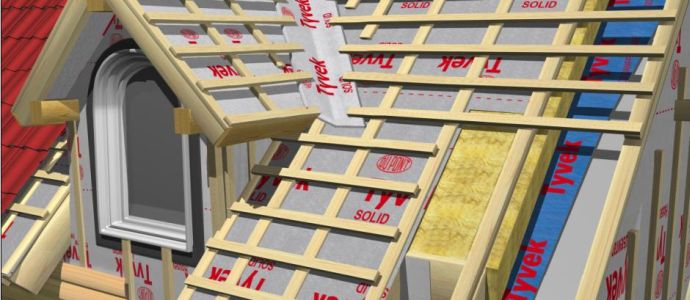

Installation of a waterproofing barrier

To eliminate the risk of moisture condensation on the inside of rafters and wall structures when using foam, the first step is to install a waterproofing barrier

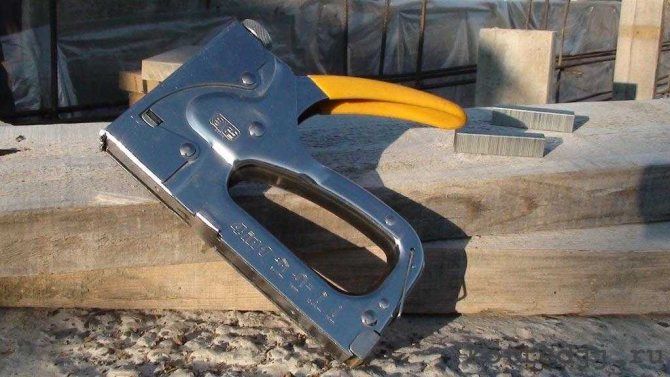

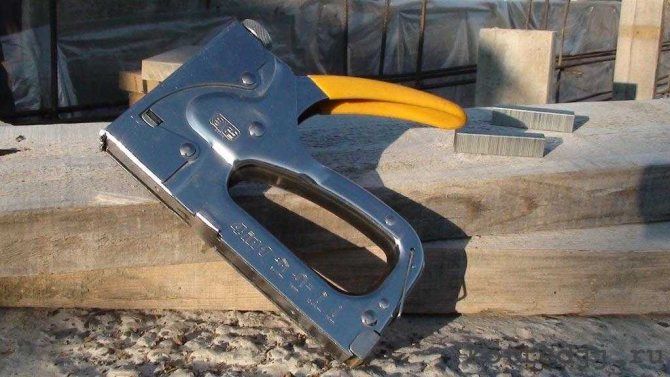

... Roll material (film or membrane) must be laid in such a way that it envelops the rafters, adjoins the back of the batten. You can fix it with brackets using a construction stapler, but it is also allowed to use double-sided tape.

The waterproofing layer should be a single piece without seams. If you have to join pieces of film or membrane, you need to overlap at least 15 cm wide and carefully glue the joints with reinforced tape.

Installation of a waterproofing barrier

If the end walls of the attic (gables) are made of timber or building blocks, you must choose one of two installation options

:

- the waterproofing film is attached with double-sided tape to the flat surface of the wall, after which the sheet heat insulator will need to be fixed with nails with umbrella hats;

- a crate of bars is mounted on the walls, the width of which is equal to the thickness of the selected insulation, a waterproofing barrier is attached on top of them according to the same principle as on top of the rafters.

In the case when expanded polystyrene is chosen as a heat insulator, there is no special need for waterproofing - the insulation will not let moisture from the room to wooden structures, if you take care of the tightness of the seams when laying the insulation.

Installation of insulation on the attic roof

After installing the waterproofing film, you can start laying the insulation (expanded polystyrene sheets). As a rule, a mansard roof is made on a rafter frame. Styrofoam sheets are best placed in the inter-rafter space. As noted above, it is necessary to choose the material taking into account the pitch of the trusses. In this case, there will be less waste. Modern equipment allows the production of polystyrene up to 2000 mm in size. Each sheet, using a knife, fits tightly (preferably without gaps) between the two rafters.

Fastening of the insulation can be carried out using wooden slats, glue or special dowels with a wide head.

The method of fastening depends entirely on the type of roof.

After we secure each sheet, it is necessary to seal the joints between the sheets and between the sheets and rafters. This is done using ordinary polyurethane foam or any other sealant that can be used for these purposes. After that, you can proceed to the final stage.

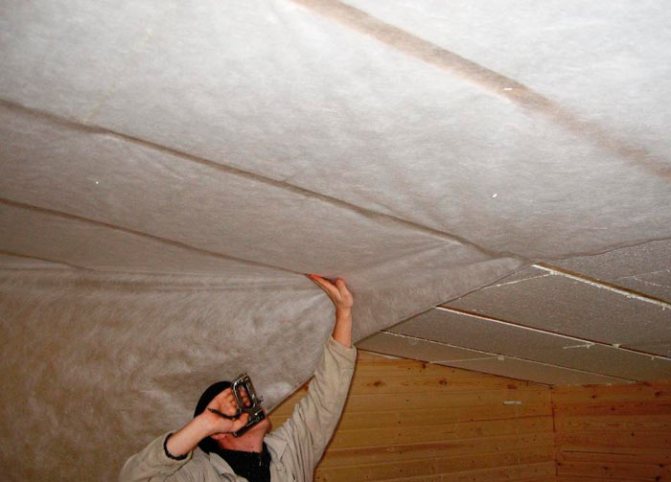

Installation of vapor barrier film and interior decoration

Installation of a vapor barrier film is necessary if the premises will be residential.

Immediately, we note that this stage is necessary only if you plan to equip the attic for residential or household needs. First, it is necessary to install a vapor barrier layer. It is necessary in order not to allow water vapor to pass through, that is, if waterproofing is necessary in order to keep moisture out of the atmosphere, then a vapor barrier. on the contrary, from the premises. It is attached in the same way as a waterproofing film, using a furniture stapler.

After that, you can proceed to finishing the room. Here, as they say, everything depends on your tastes and capabilities. The attic can be sheathed with plasterboard sheets, OSB boards or wooden clapboard.Depending on the material chosen, it can then be painted, varnished or wallpaper pasted onto it.

