The main types of adhesives

If you need glue for plastic, then you should know that it comes in two varieties: thermosetting and thermoplastic. The first is based on epoxy, thermosetting and polyester resins. The second category of adhesives can be divided into two directions, the first is made on the basis of rubbers, while the second is based on resins.

Thermoplastic compounds soften materials and dissolve under the influence of temperature. If we compare them with thermosetting ones, they do not change their chemical structure when glued, which is a significant plus. Adhesive for polypropylene can also be divided by the number of components, such mixtures can be one- or two-component. The first ones are presented ready-made in one package. This includes the Moment glue for polypropylene. And the latter are packaged in two packages, each containing ingredients for mixing. As an example of a one-component composition, consider Cosmoplast 500, which is used to join profiles in window production. If you need a two-component composition, then you can use epoxy resin adhesive, which is made on the basis of a hardener and epoxy resin. Two-component adhesive has the advantage of long shelf life. The reason is that the ingredients do not come into contact before the combination and no hardening occurs.

How to glue polypropylene - a step-by-step process

In order to glue polypropylene tightly, you must adhere to the following rules:

- pre-degrease and clean the surfaces, even if the manufacturer claims that this step is optional,

- apply the adhesive in a thin, even layer,

- withstand the parts for at least three minutes,

- leave to dry for several hours until fully set.

It is imperative to use protective gloves so that the glue elements do not get on the skin and do not cause irritation. The mixture should never get on the face. If this happens, wash yourself with running water.

Repair of polypropylene pipes with glue - secrets

All adhesives for polypropylene pipes contain polyvinyl chloride, as well as additives to improve adhesion. They must be used in rooms with temperatures from +5 to + 35C.

VIDEO ON TOPIC

To repair pipes you need:

- natural bristle brush,

- glue gun.

Stages of work:

- Cut the pipes with pipe cutters, and also sandpaper the edges of the sections and get rid of burrs.

- Connect the pipes into a single structure and mark the places for gluing.

- Disassemble the structure, degrease the areas to which the glue will be applied.

- Apply the compound with a brush in a thin layer, and also treat the socket area of the fittings with a glue gun.

- Insert the pipe into the hole of the fitting, relying on the marks made with a marker. Parts must not be rotated or wiggled. After a minute, the glue should harden. Remove excess composition with a napkin.

- To check the quality of adhesion, after a day, you can run water and test the pipes under pressure.

Also, many craftsmen use patches in the form of a tourniquet made of rubber or a coupling. You will need a wire or clamp to secure them. The gluing procedure is performed according to the same algorithm, while the water must be turned off. If the repair is carried out using a collapsible coupling, it is not necessary to shut off the water.

It is characterized by heat resistance, fast setting, high antiseptic properties.

In order for polypropylene pipes to serve for a long time after repair, experts recommend:

- use high-quality adhesives,

- do not save on consumables,

- use protective gloves,

- act carefully, make careful calculations.

The use of modern adhesives allows you to repair polypropylene pipes quickly, efficiently and with minimal financial costs.

Until recently, it was impossible to glue polypropylene or elements from it. Now on the market there are many types of glue that allow you to easily connect various elements from this material. The use of adhesives is the fastest and most economical way of installing polypropylene products.

Among the advantages of using glue are:

- The integrity of the material;

- Uniform stress over the entire surface;

- The ability to connect various elements and parts;

- Very fast, and sometimes instant, fixation of areas.

In order for the product to be firmly and reliably glued, you need to choose only high-quality adhesives and only from manufacturers who have proven themselves in the modern construction market.

Types of adhesives for working with polyethylene and polypropylene

The scope of use of polypropylene is very wide: it is actively used in the food industry, the automotive industry, and often finds its application in medicine and science. It gained popularity due to its ease of processing and plasticity.

In stores, polypropylene is usually sold in the form of granules, which can be of any color. Packaging for various products, pipes, films, disposable syringes - all this can be made using polypropylene.

Depending on the composition, there are several types of polypropylene:

- Isotactic.

- Atactic - have a waxy or oily consistency.

- Stereoblock.

- Syndiotactic - they have a viscous structure.

Some characteristics are universal for all types of polypropylene:

- Strength.

- Easy processing.

- Very low density.

