Facade decorative plaster allows you to protect any building from the harmful effects of the external environment and other factors. In addition to protection, this material allows you to decorate walls. On the modern construction market there is a huge selection of decorative plaster, but the most popular is the products of the Ceresit company.

Quality products for outdoor decoration

The manufacturer offers customers products that meet all the necessary requirements for facade coating. The company has existed for a long time and during this time has managed to establish itself as a responsible manufacturer of high quality materials.

What is Ceresit facade plaster

Factories where Ceresit plaster is produced are located in various countries. There are several productions registered in Russia, which once again confirms the demand for the company's materials. The manufacturer uses a slightly different technology for the production of decorative coatings, in contrast to competitors.

As part of the Ceresit facade plaster, there are only high-tech components that make it possible to obtain high quality material. The company offers customers a wide range of products that have different compositions and textures depending on the surface to be processed.

Advantages of the Ceresit facade system

Ceresite facade systems can reduce the consumption of basic building materials when erecting walls without increasing heat loss in the cold season. It gives a building a beautiful appearance for a long time and is much cheaper than other structures in terms of cost.

The advantages of this design are:

- to provide an attractive appearance of the building;

- low weight with high thermal efficiency

- lack of "cold bridges";

- displacement of the dew point into the heat-insulating layer, which excludes the formation of wet condensation in the walls;

- complete absence of possible freezing of walls in the event of the formation of microcracks;

- providing additional soundproofing of the walls.

Popular material specifications

Ceresit is considered to be a certified product that has passed a huge number of checks. Facade plasters from this manufacturer differ from the rest by their unique characteristics.

- The density of the mixture is 1.7 kg per dm³.

- It is possible to carry out repair work using decorative plaster at a temperature of 5-30 degrees above zero.

- Drying time of the layer for textured processing does not exceed 15 minutes.

- The material is resistant to moisture.

- Possesses sufficiently stable hydrophobic properties and low moisture absorption.

- The mixture is resistant to all kinds of dirt.

- A large selection of textures, the "bark beetle" Ceresit is especially popular.

Facade plaster from the Ceresit company has excellent characteristics when compared with some other manufacturers. For the production of products, only modern equipment and quality-tested components are used, which make it possible to obtain a mixture that will make the house or premises visually attractive and protect against harmful factors.

What makes Ceresit stand out from the competition

In order to make a beautiful outer coating, it is customary to use facade plaster, which has a grooved structure. The mixture is ideal for treating surfaces made of concrete, cement, plaster or sand.Thanks to this, decorative plaster from the Ceresit company can be applied on different surfaces and at the same time, it will retain its original texture.

Manufacturers make a special composition that allows you to get a material with a high elasticity index, especially when compared with other companies.

Ceresit plaster does not fade under the influence of sunlight and is sufficiently resistant to mechanical damage. If we talk about competitors' products, then not all of them divide the mixtures produced into winter and summer ones. This parameter is especially important to take into account in those situations when work is performed at low temperatures, at an unconventional time for repairs.

Two systems of Ceresit "wet" insulating facade

Today, two systems of Ceresit warm facades have been developed and are successfully used - CWS and WM. Their difference lies in the form of insulation used in the first case, it is expanded polystyrene, and in the second, mineral wool slabs. The rest of the construction elements are the same in both cases.

Ceresit VWS system

In this system, expanded polystyrene plates or polystyrene foam are used as insulation. These materials differ from mineral wool boards in lower specific gravity and better thermal insulation properties. At the same time, foams have a very low vapor permeability, which practically excludes the removal of water vapor from the load-bearing walls and insulation structure.

