Facade insulation work involves wall insulation from the outside. If earlier the insulation of buildings was carried out by increasing the thickness of the walls, now with the advent of modern heat-insulating materials and technology for mounting the system, other solutions have appeared.

With a steady rise in energy prices, the complex requirements for the energy efficiency of buildings are becoming higher.

Today in Russia there are two types of facade insulation: "thin plaster layer" or "wet facade" and "ventilated insulation".

Both systems imply insulation of the walls of the house from the outside - with heat-insulating materials. The difference lies in the installation technology and the finishing material.

The use of various types of material in the decoration of the facade allows you to make the building unique and individual.

Not sure which insulation to choose? We will help you!

The difference between two insulation systems ("wet" and "ventilated facade")

- Thermal insulation of the facade using the technology "wet facade»Has no restrictions on the building envelope, be it from a monolith, brick of any kind, aerated concrete, moisture-resistant materials, wood, etc. due to the lightness of the constructed system "wet type" in contrast to the "ventilated facade".

- Thermal insulation of the facade using the technology "ventilated facade»Has limitations due to the weight of the system. To start the production of work, it is necessary to conduct surveys for the strength and endurance of the existing facade due to the weight of the subsystem being constructed and the cladding of the building with porcelain stoneware or other facing material.

Warming problems

When carrying out heat-insulating works of multi-storey buildings, it is required to attract specialists involved in industrial mountaineering.

When insulating outside, it is necessary to use fireproof heaters and finishing materials that withstand exposure to high temperatures, do not melt and do not emit corrosive smoke and hazardous toxic substances.

It is not recommended to use synthetic and organic insulation; it is best to give preference to thermal insulators based on mineral or basalt.

Are you planning facade insulation?

We have been installing insulation on facades for 20 years!

↘Thousands of objects handed over.

↘Hundreds of grateful reviews.

↘ Dozens of awards and certificates.

- Departure of our specialist to study the building,

- Identifying the causes of heat leaks,

- Drafting a commercial proposal and project design,

- Execution of work according to the submitted estimate.

We are ready to perform all these types of work and services with high quality and with a good warranty period.

+7

Multichannel telephone

We will be happy to carry out any facade work for you.

Where in the Moscow region to order a facade insulation service

One of the most popular companies specializing in the production of this kind of construction and finishing operations is "Facade-Rolf". With the help of our specialists, we will be able to carry out turnkey facade insulation quickly and with guaranteed high quality. Our advantages:

- Professionalism. All employees of the company meet the requirements for their specialization and are masters of their craft.

- Efficiency. Thanks to well-established relations with suppliers of thermal insulation materials, accessories and all consumables, we will be able to insulate the facade of a building of any complexity as soon as possible.

- Reasonable prices.At the stage of concluding a contract with a customer, our specialists determine the total cost of services and the timing of work, taking into account all possible factors that can affect these indicators.

If you want to insulate the facade of the building with minimal costs and maximum efficiency, contact.

Mineral wool

This type of thermal insulator is not recommended for external insulation of facades of structures, since mineral wool has a high hygroscopicity, therefore, it absorbs moisture, under the influence of which the material is deformed and loses its thermal insulation properties. For external insulation, thermal insulation slabs of mineral wool are used, impregnated with special compounds that increase their durability and reduce moisture absorption.

Why mineral wool is considered a universal insulation, you will find out further.

Thermal insulation of facades "ventilated facade"

Suspended facade systems with an air gap are used for cladding and insulation of external walls of industrial and civil buildings and structures, as well as for high-tech residential buildings and various complexes.

Curtain facades represent a structure of varying complexity, consisting of cladding materials, heat-insulating material and a subsystem on which the curtain facade cladding material is attached.

How do we install "ventilated facades"

1. A subsystem consisting of metal guides is set on the level and is attached with anchors.

2.With the help of a dowel, an insulation (mineral wool plate) is attached to the wall

3. Then, with an air gap, the facing material is installed on the supporting subsystem.

As facing materials used are porcelain stoneware, fiber-cement panels with a decorative coating, cassettes made of composite materials or steel.

Examples of our work on the "ventilated facades" system

Thermal insulation

Thermal panels can be used to insulate both private houses and industrial buildings. Thermal panels are attached either to a previously created frame, or directly to the walls of the structure. When installing thermal panels on walls, without first creating a frame, adhesives are used.

