Wood is a good heat insulator. Despite this, the realities of the climate in our country require additional measures to prevent heat losses.

Warming a house from a bar from the inside will allow:

- reduce heat loss;

- to reduce operating costs for maintenance of heating equipment.

"Pie" of the wall of the house from a bar with insulation from the inside

The choice of the method of insulation (internal or external) must be carried out at the design stage. This is especially true for interior work, because the installation of thermal insulation reduces the area of the room, affects the placement of heating, electrical, plumbing equipment, requires the organization of a ventilation system.

Features of the choice of insulation

Before insulating a house from a bar from the inside, you need to choose a suitable insulating material.

The characteristics that the insulation should have:

- low thermal conductivity;

- low weight;

- vapor permeability;

- shrinkage;

- incombustibility;

- environmental friendliness;

- cheapness.

Mineral wool materials

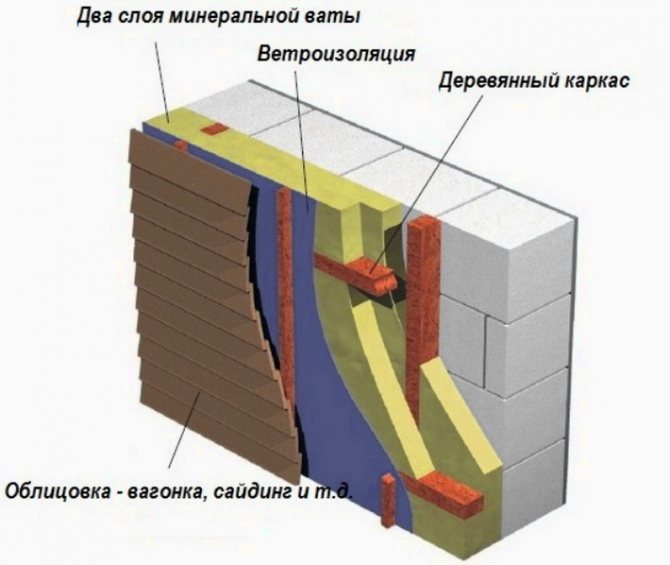

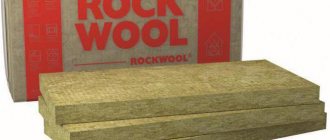

Insulation of the walls of a log house is most often done with mineral insulation.

Advantages:

- light weight;

- fire safety;

- high vapor permeability;

- environmental friendliness;

- pest resistance;

- the presence of a foil layer (allows you to exclude the installation of a vapor barrier);

- affordable price.

Thermal insulation with basalt wool inside the house from a bar

Features of insulators with different base:

- Basalt wool is a non-shrinking material in the form of slabs (ISOLIGHT, ISOLIGHT-L ROCKWALL, PAROC, Nobasil), non-hygroscopic, withstands temperatures up to 1000 ° C.

- Fiberglass plates, rolls (Izover, Knauf, URSA) have a high water absorption rate. The use of membranes, vapor barrier, waterproofing is required. Shrinkage of the material creates voids that affect thermal insulation.

- Ecowool - cellulose fibers (Isofloc, Termex, Ekovilla), slightly flammable, possessing antifungal, antibacterial properties due to the presence of boric acid in the composition. When water is added to a container with cotton wool, a composition is formed, which is best applied to vertical surfaces with special equipment. Such adhesives make it possible to insulate geometrically complex structures.

Expanded polystyrene and penoplex

The materials are chemically similar to foam. They are made from polystyrene granules. Penoplex has a more finely porous structure that is resistant to mechanical stress. Expanded polystyrene in structure is closer to polystyrene.

Advantages:

- Moisture resistant insulation - does not require additional waterproofing.

- Non-toxic - there is no release of formaldehyde resins during operation.

- Low weight makes assembly work easier.

- Resistance to fungi and mold. Does not rot.

Disadvantages:

- High flammability. Flame retardant treatment does not improve material properties.

- Low vapor permeability.

- It degrades when interacting with dichloroethane, benzene. When gluing to an insulated surface, the adhesive must be selected without solvents.

- The material is additionally processed with chemical compounds to exclude the formation of mouse nests, insect colonization.

Thermal insulation of internal walls with foam plastic

Insulation of a log house from the inside requires the use of vapor-permeable materials, therefore, the use of expanded polystyrene and expanded polystyrene is undesirable

... The resulting condensation between the insulator and the wood will lead to rotting of the wooden frame, mold will form, and fungus will appear.

Penoizol

Urea foam is produced in three forms:

- Liquid - resin, phosphoric acid and foaming agent, after mixing, are supplied under pressure to the insulated surface using a special device. After solidification, a material similar to polystyrene foam is formed.

- In sheets - liquid material is poured into molds. Further it is used as a slab insulation.

- In the form of granules - obtained from rejected sheets. It is used for insulation of ceilings, floors.

Penoizol advantages:

- Low thermal conductivity.

- Seamless filling eliminates cold bridges.

- Non-flammability.

- Moisture resistance.

- High performance of noise absorption.

- Adhesion to all types of surfaces.

- Possibility of filling voids in walls and ceilings without dismantling the structure.

- After curing, it is non-toxic.

- Saving time when performing work.

- Resists microorganisms.

Minuses:

- Low vapor permeability.

- The liquid insulator is applied with special equipment.

- Work with the material takes place at a temperature of + 5 ° C and above.

- Release of harmful substances in the process of spraying onto the surface and during the hardening period.

Insulation with penoizol inside a log house

Houses made of aerated concrete and foam blocks

Evgeny Filimonov

Ask a Question

When choosing a heater for aerated concrete, it must be borne in mind that blocks of this material are distinguished by high vapor permeability. The wrong choice of thermal insulation can only worsen the indoor climate and shorten the life of the home.

Condensation will collect at the wall-insulation boundary and cause the wall to become wet. Aerated concrete will be covered with mold and will start to rot. Mineral wool insulation, like aerated concrete, has a high vapor permeability. Such a "duet" will have a positive effect on the microclimate at home. Due to the ease of installation and relatively low cost, mineral wool is often used to insulate houses from aerated concrete.

Polyurethane foam is also gaining in popularity. For houses made of aerated concrete, this is the ideal option. The spray method is most effective to avoid cold seams.