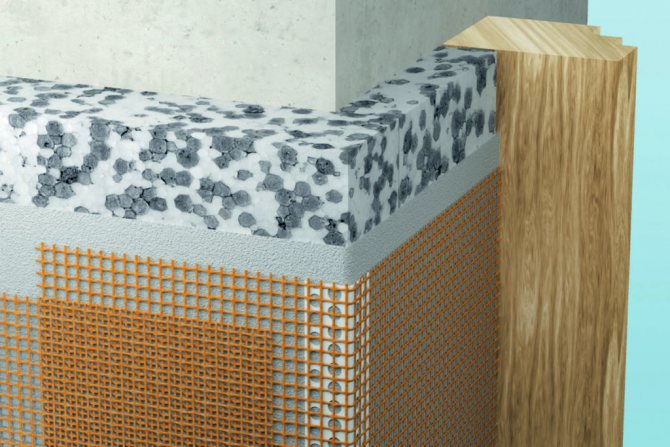

Cerezit VWS system components

Since, as a result of the performed insulation, the "dew point" will go beyond the walls into the insulation zone, moisture will accumulate between the moisture-proof insulation and the surface of the walls. This can lead to the formation of mold and mildew with the consequent destruction of the base wall materials. In order to avoid the accumulation of such moisture in the premises, it is necessary to organize general ventilation with increased air exchange, which may entail an increase in heat losses. It is worth noting that this problem occurs mainly in rooms with excessive humidity, for example, in swimming pools, saunas, showers. The vapor permeability of the finishing materials is not important, because polystyrene foam can be faced with any materials

It should be noted that expanded polystyrene is cheaper, lighter and stronger than mineral wool boards. Therefore, its use is justified for economic and technical reasons.

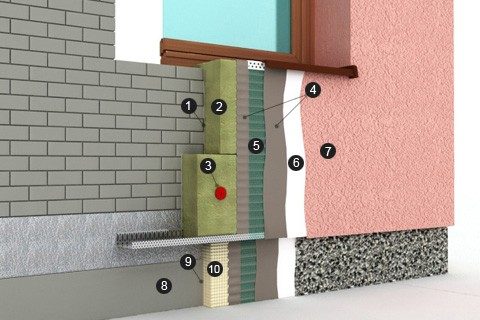

Cerezit VWS device diagram

- Glue

- Expanded polystyrene plates

- Mineral wool notch

- Dowel

- Base plaster layer

- Fiberglass mesh

- Primer for finishing

- Decorative plaster layer

- Waterproofing layer

- Glue

- Extruded polystyrene blocks

Video: an example of a Ceresit facade device with expanded polystyrene plates

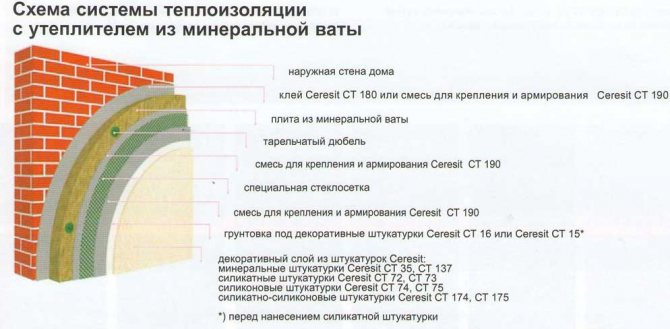

Ceresit WM system

Here mineral wool slabs are used as insulation. Unlike expanded polystyrene, this insulation has good vapor permeability and the structure can "breathe". At the same time, unlike the previous system, here facing materials must have high vapor permeability, therefore, mineral or polymer plasters are used as finishing. In addition, mineral wool is a non-combustible material, which is very important in the event of a fire.

Cerezit WM system components

Of the shortcomings, it is worth noting that this wet facade system has a high specific gravity, which makes the structure heavier, it is more expensive than foam insulation and is not as durable as they are. The price of the facade device according to the Ceresit WM system is relatively high.

