The foundation device in the house on screw piles is a kind of construction

Residential buildings installed on pile support elements do not have a basement or basement level. But they have an underground, blown from all sides by the winds. Such buildings are usually erected on marshy ground. In this regard, the space under them is always characterized by a fairly high level of humidity.

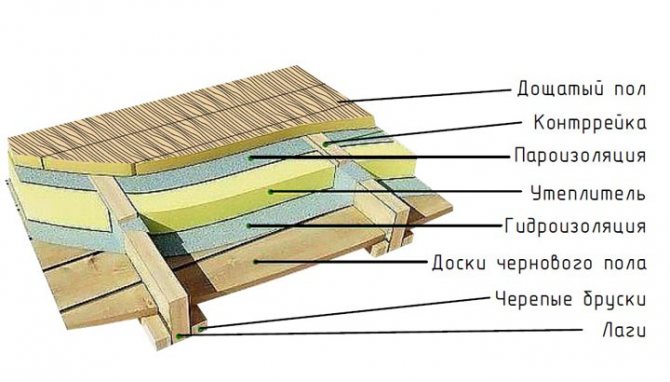

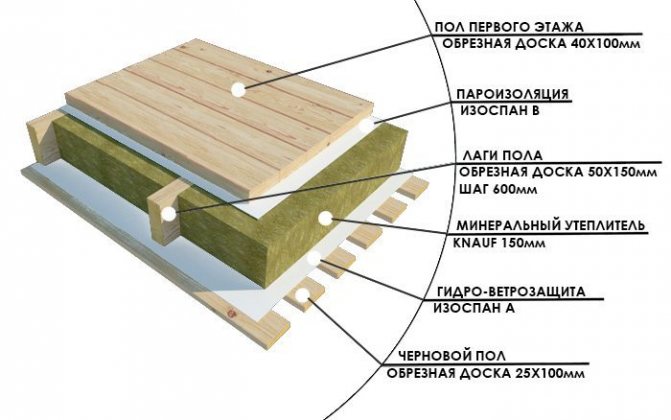

In order for the house on screw piles to be operated for a long time and not be subjected to the harmful effects of natural factors, its floor covering is arranged in several layers:

- Wooden supporting skeleton. It must be built with a subfloor.

- Windproof (vapor permeable). It is necessary to protect the used heat-insulating material from weathering.

- Directly heat insulator.

- Moisture and vapor barrier layers.

- A clean floor covered with planks.

Floor covering of a house on screw piles

The floor base for a dwelling on screw piles is erected in this way. At the same time, the performance characteristics of thermal insulation materials for such buildings should be as high as possible. It is also recommended to use high-quality steam and waterproofing products that reliably protect rooms in a wooden house on piles from moisture. If the owner of a structure on a pile foundation does not perform high-quality insulation of the floor in his home, during the operation of the building he will face the following serious problems:

- an increase in heating costs due to a decrease (and significant) in the energy efficiency of the building;

- the presence of condensation over the technical underground (directly on the surface of the floor base);

- the appearance of fungus, mold, rotting of the wooden elements of the building, caused by constant high humidity.

It is enough to competently insulate the floor in the house on a pile foundation once and forget about all these troubles forever.

Screw piles

The pile foundation is arranged when the ground is weak or we observe a high level of groundwater. It is used with a significant difference in height. But often people choose a pile foundation simply for the sake of economy and ease of installation.

Screw piles for the foundation.

Screw piles are metal pipes with a screw at the end. Such piles are inexpensive and are quickly installed mechanically by a professional team or manually by a team of guest workers.

An adjustable headrest is put on top of each pile, if the house is supposed to be made of a bar or to put a log house. If a part of the house collapses, you can correct the position by adjusting the headrest.

Adjustable head for screw piles.

If the house is supposed to be built from panels, a frame is welded on top of the piles, on which all supporting structures will rest.

The frame on which the entire structure of the frame house will be based.

The foundation on screw piles has both its pros and cons.

The pluses include:

- low cost of construction;

- fast erection;

- reliability of the foundation with high groundwater;

- the device of a cheap foundation with a significant difference in height;

- low delivery costs.

Better to choose galvanized piles. Although these piles are more expensive, they are more resistant to corrosion and will last longer. Non-galvanized piles can rot after 15 years and you will need to repair the foundation.

Cons of the pile foundation:

- cold underground;

- possible swelling of soil, pushing piles that fall into the freezing zone;

- possible draft at home;

- pile corrosion.

The main problem with pile foundations is the cold underground. The underground is cold due to the fact that the ceiling is raised above the ground and there is free space under it.

Often builders leave the basement open until "better times", because there is not enough money and time to insulate it. It is more important to finish building the house first, carry out heating there, and carry out interior decoration.

There are several techniques for insulating the ground floor floor:

- insulate the floor from below under the house;

- insulate the base;

- make a warm floor.

Each of these methods can be used for insulation.

https://youtu.be/1gisQSMN2OU

How to make insulation - selection of a suitable material

In principle, it is allowed to produce thermal insulation of the floor of a pile structure with different products. The main thing is that they are suitable for use in wet conditions. From the point of view of specialists, it is most rational to carry out floor insulation in a house on piles with the following materials:

- Styrofoam. It provides high-quality thermal protection. But you need to take into account the fact that at high humidity and low temperatures, the foam is capable of breaking down into separate small pieces. If you decide to perform thermal insulation with this particular material, take care of its effective protection from moisture.