Polyfoam, expanded polystyrene have poor vapor permeability, therefore, it is necessary to use them to insulate houses from gas blocks in extreme cases.

Stages of internal insulation of a house from a bar

If it was not possible to sufficiently insulate the house from a bar outside, then in order to reduce the energy consumption for maintaining a healthy microclimate in the premises, it is necessary to carry out a number of manipulations with the involvement of specialists or do the work with your own hands. The following stages can be distinguished:

- preparatory work;

- floor insulation;

- insulate the walls;

- insulation of the ceiling and roof.

Preparing the premises for insulation

Before carrying out the main work, perform:

- Removal of dust, dirt from the surface of the log house.

- Elimination of chips, gaps, cracks by means of: linen tow;

- jute fiber;

- polyurethane foam;

- compositions based on polymers.

Wall insulation works

To understand how to insulate the walls from the inside in a log house, you need to understand the processes that will occur after the installation of the insulating "pie".

Warm air saturated with vapors from the room will tend to the cold zone - to the wall and ceiling. When a cold surface is reached, condensation falls out (dew forms). Wetting wood, insulation is an undesirable process.

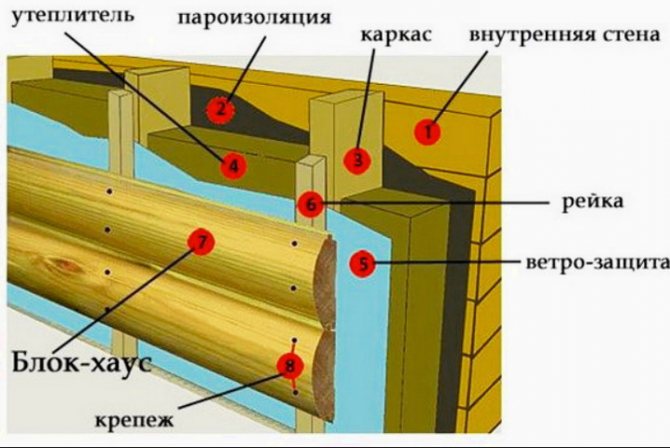

Puff "pie" for thermal insulation of a wooden house

How to properly insulate a house in order to prevent the destruction of the structure, insulation materials, the formation of a favorable environment for microorganisms:

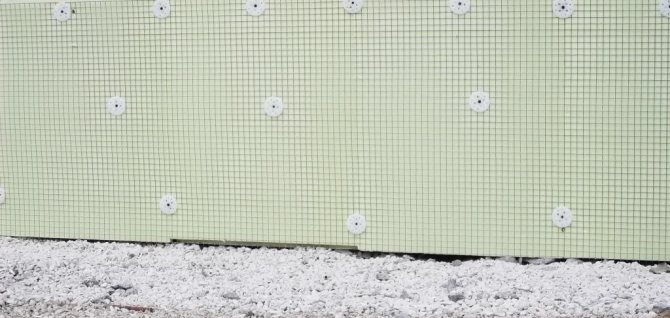

- Organization of the ventilation gap.It must be made at least 30 mm between the wall and the insulation layer. On the surface to be insulated, a lathing is made from a bar.

- Fastening a waterproofing (vapor-permeable) membrane with a stapler to the ventilation grid.

- Installation of a box for placing insulation between the bars.

- Insulation lining "vspor". The size of the insulator should exceed the linear dimensions of the cells by 1.5–2 cm (for mineral wool).

- Install a vapor barrier film. This step can be eliminated when choosing a foil-clad insulating material.

- Organization of the outer decorative layer.

A bar, wood materials used for internal insulation of a room, are treated with a fire retardant compound before installation.

The scheme of fastening the insulation to a wooden wall

Waterproofing

The main mistake when deciding how to properly insulate a house from a bar arises from confusion: where and in what sequence vapor barrier and waterproofing materials are installed.

Waterproofing membranes perform the function of protecting the insulating layer from the ingress of condensate or moisture that has penetrated through the ceilings. The porous structure of the film allows leaked steam to escape from the insulation, but protects the protection from water penetration.

On the market, you can buy material with different characteristics.

Types of waterproofing:

- Pseudodiffusion - vapor permeability 20-300 g / sq.m.

- Diffusion (Tyvek Soft, Izospan AM, Delta Vent) and superdiffusion (Eurobarrier) membranes: vapor permeability 400–1000 g / m2. The difference lies in the ability to deduce steam. The "Super" prefix means improved material properties.

- Volumetric separating diffusion membranes (Delta Trela) - polypropylene nonwoven fabric with a three-dimensional volumetric structure. Ideal for metal roofing applications. The disadvantage is the high price.

The material is attached between the wall (ceiling) and the insulation. To avoid confusion during installation, manufacturers mark the surface of the material. The membrane mounting technology is performed according to the manufacturer's recommendations.

Vapor barrier

Indoor steam is the result of human activity: breathing, cooking, cleaning, hygiene procedures. Convection of humid air, its movement from a warm zone to a cold one - the cause of condensation on cold walls.

To insulate the house from the inside, a film protection is installed, which:

- excludes steam penetration into the insulating layer,

- prevents the formation of condensation.

Vapor barrier films cover the insulating layer on the side of the decorative finish.

Types of vapor barrier:

- PVC film is a cheap material, easy to stretch and tear. Wall insulation is advisable for seasonal living.

- Reinforced polyethylene - more durable due to reinforcing viscose fibers.

- Foil materials - a thin layer of metal is applied to fiberglass, paper, foamed polyethylene. They help to reflect heat into the room. It is good to insulate baths and saunas with such material.

Installing a vapor barrier will prevent condensation and steam from entering the insulation layer

The films are fastened with an overlap (~ 15 cm) with a stapler on the frame for the insulation. The joints, the area of the staples are glued with a special tape.

The foil material is held together with reinforced aluminum tape. Holes for wiring, pipes must be sealed.

The use of vapor barrier materials inside the house impairs the removal of vapors from the premises. Proper ventilation and ventilation will create a good microclimate.

Insulation of floors and ceilings

Regardless of how to insulate the house from the outside or from the inside, work to block the flow of cold from the floor, ceiling (ceilings) must be performed.Heat leakage through these surfaces is up to 25% of the total volume. Measures to reduce heat loss are carried out as the foundation or overlap is installed.