- Impact resistance.

- Preservation of its properties at.

- Resistant to penetration of gases and steam.

- Water resistance.

- The ability to maintain strength when exposed to alkalis, various saline solutions, oils.

Adhesives that can be used to glue plastic parts are conventionally divided into two groups:

- Thermosetting. They contain epoxy, polyester or thermosetting resins. This type of glue under the influence of temperature acquires a soft shape and subsequently dissolves.

- Thermoplastic. They can be based on rubber mixtures or resins. Thermoplastic adhesive does not change its structure, but acts under the influence of an accelerator, heat or hardener. This type includes anaerobic glue.

There is another way to classify adhesives - one-component and two-component. The first ones are sold ready-to-use. This includes a sealant for polypropylene Moment, which has a transparent texture. In window production, Cosmoplast 500 glue is actively used, which also belongs to one-component.

Adhesives consisting of two components must be pre-mixed with each other and only then used. Among the two-component formulations, epoxy glue with epoxy resin and hardener is popular. It has a relatively long shelf life due to the fact that such an adhesive will not be effective until its constituents react.

How to glue polypropylene - step by step process

In the process of gluing polypropylene, you need to adhere to several basic rules:

- Before gluing, it is necessary to degrease and clean the surfaces. This step should not be skipped even if the manufacturer claims it is optional.

- Apply the glue in a thin layer, evenly distributing it on the surface.

- Before joining the parts, you need to withstand the elements to be glued for at least three minutes.

- After connecting the parts, they are left to dry for several hours until they are completely fixed.

Adhesive elements can get on the skin and cause an allergic reaction or irritation, therefore, be sure to use special protective gloves. Also, be careful with your clothes, this is not an easy task. If the adhesive comes into contact with your face, you must quickly wash yourself under running water.

Repair of polypropylene pipes - the secrets of using glue

Absolutely all adhesives contain polyvinyl chloride and additives that improve adhesion. The optimum temperature for using adhesives is from +5 to +35 degrees Celsius.

To repair the pipes, you will need a glue gun and a natural bristle brush.

Work process:

- Cut the pipes with a pipe cutter, clean the sections with sandpaper and remove the burrs from the surface.

- Align the pipes to form a single structure and mark the bonding points.

- Separate the structure, the areas to which the glue will be applied must be degreased.

- The adhesive is applied in a thin layer with a brush, the socket of the fittings is processed with a glue gun.

- Looking at the marks made with a marker, insert the pipe into the hole of the fitting. Rotation or swaying of parts is not allowed. After about a minute, the adhesive will harden. Remains of glue are removed with a napkin.

- To check the strength of the adhesion, after a day, you can test the pipes under pressure and run the water.

Often, craftsmen use special patches that look like a tourniquet made of a coupling or rubber. To fix them, you need a clamp or wire. The gluing algorithm is identical to the usual one, only in this case you need to turn off the water. However, when using a collapsible coupling, it is not necessary to shut off the water.

The construction market offers a lot of options for gluing polypropylene. One of the best adhesive mixtures is this glue is used for gluing and installing polypropylene elements and plastic parts for bathrooms, showers, for connecting tiles. Its main advantages are high thermal stability, very fast setting and antiseptic properties.

Also today, it has gained immense popularity, which is designed to connect plastic parts.

How to extend the service life of pipes after repairs?

For this you need:

- Use only high-quality adhesives.

- Send savings in consumables to the background.

- Use special protective gloves during installation.

- Make careful calculations.

- Act very carefully.

Modern adhesives allow you to perform repair work on polypropylene pipes as quickly and efficiently as possible, while you can get by with minimal financial costs. There is a huge range of similar adhesive mixtures on the construction market, so you can choose an adhesive composition for any purpose.

Polypropylene pipes are leading in the rating of demand among professional teams and self-taught craftsmen who are replacing communications in their own bathroom. Not only the price speaks in their favor, but also the ease of installation. To assemble the systems, not only thermal brazing is used, but also glue for polypropylene pipes, which does not require serious skills and the use of special equipment. Adhesive assembly and repair make the replacement of a pipeline or heating system as budgetary as possible.