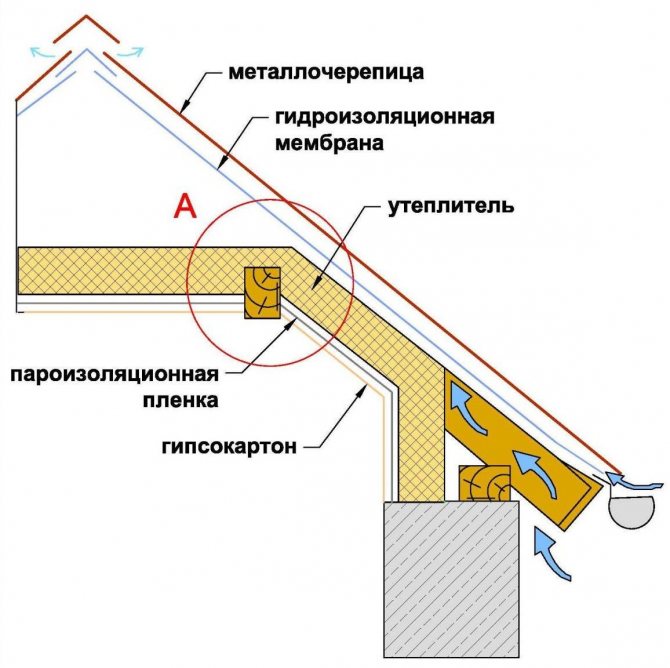

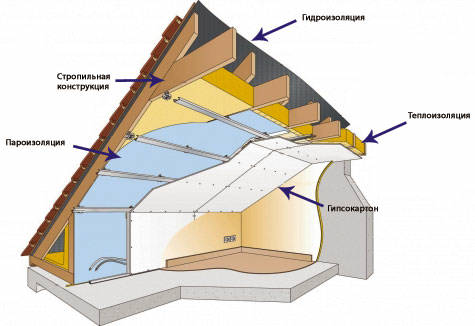

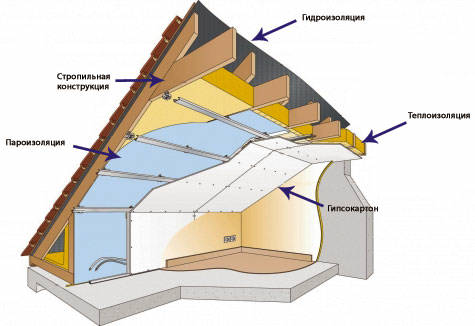

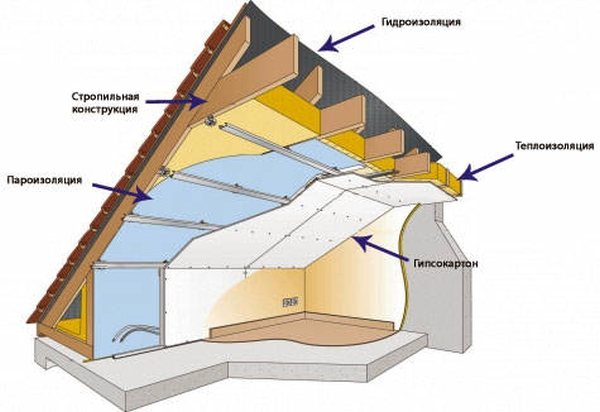

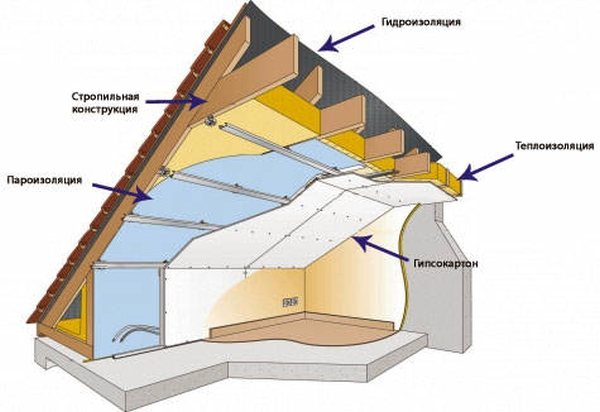

Thermal insulation scheme for the roof of the attic from the inside

Insulation of the attic roof has its own characteristics, due to the fact that the walls of the dwelling are directly adjacent to the roof, more precisely, they actually form a single whole with it

That is why it is customary to pay close attention to the insulation of the attic roof from the inside, which allows you to ensure a normal microclimate in the room.

Before starting a conversation about how to insulate the attic roof from the inside, let's figure out what layers the so-called "roofing cake" consists of, and why it is so important to arrange these layers in the right sequence:

- Roof;

- Waterproofing;

- Ventilation;

- Thermal insulation;

- Vapor barrier.

The diagram shows the correct order of arrangement of the elements of the thermal insulation system of the attic roof

What is the reason for this arrangement of layers? Elementary laws of physics. Let's imagine that a decent layer of snow fell in winter, which, by the way, is a natural heat insulator. As a result of the vital activity of people living in an attic house, warm air will rise from the inside to the surface of the roof. The snow covering it will melt. And as soon as the outside temperature drops below zero, a crust of ice forms, which no longer possesses any heat-insulating properties. The essence of proper insulation of the attic roof is to prevent snow from melting in winter and the penetration of scorching heat in summer.

Features of insulation with foam plates

When, after laying the foam plates, visible joints are formed between them, they must certainly be sealed, for which polyurethane foam is ideal, which is produced in the form of polyurethane foam. It is advisable to fill even the smallest gaps in order to prevent the formation of cold bridges.

When the attic is insulated from the inside with foam, for greater reliability, the plates are attached to the surface using nails, dowels or adhesives (see: "Insulating the attic roof from the inside, how to avoid mistakes"). But glue, even of high quality, loses its properties over time, but additional fastening with nails ensures the durability of the surface (read: "We make the roof insulation with foam correctly").

Before insulating the attic with foam, it is necessary to purchase not only insulation, but also finishing materials. Often these are products made from natural wood. Sometimes a more expensive option is used: a special frame is created, plates with a finishing layer are inserted into it.

Why a tree cannot be insulated with foam, an example in the video:

A few rules to know

The insulation from the inside of the room should have a vapor barrier layer, and from the outside it should be covered with a waterproofing layer. There must be enough free space between the insulation and the roofing material. It is necessary not only for ventilation, but also for the removal of moisture penetrating from the inside of the room with warm air.

The roof of the attic protects the house from precipitation and prevents cooling of the rest of the premises. The loss of warm air through the roof is always significantly higher than through the walls. This is due to the significant difference in air temperatures between the surfaces of the roof.

As you know, the air under the ceiling is always slightly warmer than below. And as a result of this, condensation will form on the ceiling. Therefore, the requirements for roof insulation are always more stringent than for walls.

In an effort to reduce the load on the roof rafters, sometimes lightweight insulation is used, which has a lower density. As a result of the impact of the wind on it, a low-density insulation is “blown through” and this leads to a significant loss of heat.To prevent this from happening, an additional windproof layer of vapor-permeable material is applied to the thermal insulation.

How to avoid common mistakes in foam insulation?

Incorrect installation of insulation will very soon remind of itself with unpleasant consequences. This includes leaks and deterioration of the building's thermal insulation. How to avoid moisture and cold air entering the attic floor? There are two most common mistakes that should be avoided when producing insulation.

The first is a violation or non-observance of the tightness of the joints between polystyrene foam plates. This may be due to the incorrectly selected width of the insulation or poor-quality sealing of the joints. As a result, in winter, so-called cold bridges are formed, which can significantly worsen the thermal insulation properties of the house. In addition, moisture can penetrate into the room through these leaks with all the ensuing consequences.

The second common mistake is to use ordinary cellophane film as waterproofing. Experience shows that it lasts for exactly several years, after which it loses its tightness. As a result of this, the water that gets on the insulation will do its job over time. In order for the house to be always dry and warm, in no case should you neglect the installation rules for the sake of saving time or money.

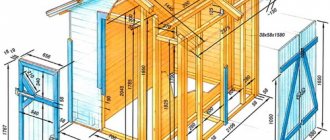

Features of the attic room

The main distinguishing feature of the attic from the attic is the presence of a layer of insulation in the walls and roof, which makes it possible to use it for the constant presence of people. The gables of the building and the roof slopes act as the enclosing structures of the room. Depending on the shape of the roof, the configuration of the attic will vary.

The most common option:

- two vertical pediments;

- two roof slopes with fractures (in the upper part, the angle of inclination is shallower, at some distance from the ridge, the overhang angle sharply increases and the overhang drops off).

From a structural point of view, the attic is characterized by a variable ceiling height. In the area of the ridge, it will be maximum. As you move away from him, it will fade away.

Roof insulation with foam and more - about different ways!