- Minwatoy. It is not afraid of biological influences, is characterized by very good heat-shielding performance, and is a non-combustible material. True, when moisture (even a small amount) penetrates into the cotton wool, its unique protective properties are lost. Floor insulation can be carried out with any kind of mineral wool - slag, glass or stone. Such a heat insulator is produced in plates and rolls. It is advisable to use mineral wool in the form of slabs (it is characterized by a higher density compared to roll material).

- Penoplex - expanded polystyrene made by extrusion. It has a low moisture absorption rate and increased strength. These characteristics set it apart for the better from the cheaper, but also less reliable foam.

Often, buildings on screw piles are insulated with expanded clay. It is easy to use, which is important for home craftsmen who are engaged in independent repair work without the involvement of specialists, it is not subject to combustion and has a low cost. But in terms of heat-shielding characteristics, expanded clay is inferior to all the previously mentioned materials.

Thermal insulation of the floor with expanded clay

It is recommended to use modern vapor-permeable moisture-windproof membranes as wind and waterproof products for the floors of structures on a pile foundation. They are quick and easy to fit, but the price of such multifunctional products can bite. Important! All elements of a wooden house on piles should be treated with compounds with special antiseptic properties.

And don't forget the vapor barrier. As such, a simple polyethylene film is quite suitable. It is laid directly on the layer of thermal insulation material.

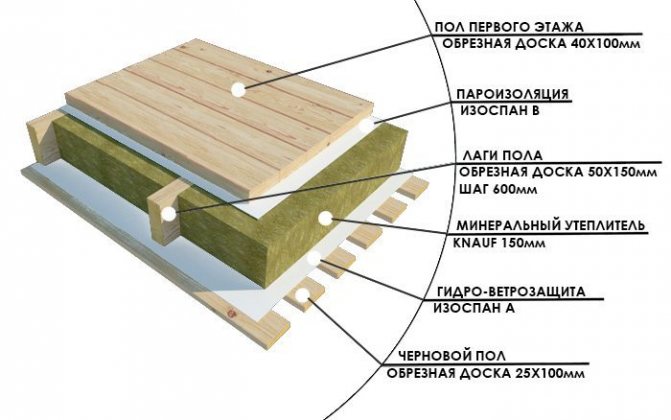

Types of log floors and methods of laying them

Wooden single layer floor

Wooden floors in a log house are distinguished by design: single-layer and double-layer. Single-layer floors can be installed with or without joists. It directly depends on the massiveness of the boards and the interbeam step. The floor in a house with a foundation on the logs of the boards is laid on beams, taking into account the distance between the blocks not more than 0.6 m.

Wooden two-layer log floor

When laying a two-layer wooden floor, add a sub-floor layer while attaching the beams to the rough boards from below. On these beams, a layer is laid for insulation: sheet, expanded clay no higher than 8 cm.

Do I need to insulate the floor? Warming of floors in log cabins must be carried out in any case. This rule also applies to houses made of other materials.

Rough floor

Before you start laying the floor in a log house, you need to take care of ventilation between the layers in order to avoid decay of the boards. High humidity is the main enemy of wood.

Subfloors provide good ventilation and add durability to log floors. They resemble a rigid frame that supports the entire structure.

They have a waterproofing function, create an additional layer of air that retains heat in the room, prevents putrefactive processes. For laying the subfloor in a log house, an uncut board with a width of 15 to 50 cm, impregnated with antiseptic substances, is used.

To do this, you can make holes in the corner joints of the house, measuring 5 - 6 cm.

Then they need to be closed with ventilation grilles. You can also make such holes in skirting boards.

The next stage in laying the floor in a log house will be waterproofing the base. This can be done using a blind area, using roofing material, and waterproofing materials. Lags, lower rims with antiseptics or recycled engine oil converge.

In accepting subfloors as the foundation of a surface, builders are somewhat mistaken. Often, the foundations are made using chipboard, plywood and other boards for construction, which are laid on logs.

Such substrates are used for the purpose of leveling the surface of the foundation, for laying the floor covering horizontally, as well as distributing a uniform load on the floors.

The easiest way to lay the floor is to install it on cranial blocks, followed by the laying of insulation, material for waterproofing and vapor barrier.

Mineral wool is the best material for insulating a floor in a log house.

After the vapor barrier layer has been laid, you can start laying the finished floor. To do this, use a grooved board, as well as chipboard. Next, the turn for the selected flooring. This is at the discretion of the owner of the house.

When laying the floor, it is very important to remember that the temperature difference between the rooms and the floor cannot exceed 2 º С, therefore its insulation is a very important moment of work. In any case, walking on a cold floor is not very pleasant, especially during the cold season.

For waterproofing, take: isoplast, roofing material, polyethylene film, PVC membranes. When the materials for insulation are selected, you can start laying the floor in a log house on logs.

Finishing floor

A fairly affordable and high-quality material for laying a finished floor is a milled board. The modern building materials market offers developers boards that have spikes in the grooves for connection. Their size is 28 - 44 x 98 - 145 mm. The dimensions of the vents on the back side are 20 mm. Air is needed for the natural circulation of air.

Also, for the finished floor, seamed boards with tongue-and-groove slats, sectional, trapezoidal and straight spikes are used. The disadvantage of this material is that it has no air. Therefore, it is necessary to control their contact on the lags. After finishing the flooring of the finished floor, you can start finishing.

Planks should be laid with an orientation to tree growth rings, which should "look" to different sides.

Concrete floors in a log house

Concrete flooring technology is quite simple.