The technology for thermal insulation of horizontal surfaces is the same:

- Cranial bars are attached to the lags, on which the subfloor is laid.

- Wood processing with bio, fire protection.

- Waterproofing is laid on the formed surface, attached to the sides of the log.

- Insulation (mineral wool, expanded polystyrene, penoizol) is placed between the logs.

- Fastening the vapor barrier.

- Installation of a finished floor.

The floor, insulated with penoizol, does not require the use of a vapor barrier film. Can I use Styrofoam? Yes, but with waterproofing.

Roof insulation

In the presence of an attic floor, the installation of thermal insulation is carried out in the same way as the insulation of walls inside the room. The order of work is identical. Nuances:

- It is important to choose the right insulation, the thickness of the insulation.

- The use of styrofoam is not allowed.

- Steam and waterproofing is laid with an overlap in the horizontal direction.

- The ventilation gap must be at least 40 mm.

- The roofing is done with perforated soffits.

- Ventilated ridge required.

profiteplo.com

Construction of the truss system

The basis of the roofing cake is the rafter system. Its correct calculation will guarantee the long-term operation of the roof and reliable protection of housing from natural phenomena.

When carrying out low-rise construction of buildings, one of the following types of roofing structures is used:

- single-slope;

- gable;

- hip (hip);

- attic;

- multi-gable;

- half-hip (gable);

- tent.

Regardless of the features of the structural design of the roof, the rules for choosing building materials, or rather, timber, are similar. Taking into account the length of the rafters, the distance between them and the size of the section of the lumber are determined.

The presence of a thermally insulated roofing cake allows you to use the attic space, even in cold weather. Now the arrangement of attics is very common, therefore, at the stage of roof construction, it is necessary to reliably isolate the insulation. For these purposes, special waterproofing membranes and barriers are used.

The main functional purpose of these materials is to collect moisture that condenses on the surface of metal sheets. Without their use, water will begin to be absorbed in the insulation, and this leads to a decrease or even loss of its thermal insulation qualities. The waterproofing is attached to the rafters with staples.

To improve the fastening of the film and to arrange a ventilation gap between the roofing and the film, it is imperative to fill the counter batten. The bars and the pitch of the board for the metal tile are selected taking into account the width of the rafter and the length of the roof slope.

SNiP P-26-76 regulates that for roofs with a slope length of less than 6 meters, you need to use a bar with a section of 30x50 millimeters. For multi-slope roofs, in which this parameter exceeds 6 meters, the thickness of the bar for the counter-lattice should be 50 millimeters. In order to improve the ventilation of the space under the roof, special holes are also made - air vents along the entire length of the slope.

What is needed for insulation

To insulate a house from a bar from the inside, it is necessary to understand the state of the walls, floor and ceiling. You can check this by conducting a thorough inspection around the entire perimeter from the inside and outside. If the timber has cracked, then voids will appear between the links, on the material of the gap, and in some places the timber can twist. You can solve the problem of insulating a house from a bar inside in several stages:

- Carry out secondary caulking.

- Carry out insulation with roll or matte insulation.

it happens that the first stage is enough to give the walls sufficient thermal insulation. This mainly concerns the kiln-dried timber.The second stage begins with the choice of material.

Heat insulators for timber walls

When choosing a heat insulator for insulating a house from a bar from the inside, you need to focus on a material that meets several of the above characteristics:

- Environmental friendliness.

- Weakly or hardly flammable.

- Simplicity of styling.

- Durability.

- Non-toxic and non-allergenic.

Among the most commonly used for interior decoration of the house: mineral wool, ecowool, polystyrene, foamy rutan. I would like to highlight the ekovta which is applied directly under the gypsum board, while the vapor barrier does not need to be laid. Ecowool is made of cellulose and is able to easily absorb and release moisture. The timber walls of the house do not stop breathing. And various additives, such as boric acid, prevent the development of mold, fungi and rodents.

One of the new materials is foamed polyethylene with a foil top layer, on one or both sides - penofol. The price of the material is from 200 rubles / m? therefore it is expensive for them to decorate the whole house. But the material is thin and the rubbing of the useful area of the rooms is minimal.

Mineral wool and polystyrene have been used for a long time and have shown themselves only on the positive side. The biggest disadvantage of foam is the high risk of fire at home. But if you do the wiring correctly, that is, not inside the finish, but along the top, and insulate with high-quality materials, the danger is minimal.

For laying foam or any kind of mineral wool, you must purchase a vapor barrier. It will protect the insulation from condensation and will not allow moisture to penetrate into the structure.

fasten from the inside to a crate made of wood or metal. For timber, it is better to take a tree, only the bars must first be dried and soaked with antiseptics, for example Senezh.

How to make the valley crate correctly

Improper installation of the valley leads to roof leakage and, as a result, expensive repairs. In this case, the counter-lattice is mounted so that there are holes for the movement of condensate and small debris.

An additional waterproofing membrane is placed on the valley, its crate is reinforced with slats.

Thermal insulation works inside

The first caulking from the inside of a house from a bar is carried out immediately after construction. For work, they take natural jute or linen material. You can use ready-made material in the form of twine or tape, which is twisted right during work. For work, a tool is used: caulk or chisel, hammer. You need to go through the walls starting from the bottom link along the entire perimeter. It is impossible to dig in one wall from the beginning, then another, the house can be skewed. Usually the caulk from the inside is combined with the outside.

A year later, when the shrinkage coefficient is the highest, they begin to insulate the walls inside the house from a bar. The work is carried out in several stages:

- Wall preparation (leveling, antiseptic treatment, secondary caulking).

- Vapor barrier lining.

- Lathing on all walls of the box. excluding internal partitions.

- Insulation installation.

- Ventilated system installation.

- Finishing finish.

Let's consider each of the stages in more detail in the video. In the video presented, it can be seen that work is being carried out in an old house from a bar:

Preparing walls for insulation

The walls are cleaned of dust and treated with antiseptics. It is necessary to protect not only from fungi and mold, but also from fire. There are complex formulations on sale that will reduce work, for example, Tikurrila or Belinka. In rooms where water is used, for example, a bathroom and a kitchen, it is necessary to additionally cover the timber with repellent impregnations. Since the walls will be additionally insulated and their appearance is not important, you can use ordinary drying oil.