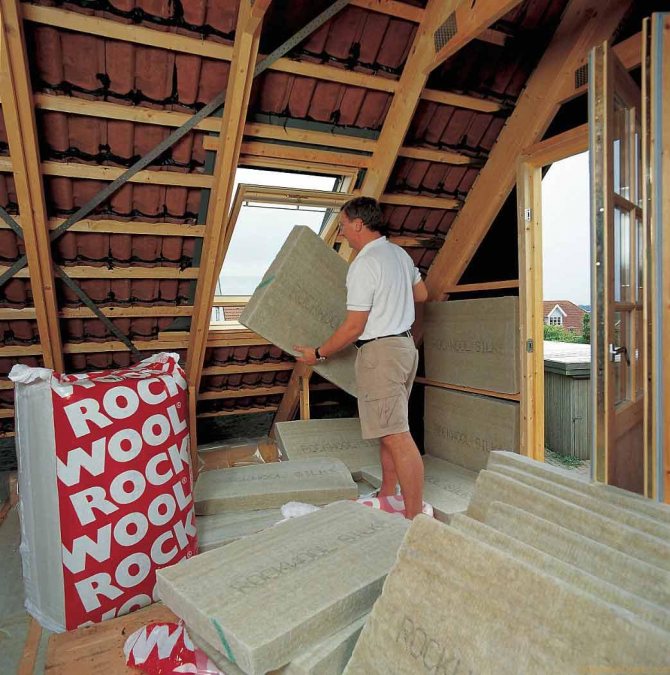

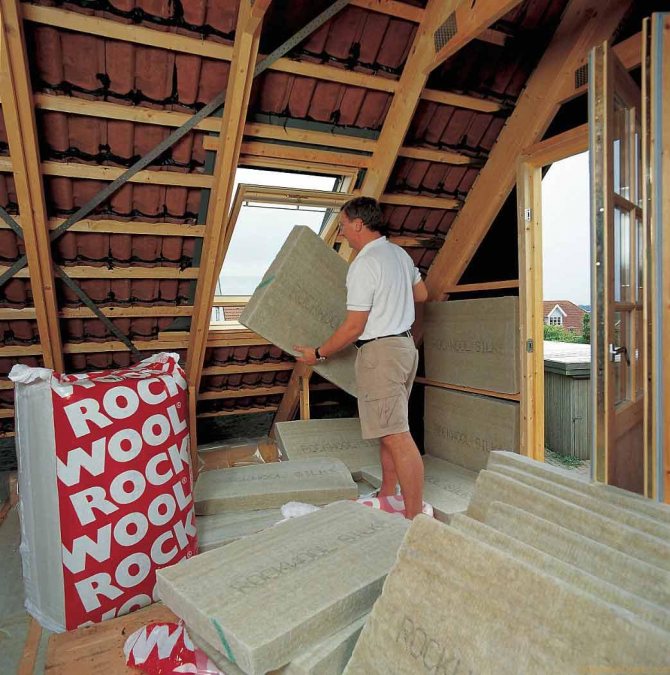

In addition to foam, materials such as mineral wool and fiberglass are also in great demand. For the convenience of the entire process, experts recommend buying the material not in rolls, but in mats - in this case, you will only need to fill in the required width of the fastening from the rails and insert insulation between them. It is very important to insulate the entire surface, and not only where it blows - only a fully insulated attic, with tight joints and the absence of "bald spots", is able to retain heat.

On top of the insulation layer, it is imperative to fill or glue a vapor barrier material with construction tape. If this is not done, very soon the mineral wool will be saturated with moisture from condensation, and the consequences from this are the most unpleasant - the room will be constantly damp and cold, gradually dampness will entail the appearance of rot and mold, which in turn will spoil the air inside the attic. No matter how much you ventilate, the smell will remain, although the reasons for its occurrence, most likely, will not be noticed.

Mineral wool and fiberglass are more expensive than polystyrene, however, unlike it, they are fireproof. In their composition there is no organic matter that can rot, these heaters are non-toxic to the human body and are convenient to install. It is worth mentioning the disadvantages of fiberglass - this material is not so convenient when laying, moreover, you need to work with it only in overalls, goggles and gloves, since small fibers and dust particles from glass can cause serious damage to the mucous membranes of the body, skin. Be sure to wear a respirator or at least a gauze bandage. Clothes after work can only be burned - washing from glass dust will not save you.

Working with mineral wool in this regard is much easier, since there are simply no such dangers.What is important to take care of is isolation from the external environment and possible wetting, since the material inside the structure can never dry out. When choosing between fiberglass and mineral wool, keep in mind that the latter option also perfectly absorbs noise. If you ask experts for advice, they will probably advise you on this type of insulation - over the years, its cost will pay off.

Attic insulation with polyurethane foam as an alternative to other materials

If you have free funds and a desire to have high-quality thermal insulation of the attic with little labor, consider such an option as polyurethane foam. In fact, this insulation is strikingly different from foam and mineral wool, if only in that it is not laid with plates or mats, but is applied by spraying. Externally, polyurethane foam resembles polyurethane foam, especially after hardening, but it is completely different from it in its structure, being a type of gas-filled plastics, that is, a relative of expanded polystyrene. Having hardened, polyurethane foam has the density of mineral wool, and with its thermal insulation properties it surpasses all other insulation materials, including penoizol. Moreover, this material is also a vapor barrier with high water resistance, that is, there is no need for additional protective layers when using it.

To insulate the attic with polyurethane foam, you only need a special sprayer, thick work clothes with a hood and sleeves, thick gloves and, preferably, a mask. The reason for the need for such equipment is not the harmfulness of the insulation at all, but its remarkable adhesion (sticking to any surfaces). If such foam gets on your hair, which is resistant not only to household chemicals, but also to gasoline, as well as weak acids, there will be no choice but to grab a razor and completely get rid of the scalp. Using the minimum means of protection, you will very quickly cover the entire inner part of the roof between the rafters with a thick layer of insulation (the average speed of work is up to 500 square meters per day). A uniform layer excludes the formation of bridges for cold and dampness, and also provides high reliability of thermal insulation, which often begins to collapse along the line of joints (if any).

However, even such a wonderful material has disadvantages. First of all, this, of course, is the price, but, given the characteristics of polyurethane foam, this is only an indirect disadvantage. The low level of resistance to esters and concentrated acids can also be attributed to the disadvantages only in part, because hardly anyone will visit the idea of pouring sulfuric acid on the roof. But the low heat resistance of polyurethane foam is a really serious flaw in the properties of the material, because, even with a low level of flammability, it begins to deteriorate already at 80-90 degrees, and at higher temperatures it can ignite. Therefore, it is worth thinking about what exactly you would like to insulate the attic, and how to minimize the shortcomings of a particular material.

Why do builders recommend Styrofoam?

If we consider foam as a heat-insulating material, then it really has wide application and has many advantages. But, in the case of the attic, some of the advantages of foam become disadvantages. Yes, this material is very convenient in work and has a low cost, but it will not provide durable thermal insulation and safety of living. In order not to succumb to persuasion to insulate with foam, you need to know the main arguments of the supporters of this material.

- Ease of installation. Few builders can give this reason, since we are talking about simplifying their work. The fact is that the foam is easy to process, it is simply cut and adjusted to the desired size. Polyurethane foam is used to fix the sheets.Thus, between the roof rafters, sheets of material are laid, which are glued to each other at the joints. This is the fastest way to insulate. This means that the master will receive a decent income in the shortest possible time.

- Material advantages. The main advantage for the owner of the attic is the relatively low price in comparison with other available materials. Other advantages include good thermal insulation properties, the ability to not shrink over time and moisture resistance.

- A small layer of thermal insulation. If you take polystyrene with a high density, then for full-fledged insulation, it is enough to lay sheets 10 cm thick.

- Convenience of overlapping "cold bridges". To exclude the possibility of heat loss in vulnerable areas, which are rafters, thermal insulation must be laid in two layers. The first layer is laid in the same level with the rafters, and the second layer covers the entire plane. To do such manipulations with foam, according to some builders, is safer than with mineral wool.

Apart from such arguments, it is possible that the popularity of foam has increased through commercial interest. Anyone who wants to sell will praise their product. And the foam, no doubt, has something to praise. But, it is important to note that it is not worth insulating the attic with foam. And there are clear and compelling reasons for this.

Related article: Rules and recommendations for the installation of shower cabins

Insulation of the attic with mineral wool

Mineral wool is often used as a material for insulation, due to its properties: it has high thermal conductivity, is not flammable and does not absorb moisture. In addition, insulating an attic with cotton wool is not a difficult process, accessible even to a beginner.

Insulation of the attic from the inside with mineral wool with your own hands

In addition to mineral wool, you can also try to insulate the walls of the attic with a similar glass wool material. Its main characteristics are similar to mineral wool, but it has greater strength and good sound insulation. In addition, it can be used at lower outside temperatures, but it does not absorb moisture better than mineral wool. Therefore, in wet rooms it is better to insulate the attic with mineral wool.

About the methods of insulation

Regardless of how warm the walls are in the attic, the floor also needs insulation. Especially if the room is used as a playroom or bedroom. Remember that this will also insulate the lower floor ceiling.

When insulating the attic, remember some important points.

Table. Important conditions for the insulation process.

| Name | Short description |

| Ease | The insulation should not weigh much, otherwise an additional load on the floor will be created. |

| Quality | It is important that the insulation used has excellent thermal insulation properties. |

All participants of our rating are suitable for these requirements. However, it is not easy to answer which one should be used to insulate the attic roof. Here it is necessary to take into account the size of the room, the type and features of the rafter structure, the characteristics of the roof, etc. In addition, the financial capabilities of the owner of the house are also important.