To do this, it is necessary to knead the concrete screed in the correct proportions, supplementing it with reinforcement.

The indisputable advantages of concrete floors in a log house are strength, quality factor and durability.

To improve the performance of concrete, self-leveling mixtures can be used.

On such a floor, you can lay any covering, and laminate, and linoleum, and porcelain stoneware, and wonderful quartz vinyl tiles, with which there is no hassle at all.

The concrete floor is laid in two ways: on logs and on the ground. We have already considered the option of laying on logs. Now let's decide on the features of laying on the ground.

First you need to determine the level of the floor in the house made of timber, mark it with a rope and a peg. The concrete foundation can be poured to a level of up to 10 cm, then it is covered with gravel at the level of the hammered peg and tamped down. The concrete floor is left to dry for a period of about 3 months. Further, a mounting screed or liquid concrete is applied to the foundation.

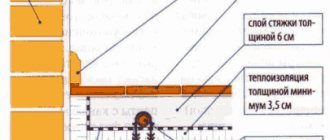

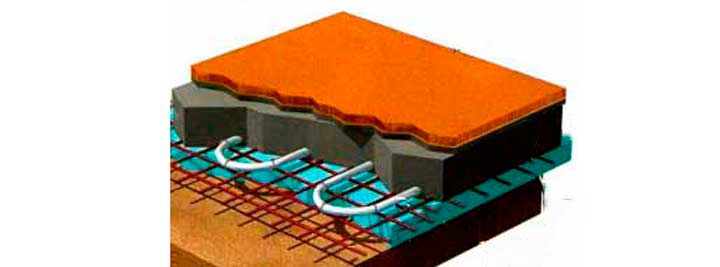

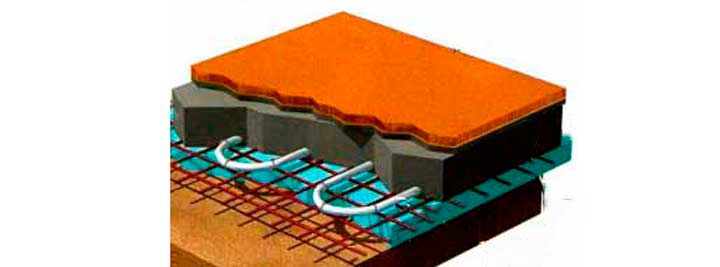

Water floors in a log house

Laying a water floor in a log house must be laid in a concrete screed.

Construction of the water floor in the house:

- thermal insulation layer 20 - 100 mm;

- concrete foundation on the ground;

- reinforcement mesh;

- a pipe of the heating system, which is attached with clamps to the cells of the fittings (step 10 - 30 cm);

- flooring underlay;

- floor covering to choose from.

A water floor is simply irreplaceable for a bathroom or a nursery.

Electric underfloor heating in a log house

Conducting an electric underfloor heating in a wooden house is quite a simple task. It can be mounted on logs and on a screed, as it is convenient for anyone.

The installation technology of such a floor is similar to that of a water floor. If the floor is installed on logs, then it is necessary to create an air layer. The cable is distributed over the fittings, gaps are made in the logs with a height of 5 cm, with a distance between each of 5 cm. The gaps are insulated with foil, the heating cable is pulled in these spaces, crossing the logs according to the principle of a reinforcing mesh made of metal.

We arrange a protected base in a house on stilts - instructions

First you need to make a rough floor. Its device is simple - you nail a wooden beam, which is called cranial, to the logs. It will act as a support for the floorboards. Be sure to treat all used items with an antiseptic. Then lay the planks onto the flooring. When using polystyrene or expanded polystyrene, it is allowed to mount a special mesh instead of the subfloor. It must be properly attached to the logs so that it can withstand the weight of the insulation used without any problems.

Rough floor in the house

In general, one must constantly remember that it is impossible to overload the piles with excess weight. After arranging the subfloor, lay a vapor barrier on it. All moisture from the atmosphere must remain outside without getting on the heat-shielding material. This part of the vapor barrier can be made of polyethylene film or roofing material. Then you put the insulation, and on top of it another layer of the vapor barrier. It will protect the cake from condensation and internal moisture.

When installing heat and vapor insulation, do not leave gaps between the individual elements of the materials used. This is fraught with the formation of cold bridges. They are very dangerous for insulation, as they quickly destroy it during operation. Now feel free to equip a clean floor in the house, using chipboards, plywood sheets, floorboards and other products for this purpose. Pro tip! Be sure to cover the piles with a warm, stationary plinth. Then snow will not fall under the house. If there is no desire or opportunity to make a warm structure, close the supporting elements with an inexpensive and quick-to-install decorative plinth.

We equip the rough floor

To do this, the so-called lags are nailed to the lags. cranial bar that supports the floorboards. Each structural element must be pre-treated with a special antiseptic to prevent wood from rotting. Many people make the mistake of "plugging" the tree, i.e. covering it with bituminous mastic. Having lost the ability to "breathe", natural material deteriorates even faster.

When arranging a subfloor, you need to decide in advance on the type of insulation, since its weight is decisive for determining the calculation of the strength of the structure.For example, the use of lightweight mineral wool allows you to make the flooring from sheet materials (for example, the same plywood). When using rigid insulators - foam, expanded polystyrene - it is better to replace the subfloor with a mesh.

Of course, the strength of the screw foundation is always calculated with a margin, but still it should not be unnecessarily overloaded. The lighter the insulating materials and the higher thermal conductivity they have, the better.