Main characteristics of Cosmoplast 500 glue

The aforementioned polypropylene adhesive acts as a one-component compound that can be used in industry and in everyday life. It can be used to glue joints at a 45 ° angle. This mixture outperforms its counterparts in a shorter drying time.The composition is resistant to water, cold and heat. It has an approximate drying time of 3 seconds and a final cure time at 20 ° C is 16 hours.

The procedure for gluing a metal-plastic pipe

Sometimes a leak occurs in a water supply system or drain pipes made of metal-reinforced plastic. I must say that such cases are quite rare, because the strength of the material is very high. Why can holes form? The aluminum pipe, which is the basis, can only leak if installation errors or serious mechanical stress on the product. This is usually caused by not respecting the bend radius during installation, in which case a hole is formed at the bend. An improperly assembled fitting can also cause a problem.

When repairing, first you need to turn off the water and apply a temporary measure - apply a special adhesive tape or make a so-called bandage for pipes from a piece of rubber. How to glue a metal-plastic pipe? If the hole is small, you can seal it with epoxy or sealant. First you need to treat the surface with sandpaper and degrease. Emery paper will create the desired roughness, which will enhance adhesion. Apply a layer of glue, then wrap the joint with a bandage in 3-4 layers, grease with another layer of glue. After 12 hours, the pipe can be operated.

If the leak occurs due to damage to the fitting, you need to turn off the water, disassemble the leaking end (remove the nut, pull the pipe out). It is important to inspect the o-ring, nipple, threads for damage and replace parts. If the pipe bursts, you will have to completely replace it.

Operating instructions Cosmoplast 500

If you decide to use the above glue for polypropylene, you should first familiarize yourself with the features of its use. It is necessary to use the mixture from a measuring container or together with Cosmoplast CA, which is a measuring device. The application should be carried out on one side of the surface, which must first be cleaned of dirt and dust, and also dried. Cleaning can be carried out using special means like "Cosmofen 60". Surfaces must be bonded and pressurized for a specified time before drying in the open air. Due to its low viscosity, the described composition may not withstand the tension of the glued gap. If there is a need to connect large gaps, then at the discretion of the Cosmoplast 564 can be used.

Plastic pipes for gluing

Unlike metal pipes, polypropylene products can be assembled independently, even without special skills. Experts prefer not to use ordinary plastic for hot water pipes or heating pipes, but use it for sewer communications. But some types of products (in alloys with metal) are quite suitable for both cold and hot water. The advantages of polypropylene pipes are undeniable:

- resistance to changing natural conditions (pressure drop, temperature drop, humidity increase),

- no corrosion,

- long service life (more than 50 years),

- ease of installation, gluing, repair,

- moderate cost,

- health safety.

Such a pipeline also has disadvantages. The elasticity of the material may decrease when heated, and the coefficient of expansion is high. Under the influence of the sun, some types of plastics age faster, which must be taken into account during installation.

The equipment of a house with a water supply and a sewage system using PVC pipes can be performed with products of different types. Depending on the constituent components and manufacturing technology, the following types of plastic pipes are produced:

- Made of polyvinyl chloride (PVC). The most rigid, gluing them is quite simple.They do not burn, do not react to UV radiation, light. Unfortunately, chlorine is used in the production process, so PVC pipes are not environmentally friendly.

- Polyethylene. Very durable, elastic, easily tolerate even freezing water, do not burst. Inside they are smooth, water does not leave plaque in them, deposits of impurities. Among the minuses, it is necessary to point out that they are not suitable for hot water - they begin to melt. Connected with clamp fittings. A separate type is XLPE pipes, which are used for the underfloor heating system.

- Polybutylene. Suitable for water with temperatures up to +90 degrees, but they are not mounted by gluing. They are used in the installation of heating systems.

- Polypropylene. They are used for hot and cold water, for sewerage, heating, very easy to install. They are connected by soldering, they can also be welded.

- Made of metal-plastic. Includes aluminum, is an aluminum alloy with plastic. Due to the three-layer base, they are suitable for water supply, heating, withstand temperatures up to +110 degrees.

Cleaning the glue

The adhesive for gluing polypropylene can be cleaned while it is still dry using the Cosmoplast 597 preparation. Rinsing the measuring container from non-dried glue is carried out using the same tool. If the glue has already dried, then you can clean it manually. When surfaces contain solvent, the already cured adhesive can be completely removed.