Next, the walls are carefully inspected for new cracks. They are buried with linen or jute fiber.If there are large voids, they are closed with a roller of tape insulation or ready-made twine from jute.

If there are large irregularities on the beam, it is necessary to cut them off, if this is not done, the crate will have to be leveled longer. In the video above, you can see how the prepared walls should look like.

Installation of a vapor barrier layer

All walls around the perimeter of the box are covered with a special vapor barrier. It is rolled along the walls and fixed with a stapler. The overlap of the material is made at least 10 cm. Installation of not all types of insulation involves the use of a vapor barrier. It is not necessary to use a vapor barrier under ecowool or penofol. Penofol does not let moisture inside, and ecowool breathes.

It is easier to roll out the vapor barrier together, since the width of the film is from 1.5 m. One rolls out and holds, the second fixes it with a stapler.

Lathing for insulation around the perimeter of the box

Installation of battens for house insulation begins with aligning the corners. In order to subsequently lay down the facing material in the corners, it is necessary to make L-shaped racks. They are made as follows:

- The height of the walls is measured and a bar with a section of 50x100 mm is cut off.

- Take a block with a cross section of 50x50 mm and cut the same length. It is necessary to fasten thin bars to the main ones from the side in the form of the letter G. It is easier to connect the bars together with self-tapping screws.

- The resulting racks are attached at the corners of the timber, leveling their position with a level.

Next, the main lathing is made of 50x50 mm bars. They are mounted in increments, depending on the size of the insulation and the material that will be used for the finishing. Usually the step between the bars is 60 cm. If you take mineral wool or another matte finish, then you can take a step of 58-59 cm, so the insulation will fit more tightly.

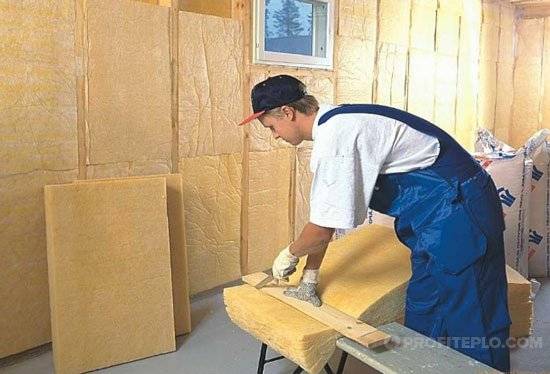

Installation of insulation on the walls

The insulation is placed between the crate, fixing it depending on its type. So the mineral wool is fixed with special anchors, the foam can be glued to a water-repellent glue, for example, Titanium. There is no need to be afraid that the insulation will fall off, the second layer of the vapor barrier will strengthen the structure.

The mats should be inserted as tightly as possible. if voids remain, they are filled with pieces of the same material, smaller ones are foamed with polyurethane foam.

If penofol or ecowool is chosen as insulation, then they are attached directly to the crate. Penofol is rolled out along the crate, the joints are glued with special tape. Ecowool is blown out with special equipment under pressure. You can fill up the ecowool manually. To do this, it is fluffed with a construction mixer or a special drill attachment. The volume should increase by 3 times. Ecowool is poured manually between the gypsum board sheet and the wall. The insulation is more tight.

After installation, other types of insulation are covered with a second layer of vapor barrier. It will prevent moisture from penetrating into the material.

Finishing the walls

After laying the vapor barrier, the finishing is done. The material is taken depending on the design, the purpose of the room and material capabilities. The most economical option is to decorate the walls of the house with gypsum plasterboard, plaster and wallpaper. But do not forget that if the purpose of the room is related to water, then they take GVL. It is moisture resistant and can be glued to ceramic tiles. The tiles are not glued to the gypsum board.

An imitation of a bar or a wooden lining is mounted on top of the crate. Wood will give the walls more thermal insulation and will not violate environmental friendliness. The only negative, the interior can quickly get bored and difficult to change.

Ventilation features

When insulating a log house from the inside, the humidity in the room will increase, since the walls will not breathe as freely. The easiest way is to make a forced ventilation system in the house and turn it on once a day for 25-30 minutes. It is placed in the attic, so it will not be conspicuous.

You can make a more complex structure that will go from a common pipe. It is run from the common pipe to the underground.The moisture will be drawn out naturally. Pros of the system: there are no electricity costs, it will be dry underground all the time.

After all the above works, the insulation of the walls will be completed. But do not relax and consider the work finished. Only 50% of the heat escapes through the walls, the rest is drawn through the floor and ceiling.

Ridge installation

At the location of the ridge, the roof slopes intersect. It is entrusted with the function of ventilation of the roof space. To improve ventilation, ventilation valves can be placed on the roof slope. To fix the ridge elements on the rafters, you need to nail an additional sheathing element.

The roof is one of the main elements of the building's appearance. When installing roofing, it is of great importance to observe the distance of the lathing under the metal tile, which is a modern material. The simplicity and speed of installation made this type of roofing the market leader.

Floor and ceiling insulation

Insulated floors and ceilings will make a log house optimal even in the coldest winters, and electricity or gas bills (depending on the boiler) will be reduced significantly.

For insulation of floors, they take the same mineral wool, polystyrene or polystyrene foam. The finished floor is disassembled and a rough crate is made along the logs. To do this, thin bars of 40x40 mm are attached on both sides of the lag and an ordinary edged board is laid on them. Above the waterproofing and lay insulation. Then a layer of vapor barrier, which will protect the material. Next, the finishing floor is mounted.

The ceiling is insulated in the same way. If there is a second floor or a heated attic, then the first floor is insulated right between the floor beams. If the space under the roof is cold, then it is better to insulate from the attic side. To do this, use: expanded clay, polystyrene, mineral wool or ecowool. The easiest way is to take ecowool, it is simply laid out on the ceiling from the side of the attic with a layer of 20 cm.