On a note! The attic is a living space, it should be not only warm, but also safe! Therefore, preference should be given to heaters that meet sanitary standards, do not contain toxins and belong to a suitable flammability class.

Video - Heat retention test for heaters

What kind of thermal insulation material do you prefer? What can you say about this? Write a comment - share your opinion with site visitors!

Several important recommendations

It is not difficult to properly insulate the roof from the inside, but before starting work, you should pay attention to the following points:

- using mineral wool or slabs as insulation, you need to take care of high-quality waterproofing of the roof;

- if damage was found during preparation of the roof surface, they must be eliminated. If this is an attic, then it will have to be fully checked for functionality in order to avoid large investments in repairs in the future;

- it will be correct to check the wiring, pipes, heating and water supply risers;

- if the roof is planned to be insulated with mineral wool materials from the inside, then they cannot be squeezed when laying;

- bending the insulating material is also not recommended. In places where it is folded, the material will acquire the ability to absorb moisture.

Attic insulation with foam - video about the material and its application

Polyfoam is the most affordable material of all insulation. Only free sawdust, as insulation, can be cheaper, but, as you know, they are in many ways inferior to even the simplest modern material. When choosing foam plates, opt for a material with a thickness of at least 100 mm.

The advantages of expanded polystyrene lie not only in its cheapness - it is also not characterized by subsidence, the plates adhere tightly, do not delaminate and, if properly laid, retain their qualities for decades.

However, one must remember that such insulation is fire hazardous - the foam burns quite well, and if you remember the close proximity of wooden rafters, then the risk increases significantly. This material is also credited with being liked by rodents - not as food, but as an excellent basis for making numerous moves. However, despite significant drawbacks, the cheapness does its job, and more and more homeowners insulate their attic with this particular material.

To install this type of insulation, you will need to pre-install a frame made of rafters stuffed with rafters, located parallel at such a distance that the expanded polystyrene sheets are close, even slightly with difficulty, pressed against their walls. After installing the foam, the structure is subject to hydro and vapor barrier, without them there is a great risk of moisture accumulation on the foam sheets and roof rafters. And everyone decides on their own with decorative finishing - it can be siding, and wooden boards, and drywall.

The fragility of thermal insulation properties

This is due to the fact that foam is used to fix the foam, which is used to fill the cracks and fasten the sheets of material together.

This method is convenient, but not durable. After installation, in fact, a sealed layer of thermal insulation is formed, since the foam easily flows into all the cracks and fills in hard-to-reach places. The protective effect of the new thermal insulation is quite high.

But, again, the attic is a special room.

Its design is constantly subject to intense environmental influences. In summer, thermal insulation is exhausted by sudden temperature changes, when the roofing material practically heats up during the day and cools down at night. In winter, snow accumulates on the roof and ice freezes, and in rainy weather the humidity rises significantly.

Such conditions will certainly affect the condition of the joints between the foam sheets, which will dry out. Losing its solidity, the foam insulation ball will become vulnerable, and heat losses will increase several times. As a result, the advantage of polystyrene not to lose its thermal insulation properties is inappropriate for attic rooms, since the main losses will occur through the destruction of the polyurethane foam.

What to look for when choosing insulation for the attic?

When buying one or another thermal insulation material, be sure to pay attention to:

- versatility of application;

- thermal insulation properties;

- the ability to repel moisture;

- the presence of soundproofing properties;

- cost;

- ease of installation;

- the service life of the insulation;

- resistance to temperature extremes;

- environmental friendliness.

Obviously, the main selection criterion is precisely ability to keep warm... Indeed, for the attic, this is especially important. In addition, it is important versatility application: it will be great if the material can be used to insulate both the roof and the floor, walls. And if you do not want to hear the noise coming from the outside, then choose a heater with noise insulation properties... All of these parameters are important. Ideally, the heat insulator chosen should match most of these.

Video - Types of insulation

Attic insulation technology with foam

As in absolutely any technique, the insulation work of the attic involves specific stages that must be strictly followed in order to obtain a good result.

Absolutely any insulation work in the attic arises from the calculation of the necessary materials in order to calculate the materials we need, let's start to figure out what specific materials we need when providing thermal insulation of the attic with foam.

- Waterproofing film - fixed on the space between the rafters and on the rafters themselves (roll-type material)

- Insulation material - in our case, foam

- Vapor barrier film

Based on the available information, we take into account how much material is required to completely close the space we need.

After that everything is calculated, you can safely start work on insulating the attic with foam.

First of all, we put a waterproofing layer, this is necessary so that weather precipitation does not fall on the waterproofer and into the room.

That is why the installation work of this layer is a very important task, which must be done extremely carefully - so as not to spoil the waterproofing layer. Then, as the first stage has been passed, we will proceed to the installation of the warmest layer - foam. It is simply placed in the frame between the rafters, having previously sawed off to size

It is simply placed in the frame between the rafters, having previously sawed off to size

Then, as the first stage has been passed, we will proceed to the installation of the warmest layer - foam. It is simply placed in the frame between the rafters, having previously sawed off to size.

But here difficulties can appear, since the attic is usually an angle roof, which is why the builders invented the option of short-term foam fasteners.

A rope is used, which is passed in turn between the rafter beams (zigzag) and clings to the pre-filled small nails, is pulled in parallel. This is made so that you can thread the foam afterwards.

We pulled the threads, carefully push the foam sheets so as not to break. We put the foam, we proceed to the last stage, insulation of the attic with foam - installation of a vapor barrier layer

We put in the foam, we proceed to the last stage, the insulation of the attic with foam - the installation of a vapor barrier layer.

When performing work on thermal insulation of the attic with foam, the following points should be taken into account:

When installing a vapor barrier layer, you need to calculate the ventilation design for air traffic

When performing subsequent work on the interior decoration, experts recommend leaving a distance between the inner lining and the vapor barrier layer of at least 15 cm - this will become part of the ventilation for the interior.

Ventilation is also necessary so that excess moisture is removed, since the foam under the influence of moisture begins to lose its own characteristics, and under the influence of moisture it can have a bad effect on the human condition.

Determine the amount of material

Before starting work on the roof insulation with expanded polystyrene, it is necessary to calculate the amount of material. It is very simple to do this: it is enough to determine the area that needs to be insulated. To insulate mansard roofs, you need to measure the area, the pitch of the trusses and decide on the required dimensions of the foam plates.Having counted how many sheets of foam plastic are needed as a heater, 6-8 more plates need to be added to the resulting amount, since there is a risk of material breakage during the installation process.

Tools and material

To insulate the roof with foam, we need the following tools and materials:

- foam sheets;

- wooden bars;

- waterproofing film;

- vapor barrier film;

- sharp knife;

- scissors;

- nails;

- construction stapler;

- polyurethane foam.

After everything you need for work has been purchased, you can start insulation. All work on insulation can be divided into 4 main stages: preparatory, installation of waterproofing film, laying of insulation, installation of vapor barrier film and interior decoration.

How to insulate a residential attic video tutorial and methods of high-quality thermal insulation

As already indicated, there are two methods available for independent implementation:

- from inside the room;

- outside the rafter structure.

The first method is used at the final stage of construction - when the house is ready for use. The second method is applicable in cases where the roof is being installed. It is before this operation that the installation of thermal insulation and all components is performed.

Attic insulation technology from the inside

So, the roof and waterproofing have been installed, all the ventilation and wind protection requirements have been met - you can start working. Beforehand, it doesn't hurt to see how to insulate a residential attic in the video - this will give confidence and theoretical experience. The process is carried out point by point:

- lay the insulation between the rafters, it must fit tightly into the gap between the rafters;

- in the presence of large slopes, the insulation is fixed with a thread that is zigzag stretched between the rafters;

- fasten the vapor barrier.

After that, you can perform cladding work (drywall, wall paneling, MDF).

