Benefits of Styrofoam

Technologically, the insulation of structures is based on the creation of the effect of thermo-water using an air cushion.

Is it possible to insulate the ceiling with foam? Polyfoam is one of the most economical materials for thermal insulation, consisting of styrene cells with air. Material thickness 50 mm is comparable in technical characteristics with the following materials:

- concrete coating 1900-2000 mm; brickwork 850 mm; mineral wool 90 mm thick; wood 180 mm.

The material is optimal for external insulation of ceilings of permanent and temporary structures, since it has the following advantages:

- low thermal conductivity - its performance is comparable to extruded polystyrene foam and mineral wool; lightness - due to its low weight, it can be used inside and outside on various surfaces; convenience and ease of installation - to insulate the ceiling with foam with your own hands, the simplest set of tools and minimal skills are enough; safety - in order to insulate the ceiling with foam plastic, no additional protective equipment and devices are required; availability - due to the low cost, the insulation of ceilings does not require large financial costs; ensuring good sound insulation; low hygroscopicity; ability to withstand loads; environmental safety; service life of at least 20 years.

Is it possible to insulate the ceiling with foam on your own

The standard scheme for fixing the foam layer is as follows:

- Waterproofing film.

- Reinforcing layer (ideal - basalt mesh).

- Polyfoam (fixed either with dowels or on a polyurethane layer).

- Plaster (applied from above to protect the foam from pests). It is the soil base that is needed.

- Decorative finishing (plasterboard, plastic panels, suspended or suspended ceiling, whitewash, painting).

The only difficulty that arises after the ceiling is insulated with foam is the increasing humidity inside the room. The problem is solved quite simply - by installing forced ventilation or an air conditioner, which is able to regulate the humidity inside the room.

If this is not done, moisture condensation will begin to accumulate in the interlayer between the foam and the waterproofing film (since it is warm inside the room in winter, and the wall itself is cool). Naturally, this will lead to the appearance of fungus, mold. Over time, it will spread not only along the ceiling, but also on the walls. Repeated violations of this technology led to the fact that after the repair, the wallpaper had to be completely re-glued after 3-5 months, since they all turned black.

Insulation and fastening methods

From the point of view of science, insulation of the ceiling with foam from the outside is the most correct and effective way of thermal insulation.

If there is such a possibility, it is the external installation type that is used. But in apartment buildings, where internal insulation is the only possible option, this method is used. Its advantage is also that it provides good sound insulation at the same time.

Sheets of material can be secured in two ways:

- special adhesives; special umbrella nails.

From the attic side, there is no need for glue fixing. The quality of fixing is especially important for internal insulation. The glue is not applied to the entire surface of the foam, you can only cover the perimeter and the center will be enough. When using adhesive mixtures on water, the thickness of the adhesive layer is also added to the thickness of the foam.

Important! Since the foam is susceptible to destruction by solvents, when you first type of fastening, you need to inquire about the composition of the mixtures. They should not contain formaldehyde, acetone, alcohol, harmful resins.

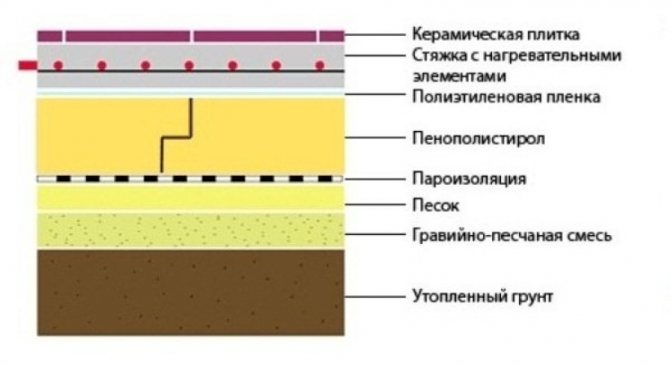

Foam boards do not have sufficient moisture resistance, therefore, when laying external insulation, additional layers are required:

- from the outside it is a waterproofing layer; from the inside (from the side of the room) - a vapor barrier layer.