It will be necessary to carry out insulation from a bar inside in any case, a new house or an old one. Drying will happen anyway, it's just a matter of time. And having completed all the work with your own hands, you can be sure that the house will not freeze even in extreme cold. And electricity meters in winter will not wind up terrible numbers.

o-bruse.ru

Installation of lathing

Before installing a frame made of profiles or timber, the walls of the house must be cleaned of dirt and peeling fragments. It is necessary to remove the trims from windows and doors and remove all protruding structures from the surface. The protruding unevenness of the wall should be knocked down, and the grooves and cracks should be repaired with plaster. After that, the facade is treated with an antiseptic compound and primed.

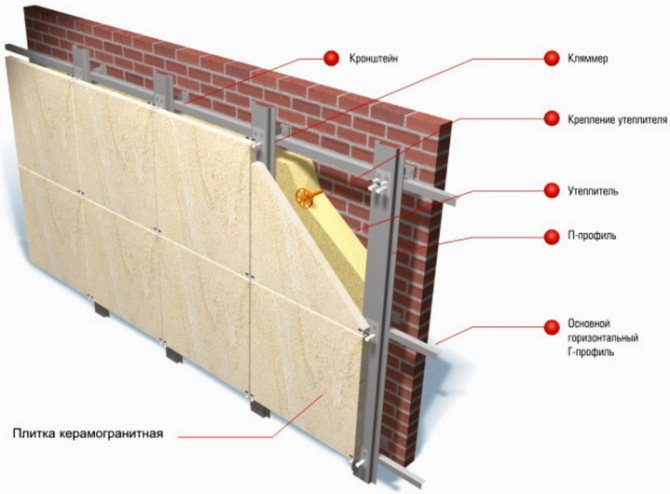

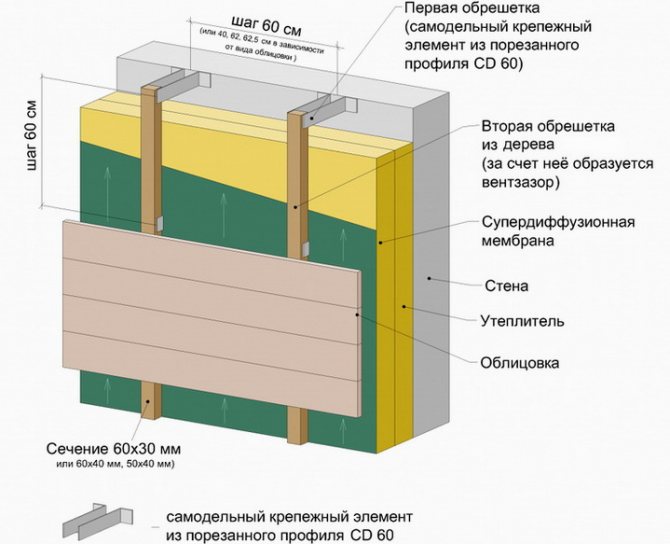

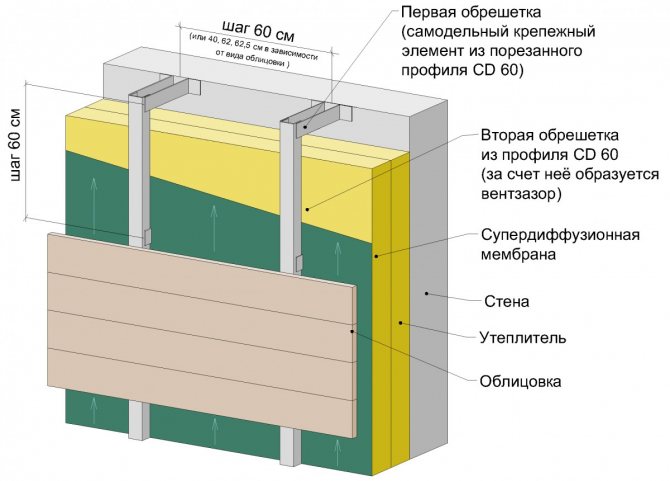

Construction of battens for an insulated facade

How to make a crate correctly if the facade will be additionally insulated? In this case, you will have to build a 2-layer structure from the rails. Insulation will be laid in the lathing of the first layer, and siding panels will be attached to the counter-lattice mounted perpendicular to it. It is better to mount the first frame on U-shaped suspensions: with their help it is easier to build an ideal plane.

Sheathing scheme for insulated facade

The panels for the final cladding of the facade should be placed horizontally so that atmospheric precipitation does not fall under them. The siding must be fixed to vertical slats, so the profiles of the first layer must be mounted horizontally.

Before installing the starting and finishing profile, a vapor-permeable film must be hung on the wall. After that, a bar in the upper part of the wall is attached to the U-shaped suspensions. Suspensions in the same row should be located no further than 40 cm from each other. They are attached to the wall with dowel-nails. The profile is fixed on the hangers with self-tapping screws with press washers 9.5 x 3.5 mm. Wooden blocks are fastened with wood screws 3, 5 x 30 mm. The correctness of the installation of the starting profile is checked by the level.

Now U-shaped hangers for the lower plank are attached to the wall. They are set at the building level. The correctness of the installation of the finishing profile is checked with a plumb line. Several threads should be pulled between both strips, which will determine the plane for installing the remaining profiles (bars). The distance between them should not exceed 60 cm. Then insulation is laid between the battens of the crate. By the way, its thickness should correspond to the thickness of the first layer of lathing.

Rules for wall insulation from the inside in a wooden house

Do-it-yourself insulation of the walls of a wooden house from the inside is possible if comply with such rules:

- Before starting work, make heat engineering calculations, taking into account the thermal conductivity and thickness of the walls, as well as insulation materials of various types and thicknesses. With all these calculations, the dew point must remain inside the wooden wall during any temperature fluctuations.

- For internal installation, you need to choose heat insulators that do not emit harmful substances and are not subject to decomposition by fungi and bacteria at high humidity.

- Porous insulation must be reliably insulated from the wall with a vapor-water-tight membrane, and from the side of the room - with a vapor-permeable membrane. In this case, the wood does not freeze and does not get wet, since only outside air with a low vapor content penetrates into it. And if condensation forms in the heat-insulating material when the dew point is shifted, then when the temperature in the room rises, it will evaporate and escape through the pores of the vapor-permeable membrane.

- There must be an air gap between the finish and the insulation protected by a vapor-permeable membrane for condensate evaporation.