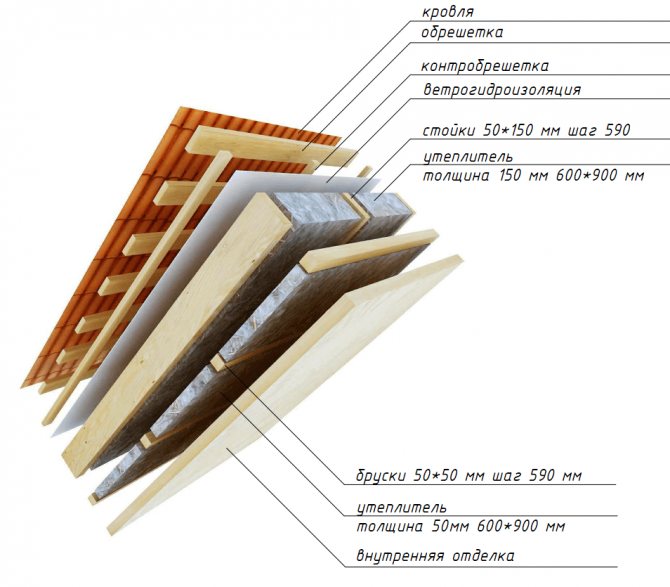

Thermal insulation installation technology from the outside

This option is performed in conjunction with roofing measures. After the owner of the building has decided what is the best way to insulate the residential attic, you can start the work process:

- fix the vapor barrier on the inside of the room with an overlap of at least 100 mm, the joints should be glued with tape;

- install the inner lathing for cladding - it will additionally fix the membrane;

- lay the mineral wool between the rafters, avoiding gaps and cracks;

- fix the hydro-barrier and counter-rail to provide a ventilated gap;

- install the lathing under the roofing material.

As practice shows, the thickness of the thermal insulation should be in the range of 150-200 mm - this is 2-4 layers of mineral wool. Each subsequent layer should overlap the joints of the previous one to prevent cold bridges.

We insulate a residential attic with our own hands: should we trust the video?

High-quality thermal insulation helps to keep the heating costs of the house to a minimum. A competent choice of material and its installation guarantee an optimal microclimate in the room, and also increases the service life of the elements of the entire structure. There is no doubt that qualified craftsmen will do the job quickly and efficiently, but in this case, you are deprived of moral satisfaction and awareness of your own importance.

If you ask some developers, then many will answer, they say, we insulate the attic with our own hands from the video, which is a dime a dozen on the Internet. And this is the right decision - most of the visual aids consider the entire procedure in detail, advice from experienced specialists is presented.

We also offer an example of useful video material:

Among other things, do not forget about the material component, but it is essential. Thermal insulation installation work is at least 50% of the total cost of the material, and this is a significant amount that can be spent on more useful things.

Attic insulation work stages

Considering all of the above, you can start to insulate the roof with your own hands using extruded polystyrene foam. Expanded polystyrene is a modern descendant of polystyrene, but it is better than it in terms of strength and insulation characteristics. Sufficiently resistant to UV radiation. It is produced in the form of sheets of various sizes and colors.

Tools and materials

So, for work you will need:

Attic insulation tools.

- polystyrene foam plates of suitable thickness;

- reinforcing fiberglass mesh;

- diffusion membrane;

- stapler;

- adhesive composition;

- cladding material (decorative plaster, lining, siding, etc.);

- wooden beam with a thickness of 3.5 to 4 cm;

- nails;

- hammer;

- saw;

- an ax and other carpentry tools.

If the roof has already been completed according to all the canons, it must be waterproofed. Waterproofing - a film over the entire area of the roof, which is located directly under the roof itself. In its absence, it is necessary to do the installation from the outside - you need to disassemble the roof and make a waterproofing coating.

First of all, you need to treat the wooden parts of the roof with antiseptic agents and give them the opportunity to soak and dry well. It is much better if the surface is treated with a fire retardant compound.

The next step is the installation of sheets of extruded polystyrene foam in the gaps between the roof rafters. To do this, you need to use special products for fasteners - staples or corners (which can be easily purchased at the store). Alternatively, they can be propped up with thin slats across the rafters.

The gap between the waterproofing layer and the sheets should be between 20 and 50 cm for better ventilation. It is necessary to mount the sheets carefully so that there are no gaps between them and the rafters. If gaps do appear, you need to fill them with cut pieces of expanded polystyrene sheets or foam for installation. Most often, the thickness of the sheets is slightly less than the thickness of the "legs" of the rafters. If this is the case, the sheets are not laid in one layer, and the fasteners (joints) of the sheets are made on different sides - in order to prevent cracks. The assembled and fixed sheets together with the mounting rails must have a flat surface without protruding irregularities and cracks.

Then a vapor barrier layer is mounted. For this, a special film is used. It can be ordinary or as a membrane: foil or perforated.

The film is mounted to the rafters using a stapler with a small overlap of 10-15 cm. All joints are glued with a special tape. This is necessary so that the vapor barrier properties do not decrease at the points of contact with the rafters. The tape should be glued across the rafters. The tension of the film should be medium, it is better to let it sag a little (up to 1 cm) in the center of the opening.

At the final phase, finishing is carried out - finishing materials are mounted. It can be fastened close to the vapor barrier, or it can be mounted on a thin lathing made of slats. If necessary, the surface is covered with wallpaper, varnish or paint.

At all phases of installation, one must not forget to make high-quality insulation of engineering systems, if any. It is better to install the electrical wiring in a non-combustible cable channel or corrugation, and use metal and asbestos materials for the chimney.

What is required to reduce heat loss

The market of modern building materials can offer the consumer a lot of insulation options. The best materials, more precisely with the most beneficial insulating qualities, will be:

Mineral wool

Time-tested environmentally friendly insulation, endowed with a low coefficient of thermal conductivity. Among its other advantages are: excellent soundproofing and heat-saving qualities.

Styrofoam (expanded polystyrene)

The most commonly used insulator.Its popularity is due to its low cost and easy installation. Available in slabs.

Polyurethane foam

A relatively new material that allows you to reduce the time spent on roof insulation in fact in half. However, its cost is quite high.

All of the above characteristics of quality and versatility are most satisfied with expanded polystyrene of the PSB-S 25 and 35 grades. Its service life is more than 80 years.

Using polystyrene, the easiest way to answer the question is how to properly insulate the roof, spending the minimum amount of time and money.

Recommended Materials

When choosing a material for insulating an attic, it is necessary, first of all, to pay attention to the climatic features of the region where the building is built, and the thermal insulation properties of the material.

As a rule, the question of what is better to use for insulating the roof of the attic depends on what weather conditions prevail.

The thickness of the layer of insulating material depends on this.

The characteristics of the material are also of considerable importance.

According to most experts, today basalt (mineral) wool is the best material for warming the attic.

The thickness of the insulation in the form of mineral wool in most regions is 150-200 mm.

It is for this reason that two layers of material are laid with the obligatory overlap of the joints.

Particular attention is paid to those places where the material is adjacent to the supporting structures.

Also popular with developers and expanded polystyrene.

Its thickness is determined based on what characteristics the material has.

It is difficult to say unequivocally, since now a huge number of types of expanded polystyrene are produced with individual characteristics.

Styrofoam is very well suited for insulation from the inside.

To seal the joints between plates and rafters, use ordinary polyurethane foam.

Some developers use polyurethane foam for insulation of the attic.

This is a relatively new material, which is essentially a modified polyurethane foam.

For internal insulation of the attic, it is also great.

The thermal insulation properties of this material are such that it can be applied in a thin layer.

Polyurethane foam has good adhesion and completely fills all voids in the structure.

Another material that is perfect for insulating the attic is penophenol.

This material is becoming more and more popular.

And mainly due to its environmental friendliness.

And it does not absorb moisture.

Thus, the use of penophenol as a heater makes it possible not only to avoid heat loss, but also to protect the room from the appearance of high humidity.

It is better not to use insulation in rolls to insulate the attic roof.

No, the properties of this material are not worse than those listed above.

The fact is that it is almost impossible to fix the required layer of such material.

It often, after laying and finishing the attic, slides down an inclined plane.

Therefore, such material is not used for roof insulation.

Advantages and disadvantages

There is still no consensus among experts on whether it is possible to insulate attic roofs with foam.