How to insulate the ceiling with foam outside:

- Surface preparation: removing dust, debris, leveling. Laying a vapor barrier - it is fixed with a stapler. For installation using a lag, lags are mounted, for a non-lagged installation method, pouring is done using wire reinforcement. Laying foam. Installation of a waterproofing layer - it must be installed with the approach to the walls. Laying the floor and trimming the waterproofing film along the edges. The finishing floor on top of the screed is laid only in the case of a residential attic, otherwise the screed is sufficient.

Important! With external insulation, with already existing logs, foam plates are easy to lay - you just need to choose their correct sizes.

The foam is cut in such a way that it fits tightly between the beams, and the gaps between the beams and the insulation must be blown out with polyurethane foam.

Insulation with beams should form a common plane. If the thickness of the beams is not enough, it is sharpened with wooden planks. A small gap is left between the insulation and the logs to ensure ventilation.

Insulation of the ceiling with extruded polystyrene foam

Ceiling insulation using extruded polystyrene foam is quick and easy. In order to understand what kind of material it is, you need to consider its characteristics.

What is extruded polystyrene foam

This one differs from other heat insulators by its high strength and consistency. Marked with EPS or XPS.

The technology for producing a heat insulator is based on polystyrene, which is exposed to carbon dioxide. The substance is obtained by pressing the extruder on it and at the outlet has a porous base with fine air bubbles.

It is beneficial to use such a heat insulator, since, having a small volume and thickness, it keeps heat well and does not allow moisture to penetrate into the house. This product can be purchased in the form of plates or rectangles with a thickness of 100 millimeters, of different colors and textures.

There are many ways to improve thermal insulation. Which one will have to be used depends on the availability of the overlap. Consider the existing ones:

- The arrangement of sheets occurs from the inside of the house.

This method is used when it is not possible to carry out work outside the premises. Basically, it is often used in houses without an attic or attic. When attaching it to the wall of a living room, a vapor barrier sheet must be used, which ensures the safety of the installation from moisture. The foam is attached to the ceiling with glue solution or dowels with wider heads.

- Works are performed on the top floor or in the technical room.

With this method of doing the work, the installation of decorative structures is not necessary. If the insulator is used from the street side, then there is no need to fix it.

- The placement of expanded polystyrene took place during construction, and it was located in the ceiling structure.

Installation takes place during the construction phase of the facility and an insulating element is placed between the power ceilings of the ceiling, which will later be covered with a special flooring.

Important! After installation, the heat insulator must be protected by non-combustible elements. Inside the dwelling - plasterboard, outside - reinforced with cement-sand screed.

Installation of polystyrene foam on the ceiling.

Technology of internal insulation of the ceiling with foam

A significant disadvantage of internal thermal insulation for a city apartment is that foam plates and finishing take precious centimeters away. Calculation of the final ceiling height requires the correct choice of foam thickness and mounting method.

When using a material with a thickness of 5 cm of lathing for finishing with clapboard, for example, it leaves in general about 8-10 cm of the height of the room. If suspended models of plasterboard ceilings are used, even more height is hidden.

How to insulate the ceiling with foam from the inside:

Surface preparation: cleaning of finishes and dust. Check the surface with a spirit level.

With noticeable differences, the surface is putty. For very large irregularities, plastering and grouting are required. If there are irregularities less than 0.5 cm, it is enough just to seal them and then sand them with sandpaper. Treatment of the surface with an antiseptic primer. Dry the surface. Foam plates are specially roughened using scrapers, sandpaper, a special knife.

A layer of adhesive solution is applied evenly over the entire surface of the sheet. Begin to install the sheets from the corner, pressing them to the surface and holding them for 1-2 minutes. Laying is done specifically with the displacement of each subsequent row by half-plates. After gluing and drying, holes are drilled in the center and corners of the sheets, dowels-umbrellas are inserted into them and hammered with metal pins. aluminum profile, then laying foam plastic and laying a vapor barrier. Installation of a clean ceiling.

When insulating from the inside, waterproofing is not required. If the final ceiling is mounted on a crate, these are plastic panels, plasterboard ceilings, lining, no additional fixing of polystyrene is required.

Important! Special polymer types of adhesives are not cheap, so you can save money by using a dry adhesive mixture mixed with water. You need to close according to the instructions, stir again after 5-7 minutes, after cooking it should be used within one hour.