The principle of action of adhesives for various types of plastics

If during the installation of plastic pipelines by welding, the so-called thermal (hot) effect is required, then the gluing of plastic and polypropylene pipes is carried out in a "cold" mode.

Joints of a plastic pipe by gluing

The principle of bonding is based on dissolving the outer surfaces of the abutting elements using special chemicals, which usually include cyclohexane, methyl ethyl ketone or tetrahydrofuran compounds. But at the same time, in most cases, the basis of the glue is the substance from which the plastic pipe is made.

That is why the choice of adhesive for plastic pipes should be based primarily on the properties of the materials to be glued. Compounds for polypropylene pipes are unlikely to be suitable for gluing PVC or polyethylene pipes.

In any case, if you prefer the adhesive technology for connecting pipeline elements, then carefully study the recommendations of the manufacturer of pipes or fittings.

Most often, manufacturers offer for their products only certain adhesives (mainly produced by their own forces), otherwise it is not worth counting on guaranteed quality of joints.

Characteristics of Dow Corning 7091 Adhesive Sealant

This polypropylene adhesive sealant is a viscous fluid mass that is used to seal joints and protect various surfaces. The composition can be used for gluing homogeneous materials to each other. Among the main characteristics of this glue are the following:

- the ability to seal and glue different materials;

- heat resistance;

- resistance to ultraviolet rays;

- durability;

- high adhesion to different materials;

- high elasticity of the seam.

It should be remembered that the sealant can be acidic, which indicates that the composition has the ability to release a certain amount of acetic acid during the curing process. This can lead to the destruction of non-ferrous metals and their corrosion. This should also include marble and some other materials. This adhesive is versatile, convenient and easy to use, has the qualities of water resistance and resistance to chemicals and vibration. It can be operated at temperatures from -55 to +180 ° C.This transparent polypropylene adhesive cures at room temperature and has good adhesion to common materials without additional priming. The composition is capable of acting as an adhesive with a layer thickness of up to 5 mm; it can be used as a sealant if a layer of up to 25 mm is formed. When applied, it has a pasty, non-sticky consistency. After completing the curing phase, the consistency resembles elastic rubber. Among the qualities, one should highlight the ability to seal homogeneous materials and those that have different coefficients of thermal expansion.

Pipe installation technique with glue

Adhesive for plastic pipes

The apparent simplicity of the work should not be misleading: the installation of a water supply system or a heating system is a responsible process. Glued pipes for water are no less durable than brazed ones, provided that the work technique is followed. Adhesive for plastic pipes monolithically connects the nodes and prevents leaks for up to 30 years.

Characteristics of the composition of the glue

The composition of the glue for propylene pipes is close to the plastic itself. It is based on polyvinyl chloride. The rest of the additives affect the composition slightly:

- Styrene-butadiene rubber provides assembly flexibility valuable for hot water pipelines;

- the additive increases the density and strength, which is important when working on a system with high pressure or the risk of water hammer;

- methacrylate provides resistance to temperature extremes.

The formulations are sold in ready-made form and in the form of components for mixing. The recipe for preparation and mixing proportions are indicated in the instructions. Before gluing polypropylene pipes, carefully read the information on the package. Previously, dichloroethane was used, now this composition and units designed for this chemical compound have been taken out of the market by more reliable and durable brands. Good reviews were collected by the brands Griffon, Tangit and Gebsoplast. Universal pipe adhesive seals:

- polyvinyl chloride;

- polycarbonates;

- polyamide;

- acrylonitrile butadione styrene;

- polymethyl methacrylate.

Bonding pipes

Stages of gluing PP-pipe

Operating procedure:

- Plumbing elements are marked and cut with plastic scissors or a pipe cutter.

- For control, the nodes are laid out along the wall.

- The ends of the pipes are aligned and encrypted: burrs will restrict access to the adhesive and reduce the tightness.

Note! The temperature in the room for work should not be lower than 5 degrees Celsius and above 35.

- The ends of the pipes are cleaned, the chamfer is removed from the thick-walled and reinforced ones.

- The ends, the socket from the inside, if this type of connection is used, and the surfaces of the fitting are degreased.