If we talk about it as a heat-insulating material, then it has many positive aspects. However, roof insulation with foam turns some of its pluses into minuses. Those who advocate foam insulation of the attic argue for the following positive points: Convenience and ease of installation. The material is easy to cut to the required size and can be easily and simply fixed with a mounting tape.

Therefore, often this insulation is laid between the rafter legs and the joints of the plates are glued with tape.

We can say that this is the simplest option for insulation. The main plus for home owners is the reasonable price of the material. In addition, the product does not shrink and has good thermal insulation qualities and good moisture resistance, which is very important for roof insulation. material with a high density, then there will be enough slabs with a thickness of 10 cm. Due to this, you can maintain the useful height of the room. According to some masters, the rafters are cold bridges, so they also need to be covered with heat-insulating material. If we talk about mineral wool and foam, then with the help of the latter, this can be done much easier and faster.

It is enough to lay one layer of material between the rafters, and fix the second on top with overlapping rafter legs.To be completely honest, it is worth noting that some experts, on the contrary, do not recommend insulating the attic with foam: The roof should be insulated with materials that will ensure the dryness of the wood and have sufficient vapor permeability. This is necessary for natural ventilation of the wooden rafter system. Since foam has a low vapor permeability, it will not be able to remove excess moisture from wooden structures, which will quickly lead to their deterioration. Since gaps form between the foam sheets and the wooden structures themselves, they are often sealed with polyurethane foam ... This allows you to fix the insulation well and achieve airtight thermal insulation.

But the trouble is that, due to temperature changes and external influences, the foam seam quickly collapses, as a result, cold bridges form in the joints. Polyfoam not only refers to combustible materials, it also releases toxic compounds during combustion. This is especially dangerous, after all, the material insulates the attic from the inside on large areas. Even if the roof covering is non-combustible, the foam will do its dirty work. Insulation of the attic roof with this heat insulator is undesirable due to harm to human health.

When this material is attached to the walls of the house from the outside, it does not affect the person, but from the inside of the attic, no interior decoration will protect from the styrene released. When exposed to heat, the rate of release of toxins from the foam increases

This can be due to the internal heat in the house or the sun-hot roof. As you can see, this material has so many disadvantages that it is much better to insulate the attic with expanded polystyrene. It is considered non-flammable and does not emit harmful compounds. Moreover, expanded polystyrene is a vapor-permeable product, which is much more beneficial for a wooden roof frame.

Insulation layer thickness and the principle of similarity

The attic sandwich includes:

- roofing material (tiles, metal tiles, bituminous roofing);

- waterproofing membrane;

- insulation;

- vapor barrier membrane;

- decorative finishing of the ceiling.

Schematic diagram of the construction of the attic roof insulation with foam

In each specific case, the calculation of the required thickness of the roofing insulation is carried out taking into account the climatic zone and the properties of all 5 layers listed above. On the net you can find many options for building heat engineering calculators. Some of them are provided by firms - manufacturers of insulation materials, but we recommend using the options developed by independent authors.

Here, for example, a calculator from ROCKWOOL: https://www.calc.rockwool.ru/

You should be aware that without basic knowledge of building structures and thermal physics, it is almost useless to use programs of this kind.Therefore, it will be necessary, at least, to become familiar with the law of heat transfer through a flat wall and the role of the main significant parameters - the thermal conductivity λ, the thickness of the S layer and the difference between the internal and external temperatures Δt. Otherwise, you may not notice a gross error in the inserted data and be guided further by an erroneous calculated value.

Special foam sheets with rafter grooves.

The calculator does not provide an unambiguous way of calculating. The data obtained depends not only on materials and structures, but also on the desired level of comfort in the room, as well as the intensity of heating that you can afford while living in the attic. Therefore, statements such as “insulation of the attic with foam in central Russia makes sense with a layer thickness of at least 300 mm” or “you need to focus on the height of the cross-section of the rafter beams” are not of particular practical importance. However, if, according to the thermal calculation of the attic roof, you get the required foam thickness of less than 150 mm, this with a probability of 99% indicates a mistake, even if the house is located in Krasnodar or Sochi. The same can be said for excessive (over 350 mm) calculation results.

The principle of physical similarity allows to simplify the choice of the thickness of the insulator and the power of the heating system. This is possible if you have information about a house with an attic in your area, similar in design to the one in which you have to work.

How to calculate the required thickness of insulation in practice

Suppose you know that the sample house is equipped with a 5-layer roofing sandwich with a total thickness of 25 cm of mineral wool as the main insulation. At the same time, the practice of living on this attic floor indicates the sufficiency of isolation. In this case, using the proportion Smv / λmv = Sп / λп, the equivalent value for the foam is determined:

Sп = (Smv x λp) / λmv = (25 × 0.034) / 0.040 = 21.35 (cm)

As an example, the average values of the thermal conductivity coefficients of various grades of the materials under consideration were taken.

Insulation of the attic with mineral wool arguments Pros and Cons

When choosing building materials, many of us prioritize the price, and only secondarily, the characteristics. And the reason for this is not so much the recent crisis as an elementary desire to save money. True, this will not work with mineral wool, it does not apply to budget materials. However, just the characteristics will more than justify everything that will be spent on mineral wool, which is refractory (withstands temperatures up to 1000 degrees), moisture resistant, has a considerable reserve of hardness and, among other things, is an excellent sound insulator. And all this is only in addition to the excellent thermal insulation properties.

Warming the attic with mineral wool is as easy as the work described above with polystyrene foam plates. However, in this case, neglect other insulating layers, such as the superdiffusion membrane, which is located directly on the battens with a transition to the rafters. Already on top of this moisture-proof layer with a small air gap, slabs of basalt mineral wool are laid, which is then covered with a vapor barrier and only then with decorative decorative panels or plasterboard. Minvata can also make internal wall insulation.

However, it should be borne in mind that mineral wool is far from a safe material and it must be chosen carefully, giving preference to well-known manufacturers. The fact is that the slightest violation of norms and standards in the manufacture of mineral wool makes it extremely hazardous to health. Companies that have long established themselves on the Russian market guarantee the quality of their products, but dozens of little-known companies engaged in the production of mineral wool give such guarantees, for the most part, unfounded.

The best thermal insulation materials for the attic roof

In the modern building materials market, you can buy literally everything: from the good old mineral wool to the still not very popular foil insulation. Let's get acquainted with the materials that are best suited for insulating the attic.

| A photo | Name | Rating | Price | |

| #1 |

| PIR plates | ⭐ 100/100 22 - votes | Find out the price |

| #2 |

| Sprayed polyurethane foam | ⭐ 99/100 19 - votes | Find out the price |

| #3 |

| Extruded polystyrene foam | ⭐ 98/100 11 - votes | Find out the price |

| #4 |

| Styrofoam | ⭐ 95/100 2 - voices | Find out the price |

| #5 |

| Ecowool | ⭐ 94/100 13 - votes | Find out the price |

| #6 |

| Mineral wool | ⭐ 92/100 46 - votes | Find out the price |

| #7 |

| Glass wool | ⭐ 89/100 3 - votes | Find out the price |

What insulation for the attic roof would you choose or recommend?

Take a survey

No. 7. Glass wool

The material is inexpensive, and therefore has gained wide popularity. It will help to save on insulation of the attic, sold in rolls and slabs (the second option is more convenient to install). Glass wool is made from wastes remaining in the production of glass and quartz sand, which undergoes special cleaning beforehand.

Glass wool

Produced by brands such as Isover, Ursa, Neman, Knauf etc.

pros

- low cost;

- light weight;

- resistance to rodents (there are no natural ingredients in the material);

- elasticity (the material is laid with the most snug fit to the rafters);

- finally, the material is flexible, and therefore even on difficult sections of the roof there will be no problems.

Minuses

- high hygroscopicity (ventilation is needed outside so that moisture evaporates, and from the inside - a layer of vapor barrier material);

- fragility (fibers are destroyed, and small particles spreading as a result can be hazardous to health);

- the use by some manufacturers of formaldehyde as a binder (it is better to give preference to more expensive, but safe insulation).