In rooms with a high air temperature, in addition, foil and foamed foil insulation in rolls can be laid on foam plastic, while the finishing ceiling is made only on the frame.

Styrofoam installation

There are 2 main ways of insulating a wooden house with foam:

- using crate;

- landing on glue.

Fastening of expanded polystyrene plates with crate

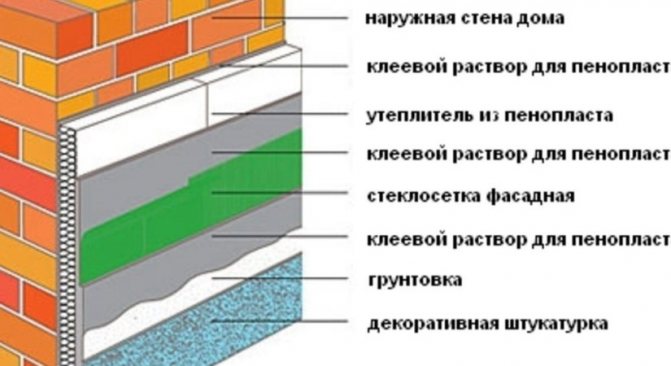

When insulating a wooden house with foam outside, the technology of creating ventilated facades has proven itself well.

The main stages of work:

- To create the lathing, vertically arranged boards are stuffed onto the insulated wall. To calculate the distance between them, you need to add the thickness of the rail to the width of the foam and reduce the resulting bag by 5 mm.

- A vapor barrier film (vapor barrier) is attached on top of the boards with a stapler.

- Rails are stuffed onto the vapor barrier with the help of nails. The distance between the slats should be slightly less than the width of the insulation.

- Expanded polystyrene plates are tightly installed between the slats.

- To seal the foam, use dowels in the form of a fungus. They are screwed in five places. The slots should be blown out with polyurethane foam, and after it dries, lay a diffusion membrane. It is she who removes excess moisture from the house. The smooth side of the membrane is attached to the wall to ensure proper air circulation. The joints are glued with any available adhesive tape.

- Finishing stage - exterior decoration.Most often, thin-layer plaster, siding or lining are used as materials. Their use makes it possible to increase the fire resistance of the walls.

Landing on glue

Foam insulation from the outside by gluing is carried out without creating a frame, the plates are attached to the walls themselves. The disadvantage of this method is the need to hide the joints of the plates and the caps of the dowels under the putty. Plus ─ no need to waste time creating the crate.

Installation procedure:

- For people without experience, it is better to start work on foam insulation from the less visible side of the house. First, stir the glue and leave for 5 minutes, then mix it again. For greater savings, cement mortar is used as the material for fastening. A starting profile is attached to the prepared wall in a horizontal position.

- Using a spatula, glue is applied in a thin strip along the entire perimeter of the slab, and then pointwise in several places in the center. After that, they are firmly pressed against the wall, checking the evenness with the help of a building level.

- If necessary, align with light pats of the hand or using other available means.

- The rows of expanded polystyrene should be laid horizontally, starting from the bottom, in a checkerboard pattern. Slabs are cut with a knife. Openings around windows and doors are lined with a layer of non-combustible insulation. It is advisable to cover the formed cracks with glue.

- After the glue has completely dried, which usually happens after 1-2 days, the insulation plates need to be fixed. To do this, use dowels, fungi. The corners also need to be strengthened by placing the perforated corner on the glue. There is no time to waste time with finishing work, because the foam loses its properties in the sun. Before starting work, the gaps between the plates are foamed. Polyurethane foam is chosen without toluene, because it is dangerous for the foam. The reinforcement mesh is glued to the wall with a small margin. The same is done with the next section.

- The surface is rubbed with sandpaper after 2-3 days, when the glue is dry, then finishing is carried out.

As you can see, foam as a heater for a wooden house outside has its pros and cons.

How to fix polystyrene foam to wooden walls at home

Insulation of the facade of a wooden house is carried out using frame technology. It is a construction of a frame in which the insulation is placed. All work is done in stages.