How to make a plinth - choose your option

When installing a house on a pile foundation, there is no basement in the structure of the structure. It, as it was said, must be done. Often, instead of a full-fledged basement, its decorative imitation is erected - a pick-up. It perfectly protects the underground from snow drifts and wind. To perform such an operation, you can use one of two methods:

- Rubble or brickwork. Such a pick-up is built in half a brick. The first row of stones is laid on a sand cushion (it needs to be compacted very well). The pick-up is waterproofed using roofing material.

- Frame imitation of the base. This technology makes it possible to build an analogue of a ventilated facade. It is very economical and fast in execution. The frame is erected by installing galvanized profile battens or wooden beams directly on piles. Then this structure is sheathed with roofing material, and PVC sheets under a brick or stone are attached on top. Polyvinyl chloride products should be fixed with nails (if the crate is made of wood) or universal screws (metal profile).

Frame imitation of a plinth

Zabirka makes it possible to reduce the consumption of insulation: it can be laid in a thinner layer. May it always be dry and warm in your house!

Why insulate floors?

Scheme of standard insulation of a wooden floor on logs

When erecting a frame house on complex soils, a pile foundation made of various structural materials is most often used. All supporting structures are supported by a grillage mounted on the pile heads. Moreover, the grillage can be buried or raised above the surface of the earth, but in either case, when building a house on a pile foundation, there is no basement in it and additional measures are required for high-quality insulation of both closed and ventilated underground space.

For your information: The experience of operating frame-panel and frame houses shows that poor-quality floor insulation leads not only to an increase in heating costs, but also practically halves the service life of the subfloor, leads to the appearance of fungus, putrefactive bacteria that have a negative effect on the human body ...

In order to make the correct insulation "cake" for the floors of a frame house, it is not enough just to lay the insulation on the underlying surface of the subfloor. At a minimum, a heat engineering calculation should be performed, which takes into account multiple parameters:

- Minimum and maximum ambient temperature and humidity according to the seasons of the year;

- Composition and characteristics of the soil;

- Acceptable indoor temperature;

- Coefficient of thermal insulation of structural materials of the rough and final floor;

- Thermal conductivity of walls and other enclosing structures;

- Features of the used construction materials;

To make a high-quality calculation of the heat-insulating circuit, in most cases only specialists, and highly qualified, can do the installation work, but the installation work can be done with high quality and with your own hands, "while killing two birds with one stone." Firstly, significant cost savings are obtained, and secondly, confidence in the high-quality performance of hidden work, which cannot be controlled without disassembling the finished coating.

Insulation of floors in a frame house on a pile foundation

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Pile foundations have gained massive popularity due to the relatively low price and the possibility of using them with poor soil characteristics. Such structures are quickly assembled and can be used for almost any type of structure. Thermal insulation of the floor pie in a frame house on piles has its own characteristics, which must be taken into account in order to avoid problems during further operation.

Materials used for insulation and features of their application

In order to insulate a wooden house on stilts, various insulation materials can be used. The most popular option for the production of work is the laying of mineral wool. Since this material does not have a sufficient level of moisture resistance, you should definitely take care of its reliable protection with the help of competently executed steam and waterproofing.

Quite often, foam is used to insulate the floor of a wooden house. This material has serious performance characteristics, however, it has a significant drawback, as it is combustible. Nevertheless, it is widely used in private housing construction.

In recent years, modern and progressive heaters have been rapidly gaining popularity, the number of which on the market is constantly increasing. These include penofol, penoplex and other similar materials. Their use allows you to achieve an impressive effect even with a small thickness of insulation.

As a budget option for insulation, such traditional material as expanded clay is usually considered. Its main advantages are well known - low price and availability. Obviously, in some cases, the financial criterion turns out to be decisive.

I made my choice in favor of the pile-screw foundation quite quickly. Of course, I had to study some literature, but the main argument was the choice of neighbors in our summer cottage village. And most of them settled on this technology. Our soils are porous, saturated with moisture (the river is nearby), the relief is uneven, so piles are a technically justified option. And taking into account the savings in time and money, it is also very profitable.

Building design features

When erecting a building on screw piles, it is necessary to take into account that the house does not have a basement or basement, but there is a ventilated underground. Such foundations are used mainly in swampy areas, therefore, the increased humidity of the space under the house will become another important factor during operation.

When building a house on screw foundations, it is important to pay great attention to the performance characteristics of the insulation and additional layers.

Waterproofing and vapor barrier will become reliable protection of heat-insulating material and internal premises from high humidity, neglect of which will soon lead to serious problems.

The composition of the floor of a frame house

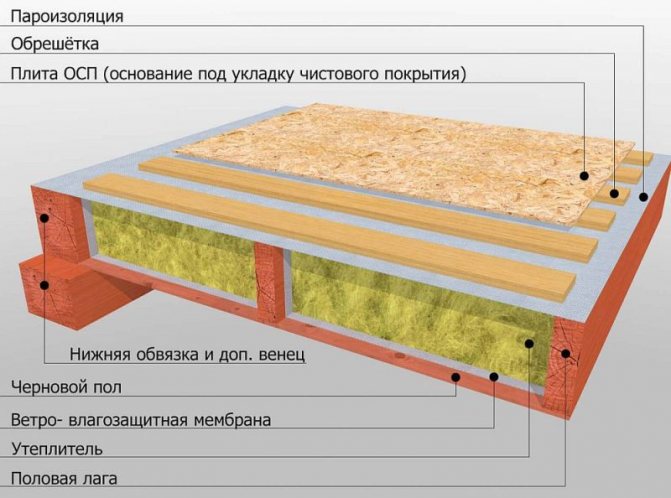

To erect a floor over a ventilated space, you need to lay the layers in the following order:

- load-bearing wooden frame (with a sub-floor, “bearing” insulation);

- a layer of vapor-permeable wind protection (to protect the insulation from "weathering");

- thermal insulation material;

- steam and waterproofing;

- construction of a clean floor (board + finish floor).