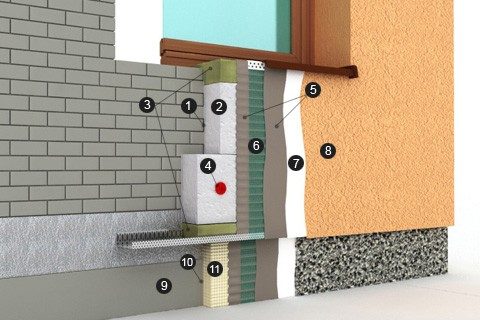

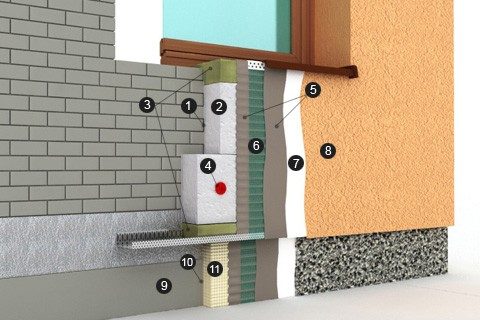

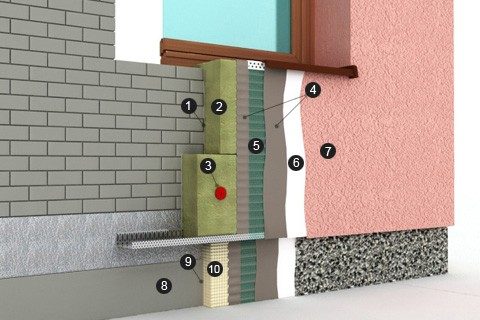

Cerezit WM device diagram

- Glue

- Mineral wool slabs

- Dowel

- Basic plastering words

- Fiberglass mesh

- Primer for finishing

- Decorative plaster layer

- Waterproofing layer

- Glue

- Extruded polystyrene blocks

Installation instructions for Ceresit mineral wool façade system

Comparative characteristics of Ceresit wet facade systems

Cerezit VWS

Cerezit WM

Advantages

Advantages

1. Does not lose thermal insulation properties when exposed to moisture

1. Mineral wool slabs are made from natural rocks

2. Environmentally friendly facade

2. Resistant to very high temperatures, fire resistant

3. Lightweight and durable

3. High coefficient of vapor permeability

4. More manufacturable due to strength characteristics

4. Resistant to most chemicals

disadvantages

5. Good sound insulation properties due to the fibrous structure of mineral wool

1. Low vapor permeability coefficient

6. Suitable for any wall base

2. Low sound insulation properties

disadvantages

3. Not resistant to the effects of most organic solvents

1. Heavy material

2. Relatively high cost

What types of Ceresit plaster exist

Facade plaster from Ceresit ct is divided into different types depending on the composition.

- Silicone. They are most often used for finishing walls. The composition does not allow the appearance of fungus over time, helps to eliminate small cracks. Refers to the category of expensive material.

- Acrylic. They allow you to remove defects on the surface of the walls. They do not have a sufficient vapor permeability index, they are distinguished by a smooth texture and strength.

- Cement. Due to the content of a sufficiently large amount of cement in the composition of the material, they turn out to be very durable, they pass air well. They are very easy to apply. Cement mixtures are very flexible, which greatly simplifies the processing of walls and the time spent on repairs.

- Silicate. The main substance in the composition of the material is silicate resin. Ready mixes are very elastic and durable. In most cases, such plaster is used to treat walls indoors. Can be used in rooms with high humidity. Less commonly, silicate Ceresite is used for outdoor work if a wet facade is present.

- Mineral. It is customary to use it exclusively for external coating of building facades.

Variety of options

Also on sale are compositions intended for further staining and coating without staining. The Ceresit company offers mixtures with which you can work at low temperatures - "winter" and at high - "summer".

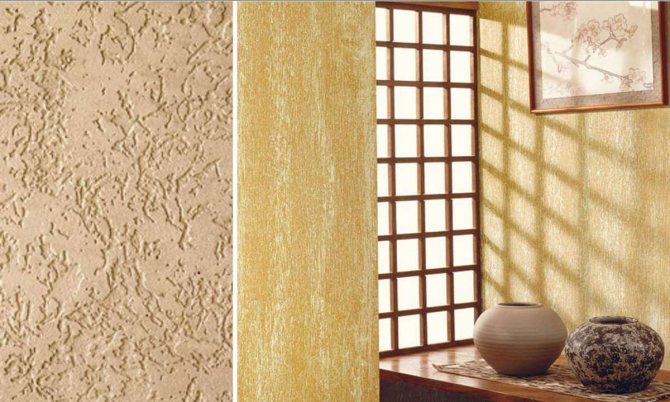

Ceresit plaster texture

Mixes of this type have only two textured patterns. A certain texture can be obtained if there are special granules in the ceresit mixture and by using a special application - "bark beetle". This texture is applied in an extremely thin layer. The plaster contains many small grains that allow you to get an interesting pattern. It can be used for both interior and exterior work.