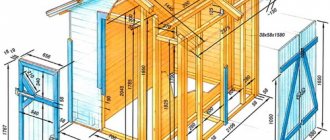

An example of a frame system for house insulation

How to choose Styrofoam

The thickness of the foam for ceiling insulation depends on the technology chosen. On the market, the thickness of the slabs varies from 20 to 100 mm:

- thickness of 100 mm is used for non-insulated attic spaces and roofs; thickness of 50 mm is used for both internal and external insulation of ceilings; thickness of 20-30 mm is used if there is external insulation of the roof and ceiling.

For insulation of the ceiling with foam, what thickness should it be? For external thermal insulation of ceilings, a thickness of 10 cm is optimal, for internal insulation - 4-5 cm.If an attic, which is used as an attic, is insulated, foam plastic with a thickness of no more than 5 cm is taken.

The most common sizes of slabs produced: 0.5 * 1 m, 2 * 1 m, 1 * 1 m. Styrofoam is well cut, and you can take any size, but it is more convenient and economical to use:

- for small rooms, apartments, balconies and loggias - option 0.5 * 1 m; for private houses - dimensions 1 * 1 m; for very large ceilings - 2 * 1 m.

Foam density characteristics for optimal selection:

- for external insulation - 25 kg / m3; for insulation of basement floors - 35 kg / m3; for internal insulation of residential premises, external insulation of non-capital and warehouse premises - 15 kg / m3.

For styling with your own hands, in addition to foam, you will need:

- dowels-umbrellas; glue mixture; perforator; drills; mixer and glue spatulas; building level.

The amount of material is calculated based on the ceiling area and 2-4% for waste.

Reasons for the formation of condensation

If, after insulation with foam, it drips from the ceiling, the thermal insulation is made of poor quality: the low surface temperature collides with steam and warm air rising upward, resulting in the formation of moisture droplets that settle on the coating.

Drops appear when steam cannot escape, and the higher the humidity in the room, the lower the dew point temperature. The formation of condensation leads to the appearance of mold and mildew, deterioration of thermal insulation.

The most common causes of condensation can be:

- ill-conceived ventilation design; lack of an insulating layer or its incomplete protection; improper arrangement of insulating layers; poor-quality insulation, which leads to freezing of the ceiling covering; with temperature changes resulting from different insulation in different areas.

Especially often, temperature drops can occur:

- in cellars on the ceiling; in freestanding garages and sheds; on balconies and loggias; in poorly ventilated rooms; when insulating roofs with a large angle of inclination, where waterproofing or insulation can roll down, forming cold areas.

If there is condensation, what can be done

If there are already flaws in the thermal insulation, the process of eliminating them is quite laborious:

- insulate the finished coating from the cold floor: insulate with mineral wool, cover with expanded clay, apply a layer of brick chips, lay down foam insulation; the condition of the insulation should be checked: disassemble the insulation cake and carefully investigate whether there are any breaks and damages, as well as whether there is water absorption; if moisture penetrated to the inner layers of the finish, you need to free the surface to the main ceiling (concrete surface), dry the ceiling using a construction hair dryer, then replace the insulation.

In order for the condensate to flow down, it is required to create an inclined surface on the horizontal surface of the ceiling. Depending on the location of the slope, a drain for water is adjusted with an outlet to the outside, under which a container is placed to collect water. Near single buildings, grooves are made through which water enters the soil.

For the device of an inclined condensate drain on the ceiling, you will need: polyethylene film material equal in size to the ceiling area, sheets of galvanized iron, plastic pipes.

Useful video

Next, in the video, let's see an example of insulation of the ceiling on the balcony and loggia with polystyrene foam with our own hands:

Thermal insulation of the ceiling ensures a comfortable temperature in the home and significant savings in heating costs. Considering that the cost of polystyrene is low, and the technology of its installation is simple, this is one of the best options.

(3estimates, average: 3,67of 5) Loading ...

In the article we will discuss the insulation of the ceiling with foam with our own hands: how is it done, what are the advantages and disadvantages of choosing this particular material for thermal insulation, and are there any alternatives. Let's figure out how you can use foam to insulate ceilings. How are ceilings insulated? If we discard too exotic options , there will be two main categories of materials for insulating ceilings from the inside: Mineral wool in all its forms. An inorganic fiber that does not emit any harmful substances and is very inexpensive. The main disadvantage of mineral wool is hygroscopicity.