- The glue is applied with a gun and smoothed with a brush with natural bristles: nylon can dissolve in the composition.

- After the exposure interval specified in the instructions, the nodes are tightly connected with effort.

After 24 hours, a test run of the carrier through the assembled water supply system is possible.

Application features

Sealing surfaces must be degreased, cleaned and dried. Degreasing is possible with solvents such as acetone or isopropyl alcohol. The required amount of sealant should be applied to one of the surfaces, and then connect the two bases. It is possible to correct the relative position of parts within 15 minutes after application, until a film forms on the surface of the glue. If the conditions of room temperature and relative humidity of 50% are met, then the vulcanization rate will be 2 m per day. If the moisture content is reduced, the setting time will increase.

Working with a cast iron radiator with a leak

It happens that the heating battery has leaked - the threaded joint has deteriorated, a leak has appeared on the section. For repairs, you will need epoxy glue and a bandage.The material is impregnated with glue, applied to the area of the hole. After setting, you can paint over this area in the base color. This measure is considered temporary, and after turning off the heating, it is better to replace the radiator.

Cold welding of batteries is also used. A special tool is kneaded in hands, applied to the site of damage. It quickly melts, sets and allows the "patch" to exist until the heating is turned off.

You should not try to glue radiators with a strong leak, which led to an emergency. It is better to immediately call a team of specialists who will stop the leak and replace the radiator with a new one.

Welding polyethylene

The strongest seam is obtained when welding polyethylene. If done correctly. The fact is that polyethylene is molded hot, usually under very high pressure, which reaches hundreds of kilograms per square centimeter. And when it is reheated at atmospheric pressure until melting, it tends to shrink, a little, but this is enough to make it difficult to weld. Two types of welding can be distinguished: welding of film and welding of thick polyethylene (cans, pipes, etc.)

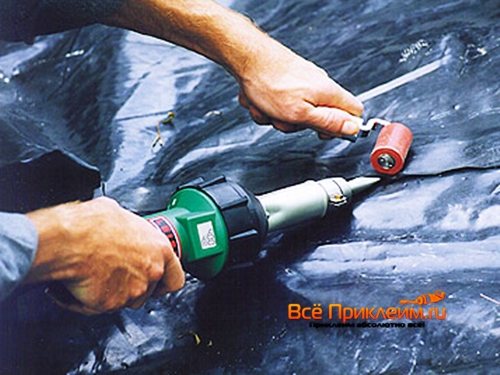

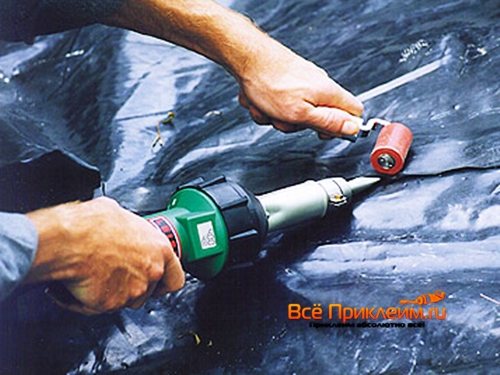

For welding the film, heated objects or a special apparatus for gluing polyethylene, more precisely, welding, are used. It works like this: both layers of film are pulled along a heated wedge, and then immediately welded with a pair of compressed rollers. With the correct selection of the temperature and pressure of the rollers, an excellent result is obtained - complete tightness of the seam.

This is what the machine for gluing polyethylene looks like

But with a little practice, you can learn to glue polyethylene, even with an electric soldering iron or an iron through paper, so as not to spoil its sole. The clean edges of the film are laid on top of each other and lead through the paper with the edge of the sole of the heated iron.

A clean tip soldering iron, when turned on through a voltage regulator, will weld the seam even better without the need for paper. You can also make a clamp on the sting with a small, conveniently shaped metal nozzle. Then the sting can be used for its intended purpose, and the polyethylene will not be stained with solder or carbon deposits from the flux.

Gluing thick polyethylene is more difficult and requires a lot of skill. The best heating method: a portable gas burner (it is convenient to work with it), or a hair dryer with a nozzle for a narrow stream of + 250 ° C.

The process of gluing thick polyethylene using a construction hair dryer with a nozzle

The procedure can be as follows:

- Clean and dry surfaces thoroughly before welding.