The second type of texture is a "lamb". It allows you to hide defects on the wall surface, irregularities. The surface becomes more beautiful and original.

Each of the textures is provided in different colors. If necessary, you can paint it yourself. It is best to use paints from the same manufacturer for this. It is worth noting that components such as acrylic, silicone or silicate may be present in Ceresit paints.

Disadvantages of Ceresit Wet Facade

With such advantages of this insulation system, it is difficult to talk about the disadvantages. But basically all these disadvantages are associated with the installation work on its installation.

- Temperature range of installation works - from -5˚С to + 50˚С. This means that in the cold season, in order for the mixture not to solidify, it is required to make a special plastic cover.If the temperatures are negative, then a heat gun will be needed for work, the duration of which depends on the thickness of the layer of the applied mixture, which must dry completely. And this means that the costs of electricity are so high that there can be no talk of any low cost of this method of external insulation of the facade.

- Strict environmental humidity requirements for this type of work are also a significant disadvantage. If the humidity of the ambient air exceeds 40%, then the mixture will dry unevenly and not completely. This means that the surface will be covered with plaster stains that have dried at different times. The same applies to installation work during precipitation.

- Hot weather is also not conducive to high-quality insulation according to the Ceresit "wet facade" system. The mounting technology does not allow work in direct sunlight. Uneven heating of the mixture sections will lead to solidification of the surface in violation of those conditions, which in turn will provoke cracks and delamination of plaster layers.

How to properly prepare the mixture

In order to properly prepare the mixture, you need to take a container, for example, a bucket. It is worth noting that it is best to use a stainless product. The plaster is mixed using a special construction mixer or in a concrete mixer.

The almost finished mixture is left for a few minutes to allow the granules to dissolve. Next, you need to thoroughly mix the solution again. Finished decorative plaster should be used within three hours. After that, it will begin to dry out gradually and will no longer be suitable for repair.

Plaster technology

In order for the material to be applied correctly, a special technology must be followed, which all professionals adhere to.

Before applying the finishing material, it is imperative to first prepare the base. The surface is cleaned of all present coatings, dirt and debris. If necessary, then the walls are aligned in accordance with the base.

If the material is used for external covering, then the border that is located between the facade and the foundation must be covered with a special basement profile.

Be sure to apply a reinforcing layer, the thickness of which is 2-3 mm. The reinforcing mesh is laid in such a way that it is completely buried in the mixture. Then another reinforcing layer is applied to the mesh. The surface is left to dry for a while.

For finishing with ceresit bark beetle plaster, you should follow these steps.

- The prepared surface is treated with a primer so that the plaster adheres better to the wall.

- To work with the Ceresit material, it is advisable to use a primer paint from the same company. It should be the same color as the topcoat.

- Decorative plaster is applied to the primer layer. The layer should be thin enough and not exceed the thickness of the grain used in the composition.

- You need to apply the plaster in small areas, each of which is carefully leveled.

- After the layer of decorative coating stops sticking, using a special polyurethane float, you can make the desired texture and pattern.

How to create a texture

You can rub the decorative coating in different ways, depending on what kind of pattern you want to get in the end result. For example, horizontal or vertical movements, circular. A polyurethane or plastic float is used to create the texture.

We create the texture

Decorative plaster Ceresit allows you to make a building or premises more attractive in appearance.Due to the huge number of features and advantages, the material of this manufacturer is considered to be one of the best in the modern construction market.

Facade insulation technology with mineral wool and expanded polystyrene, which is better to choose?

A house constructed of wood keeps warm enough even at the lowest temperatures. But, it is worth noting that this can be said about new buildings. But what to do if the house has served its owners for more than a dozen years and no longer keeps heat so well in winter. It's easy enough to avoid such problems. It is possible to mount a facade insulation system, and the building will not only warm the family living in it for many years, but will also acquire a new appearance.

You can make such a system yourself, just know the insulation technology and get acquainted with the stages of work in more detail. This article can help. It all depends on how good you are with the tools and the desire to make your home warm and beautiful.