This is, for example, the Isover Geo line, which contains the Pitched Roof material (non-combustible and safe).

Glass wool prices

Glass wool

No. 6. Mineral wool

It differs from the previous version in that it is made from igneous rocks, resulting in a material with higher elasticity and strength, but less brittleness. Consequently, the performance characteristics of mineral wool are much better.

Mineral wool

The material also absorbs moisture, but in a much smaller amount than glass wool, and therefore it is still better to use a vapor barrier layer. Good vapor permeability, due to which (provided appropriate conditions for moisture evaporation) the insulation will last long enough.

On a note! There are no harmful components in the products of well-known manufacturers, which is confirmed by sanitary certificates.

Ease of installation of modern basalt wool is also provided by the developments of some companies. For example, insulation ROCKWOOL, sold in the form of plates, is spring-loaded at the edges, due to which it fits as tightly as possible. Other well-known manufacturers include Technonikol, Izovol, PAROC and etc.

pros

- low thermal conductivity;

- ease of installation;

- fire safety;

- good vapor permeability (the material "breathes");

- resistance to temperature extremes, biological and chemical influences.

Minuses

- rather high price (for materials from well-known brands);

- the need for treatment with water-repellent agents;

- weight (it is more than, say, foam).

Mineral wool prices

Mineral wool

No. 5. Ecowool

Thermal insulation material of organic origin. It is made from cellulose fibers obtained during the processing of wood, recycled materials, cardboard, which have excellent thermal insulation properties.

Ecowool

The density of the insulation reaches 75 kg / m³, and its degree of flammability corresponds to G2.

pros

- optimal thermal conductivity;

- density;

- fire safety;

- absence of hazardous substances in the composition (material is environmentally friendly);

- protection from decay and rodents (due to antiseptic treatment).

Minuses

- high hygroscopicity (vapor and waterproofing is required - PET film or polymer membrane);

- the need for special equipment for installation, skills and experience are required for the work.

We also note that ecowool is laid in one of two possible ways:

- dry;

- wet (an adhesive solution is used, thanks to which the material adheres as tightly as possible, due to which the insulating layer is made more durable).

Ecowool prices

thermal insulation basalt cardboard

No. 4. Styrofoam

It is inexpensive, but for the attic it is a very dubious option. Yes, foam is still popular, and therefore took its place in our rating, but we will try to tell you why it is unsafe to use it for insulation.

Styrofoam

pros

- ease;

- cheapness;

- ease of styling.

Minuses

- inconsistency (as a rule) with the declared characteristics; during production, no technical requirements are often not taken into account;

- rapid destruction (the material crumbles into small granules, due to which it loses its thermal insulation properties);

- flammability, and toxic substances are released during combustion.

Those companies that take the quality of their product seriously try to improve it. However, the foam of the most famous brands still has worse characteristics than other thermal insulation materials. By the way, in European countries it cannot be used at all in residential buildings, but in Russia people, wanting to save money, still endanger themselves.

Styrofoam prices

Styrofoam

Number 3. Extruded polystyrene foam (EP)

Extruded polystyrene foam

This material differs significantly from polystyrene (and for the better) not only in its characteristics, but also in the manufacturing technology. It is more expensive, but considering all the advantages, the price is quite justified.

pros

- good thermal conductivity;

- belongs to the G2 flammability class (that is, self-extinguishing takes place);

- extremely low hygroscopicity;

- high strength;

- the plates have a consistent geometry that does not change during operation.

Minuses

- the release of toxic substances during a fire (albeit not as much as in the case of foam);

- lack of elasticity (it is difficult to lay the material without gaps; they, as a rule, are blown out with polyurethane foam).

Note! Due to the fact that the manufacturing technology of the material is very complex, counterfeits are practically not found on the shelves. Only large companies that can afford it are engaged in the production of EP.

If we talk about specific manufacturers, then, of course, there are leaders here. One of them is the brand "Penoplex", the slabs of which can be laid without waterproofing and used when arranging a continuous sheathing for the roof.

Prices and reviews for extruded polystyrene foam

# 2. Sprayed polyurethane foam

Sprayed polyurethane foam

The use of this material allows you to create a seamless coating of high strength (no seams and cold bridges). Sprayed heaters are different, but polyurethane foam is still considered the highest quality.

pros

- slight load on the rafters;

- excellent thermal conductivity (below 0.03 W / m × ° С);

- there is no need for preliminary preparation;

- vapor barrier is also optional;

- excellent adhesion to various surfaces;

- anti-corrosion effect (metal elements do not rust after spraying);

- finally, the material does not allow moisture to pass through.

Minuses

- quite high price;

- insulation cannot be done independently (special equipment is required).

The layer turns out to be dense and thin, it, among other things, will also serve as additional sound insulation, and this is especially true if the attic is used as a bedroom.

Prices for sprayed polyurethane foam

sprayed polyurethane foam

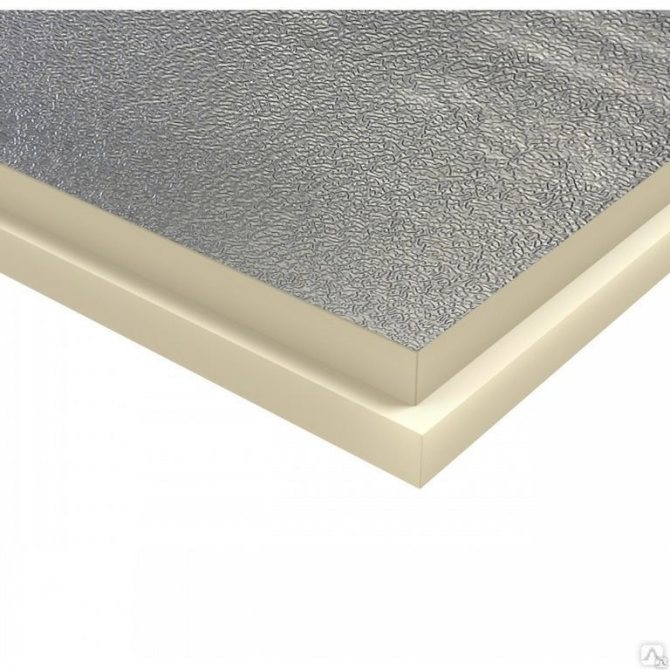

# 1. PIR plates

This material, which combines the advantages of popular thermal insulation materials, has appeared relatively recently. Differs in fire resistance, good thermal conductivity, hydrophobicity and strength. For the manufacture of PIR plates, polyisocyanurate foam is used - a material with a rigid structure, consisting of small cells filled with gas.

PIR plates

On a note! The material is produced in the form of conventional and foil plates (with additional metallized protection). To connect the slabs to each other, groove-ridge locks are provided, allowing you to create a seamless coating on a flat surface.

pros

- excellent thermal conductivity (0.022 W / m × ° С);

- rigidity;

- high strength;

- hydrophobicity;

- fire safety.

Minuses

- it is only one - high cost (about 15,000 rubles per cubic meter).

Leading companies involved in the production of insulation materials have already started producing PIR boards. For example, products Technonikol is gaining more and more popularity.

Important! In addition to the heaters described above, the following are also used for attics:

- expanded clay;

- woolen mats;

- fibreboards.

But they are much less common due to complex installation or inappropriate technical characteristics.

Reviews and prices for PIR plates

Insulation properties

One of the most common and affordable insulation materials is polystyrene foam. It is a gas-filled foamed polymer. Almost the entire volume of material is occupied by air, which is contained in separate closed cells.

Due to their structure, such polymers have a number of properties that make it possible to use them as heat insulating and structural materials:

This is how the attic insulation looks like layer by layer

- low value of the thermal conductivity coefficient (0.035 - 0.037 W / (m * K));

- depending on the brand, the density value ranges from 11 to 35 kg / m3;

- the degree of flammability G1 - G4 (for insulation it is better to use low-combustible materials marked G1);

- resistance to biological destruction.

In addition to the listed advantages, you should pay attention to a number of disadvantages that should be considered when used in building structures:

- fragility of the material;

- prone to destruction under the influence of direct sunlight;

- instability when exposed to chemical solvents;

- the material has a certain amount of water absorption, which entails the need to use a protective waterproofing layer;

- when heated above 90 - 95 ° C, harmful substances are released into the air of the room.