Moreover, at high humidity, it significantly reduces its heat-insulating qualities. On the contrary, it does not require thorough hydro and vapor barrier; however, it is combustible and relatively expensive. In addition, he is often accused of emitting harmful substances into the atmosphere.

The situation is controversial and unprovable, so let's leave this point without comment. Properties of foam as insulation Actually, we have already outlined them in part.Let's dwell on the features of the material in a little more detail. Advantages Please note: in a wooden house, vapor barrier can be dispensed with only when the foam plates are laid without gaps: the seams between them are foamed or glued with adhesive tape. Moisture is harmful to both beams and rafters.

However, the sealing of the seams is also desirable from the point of view of minimal heat loss. Here, as you can see, the vapor barrier is made. And this is quite justified: it will protect the wood of the beams from moisture. Foam does not cake over time, unlike glass wool. It fully retains its thermal insulation qualities throughout the entire period of operation. With the same thickness of the insulation layer, foam is more effective than any mineral wool. Foam is more expensive than mineral wool.

With the same thickness, it is much more expensive. Adjusting it to the size of the finished sheathing is somewhat more difficult. However, if the insulation of the ceiling from the inside in a private house is performed from scratch, it is not a problem to make a crate in the width of the sheet. About fire safety it has already been said: foam is combustible. Disadvantages Nevertheless, when asked whether it is possible to insulate the ceiling in a private house with foam, the answer will definitely be positive. Can.

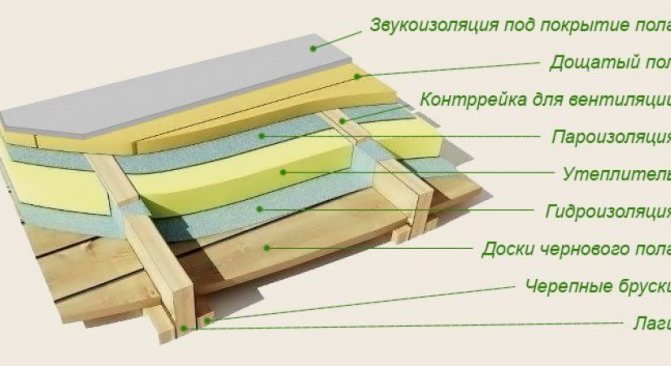

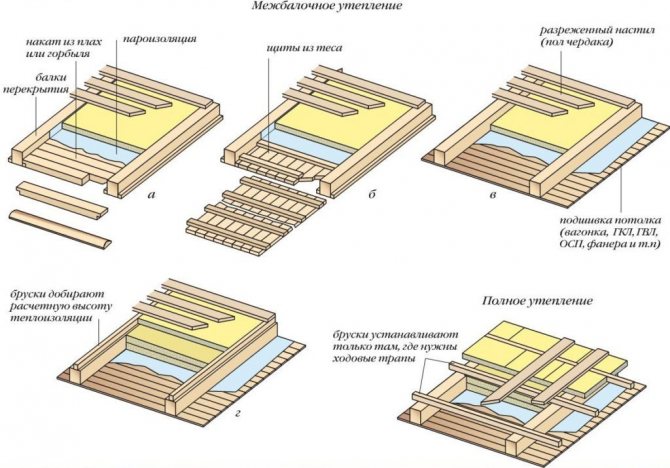

Moreover: if the cost of insulation does not bother, it will be the best choice. Insulation with foam is effective and durable. Methods of insulation How to insulate the ceiling with foam? Let's separately analyze several cases with different ceilings (see How to insulate a ceiling on a balcony with your own hands). Scenario 1 Given: a private house with a cold attic.

The ceiling is hemmed with plywood or OSB from below to the wooden beams. We put foam plates on top of the space between the beams with a minimum gap. Of course, after clearing this space of debris. The foam is placed in the space between the beams. Carefully foaming the seams between the plates and beams. There should be no gaps.