Floor insulation scheme for a house on piles

All materials for a building on screw foundations must be laid in this order. Some sources give an erroneous installation of the vapor barrier from the cold air side, but this does not make sense. Steam is generated in a warm room and settles on colder surfaces, thus forming condensation.In order to prevent the penetration of condensate into the thermal insulation layer and to reduce the degree of protection of the building from cold, vapor barrier is provided.

Why is insulation necessary

The need for heat-insulating material is not always clear to a person who is far from construction. From the point of view of the future home owner, it is much easier to build on the load-bearing capacity of the structure.

Neglect of thermal insulation standards can lead to the following problems during the operation of the building:

- condensation on the floor surface on the technical underground;

- reduced energy efficiency of the building and increased heating costs;

- high humidity leads to decay of wood, the appearance of mold and mildew, as a result of which wooden structures quickly fail and require expensive repairs.

Insulation of the floor in a frame house allows you to avoid these troubles and ensure a long service life of the building and all its structures separately.

Insulation materials

Attention should be paid not only to the insulation material, but also to vapor barrier, waterproofing and wind protection.

The choice of insulation

Various materials can be used as an insulating layer. It is important to consider the possibility of operation in high humidity conditions. The most rational solutions are the following options:

Mineral wool insulation. Minvata has a lot of advantages, including incombustibility, high thermal insulation characteristics. Not subject to biological influences. The disadvantages include the fact that if water gets on the material, it sags and loses its properties. Compared to other types, this insulation has a fairly high cost. Mineral wool is available in rolls and slabs. For the floor of a house on screw foundations, it is better to use slab insulation, since it has greater rigidity. Depending on the type of raw materials, stone, glass and slag wool are distinguished. It is important that when working with material, builders need to have protective equipment: overalls, gloves, a mask.

Styrofoam attractive in price and has good thermal protection characteristics. It is worth considering that when exposed to low temperatures and high humidity, it can crumble into small balls. Such damage leads to a violation of the thermal protection of the building. If foam is used, it is important to protect it most carefully against moisture penetration.

Extruded polystyrene foam (known to everyone as "Penoplex") looks very similar to polystyrene, but is devoid of its main disadvantages. The material has higher strength and low water absorption. Thanks to this, there is no need to fear for its destruction at low temperatures. In addition, extruded polystyrene foam is produced with special additives that allow it to fall into the group of non-combustible materials. The heat-shielding characteristics of these three materials are almost identical.

As another cheap option for warming the floor of a house on screw piles, you can cite expanded clay... It is inferior in terms of thermal insulation performance to all other materials, but it is affordable. It is non-flammable and easy to work with. It is a round shaped transverse clay particle.

Selection of related materials

The next step is to choose waterproofing and wind protection... Modern manufacturers produce materials that combine both of these functions at once. The structure of the ceiling in a house on screw piles is somewhat reminiscent of an inverted mansard roof pie, for the construction of which builders often use moisture-proof and vapor-permeable membranes. This multifunctional material saves styling time.

Materials for insulating floors and underfloor space

You can make high-quality insulation of floors in a frame house on a pile foundation using a variety of heat-insulating materials:

Mineral wool insulation

When moisture enters the surface, mineral wool does not collapse, but loses its thermal insulation properties. Depending on the raw materials used in the production of mineral wool, the raw materials are divided into stone slag and glass wool, which differ somewhat in their thermal insulation characteristics and physical properties. Available in slabs and rolls. Absolutely does not burn and does not emit harmful chemicals.

When moisture enters the surface, mineral wool does not collapse, but it loses its thermal insulation properties and, depending on the raw material, can change its geometric dimensions. It is presented in the form of slabs and rolls, and the tile material has a high density and can be coated with finishing and adhesive materials using wet technologies. Rolled varieties have a lower specific weight and are intended for use on vertical wall surfaces and for thermal insulation of ceilings. Prevents the dispersal of rodents.

When working with mineral wool, it is imperative to use protective equipment. The stacking technology allows you to perform work with a limited number of workers or with your own hands, which neutralizes the high cost of insulation;

Warm floors in the garage

Expanded polystyrene and polyurethane foam

Untreated polystyrene foam is highly flammable and burns with the release of a large amount of harmful substances

Expanded polystyrene is a fairly common insulation used for external and internal insulation of walls, floors, attics and metal structures. It has low moisture absorption and a service life of at least 60 years at temperatures from -40 to +50 degrees.

Untreated polystyrene foam is highly flammable and burns with the release of a large amount of harmful substances. Building structures are insulated with polystyrene foam, foamed with carbon dioxide and additionally treated with antipyrine, which you should pay attention to when buying insulation. When insulating with expanded polystyrene, it should be remembered that the material promotes the resettlement of insects and rodents, which requires additional measures to protect the structure. Extrusion polystyrene foam is also used as a heater for foundations, floors and walls, the manufacturing technology of which provides a material with a microporous closed structure.