Thermal insulation of walls with mineral wool

- Step 1. A frame made of timber with a section of 50x50 mm is fixed on the wall. The bars are mounted vertically with self-tapping screws and dowels, the distance between the posts should be 1.5-2 cm less than the width of the insulation. It is imperative to control the vertical arrangement of the racks with a building level so that all the elements of the crate are in the same plane.

- Step 2. Slabs of mineral wool are alternately inserted between the beams, slightly crushing the edges. After installation, the material is easily straightened and tightly fills the crate cells. If necessary, the plates are cut with a knife or fine-toothed hacksaw.

- Step 3. If the insulation is planned to be mounted in two layers, horizontal jumpers from the timber are fixed on top of the racks with self-tapping screws at the same distance. Next, the mineral wool slabs are fixed again.

- Step 4. A windproof membrane is attached on top of the insulation. Since its width is not enough for the entire area of the wall, it is fixed with horizontal stripes, starting from the lower part of the facade. It is most convenient to use a stapler to fix the membrane. Each subsequent strip is laid with an overlap of at least 10 cm. To increase the tightness of the coating, the joints are glued with tape along the entire length.

- Step 5. Further, strictly according to the level, the guides for the siding are installed using mounting plates. The plates are fastened with self-tapping screws to the crate with a pitch of 40 cm.An air gap of about 3-5 cm should remain between the guides and the windproof membrane.

After that, they begin to clad the facade with siding panels. As you can see, the technology is quite simple and everyone can do it. The most important thing is to firmly fasten the plates so that they do not dangle between the posts. If there are gaps, the heat will go out and all efforts will be in vain.

What kind of insulation to choose?

For internal insulation of wooden houses usually applied such materials:

- Warm seam... This concept includes natural and synthetic sealants. From natural tow, flax or linen rope are used. Synthetic sealants are available in tubes. They contain sealing compounds based on rubber, silicone or acrylic plastic.One of these materials is used to fill the gaps between the logs that have formed after the wood has dried out.

- Mineral wool... Basalt wool is usually used in slabs. Glass wool is not used for internal insulation, since small fragments of fiberglass irritate the skin and respiratory tract. Basalt wool allows steam to pass through and can accumulate a little moisture, so it requires mandatory waterproofing from the tree. Minvata is non-flammable.

- Expanded polystyrene in slabs... It is used in the form of various modifications (penoplex, polystyrene). It is preferable to insulate the walls with penoplex. This fine-mesh material has greater strength and better thermal insulation properties than foam. Expanded polystyrene does not require vapor barrier, since it practically does not allow steam to pass through itself, but it needs waterproofing. In terms of its ability to retain heat, it is about 1.5 times higher than basalt wool.

- Penofol... It is a fine cellular polyethylene foam covered with aluminum foil. Available in rolls. In this case, it is worth using a 3 mm material with a one-sided coating to reflect the heat radiation towards the room. Usually penofol is used for combined insulation, protecting the foam from moisture.

Differences in the insulation of aerated concrete, wooden, brick house

The method of insulation depends on what material the walls of the house are made of. If we compare houses made of wood, brick and aerated concrete, then we can highlight the following points that deserve attention:

- Unlike brick walls and houses made of aerated concrete, a prerequisite for the installation of a heater for a wooden house is the installation of a crate to ensure ventilation. The installation of the lathing of block walls is carried out only for siding or other hinged cladding;

- the most suitable insulation materials for aerated concrete and brick walls are materials with a high moisture resistance (penoplex, expanded polystyrene), while for wooden houses, breathable mineral wool slabs are ideal insulation;

- the thermal conductivity of a brick wall is higher than that of aerated concrete, so the wall must either be insulated with a thicker layer of insulation, or the thickness of the brickwork must be increased;

- with external insulation of a wooden house, the surface should be carefully prepared by treating it with antiseptics;

- most often, for fixing the layers of the pie of a wooden wall, the installation of sheathing from chipboard or OSB is required.

In addition, all indicators of the materials from which the walls are erected should be borne in mind, such as moisture resistance, thermal conductivity and thermal resistance.

Insulation installation technology

In any case, the internal insulation of wooden walls begins with sealing joints logs or beams (warm seam).

After that, the dry inner surface of the walls is processed several times antifungal agents... Sheathing bars are also treated with these drugs. After complete drying, they begin to install the thermal insulation.

The walls are insulated in the following sequence:

- Laying a vapor-water-tight membrane... The film is fixed on the beams or logs of the walls in a taut state using staples and a construction stapler. Neighboring panels are laid with an overlap of 15 cm wide. The edges of adjacent panels are glued with construction tape. This layer does not allow steam or water to pass through. Usually, a Megaspan B membrane is used for this, laying it with the rough side to the wall, and the smooth side to the insulation.

- Installation of lathing... To do this, you need bars with a cross section of 50 × 50 mm (the thickness is selected according to the thickness of the insulation layer, that is, with a two-layer laying of mineral wool, the cross section of the bar is 50 × 100 mm). The bars are screwed vertically to the wall with self-tapping screws. The distance between them is 2–3 cm less than the width of the mineral wool slab.

- Placement of thermal insulation... Between the beams of the lathing, slabs of mineral wool are tightly inserted end-to-end.If 2 layers are mounted, then the plates of the upper layer should overlap the joints of the lower one. After laying, the surface of the slabs should be flush with the battens of the sheathing.

- Securing the vapor-permeable membrane... A vapor-permeable membrane is stretched over the insulation. It is attached with a stapler to the lathing bars with an overlap of 15 cm. This film protects the mineral wool from water drops, but allows steam to pass freely. Usually, Megaspan A membrane is used for this, which is laid with the fleecy side to the thermal insulation material.

- Installation of lathing and finishing... The lathing for the thermal insulation material is built up horizontally with bars with a cross section of 50 × 50 mm, screwing them in with self-tapping screws. Finishing material (wood panels, gypsum plasterboards) is attached to this crate.

Installation of expanded polystyrene plates slightly different in technology:

- laying a vapor-tight membrane on the wall is not required, since this material practically does not allow steam to pass through;

- over the expanded polystyrene, a vapor-water-tight membrane is fixed (Megaspan B with the smooth side to the insulation) or penofol with foil towards the room (15 cm overlap film, penofol end-to-end with gluing the joints with metallized tape).