Facade insulation technology and materials

Today there are many technologies for facade insulation. Each technology implies the use of different materials. If you turn to professionals in hardware stores, you will be offered a large assortment of heaters. It remains only to choose the insulation system that suits your home and wallet.

Insulation materials are most popular today:

- Expanded polystyrene.

- Mineral wool.

If we turn to technologies, then the most popular systems have gained in recent years:

- Thermal insulation of facades knauf.

- Insulation of ceresit facades.

Let's look at the systems for insulating the facade of a wooden building based on the above materials and systems in more detail.

Insulation of the facade with expanded polystyrene

This material is called differently among specialists - polyurethane, expanded polystyrene, styropone. In common use, most often it is called polystyrene (see insulation of a house with polystyrene). The material is in the form of slabs and keeps heat quite well. It is easy to install, but it also has disadvantages. This is one of the most fire hazardous insulation materials. Therefore, when choosing polyurethane plates for insulating your home, you need to focus on those that have flame retardant impregnation.

Before any insulation of external walls, they must be well cleaned. To do this, remove all unnecessary from the facade, it can be various decorative elements, or the remnants of the previous cladding. The walls are well cleaned with a brush from dust and dirt.

Then a wood primer is taken and applied to the walls. Apply the primer in two layers. In this case, the first layer must be allowed to dry. The basement of the building can be processed 1-1.5 m from the blind area.

It is best to take a penetrating type of primer.

The next steps are vertical sagging. This is done for that. To see where there are irregularities on the wall, because in the end we want to get not only a warm, but also a beautiful building. A special grater is used to wipe the sheets in the places of irregularities.

The next step is to prepare the glue. The glue is taken special for this type of insulation and prepared according to the instructions declared by the manufacturers. Usually this ratio is equal to 1 liter of water x 5 kg of dry glue.

It is necessary to apply the glue on the foam plastic, retreating 30 mm from the edge along the entire glued surface. Styrofoam should be glued horizontally, from top to bottom. Dowel - umbrellas are attached between the plates at the joints. They additionally fix the slabs to the wall. Each new row should be started with half of the slab, placing the slabs in a checkerboard pattern.

The seams of the next row should be staggered from the previous one.

Near windows and doors, as well as after three rows, one row of mineral wool is laid - 40 cm. This is done according to fire safety techniques. And such a strip of cotton wool is called a fire belt.

All slopes and corners are fixed with metal corners.The seams between the plates are closed with liquid foam or special grout.

You should not use polyurethane foam. It will look bad afterwards.

After that, a layer of glue with a reinforcing mesh is applied over the finished insulation. A double mesh is used on the base. A layer of glue is again applied on top of the mesh. And let the whole system dry well.

It is best to carry out such work in the warm season, at temperatures from + 10 to +30 degrees.

The next step will be the decorative finishing of the facade of the building with plaster. It is worth using polymer plasters. They are more resistant to temperature changes and high humidity. They also perform well in the hot sun and do not fade.

Facade insulation technology with mineral wool

Mineral wool is the most suitable material for insulating a wooden house. This material is made in factories from bolzat fiber and metal slags. Therefore, it is natural. Its resistance to fire is also very important. And this is so true for wooden buildings.

The service life of such a material is several times longer than that of foam. Mineral wool will insulate your home and will not change its physical properties for 50-60 years. For foam, this period is 10-20 years. With foam insulation in a wooden house, additional ventilation is needed, and mineral wool is a breathable material, which means that the tree will not lose its ability to breathe after such insulation.

During installation, this material is somewhat more complicated than polystyrene, but such insulation will also serve you longer. If you carry out the insulation correctly and complete all the stages of installation, then there is no doubt. More than one natural disaster is no longer terrible for your home. Of course, if it's not a great flood.

When working with mineral wool, be sure to use a respirator, as its small particles can easily enter the respiratory tract.

Mineral wool insulation cake

The entire installation work of such a system can be divided into three stages:

- Preparatory work and fixing the mineral wool.

- Reinforcement

- Facade decorative treatment

At the first stage, just like with foam insulation, all dirt is removed from the facade throughout the house.