- Prepare a polyethylene joint filler. It is best to take a narrow piece of the same material.

- Heat the edges of the seam before melting, let them “settle” a little. But do not get carried away with this process.

- Start adding the additive (see item 2), fusing it evenly on both sides of the seam to a thickness equal to the material.

- Allow the seam to cool completely.

The same method is applicable when deciding how to glue polyethylene foam. The surface of the foamed polyethylene is not very conducive to adhesion, and it is better to weld it carefully.

For another way to weld thick polyethylene, see the video:

Emergency repair of water supply and heating pipes

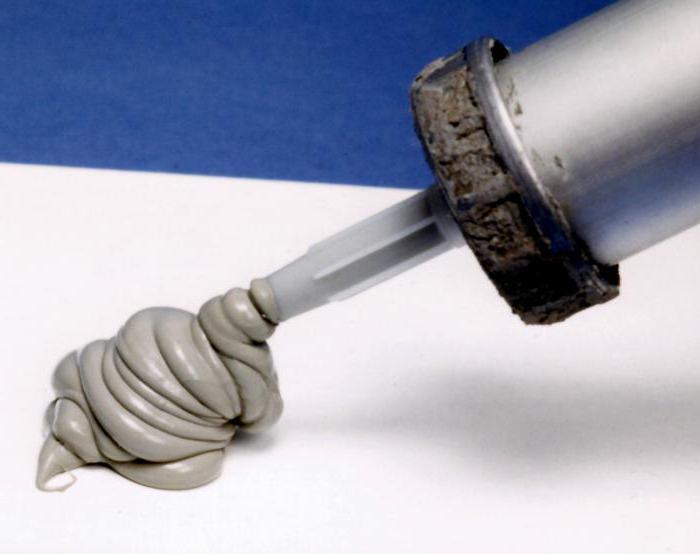

Installing sealant in the gun

The cause of the leak can be found in the wrong assembly of units or an illiterate selection of system components. Deterioration and operating conditions affect. For any reason, the leak must be eliminated urgently: the water pressure will expand the crack, exacerbating the problem. One of the advantages of plastic pipes is the possibility of emergency repairs with improvised means. To eliminate leaks on metal counterparts, at least a grinder and press pliers for copper pipes will be needed to cut out the damaged area and install a new one using fittings or threaded connections.The question of how to glue the plastic pipe is easier to solve: even the epoxy glue available on the farm will do. The craftsmen who work professionally with plumbing equipment also have special repair kits, including glue for HDPE pipes, sealing tape or silicone gel. Elimination of a small leak is carried out in stages:

- The system is disconnected from the water supply and dried. Attempts to wrap a pipe under pressure will not be successful: the edges of the crack will not come together tightly, and the water will not allow the glue to fully seize.

- With alcohol or acetone composition, the area is degreased and cleaned of dirt. Light sanding will give the roughness necessary for a tight bond.

- Any technique is suitable for gluing, but the method of strengthening the spirally applied plumbing sealing tape is called stronger and more durable.

- Silicone gel will only cope with pipes that are not designed for strong internal pressure of the media, and temporary repair of small cracks.

- When choosing a sealant, it is necessary to check the type: neutral is suitable for all types of media, acidic will not withstand similar solutions. When choosing how to glue a heating pipe or water supply, give preference to the type of sealant that suits you for the price, everyone will cope with their task.

- The composition is applied to the pipe with an assembly gun and leveled. The edges of the crack that is being glued must be dilated as much as possible so that the compound penetrates the inner surface. At this stage, the master needs the help of an assistant knocking out a section of the pipe.

- The gluing of polypropylene pipes takes place from 12 hours to a day, water can only be started up after this period. The test run is done smoothly and gradually so that the water hammer does not damage the seam.

Epoxy two-part adhesive for PP pipes is also used, but before application, the components are mixed according to the instructions.

What glue to use for gluing polyethylene - composition

The easiest way is to purchase structural adhesive in the store, which contains methyl acrylate. Its properties provide fast softening of polyethylene and its further adhesion. The glue also contains inorganic and organic acids and xylene, chromium anhydride and various additives.