An example of applying polyurethane foam to a floor surface

The material has a higher strength, is less susceptible to destruction by rodents, but has less vapor permeability, which requires additional ventilation of the internal space. It is indispensable in the manufacture of floating underfloor heating with a lightweight concrete screed with the installation of heating elements of any type. The polyurethane foam used as a heater differs from polystyrene foam not only in material, but also in manufacturing technology. Slab polyurethane foam varieties are used for a small amount of work, performed mainly by hand, but when insulating significant construction volumes, work is performed right on the spot using special equipment, as shown in the video.

Foamed polyethylene

As one of the layers of the insulation cake of the floors and walls of the frame house, especially in the places where heating devices are installed, foamed polyethylene foam, Penofol, is used, which creates reliable steam, wind and moisture protection.When insulating the surfaces of a frame house with Penofol, an additional screen is created of chemically pure aluminum that reflects infrared radiation, which is shown in sufficient detail in the video.

When insulating a building with Penofol, an additional radiation barrier is created, which has a positive effect on the internal microclimate. The material is produced in rolls with various thicknesses, one-sided or double-sided foiling and the presence of an adhesive layer. When working with Penofol, special skills and protective equipment are not required, and all operations are easily performed by hand;

Cellulose based insulation

To insulate the closed cavities of frame walls, floors and interfloor floors, cellulose insulation based on paper waste is used. The material practically does not burn, is not subject to decay, is vapor-permeable, which has a positive effect on the durability of especially wooden frames. It is not afraid of water, as is the case with mineral wool, without letting moisture into the depths and easily giving it to the surrounding air without losing its insulating properties.

Do-it-yourself floor insulation in the country or in a private house

Ecowool is produced on modern equipment, as shown in the video, but it can be made in small volumes and independently.

The most commonly used dry and wet mechanized paving technology. Insulation with cellulose wool is performed using special equipment, when the material is "blown" into building structures, ensuring reliable filling of voids and high quality insulation.

Insulation of the floor in a frame house on piles

A significant difference between houses on pillars or piles from houses on slab and strip foundations is that with a large distance from the ground, the floors in them cannot be poured monolithically, but will always have a frame structure. At the same time, there is absolutely no difference what the outer walls are made of: from bricks, blocks, timber, or they are made in the form of a sandwich using frame-sheathing technology.

Multilayer walls have almost the same structure in common with the floor - the only difference is that floor insulation in a frame house on piles can be performed using more materials. What these materials are and how to use them correctly, we will tell you in this article.

A house on stilts can be placed on any soil and relief

Finishing floor: a variety of choices

For the finished floor, you can use any materials: from chipboard and laminate to floorboards. Since my house was built of wooden beams, of course, I wanted to use only natural materials for decoration. Therefore, I chose a pine board - inexpensive, environmentally friendly, moreover, it allows you to maintain the same style of both the architecture of the building and the interior. And the smell ... Those who are lucky enough to live in a wooden house will understand me!

And for those who choose a different finish for the finished floor, one last tip: do not forget that each material requires appropriate preparation, including different soundproofing pads and the distance between them. This also affects the quality of the insulation.

And, of course, my wish: may your house be light, cozy, and most importantly - warm! Both in the literal and figurative sense of the word!

Why don't I use a wind and moisture protection film in the lower floor of a frame house on piles or on tape? This question comes up quite often. Let's talk about the bottom floor pie in general and VVZ film / membrane in particular.

Features of floors supported by a grillage

Point foundations, which include piles, are good because they allow you to put a house on rough terrain without special costs for earthwork, make it possible to get a reliable foundation in areas with weak soil or close to the position of groundwater. They can be pipe-monolithic, driven reinforced concrete, but in private construction, metal screw piles are usually used.

In order to be able to support the walls, a channel with a wide shelf is welded along their axes to the heads (if masonry is being carried out), or they simply make a wooden strapping if the house is timber or frame.

Wooden grillage on metal screw piles Strapping beams are attached to the grillage, and to them - the racks of the wall frame

But in a frame house, for example, a brick cladding may be provided, therefore a metal grillage, which will serve as the basis for the floor, can also be provided for it (read about the construction of a foundation with a grillage in the article).

Insulation materials and their properties

The floor, like the outer walls, is a building envelope, as it separates the warm rooms of the house from the ground. Accordingly, it is also subject to the rules on the need to lay effective thermal insulation, protected by anti-diffusion layers.

Basic insulation scheme

Unlike vertical structures, not only rolled mats or slabs can be used to insulate the floor, but also loose or loose materials (the methods of insulating a frame house are described in detail in our article). You just need to remember that they should be light, since the structure does not have the ability to lean on the ground. Therefore, such a rather weighty material as expanded clay cannot be used in this case.

And what can you do? We hope that the next chapter will help you in choosing the right insulation.

Plates and cut mats

The use of rolled soft insulation or more rigid rectangular blocks is a traditional option for floor insulation.

Variety of materials

These materials include:

- Mineral wool (GOST 4640-2011), produced either from the melt of gabbro-basalt rocks, or from volcanic or metallurgical slags. The advantage of these wool is not only in the coefficient of thermal conductivity necessary for this design, but also in almost absolute incombustibility. According to the standard, the temperature limit for them ranges from -180 to + 700 degrees (read about the insulation of a frame house with mineral wool in the article).

- Foam plastics (GOST 15588-2014). Under this term, slabs of foamed plastics can be hidden, two types of which are actively used in construction. One is polystyrene and the other is polyurethane. The latter is also molded into slabs, but due to the higher price in this form, it is less popular among the people. If it is used, it is more often in the form of foam, but expanded polystyrene is in great demand. PPS plates are of three types: the cheapest type "P", which is cut from one large block, has a pronounced granular structure, and "T", formed by pneumatic, vacuum or combined methods. Both options can contain graphite, which is added to improve thermal insulation performance.