When insulating a facade with mineral wool, experts say that it is possible not to prime the surface. My opinion is that it is better to prime. Let it be just one layer. You can use the same wood penetrating primer.

After drying, take the mineral wool glue. The glue is prepared in the same way, but it is worth noting that the glue is needed specifically for mineral wool.

Glue for foam insulation is very similar in composition to glue for mineral wool, but it is not permissible to mutually replace them!

The glue should be applied to the slab sheet and pressed firmly against the wall. Dowels can be used to further strengthen the material. Mineral wool can peel off from the wall of the house over time, dowels will prevent this.

The next step will be to reinforce the already insulated facade. This stage will allow you to protect the mineral wool itself from the harmful effects of the environment. After the reinforcement is completed, your house will not be covered with small cracks.

A special glue is applied, which will protect the entire structure and a special reinforcing mesh is attached to it. It is durable and resistant to chlorine. From above, all this is covered with another layer of glue. This system is allowed to dry well.

After drying, the decorative stage begins. It will give the building a beautiful and aesthetic appearance. Usually they use polymer plaster, mineral or polymer.

This system, undoubtedly, is effective when insulating a wooden house, but it also has its negative side. This design is quite expensive. (the issue is discussed in more detail in the article on mineral wool insulation)

How to make a high-quality installation of facade insulation

To perform better work, you can contact a specialized company where they will definitely draw up a technical card for insulating your home. The technical sheet contains information about the insulation system that you choose.

The good appearance of the house is not only the well-being of the family and its social status, but also the protection of the walls from all kinds of negative influences. Having drawn up a professional technical map of the insulation system, you can easily understand how much money is required to complete a given work. You will be provided with a full estimate and separately scheduled costs for materials and the work itself.

The technical card should be drawn up by professionals and from it you can easily find out the name of the insulation system that you will be offered. Most likely, it will be knauf or ceresit. These two systems are similar to each other and have worked well. Let's get to know them better.

Facade insulation knauf

This is a highly developed thermal insulation system for facades. It has two types:

- Knauf - warm wall 1

- Knauf - warm wall 2

This system allows you to insulate both large multi-storey buildings and small private ones. And if such a system is installed immediately during construction, then you can make the walls thinner and save on building material.

Knauf 1 differs from Knauf 2 in that the first is made on the basis of foam insulation, and the second on mineral wool. The first and second have passed all tests and are approved for use for all buildings. The exception is for the first childcare facilities and hospitals.

The installation of this system is similar in the first and second cases. The only difference is insulation.

First, the wall is cleaned and the insulation is glued with a specialized Knauf-Sevener adhesive mixture. The insulation is also fixed in the system with dowels. Then a layer of Knauf glue mixture is again applied and reinforced with a fiberglass mesh. After priming, Knauf - Diamant decorative plaster is applied to this mesh. Installation of the second is similar to the replacement of the main insulation with mineral wool.

As you can see, the installation of a specialized proprietary system differs only in plastering and glue application. Knauf material is considered to be of higher quality and meets all safety requirements.

Similar to the Knauf system, the ceresit system is used today.

Insulation of facades Ceresit

The ceresit system is also divided into two types:

- Ceresit MV

- Ceresit PPP

The materials of this company were developed by German specialists. When building such a system, only materials from this company are used. Ceresit MV differs from Ceresit PPS in that in the first case, mineral wool boards are used, and in the second, polystyrene.

Ceresite insulation technology is not very different from all the other technologies mentioned above.

First, the walls are cleaned and Ceresit CT - 190 glue is applied with mineral wool, with foam plastic - Ceresit CT - 85. After that, insulation is glued onto it, then a reinforced mesh and again a layer of Ceresite glue.

After drying, use Ceresit decorative plaster.

The main difference between this system and Knaf is its lightness. Each layer of this design is up to 10 mm thick. Knauf, on the other hand, has a thickness of about 15-20 mm.

In terms of price category, these two systems are practically the same. Knauf is a little cheaper.

From which system you choose to insulate the facade of your building, it depends on how warm the long winter evenings in your house will be. If you decide to make such a system yourself, then you will need patience and a little skill, which we described to you in this article.