Otherwise, moisture will condense on the roof and cause the rafters to rot; in addition, gaps will indicate heat leakage. Do not forget: warm air tends upwards. If you plan to use an attic, we cover the ceiling with boards or OSB along the beams. Please note: if OSB is taken with a thickness of 15-18 millimeters, a distance between the lags of 40 centimeters is recommended. If the beams are less often, additional lathing will be needed. Scenario 2 Given: unplastered reinforced concrete floor without significant irregularities and differences in height.

How will the insulation of the ceiling look like foam (extruded polystyrene foam) or foam in this case? Let's start with the main thing. The ideal option in this case is to insulate the ceiling from above, not from below. Why? The dew point (condensation) in the case of insulation from the inside will be on the border between foam and concrete. If the tightness of the foam layer is broken, the concrete will begin to dampen and collapse (see.

Foam ceiling slabs - do-it-yourself professional ceiling decoration) Reinforced concrete floors are an excellent heat accumulator. After warming up, the walls and ceiling can provide a comfortable temperature in the house for several days, even when the heating is not turned on and it is cold outside. Having insulated from the inside, we lose this advantage. It is better to insulate a reinforced concrete floor from above. What to do if, for some reason, insulation from the outside is impossible? Foam plates are glued end-to-end directly to the concrete.

The choice of glue is great: a variety of liquid nails, universal synthetic adhesives (Titanium and its analogues), acrylic putty. If the ceiling is uneven and it is difficult to glue the foam firmly, special fasteners are used. The seams are carefully sealed. For this, polyurethane foam, and the same acrylic putty can be used. Outside, a reinforcing fiberglass mesh is glued.It will additionally bind the foam sheets and become the basis for applying decorative plaster.

The mesh strips are glued with a ten centimeter overlap and a layer of any decorative plaster is applied. It can be both smooth and structural - everything is in your hands. Scenario 3 What will it look like to insulate the ceiling with foam from the inside in a private house if there are reinforced concrete slabs overhead with significant differences in height or distortions? And again, for some reason, insulation from the outside is impossible (for example, there is an observation deck above your head)? We use a crate with a decorative ceiling lining with PVC wall panels for insulation. We mark and fix a galvanized profile crate for drywall to the ceiling.

The UD profile is attached in level to the wall, the CD profile is located perpendicular to the future panels at a distance equal to the width of the foam sheet - 50 centimeters. A step between the suspensions of 60-70 centimeters is quite enough: the ceiling will be light. The frame can also be made of wood. But then a layer of vapor barrier is desirable in order to protect the tree from moisture. We put a spacer between the profiles of the foam plate and seal all the seams with polyurethane foam. We sew with panels. The method of their installation has been described many times and does not present any problems. If the unevenness of the walls left noticeable gaps between the ceiling and the edges of the panels, we cover them with a ceiling plinth.

The ceiling is ready. PVC panels allow you to make the ceiling very neat with minimal costs. Conclusion Of course, we have described not all possible ways to insulate the ceiling with foam. However, now you understand the general principle of how thermal insulation is performed with this material, and you will be able to think through the technical details yourself. Good luck in the repair!

A very large percentage of losses occur through the ceiling of the upper floor in a non-insulated attic.

This is due to the fact that the heated air always moves upward. One of the most effective ways to prevent heat loss is to insulate the ceiling with foam. When used in a private house, insulation has many advantages.

Do-it-yourself attic ceiling decoration - we insulate with foam from the inside and outside

Insulation of a residential attic differs in that the foam plates are stacked between the rafters, as shown in the photo. It is best in this case to act before the roof appears, that is, to fasten the materials on top of the rafters. At first, it is recommended to lay a layer of vapor barrier - this way you protect the wooden rafters from condensation and decay. Then the foam itself is laid directly. It is recommended to lay a layer of waterproofing on top of it - although the material is not inclined to get wet, it is better to play it safe once again, because moisture can penetrate into the deeper layers of the insulating "pie".

If, for some reason, thermal insulation is laid from the inside of the attic, the process differs only in that the foam plates are adjusted to the distance between the rafters so that they fit tightly into this space, as the photo demonstrates. In this case, you can do without any glue. A vapor barrier is attached on top of the foam, and then you can start installing the final finish, for example, lining. It should be noted that the effective thickness of the insulation, both in the case of mineral wool and in the case of foam, should be at least 10 cm.It can be either two plates of 5 cm each, or one 10 cm thick.