Thermal insulation panels are lightweight and do not create additional stress on the structure, they are easy to install and reliably protect buildings from external destructive factors. Thermal panels do not require special care during operation, and are also a durable material.

How much does it cost?

| Name of works | Types, list of works | Unit | Price, rub) | ||||||||||

| Device - "Wet facade" Expanded polystyrene PSBS-25F - 100mm watch an example | Facade preparation, cleaning, priming, installation of thermal insulation boards, dowelling, applying a reinforced layer, priming, applying a thin layer of finishing decorative plaster. | m2 | 1290 RUR | ||||||||||

| Device - "Wet facade" Mineral Wool Slab -100mm watch an example | Facade preparation, cleaning, priming, installation of thermal insulation boards, dowelling, applying a reinforced layer, priming, applying a thin layer of finishing decorative plaster. | m2 | 1290 RUR | ||||||||||

| The device of the hinged ventilated facade - 120mm watch an example | Installation of a subsystem, fastening of slab insulation, installation of porcelain stoneware slabs or other | m2 | 2000 RUR | ||||||||||

| Insulation installation | Installation of thermal insulation boards - leveling on a plane using facade glue | m2 | 350 RUR | ||||||||||

| Facade reinforcement | Leveling the facade with an adhesive in two layers, with the application of an alkali-resistant mesh | m2 | 350 RUR | ||||||||||

| Decorative plastering | Application of finishing decorative plaster on the prepared base | m2 | 380 RUR | ||||||||||

| Wall priming watch an example | Cleaning the facade from dust, priming with a deep-penetrating primer | m2 | 60 RUR | ||||||||||

| Dowelling | Fixing the insulation after gluing, using dowels | m2 | 120 RUR | ||||||||||

| Reinforcement of window slopes | Leveling the slope with an adhesive in two layers, with the application of an alkali-resistant mesh | mp | 270 RUR | ||||||||||

| Facade painting watch an example | Painting the wall surface in one layer on the prepared base | m2 | 90 RUR | ||||||||||

| Insulation of window slopes | Priming, installation of insulation, reinforcement, priming, decorative plaster on the slope | mp | 320 RUR | ||||||||||

| Insulation of the basement watch an example | Surface priming, installation of insulation, dowelling, reinforcement, priming | m2 | 850 RUR | ||||||||||

Insulation characteristics

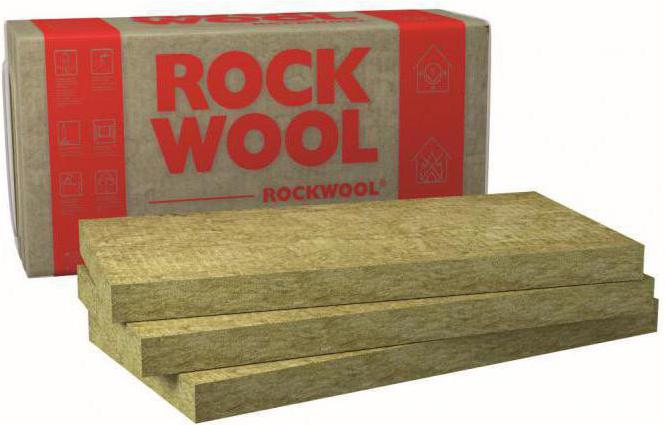

Rockwool mineral wool is one of the best materials, which has many enhanced characteristics. The most important of them are:

- Excellent soundproofing. Due to this, the fibers are chosen for improving the acoustics of premises, for the manufacture of noise protection screens.

- Low thermal conductivity.

- Sustainability, certified by EcoMaterial Green.

- Water vapor permeability.

- Fire resistance - mineral wool can withstand temperatures up to 1000 degrees C, while other manufacturers have this figure - 600 degrees. In a fire, the fibers do not shrink, therefore, voids that are very dangerous at high temperatures do not form inside.

- Ease of installation.

- Opportunity to choose external insulation in rolls or plates.

- Durability. Moreover, during the operation, the fibers do not collapse, do not deform, and keep their dimensions well.

In addition, which is very important, Rockwool insulation does not rot, it is not affected by rodents and various microorganisms.