- Ecowool (GOST 16381-77). This term is usually called cellulose insulation containing fire retardant and biocidal additives, but according to the standard, by the type of raw materials used, ecowool may differ. That is, they can be made not only from inorganic substances, but also from organic matter or their combination. So do not rely on the absolute environmental friendliness of this material, which is so promoted by its sellers. However, it is quite suitable for floor insulation, especially if it is not loose cotton wool, which can lose volume, but slabs or mats.

Installation of insulation and features of its protection

When installing slab insulation, the main condition is the selection of the dimension of the material or its cutting so that it completely fills the cells between the lags, without the formation of cracks. The absence of cold bridges allows you to achieve the same thermal protection indicators throughout the entire area of the house. They are also ensured by the presence of an airtight layer on the outside of the structure.

The options can be as follows:

- For wadded materials, this can be an interlayer of OSB or DSP boards, the joints of which are sealed with polyurethane foam. But then, under the insulation, you also need to lay a waterproofing film.

On top of such a structure there should be a waterproofing film.

- Sealing the bottom of the house can be done by external spraying on the sheet base of the floor with polyurethane or polyurea foam. Then, the structure will not only be waterproof, but also receive additional insulation.

Thanks to Penoizol, the bottom becomes airtight and adds additional insulation

- For the same purpose, you can use roll materials based on a polyethylene base such as Tepofol, Penofol, Izolon, with a foil coating. The strips are glued into a single canvas, which is laid on its pile field even before the installation of the strapping beam. Then the floor frame is mounted on top, and the material is fastened from below with a plank crate. The area of the canvas should be such that the edges can then cover the vertical sides of the structure.

Alternatively, we additionally insulate with Tepofol

These types of protection are used when using wadded materials - due to their weak mechanical strength, hygroscopicity and air permeability. Ordinary foam (type P) also needs protection, but extruded polystyrene foam itself is an impermeable material, and its qualities make it possible to do without additional protective measures. The main thing is that the joints between the plates are well foamed.

Bulk materials

Since a hard subfloor is still mounted on top of the log, the density of the insulation, which does not have to withstand any mechanical loads, does not really matter. Therefore, the following bulk materials can also be used as insulating filling of the structure:

We carry out installation of insulation

Laying mineral wool between logs for floor insulation

Insulation of floors and walls in a frame house is performed most often with mineral wool, but even when using the above insulation materials, the technology differs very slightly.

- Preparation of the load-bearing structure. The floors in a frame house are laid on a solid structure formed by lags of sufficient cross-section, installed in one or two layers. The required bar thickness is calculated according to special tables, depending on the size of the space to be overlapped and the required load. In either case, wood must be treated with protective preparations. When choosing a lag section, it must be borne in mind that the thickness of the insulating layer must be at least 200 mm. These works can be done by hand, and the sequence of their implementation is shown in the video.

On a note. In no case should the wood be treated with compounds that block the access of air to the wood fibers. When air is cut off, wooden structures are destroyed three times faster.

- Subfloor manufacturing:

- A frame made of boards or plywood is fixed to the installed logs, which will serve as the basis for the space between the logs filled with mineral wool or other type of insulation. Next, a waterproofing layer is mounted on the prepared frame, which prevents the insulation from getting wet.

- The choice of waterproofing membranes should be treated very carefully, because as testimonials testify, very often membranes of unknown manufacturers are destroyed after several years of operation. After thorough sealing of the seams inside the box formed between the lags, it is filled with a layer of insulation, the thickness of which depends on the thermal conductivity of the material to be laid and the calculated heat resistance of the floor.

- When working with mineral wool, the width of the insulation plate increases by 2-3 cm, and the thickness - by 1-1.5 cm relative to the distance between the logs, to ensure that there are no gaps and voids.Above the laid cotton wool, a vapor barrier is necessarily arranged, which will be correctly made not from an ordinary plastic film, as some grief masters believe, but using a special vapor barrier membrane that allows breathing not only the insulation, but also the wooden structures hidden under it.

- According to reviews, the technology of using two specialized membranes when working with mineral wool insulation and wooden structures guarantees only high performance, but also the longest service life. Plates made of expanded polystyrene or polyurethane are laid in the same way as mineral ones, with the only difference that the allowances for a tight fit are much smaller.

- All work on the construction of the subfloor can be done with your own hands, having in your arsenal a minimum set of tools, watching the video and compiling step-by-step instructions for yourself on the procedure for performing the work;

- Some nuances of working with bulk insulation. When insulating the internal cavities of the walls and floors of a frame house with cellulose wool, the device diagram changes somewhat. All technological operations remain the same, with the exception of laying the insulation material, which will be blown into the formed cavities after the completion of the subfloor installation. It is impossible to correctly perform the work on high-quality filling of voids with cellulose mass with your own hands, therefore it is necessary to invite specialists with the appropriate equipment. A special device ensures the correct distribution of the pulp throughout the filled volume and the necessary density of cotton wool to ensure the calculated thermal parameters.

Sometimes the question arises of how to properly insulate the floors and walls of a frame house from the outside or from the inside. Both the one and the other method, as evidenced by the reviews, provide high-quality insulation, and if necessary, to block the cold bridges formed from the frame racks, cross-insulation is applied to an additional crate.