Insulation of the apartment is possible only from the inside. If the ceiling is rough, then the slabs can be glued directly to the concrete joint to joint, as can be seen in the photo. The choice of adhesives is extremely large, ranging from liquid nails to polyurethane foam. Even regular PVA glue will do. However, if you are concerned about the strength of the fastening, it is best to combine special dowels with umbrellas (shown in the photo) and any glue of your choice.

It is important to seal up all the seams, for which you can use both putty and polyurethane foam. If a stretch ceiling is installed on top of the foam, you can leave it as it is. In the event that decorative plaster is applied to the surface, a reinforcing mesh is glued to the front side of the expanded polystyrene plates, which will provide a strong adhesion between the foam and the plaster layer, and will also bind all the plates together. Then it remains only to properly plaster the ceiling, but this is a completely different topic.

- Author: Mikhail Malofeev

Rate the article:

- 5

- 4

- 3

- 2

- 1

(1 vote, average: 1 out of 5)

Share with your friends!

Advantages and disadvantages of foam

The material is an accumulation of styrene balls with air inside.

Air and inert gases are the best insulation materials in the world. The more air in the material, the better its thermal insulation properties. The advantages of polystyrene (expanded polystyrene) include:

Table with the characteristics of foam

Low thermal conductivity. The main characteristic of a heat insulator is its ability to conduct heat. The lower it is, the warmer it will be in the room. The thermal conductivity of foam is about the same as that of mineral wool or extruded polystyrene foam. Low cost. Carrying out repairs or construction is always costly.

Polyfoam is an effective material that does not require large financial investments. Low weight. The mass of expanded polystyrene allows you to use it for insulating ceilings from the inside without any problems. The material adheres well to a horizontal surface. The smaller the mass of the insulation layer, the easier it is to fix it and the less likely it will fall off during operation.

The light weight for events in a private house also reduces the cost of material delivery. Simplicity of installation. The characteristics of the heat insulator allow even a non-professional to do the job. To insulate the ceiling with polystyrene, you do not need to make a lot of effort. Safety. When self-warming in a private house, it is important to ensure the safety of the work manufacturer and residents in the future. The structure of the foam is such that even when destroyed, it crumbles into sufficiently large balls.

They cannot harm a person. This distinguishes polystyrene favorably. for example, from mineral wool, when using which it is necessary to use masks and gloves.

Dimensions of material for insulation

The positive qualities of the foam allowed it to firmly establish itself in the building materials market. But it has its own characteristics and limitations. Insulation with expanded polystyrene has the following disadvantages:

Styrene balls do not absorb water, so the foam has a rather low degree of water absorption.

The difficulty lies in the fact that water can get into the space between the balls. Under normal conditions this is not a problem, but if the ambient temperature drops, damage will occur. The bond between styrene balls is not very strong.

When water turns into ice, it expands, affecting individual particles of the material. With the simultaneous action of water and cold, the foam simply crumbles. Low fire safety. Polystyrene is not resistant to high temperatures.

Now manufacturers are introducing special additives into the composition that make polystyrene a low-combustible material, but the problem remains. Low strength. This drawback is important for floor insulation. For installation on the ceiling from the inside of the room, it is not necessary to use durable materials; weight becomes a more important factor here. Thermal insulation from the side of the attic with foam is also possible, but due to its strength, it is placed between the logs or under a strong reinforced cement screed. Unnatural origin. This is also more a feature than a disadvantage.

Insulation materials of natural origin, such as sawdust or expanded clay, have low efficiency. Another type of natural insulation is ecowool. The material is effective, expensive. The last two points are not serious drawbacks when insulating the ceiling in a private house, so we can say that the foam proved to be an excellent heat insulator with a score of 5: 2.

Fastening the foam to the ceiling

The low weight of the insulation does not require complex work to attach it to the ceiling surface. You can use simple cement-based glue: it is available in any hardware store and is cheap.

There is one trick for saving glue. It can be applied in the corners and in the center of each side. The consumption of the adhesive will decrease, but this will not affect the quality of the fastening. There is an option to use special glue for foam, but it has a high cost. In terms of characteristics and quality, it is not inferior to the above material.