Correctly mounted internal thermal insulation not enough to keep the walls of a wooden house warm. Internal insulation provides for reliable insulation of the walls from steam penetrating into the wood from the room.

Previously, this steam escaped through the pores, but after warming, this path is blocked. This means that excess steam must now be removed. forced ventilation... This is best done with an air heating system. In it, forced ventilation and air heating are performed in one cycle.

Exhaust air with excess water vapor is removed from the room constantly. In such conditions, the accumulation of condensate in the insulation does not occur. At the same time, steam does not penetrate into the wood and does not moisturize it.

You can insulate a wooden house from the inside yourself. However, this method of thermal insulation requires some knowledge and strict adherence to the rules. If the technology is violated, the walls of the building quickly collapse.

Forced ventilation and air heating eliminates the accumulation of moisture in the insulation and the deterioration of the microclimate in the house, even in case of severe frosts.

Do-it-yourself master class on wall insulation with mineral wool in a wooden house from the inside, look at the video:

A video tutorial on the use of a warm seam for insulating a wooden house, see below:

holodine.net

Thermal insulation with extruded polystyrene foam

- Step 1. On the wall, along the level, mark the location of the hangers for the guides. The hangers should be fastened along the entire facade with a step of 40 cm. Holes are drilled at the marked points, dowels are inserted and the hangers are fixed with screws.

- Step 2. Take an EPSP board, apply it to the wall and press it a little so that traces from the suspensions are imprinted. Following these traces, cuts are made in the insulation with a knife or a special cutter. Then the slab is again attached to the wall and put on the suspensions, pressing it tightly to the base. Step 3. The rest of the plates are fixed in the same way, trying to make the joints as thin as possible. If in the process of work gaps have formed here and there, they must be sealed with polyurethane foam with a pistol.

- Step 4. After sheathing the facade with insulation, proceed to the installation of guide profiles for siding. The profiles are attached to the suspensions that protrude from the heat-insulating layer; a 2-3 cm wide ventilation gap is left between the guides and the insulation. Next, the siding is attached.

This insulation can also be attached using umbrella dowels and special glue. In this case, it is more convenient to first mount the crate to which the siding will be attached. Glue is applied to the insulation, then the plate is inserted between the guides and pressed against the base. Upon completion of the installation, the slabs at the joints are additionally fixed with umbrella dowels.

The reasons for the cold snap in the house and the procedure for work on thermal insulation

Usually houses built of wood are particularly comfortable: they are cool in summer and warm in winter. Most often, a cold snap in a wooden house can be caused by 2 main reasons. It:

- poor-quality or improperly mounted outer heat-insulating layer;

- the appearance of cracks in the walls of the house as a result of improper installation, or drying out.

After the reasons for the cold in a wooden house have become clear, you can proceed to familiarize yourself with the list of upcoming works aimed at its internal insulation.

This process will take place in several stages:

- First you will need to prepare the surfaces.

- Then seal up all the gaps.

- Equip a vapor barrier layer.

- Mount the crate.

- Install a layer of thermal insulation.

- Equip the ventilation system.

- Next comes the turn of finishing work.

And now about all these stages in more detail.

What is required for work

The most important thing is to choose the right material. In order for the installation of thermal panels with clinker tiles to go without problems, it is worth preparing all the elements in advance. To work you will need:

- Thermal panels. To determine the amount of material required, you need to measure the surface and then multiply the height by the length. It is worth subtracting doorways and window openings from the amount. The material is sold not in packages, but in square meters.

- Elements are angular. They allow you to give the building a neat and complete look. To calculate the required amount of this material, you should measure the length of all internal and external corners of the facade.

Surface preparation for insulation

The first stage of insulation works involves preliminary preparation of surfaces.

First, clean all surfaces of the walls from dirt and dust. And then you can proceed to the careful processing of wooden walls with a special compound that protects the tree from the reproduction of insects. It is very good if the composition you choose will additionally perform a function that prevents the process of decay of wooden surfaces, and protect it not only from moisture, but also from the danger of fire.

And yet, at the same stage, you need to take care of the safety of electrical wiring. If there is a variant of its surface location, then it must be separated from the wall. Close up the cracks

After completing all the above procedures, you can proceed to the second stage of insulation. It provides for the implementation of work to eliminate the existing cracks. They must be carefully caulked. Many people know that after a house is built from a bar, it is necessary to carry out an additional procedure to eliminate cracks, after about 1 year.

Naturally, this is done if the house remained uninhabited. During the operation of the premises, the re-caulking of the cracks can be carried out later, after about 3 years. What is the best way to seal the cracks? Usually, a material such as jute fiber is used for these purposes.

From the tools you will need a chisel, preferably wide and rather thin. For cracks of an especially large size, a tape tow is used, which, before being placed in the gap, is twisted in the form of a roller. It is necessary to fill the slots until the material used is no longer placed in them.

Thermal insulation with ecowool

Wall insulation with ecowool can be done in two ways - dry and wet. The first method is not reliable enough, since the material is blown through small holes in the protective film, and it is impossible to control the density and uniformity of filling. In this regard, the wet method is more convenient, the whole process takes place in plain sight. It is this second method that we will consider.

- Step 1. The walls are cleaned of dust, cracks and other defects are eliminated. The siding guides will be strengthened strictly in level with a step of about 50 cm.The fastening of the rails must be carried out using mounting plates so that the frame thickness is at least 10 cm.

- Step 2. Ecowool is poured into a blow molding machine, a water-gel solution is added there, and mixed until smooth.

- Step 3. Turn on the installation and apply a viscous mass to the walls in a dense layer. Joints and corners are especially carefully processed so that no voids remain.

- Step 4. Allow the insulation to dry completely, after which the siding panels are mounted to the crate.

In a similar way, the house is insulated with penoizol and polyurethane foam. Many companies lease a spraying unit, which is much cheaper than buying equipment. But in order to do everything efficiently, certain skills are required, and it is better for a beginner to hire specialists for this.