Features and materials for attic insulation

You need to understand that this room, unlike all others, is colder, since it does not have any "heat cushion" on top. Therefore, the insulation, which we will do with our own hands, must be of especially high quality. Based on this, the material is selected.

The difficulty lies in the fact that the surfaces are uneven, since there are rafter beams under the roof, and they will all have to be bypassed. The waterproofing layer will have to be removed under the roof in order to drain the condensate. When organizing work, you need to take into account that the end walls of the attic also need to be covered - it is through them that a large amount of heat escapes. Each house has its own architecture, roof shape and material of roofing and walls.

Therefore, for each dwelling there may be some special, clarifying recommendations for warming the attic space. Therefore, we will dwell only on the basic, mandatory activities that need to be carried out

Each house has its own architecture, roof shape and roof and wall material. Therefore, for each dwelling there may be some special, clarifying recommendations for warming the attic space.Therefore, we will focus only on the main, mandatory activities that need to be carried out.

The choice of material depends on many factors. Roof structure, roofing, local climate and much more. We list only the features of some materials that can be used.

Styrofoam

One of the cheapest, and therefore popular materials for insulation. Easy to process and install. But experts point out that its vapor permeability is small. Consequently, the room may be damp. In addition, as the wooden rafters "dry out", the gaps between them and the foam plates will increase. And these are the slots for drafts. There is one more remark. In such a covering, mice very often equip their homes, and then it will be quite difficult to fight with them.

Mineral wool

Basalt mineral wool is excellent in all respects. Having great strength, it does not absorb moisture, is fireproof and practically does not conduct heat. Since it has elasticity, it adheres well to the installation site, resting its edges against the rafters. Glass wool is more durable and more effective as a sound insulator

It can withstand lower temperatures, but requires special precautions to handle.

Description of the workflow

We will figure out how to insulate the attic for winter living, making it a full-fledged living space. For simplicity, the technology will be divided into several parts, each of which must be carried out in accordance with the recommendations.

Attic preparation and settlement work

To prepare well for work, it is worth following a few simple steps:

| Illustrations | Description of work |

| Free up space... Nothing should interfere with you during the work, so all unnecessary things need to be removed or laid out so that you can carry out the insulation without being distracted by carrying objects from place to place. |

| Carefully inspect all structural elements... If you have damaged areas, as in the photo, then they need to be strengthened or even replaced. The roof structure must be solid. If there are areas with mold, be sure to treat them with an antiseptic. |

| Roof and wall joints are closed in new buildings... The junctions are insulated with mineral wool and sewn up with a board. Try to prevent cold penetration through these areas. | |

| Measurements are made... You need to determine the area of the surfaces to be insulated. For this:

| |

| The optimal thickness of the insulation is determined. To do this, you need to know the coefficient of thermal conductivity of the foam, which depends on its density. Information is always on the packaging or in the documentation; by this indicator, it is easy to determine which layer of material is needed for high-quality thermal insulation. |

If you have damp areas in the attic, then you need to fix the roof leaks. To quickly and accurately identify all problem areas, it is best to inspect during the rain or immediately after it.

Required materials and tools

When you have all the necessary calculations on hand, you can purchase materials.

Their list looks like this:

- Styrofoam... This insulating material is most often sold in sheets of 1x0.5 meters, there are other sizes, choose the option that best suits your size. Often it is impossible to find polystyrene of the required thickness, in this case two layers are laid in order to obtain the desired effect from insulation;

It will not be difficult to put the desired layer, there are foam of different thicknesses on sale

- Waterproofing film... This material is necessary to create a moisture barrier and prevent the formation of condensation in the structure.If there is waterproofing under the roof, then the film is placed only on the inside; if it is not there, then the membrane must be placed under the insulation;

Insulation material is an indispensable part of the structure

- Polyurethane foam... With its help, all joints and cracks will be sealed. Be sure to use foam, since it is difficult to tightly join the foam sheets, and a significant part of the heat will be lost through the voids;

If you purchase a professional version of the foam, then you will need a special gun for application.

- Bar or board... They are necessary to create a lathing on top of the insulation, which will provide the required ventilation gap and will become the basis on which the finishing materials will be attached. Instead of wooden elements, a metal profile for drywall is sometimes used;

The bar will serve as a frame for finishing and a fastener for insulation

- Fasteners... To fix the film, staples 6-8 mm long are used, which are clogged with a special stapler. The block or board is fixed with self-tapping screws, the length of which must be at least 40 mm more than the thickness of the elements to be fixed.

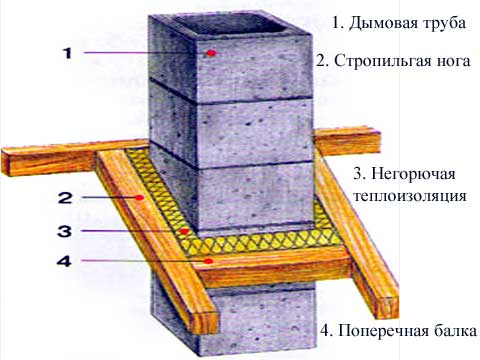

If a chimney comes out through the roof, which heats up to high temperatures, then the space around it is closed with mineral wool. It serves both as a heater and as a thermal insulator.

Mineral wool is not afraid of high temperatures

To work, you need the following tool:

- Construction stapler... With its help, you will very quickly and very reliably fix the waterproofing material;

The stapler greatly simplifies the work

- Hacksaw. Use a tool with a fine tooth size, as it is suitable for both wood cutting and styrofoam cutting;

The finer the teeth, the better the cut quality

- Foam gun... Used if you have professional cylinders. I recommend using this particular option, since the composition is applied with a gun much more accurately and more economically;

The gun facilitates the application of polyurethane foam into narrow crevices

- Screwdriver... Needed for fastening rails and other structural elements. The kit must include nozzles of a certain configuration.

Description of the workflow

Warming the attic with expanded polystyrene is a simple process, but responsible. The fact is that the thermal conductivity of roofing materials is very high, so the foam layer will serve as the main protective layer, and not an additional one, as on the walls.

Instructions for doing work with your own hands looks like this:

| Illustrations | Description of work |

| Roof structure is waterproofed. If the film was not laid under the roof, then the thermal insulation of the attic from the inside begins with fastening the film.

|

| The exact distance between the rafters is measured... The more precisely you cut the foam, the denser it will be in the openings and the better the insulation quality will be. Therefore, measure each opening separately, then carefully cut the sheets into pieces of the desired size with a special knife or hacksaw. |

| Sheets are neatly inserted into the openings... The work is carried out from the bottom up, try to place the foam as tightly as possible and join the sheets tightly. If you see that the element does not fit, you do not need to break it and push it into the structure by force, cut the required sections so as not to spoil the insulation. | |

| The space is laid down to the very ridge... To reach the very top, use scaffolding or a ladder. If the elements are cut accurately, then they will hold well even without additional fastening. |

| The space around the pipe is insulated with mineral wool... How this is done is shown in the diagram, mineral wool is laid along the perimeter, this material has a lower density and it can be pushed into voids so that they are tightly clogged. |

| All slots are filled with polyurethane foam. Everything is very simple here, the main thing is not to miss a single void on the surface. The advantage of foam is that it can fill small joints and voids 10 or more centimeters wide. Do not worry about the excess, after hardening, you can cut them off if necessary. |

| A vapor barrier is attached on top of the foam. I will not analyze the pros and cons of options with and without a membrane, since the technology assumes the obligatory presence of such a layer. Those who do not lay the film often say that its price is high and the costs of the project are increasing, but saving on the reliability of your home is not the best solution. |

| A frame is attached on top of the vapor barrier. This stage of roof insulation is simple: a crate is assembled from a profile or bar, on which the finishing will be attached. The design fixes the insulation and creates an even base for finishing. |

| Finishing is attached. It can be any material of your choice. |

If you need to insulate the attic with foam, and the thickness of the rafters is not enough for this, then the installation is carried out in two layers. Moreover, the outer layer is attached over the beams and pressed with a special washer.

This is how insulation is made in two layers.