The advantage of using a mixture is that no additional processing of the material is required. However, glue for polyethylene is quite toxic, so it is recommended to carry out work in the open air. The glue acquires its best properties at a temperature of + 35C, it is not afraid of moisture, but it is highly flammable. It is better to buy it in specialized stores so as not to run into a fake.

If there is a need to combine polyethylene with polyethylene, it is more convenient and easier to resort to heat treatment.

This technique allows you to obtain a strong, inseparable seam. Among the disadvantages of the method, it is worth noting the deformation of the edges of the product.

On sale are mixtures for combining polymers, similar in consistency to a thick paste. The kit includes an activator. After adding it to polyethylene glue, it acquires the required consistency, and it can be used in the near future.

We glue polyethylene - step-by-step instructions

To glue polyethylene, no special knowledge and skills are required. Even beginners will cope with the task at home.

The order of work is as follows:

- Clean the surface and degrease it. Some manufacturers claim that this step is optional, but experts still recommend taking a few minutes and never skipping it.

- Apply glue to the treated material. It will take only a few minutes to solidify, so the parts need to be attached to each other, without delay.

- Leave the glued polyethylene elements for several hours until the glue has completely set.

In general, this algorithm is similar to working with any glue. However, it is worth taking care of the use of protective gloves, since the glue can cause allergic reactions and is quite toxic.

It is more convenient to apply the adhesive with a glue gun that can be loaded with ready-made cartridges. The mixture of them is distributed evenly, so it is easy to achieve the desired dosage. If you are planning a large amount of work, this unit is worth the investment.

VIDEO ON TOPIC

How to glue foamed polyethylene

Foamed polyethylene has a porous structure, therefore it provides high-quality heat, steam and waterproofing.

Due to its low price, ease of operation and installation, it is actively used in construction. The most popular brands are Izolon, Vilatherm, Energoflex, Polifom, Temaflex.

If the need arose glue the foam insulation, experts recommend two-component adhesives based on methyl acrylate. Such compositions are distinguished by high adhesion and are suitable for working with polyvinyl chloride, polyethylene, polypropylene. An example is the well-known Easy-Mix PE-PP adhesive from WEICON.

Usually, in order to achieve high results in gluing foamed polyethylene, the following procedures are additionally required:

- surface treatment by sandblasting or grinding,

- physical treatment, such as thermal fire,

- chemical treatment (usually the fluorination method is used).

But when using "Easy-Mix PE-PP", you can do without additional preparation and surface treatment due to the "primer" included in the composition, which changes the structure of the materials to be glued, after which they easily adhere.

The use of Easy-Mix PE-PP glue for working with foamed polyethylene both on a production scale and at home allows you to reliably and quickly bond materials, while it is ready to use immediately after opening the package, it is easy to dose and mix, as well as to apply.

The glue has a soft pasty consistency, is not afraid of conditional "aging" and retains its properties for a long time even in open areas.

Bonding preparation process

Preparation is required before gluing polypropylene parts. It consists in checking everything necessary and assembling the general structure without the presence of glue in order to put marks in the places where it is needed.

A water-soluble compound used in water-based powders and adhesives. The action to insert while the pressure moves from the center to the sides. Insert pressure in the center of the object on the sides. A tool used in carpentry and construction that allows two elements to be mechanically fastened.

A system that allows you to fix the hoist. A material made from the same or different compositions, bonded with glue or silicone. Nitrocellulose is an ether of nitrogen cellulose. Polymer with high chemical and heat resistance. It can be used in release coatings.

An example of preparation for gluing polypropylene pipes:

- It is necessary to make sure that the air temperature of the room where the bonding will take place fluctuates between + 5 ° C - + 35 ° C.

- It is important to check the availability of tools. A glue gun, pipe cutters and a natural bristle brush should be at hand.

- With scissors (pipe cutters), it is necessary to cut the pipes into segments of a certain length.

- Next, it is advisable to clean the edges of the slices using sandpaper. Any burrs that might obstruct the sealing of the joint must be removed.

- Now you need to assemble the entire structure, try on and make marks with a marker in the places of future gluing, as well as marks the depth of entry into the pipe fittings. Then you can disassemble the structure.

- Stir the glue well before application. The marked areas must be degreased and cleaned with cleaners.