Vapor barrier layer: nuances

The presence of a vapor barrier in a wooden house is very important, since as a result of insulation, the wall is blocked between 2 heat-insulating layers. In this case, the degree of humidity in the room increases, since the walls arranged in this way are not able to breathe. What to do in this case? A high-quality ventilation system saves, only with its help is it possible to effectively combat moisture. If you do not allow dampness on the walls, then you will avoid the occurrence of the process of decay of the tree.

Simply put, you need to equip a high-quality vapor barrier. It is performed using a special film, which is placed on the wall surface with its rough side towards the wooden surface.

Eaves overhang device

First of all, you need to build up the first of the battens of the crate, additionally fixing a board 15–20 millimeters thick on it, which will ensure a rigid fixation of the coating material - it will not sag.

For stone buildings, the size of the roof overhang should not be less than 450 millimeters, and for wooden houses - 600 millimeters. When the rafter cannot provide the required overhang length, it is increased using a filly. Be sure to install an end board.

To ensure the collection of condensate and a sufficient degree of ventilation of the under-roof space, a drip is mounted, behind which the edge of the waterproofing material is taken out. The membrane is attached to the drip tip with self-adhesive tape.

The drainage structure begins to be installed before the installation of the metal tile:

- Above the rafter or on the starting board of the lathing, the holders for the gutters of the system are fastened with a step of 60-80 centimeters and the slope of the gutter, based on 3-5 millimeters per one linear meter.

- The gutter of the gutter must be installed immediately, since the eaves plank is lowered into it, which is fixed to the bottom board of the sheathing. The bottom edge of this strip should overlap the top of the gutter.

- After the installation of the fine mesh for insects, the preparatory work on the eaves is considered complete.

Lathing and thermal insulation layer

You can mount the lathing layer on the walls using a wooden beam. It is also allowed to use a metal profile, but only in the case of subsequent sheathing with moisture-resistant gypsum plasterboard sheets.

In order for the corners of the crate to be even and correct, it is necessary to take care of the preparation of the corner posts in advance. To do this, measure the height of the room and cut the bar in accordance with this value. The section of the timber used for these purposes should be 50 × 100 mm.

Next, you will need a bar of the same length, but with a section of 50 × 50 mm. This part of the bar is positioned along the edge side of the first length of bar with a cross section of 50 × 100. Self-tapping screws are used to secure it.

As a result of these manipulations, you should get a stand that resembles the letter "G" in its outline. Each corner of the room should be equipped with such a rack. When carrying out fastening, do not forget to check the verticality of their location.

Now you can start installing vertical bars with a step of about 0.5 m. The bar should have a cross section of 50 × 50 mm. Do not forget that all wooden parts of the lathing must be pre-treated with a protective compound against decay and fire.

After the lathing is completed, you can proceed with the installation of the thermal insulation layer. For these purposes, a material such as mineral wool is well suited. After you have unrolled the roll with the material, you need to cut it in accordance with the desired height value. And the width of the insulating layer should be 2 cm greater than the distance available between two vertical bars.

Having placed a strip of heat-insulating layer between the bars, you need to fix it to the wall with anchors. Please note that anchors with large round caps are used. The second layer of insulation is fixed to the surface of the bars. The vapor barrier, or rather the film used for its device, will help to avoid dampness, and still will not allow small particles of mineral wool to get into the air. The vapor barrier layer is attached to the bars using a construction stapler.

The main mistakes of insulation

External insulation of the walls of a country house must be carried out in accordance with the requirements and rules for the installation of materials. Errors that most often occur during insulation contribute to improper circulation of air flows and the formation of moisture inside the cake, which leads to a weakening of the thermal insulation qualities:

- incorrect calculation of thermal resistance;

- in the absence of a basement strip at the bottom of the wall, the insulation may come into contact with the ground;

- polystyrene foam during installation should not be left in the sun for a long time;

- the gaps between the insulation plates lead to the appearance of cold bridges;

- Expansion dowels should be installed at the corners of the building and around doors and windows to secure the material.

In addition, you should not save on materials, since in addition to their correct installation, the low quality of the material should not cause poor-quality insulation.

Thus, when the walls are insulated, the living area is preserved, a careful study of details is required to calculate the amount of materials and determine the order of installation work.

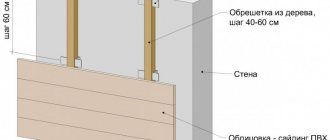

Requirements for the materials of the crate

The lathing for siding can be either wooden or metal. The choice in favor of a wooden frame by some builders is often made for reasons of economy, but it will not work to correctly make a crate for siding by simply stuffing the first wooden blocks that come across the walls.

Wooden lathing is a more economical option compared to metal

Quite strict requirements are imposed on the material for the lathing:

- For the frame, you can use bars with a section of 30 x 40, 40 x 40, 40 x 50, 50 x 50 and 50 x 60 mm. The heavier the siding, the thicker the planks should be.

- When buying wood, you should choose the most straight bar. You need to purchase it with a certain margin (when drying, some bars can be severely deformed).

- Before installation, the wood must be properly dried. It must be dried in a dry place, not accessible to direct sunlight. The bars should not be stacked close to each other. This will provide free ventilation between them.

- The moisture content of the wood should not exceed 15%, so the drying of the timber should take 10-15 days.

- Before installation, the bars should be treated with antiseptic compounds.

- Wooden lathing is installed only during the period with established dry and warm weather.

The metal crate for siding is devoid of the drawbacks of wood, but when purchasing material for the frame on your own, you need to remember that a galvanized CD 60 profile with a thickness of 0.4-0.55 mm is best suited for its construction. Rails equipped with stiffeners have higher strength characteristics.

It is better to make a metal crate under the basement of the house, as there is usually high humidity

Builders who are going to mount the siding with their own hands need to know that it is not recommended to install a wooden frame in the basement of the house, since the moisture near the ground will necessarily be increased, and the crate will not last long.

Lathing: pros and cons

Installation of siding on a crate allows:

- revet uneven surfaces without additional costs for leveling them;

- hide the routing of pipes and electrical wires under the cladding;

- to carry out insulation according to the "ventilated facade" method;

- fix the insulation with the crate;

- make the cladding collapsible and provide access to communications for their repair.

The installation of the lathing increases the cost of finishing work, but this drawback is many times overshadowed by the advantages listed above.