Styrofoam slabs are easy to cut: a simple painting knife is enough for this

There are several points to consider when choosing an adhesive:

- the packaging must indicate that the composition is applicable for the installation of polystyrene foam plates;

- There are two types of adhesives: for gluing boards and for gluing boards and a protective layer. The first option is the cheapest and is used only for the installation of foam. The second option is more expensive, but suitable for the installation of reinforcing mesh.

The consumption of glue depends on the ceiling surface: the more equal it is, the lower the consumption. The experience of numerous builders shows that the average consumption is 5 kilograms of composition per square meter.

Warming methods

When insulating in a private house, it is recommended to insulate the ceiling of the upper floor from the attic side

Do-it-yourself foam insulation of the ceiling can be carried out from the outside and from the inside. The cold air side option provides more efficiency and is scientifically correct. When insulating in a private house, it is best to insulate the ceiling of the upper floor from the attic side.

This method is difficult if insulation is carried out in an apartment building. In this case, insulation from the inside is practically the only possible option. Insulation in the apartment is carried out not only to protect it from the cold, but also from noisy neighbors.

If you insulate the ceiling with foam from the inside, you can significantly reduce the noise level and create favorable conditions for relaxation.

As mentioned earlier, the combination of water and polystyrene is undesirable, therefore, when laying, two additional layers are provided: from the cold air side - waterproofing, and from the inside of the room - vapor barrier.

The procedure for carrying out work with insulation from the attic side:

- clearing the surface of debris, dust and dirt; if necessary, leveling; vapor barrier; laying logs (if needed); laying foam (it is necessary to provide a small gap between the insulation plates or between the insulation and the logs, the foam expands slightly after laying); waterproofing; filling the screed (for the method without logs) with laying of wire reinforcement with a diameter of 3-4 mm; clean floor.

Installation of the frame on the ceiling Fastening the sheets to the ceiling Vapor barrier of the insulated ceiling

The last point is an optional step. You can leave a cement screed as a floor covering in the attic.

Thermal insulation of the ceiling in a private house from the inside is performed in the following order:

- cleaning the ceiling; installation of the frame (wooden or aluminum profile, the stage is not necessary); fixing the foam sheets; vapor barrier; ceiling sheathing.

Thermal insulation methods for wooden ceiling structures

Numerous technologies for insulating ceilings in wooden houses are divided into two groups according to the place of installation of the insulation:

- from the side of residential premises (from the inside);

- from the side of the attic (outside).

Both approaches have their advantages and disadvantages.So, insulation of the ceiling in a wooden house from the inside will save money, but will reduce the useful volume of living quarters, and insulation laid outside will require additional protection from mechanical damage and more powerful hydro and vapor barrier, which will entail an increase in insulation costs.

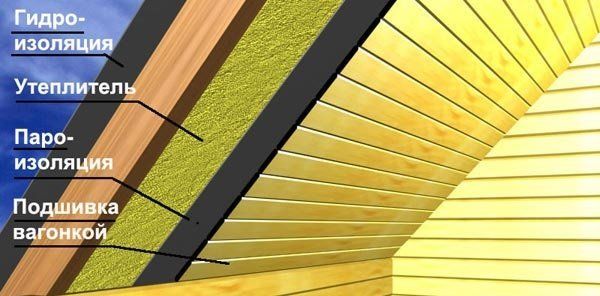

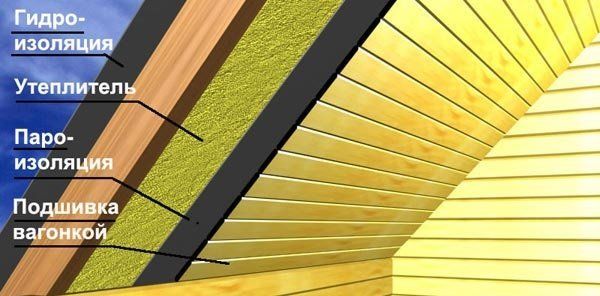

In the classic version, the thermal insulation layer has the following structure:

- external vapor barrier;

- insulation material;

- lathing;

- internal vapor barrier;

- sheathing.