

Ball valve for underground installation

If a crane needs to be repaired or replaced, you must first determine the most suitable type of crane for your particular case.

So, the main types of ball valves are as follows:

- full bore - with a throughput of 90-100%;

- partial bore - with a throughput of 40-50%;

- standard - with a flow capacity of 70-80%.

With regard to the materials used in the manufacture of ball valves, durable plastic, brass and alloys with its content are most often used here.

Brass ball valves are highly durable, do not rust and perfectly withstand significant temperature changes.

Plastic ball valves are slightly less durable and do not tolerate high temperatures. For this reason, they are best used as shut-off devices for gas and cold water pipelines.

For heating and hot water pipelines, the best option would be to install a ball valve made of brass.

When choosing a ball valve, among other things, it is necessary to determine what its purpose will be and how it is supposed to be fastened.

There are the following main types of ball valve mountings:

- coupling ball valves;

- flanged ball valves;

- welded ball valves;

- combined ball valves.

Consider the features and scope of each type of cranes.

Brief explanation of the meanings of individual terms

In accordance with GOST 28338-89, the nominal diameter DN is a parameter used for pipeline systems to characterize the connected elements. It is indicated without designation units and is approximately equal to the inner diameter of the pipes to be connected, measured in millimeters. The exception is plastic pipes, in which the outer diameter is taken as the nominal diameter. According to the instructions of GOST 26349-84, the nominal pressure PN is the constant internal overpressure of the medium, which pipes and fittings can withstand during their entire service life (50 years) at a water temperature of 20 ° C.

The main advantages of modern ball valves are: high tightness, small dimensions, high wear resistance of the ball, simplicity of design, speed of changing the operating mode (blocking of gas and water flows), low operating costs, low accident rate, ease of control - turning the handle by 90 °.

The design of the body provides this valve element with ease of use, even when it is installed in a practically inaccessible place. A wide range of ball valves on the modern market allows you to choose the ones that are best suited for solving the tasks at hand.

The ball valve is installed on water supply, gas supply and heating pipelines. The device serves to completely or partially shut off water or gas in the system. Simplicity of design and reliability lead to widespread use on both domestic and industrial pipes. How to choose the right valve and install it, read on.

The shut-off element of the ball valve (4) is driven by the handle (11), which can be made in the form of a flywheel or a lever. The handle is attached to the valve body with a nut (9) and a locking ring (10).

In the closed position, the ball-valve fits snugly in the body of the device. Additional sealing is provided by a gasket (5) located around the perimeter of the ball. To fix the valve in one position, a stem is used, which is screwed to the valve body (3) and a spindle nut (8).

All elements connected to each other are reliably sealed with Teflon gaskets (6,7).

Application of combined ball valves

A number of manufacturers are engaged in the production of a specialized type of ball valves - combined. Combined ball valves combine several methods of installation to pipes at the same time.

By the number of nozzles, combined cranes are classified as follows:

- checkpoints;

- corner;

- three- and multi-way ball valves.

The latter type of combined cranes is applicable when it is necessary to redirect or mix working media.

Ball valve selection criteria

Ball valves are selected depending on the following parameters:

- device design;

- bandwidth;

- material of manufacture;

- fastening method;

- manufacturer's firm.

Types of valves depending on the design

Depending on the design, the ball valve can be:

- straight-through. The main distinguishing feature is low hydraulic resistance. In most cases, it is installed to regulate the flow of liquid into heating systems;

- checkpoint. The straight-through valve for water or gas is installed on a flat section of the pipeline and serves to completely shut off the incoming flow;

- angular. The angle valve is mounted on the bend of the pipeline. The purpose of the device is to block the incoming stream;

- mixing or three-way. Installed on systems when it is necessary to mix two streams of incoming fluid.

The choice of the design of the ball valve is necessary depending on the function performed and the characteristics of the pipeline.

Bandwidth selection

Depending on the capacity, ball valves are divided into:

- full bore, capable of passing 90% - 100% of the incoming liquid (gas);

- standard, which pass 70% - 80% of the liquid;

- partial bore (40% - 50%). Devices are installed when it is necessary to reduce the incoming flow.

Selection of material

Ball valves can be manufactured:

- made of brass. A durable material that can withstand high pressure and temperature, and is practically not subject to corrosion. In addition, brass valves are lightweight and aesthetically pleasing;

- made of bronze. The material is also durable, but more expensive than brass;

- made of plastic.The devices are mounted exclusively on plastic pipes. Not suitable for other types of systems;

- made of stainless steel. The excellent characteristics of the device determine its use in industrial pipelines.

For standard house systems, brass valves are most suitable, which can be installed on piping made of any material.

Choosing a mounting method

According to the method of fastening, ball valves are divided into the following types:

- threaded (coupling). The coupling valve is most often used in private pipelines with a small diameter (up to 65 mm), both for gas and water or. The threaded valve is easy to install. To install the device, provided that the pipes are pre-threaded, no special tools and specialist skills are required;

- flanged. The valve, installed using special elements (flanges), is mainly used for installation on industrial pipelines with a diameter of 50 mm or more. The flanged valve is more tight and durable;

- welded, installed on metal pipelines by welding. The fastening of the welded valve is the most reliable, however, certain skills are required to mount the device. In most cases, welded valves are installed on industrial gas pipelines where high tightness is required.

Manufacturer's choice

The reliability and durability of a ball valve primarily depends on the manufacturer. Experts recommend purchasing shut-off valves manufactured by the following companies:

- Valtec is an Italian-Russian company specializing in the production of engineering plumbing for heating and. Low cost and excellent quality attract the attention of consumers;

- Danfoss (Denmark). GBC welded valves are highly durable and can be used in various systems, including room air conditioning;

- Becool (Russia). Valves of the BC - BV series are resistant to aggressive media, have a high level of tightness and can be installed on various pipelines.

Using flanged ball valves

The flanged ball valve is generally used for installations in pipelines over 50 mm in diameter. The use of gaskets during installation allows to ensure the strength and high hermetic properties of the pipe connection with the ball valve. Flanged ball valves are designed for significant loads, as they are characterized by a high degree of strength.

Flanged ball valves are classified as follows:

- collapsible - the body of which consists of 2 parts and can be easily disassembled to replace worn out or damaged parts (locking element, gaskets, etc.);

- non-separable - having a cast body; in case of failure, a complete replacement of the ball valve is required.

Advice! Union ball valves are widely used in food, chemical and other industries. The advantage of such ball valves is due to the possibility of their multiple dismantling, which is very convenient in operation.