New solutions in house insulation

Modern options for external thermal insulation of facades allow make finishing using mineral slabs, mineral wool, sandwich panels, thermal insulation fibreboards. During operation, consumers appreciated the undeniable advantages:

- Protect walls from the influence of harmful external influences;

- Load-bearing walls are not overcooled, condensation does not form;

- Additional soundproofing effect;

- The walls "breathe" freely and at the same time keep warm;

- The service life of the building facade is extended.

The modern assortment of materials for facade insulation allows you to choose the best option based on the type of structure, taste preferences, and also according to your financial capabilities.

Product overview

produces several brands of mineral wool. Among them, the most in demand:

- Wentirock Max. This is a mineral wool in the form of mats, intended for use in the insulation of enclosing walls, high partitions and external walls, followed by cladding in the form of glass, stone, corrugated board. The cost of Wentirock Max mineral wool - from 600 rubles. for 1 sq. m with dimensions of 100 x 60 x 10 cm.

- Conlit. This is the name given to slabs and fittings. Available in two versions - with and without aluminum cladding. Some products are finished with a layer of fiberglass. This type of product is intended for installation at facilities with increased fire safety requirements. To fix the Conlit slabs on the surface to be faced, you will need to additionally buy a specially designed glue for this.

- Light Butts. They are lightweight, water-repellent thermal insulation boards that do not shrink and are easy to install. The cost of "Light Butts" mineral wool depends on its thickness (5 or 10 cm) and the size of the plates and varies from 450 to 565 rubles.

In total, the manufacturer produces 24 types of insulation, which allows you to choose the most suitable option for a specific purpose.

Insulation under plaster

Insulation of the facade with mineral wool for plastering excludes the use of steam and wind insulation and lathing. The work is carried out according to the following plan:

- Fix the mineral wool on the surface of the facade using glue or disc dowels.In this case, you need to ensure that there are no gaps anywhere, and the joints of the slabs of the next row were located approximately in the middle of the previous row.

- Reinforcing mesh installation. The canvases are laid with an "overlap" of 10-15 cm - this will prevent cracking of the plaster.

- When the reinforcement layer is dry, the exterior finish is done.

- Using a spatula, remove glue drips.

- If it turns out that the reinforcement has not leveled the wall surfaces, you can first use a rough plastering

- Finish cladding. To improve the aesthetic performance of the building, it is advisable to use decorative plaster.

Insulation technology

Experts advise very carefully and seriously to take the recommendations for installing insulation and properly prepare the walls - only this guarantees the quality of the result, and the process itself will not take much time. How should the facade be insulated with mineral wool? Installation technology consists of several stages. It:

- Work of markup.

- Installing a profile.

- Insulation installation.

- Fixation of insulation material.

- Reinforcement.

- Waterproofing support.

- Surface finishing.

After marking, it is necessary to remove cement smudges, protrusions, protruding metal pins from the walls, and then remove wires, drain pipes and other objects so that over time rust from them does not appear on the surface of the facade. Next, all cracks should be repaired with a solution. After that, it is necessary to apply a substance protecting against fungus on the entire surface to be insulated. Moreover, this must be done, even if the fungus on the wall surfaces is not noticed. If the walls are wooden, they need to be impregnated with an antiseptic.

Winter insulation: is it necessary to do it and close the insulation for the winter?

To insulate or leave until spring is, of course, the owner's decision, but if you plan to use heating or even live in the house, then the unequivocal answer is to insulate! When heating an uninsulated house, heating costs increase sharply, freezing of structures, increased humidity, low room temperatures and an unhealthy microclimate are possible. Therefore, despite the difficulties of winter insulation, it is still highly desirable to complete these works as soon as possible.

The greatest difficulty in winter insulation is created by the low air temperature, at which it is difficult to work outdoors, especially with numerous small or fragile parts, of which there are a lot when fixing the wall cladding. In winter, the wall surfaces will also be cold, which is critical when carrying out "wet" works with cement mortars, such as when performing a plaster facade. In addition to cold, negative factors are precipitation in the form of snow or rain, which will prevent the mortar mixtures from drying out, and can also get into the interior of the structure.