Design features

Buildings with pile-type foundations are most often installed on soils with a high moisture content (near water, in swampy areas) or on slopes. Such a dwelling has nothing under the floor: no basement, no basement. In addition, drafts constantly blow under the floor and high humidity is observed. Because of this, a house built on screw piles necessarily requires thermal insulation. Then it will last longer and it will be more comfortable to live in it.

The arrangement of such a floor is rather complicated. It should be multi-layered. The construction resembles a "pie" for roof insulation. It should be thought out even at the stage of building a house.

The underfloor heating structure should include:

- Supporting frame made of wood with subfloor.

- Wind insulation layer. It must allow steam to pass through, but protect the insulation from weathering.

- A layer of insulating material.

- Steam and moisture insulating coating.

- Internal floor of the room, covered with boards and finishing materials.

Design features

One of the conditions for the reliable arrangement of a frame house is high-quality materials. If you use cheap products for floor insulation or skip one of the layers, this will lead to very undesirable moments. Significant heat loss will occur through the floor. As a result, the cost of heating the room will increase. And high humidity, condensation will provoke the development of fungus, rotting and destruction of wooden boards and beams. As a result, the service life of the floor and the entire room will decrease, and regular expenses for repairs will be required. To avoid all these problems, it is precisely reliable insulation that will allow.

Advice! Due to the structural features of the structure, the floor should not be too massive and weighty.

Before starting construction work, you should choose a heater.

How to insulate the floor of a house on stilts?

The choice of materials for insulating the space under a wooden house on piles is not small. The main condition is the product's resistance to moisture. The most popular heaters are: polystyrene, expanded clay, mineral wool, penoplex.

Each of them has its own pros and cons:

- Styrofoam. The material is lightweight, inexpensive, and easy to install. But with the simultaneous effect of water and frost on it, the polymer material begins to crumble, crumble. Therefore, when insulating an underground space with foam, it is important to think about good insulation from water.

- Expanded clay. Also not the most expensive material. Anyone, even a novice builder, can insulate the underground space with expanded clay. Natural material (foamed clay), absolutely non-combustible, not heavy. But expanded clay does not have the highest thermal insulation properties.

- Minvata. This material is even more afraid of water than foam. When wet, it loses its thermal insulation properties, it is impossible to dry wet mineral wool. But the material is very resistant to the appearance of fungus or mold, insects or mice do not start in it. Another important property of mineral wool is that it is completely non-combustible. Insulation installation technology is simple, mineral wool is sold both in slabs and in rolls. Better to buy in slabs, it has more density. Basalt wool perfectly absorbs noise, does not create a large additional weight load on the piles.

- Penoplex. Compared to expanded polystyrene, expanded polystyrene has a higher strength, increased moisture resistance. Therefore, the higher price for this product is fully justified by its insulating characteristics and reliability. Sheets of this material are lightweight, cutting and mounting them is not difficult. Penoplex does not rot, is not affected by mold.

In addition to insulation, you should also take care of additional materials for arranging the floor. To protect the flooring from wind and moisture, it is better to spend more money, but purchase modern special membranes. Laying them is not difficult. For the installation of a vapor barrier layer, an ordinary polymer film is suitable. You will also need an antiseptic (antifungal) impregnation for all wooden parts of the structure.

Sequence of work for floor insulation

You should start by assembling a rough structure. For this, wooden beams are nailed to the logs, they will serve as a support. Next, boards are attached to them in the flooring. Wood elements must be treated with antibacterial impregnation.

If it is planned to lay polystyrene or expanded polystyrene as insulation, then it is permissible to make a subfloor from a grid. But it must be strong enough to withstand the weight of the insulation.

Important! In the case when a heated concrete floor will be made, it is recommended to reinforce the structure with transverse jumpers.

The next layer is the grillage waterproofing. It must reliably protect the insulation from moisture ingress into it. For such protection, roofing material, membrane or plastic film is suitable. It is overlapped, leaving no gaps, with slight sagging between the lags. The joints of the film must be glued. Next comes the turn of the insulation. There should be no gaps between its sheets or stripes.

A layer of film is again laid on top of the insulation to isolate it from steam. This layer will provide protection against condensation and moisture from inside the house. The easiest way is to fix the film with a construction stapler, it must be overlapped.

After all this, they begin to arrange the final floor. It can be made from wooden boards or plywood sheets, chipboard plates are suitable.

Pine is an affordable material. More expensive types of wood are oak, aspen. These types of wood are distinguished by their reliability, strength and durability. It is important that the wood is dry and has a moisture content of no more than 20%. Otherwise, when the boards dry, cracks will start to appear in the flooring.For additional insulation and decoration, the floor is covered with linoleum with insulation, carpet, laminate on a cork backing. The floors in the bathroom and toilet are decorated with tiles. You can equip a system of underfloor heating throughout the house.

External insulation

If the house is already built on stilts, then it will be necessary to perform external thermal insulation of the space under the floor.

The layers are laid in this order:

- A vapor barrier film is attached to the logs, with an overlap of at least 10 cm. The easiest way is to fix it with a construction stapler, you can glue it.

- A layer of insulation is installed. It is attached with self-tapping screws to a wooden base.

- It is important to protect the insulation ball with a layer of wind membrane; it allows air and moisture drops to pass in only one direction (from the heat-insulating material to the outside).

For greater protection, plank the floor from the outside and erect a decorative plinth. Insulation of the floor in a house on high piles will play the role of a ceiling when building a basement or arranging a basement room.