EKOVER basalt slabs are made of stone wool with a small amount of polymer binder. At low temperatures, the properties of the insulation practically do not change: the plates do not become brittle, do not change their elasticity, in contrast to plastic insulation - polystyrene or polyurethane. Due to the properties of stone fiber and hydrophobic impregnations, the material is practically not affected by atmospheric moisture, and in the event of wetting or freezing, the stone wool slabs are easily dried due to the highly porous structure and completely restore their thermal insulation properties.

Often, the developer is faced with the question of whether it is possible to leave the insulation uncovered until spring. It should be remembered that mineral wool insulation is intended for insulation in structures, subject to protection from moisture and ultraviolet radiation. The stone base of the material is not afraid of such influences, however, the binding and modifying components, like any organic substances, will be destroyed under the influence of the sun and moisture.Of course, in winter, the intensity of solar radiation and the ingress of liquid moisture are limited, but nevertheless, the sooner the insulation is covered, the higher its performance and durability will be.

Mechanical fastening of insulation and frame structures

With the "dry" method of fastening, that is, using dowels or when installing slabs, there are no special requirements for winter installation, except for the correction for frozen hands and increased fragility of the plastic parts of the dowels. It is necessary to avoid getting snow under the insulation and into the joints between the plates, and also try to close the thermal insulation layer with a cladding or windproof membrane as soon as possible. By the way, with external insulation of capital walls, no films are placed between the wall and the insulation, and vapor barrier is not applied from the inside. Outside, a hydro-windproof membrane can be used (in the assortment of many domestic manufacturers of films it is marked with an index A), although due to the low compressibility and low air permeability of EKOVER plates, it is allowed not to install any combustible films. When insulating frame walls, as well as in the case of wall insulation from the inside and in any ceilings and floors from the side of a warm room, it is necessary to use vapor barrier films (usually marked with indices B, C or D).

Plaster facades

The so-called "wet" processes are associated with the insulation of these facades. Adhesion of insulation boards is carried out on cement glue containing water in the composition, and a reinforced preparatory and then textured decorative layer is applied on top. Facade plastering technology implies significant financial expenditures on mixtures, more durable insulation, fasteners, work, so it is better to postpone the installation to the warm season. If, nevertheless, winter work cannot be avoided, then you can act in two ways: apply antifreeze additives or make a warm circuit around the building.

Antifreeze additives in cement mixes can reduce the freezing point of water and accelerate the setting of the mix in the cold. These additives can be purchased separately and self-administered when mixing mixtures. In this case, there is a risk of not observing the proportion or getting incompatibility of the additive with polymer modifiers of plaster mixes. Antifreeze additives can be added to the formulations during their production - these are special "winter" mixtures. Nevertheless, this method with antifreeze additives has the likelihood of white efflorescence, cracking and less strength as a result of hardening of the mixtures. In addition, the “painless” temperature range for additives is usually limited to -10 ° C.

A more reliable, but also costly way is to create a "hothouse", that is, to install scaffolding with a stretch of protective film around the perimeter. Under the curtain, precipitation is not terrible, and due to the heat guns, you can maintain the temperature above + 5 ° C around the clock.

Preservation of the plaster facade for the winter (up to 6 months) is possible according to technical regulations at the stage of the end of the preparatory reinforcing layer, which will protect the insulation from the effects of precipitation and the sun, and after priming it will remain a reliable basis for applying decorative plaster in warm weather.

Winter insulation, of course, requires higher costs from the developer than in summer, but these costs will still be overshadowed by an increase in payments for heating the house. The most economical is to insulate the house in traditional ways with the creation of ventilated gaps. Plastering technology will require significant investments and skills, therefore, if possible, it should be transferred to the warm season.

Installation under siding

If siding is used as the final finish, it is best to arrange a ventilated facade by insulating the facade with mineral wool.The technology of this action is as follows:

- Fix the vertical profile. All elements are installed at a distance of 40-50 cm from one another.

- Mineral wool "Rockwool", which is fastened with disc dowels, is laid in the space between the vertical posts.

- The insulation is covered with a waterproofing membrane. The joints are glued with butyl tape. This must be done to protect the insulation from moisture. Depending on the wall material, staples or liquid nails are used to fix the vapor barrier film.

- Installation of a counter-lattice.

- Siding installation.