What is the difference between polystyrene foam and polystyrene foam?

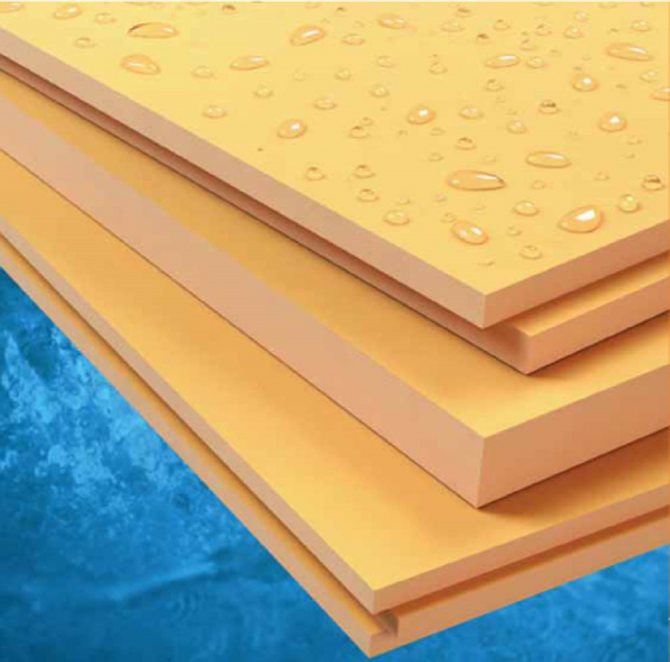

Water absorption (%) - a parameter that determines how much water a material can absorb:

These figures indicate that polystyrene foam can absorb only 400 grams of water during the specified period, while polystyrene is capable of more - 4 liters.

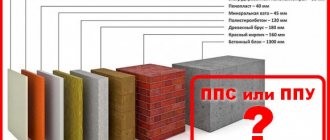

Blocking heat from passing through a wall in the same house can help reduce heating costs. The low thermal conductivity provides an economic benefit as it becomes possible to reduce the thickness of the material. The lower parameter of thermal conductivity of polystyrene makes it a unique material, capable of better than other similar products keep warm:

- 0.036–0.050 W / (m · K) - foam;

- 0.028 W / (m K) - expanded polystyrene.

Density - mass parameter, allowing to determine the weight of 1 m 3 of material in kilograms:

- 15–35 kg / m 3 - polystyrene;

- 28–45 kg / m 3 - expanded polystyrene.

To understand how the mentioned parameters compare favorably with the materials in question from other construction products, you can familiarize yourself with the following numbers:

- 0.058 W / (m K), 368 kg / m 3 - wood;

- 0.05 W / (m K), 1200 kg / m 3 - foam concrete;

- 0.2 W / (m K), 1800 kg / m 3 - brick.

Strength (limit) - a parameter, the value of which can be found out if you put the material on any supports so that they hold it along the edges, and then begin to apply pressure to the middle of the product until it breaks. As a result, the required values can be obtained for each of the materials:

- 0.07-0.2 kgf / m 2 - foam;

- 0.4-1.0 kgf / m 2 - expanded polystyrene.

Strength (compression) - a parameter due to the effect of a pressure force on a material placed on a flat plane until its thickness is reduced by 10%. The high strength of expanded polystyrene determines it as the most resistant material:

- 0.05–0.20 MPa - foam;

- 0.25-0.50 MPa - expanded polystyrene.

Working temperatures - both materials can be used in approximately the same temperature conditions: from -50 ° C to +75 ° C.

Life time - the undoubted leader of the two materials under consideration is expanded polystyrene, since it is several orders of magnitude more durable than polystyrene. Its lifespan is at least 50 years, while foam can retain its properties for no more than 25 years.

Against the background of polystyrene foam, polystyrene foam looks like a more practical product that has a number of advantages, which include:

- high strength;

- resistance to moisture;

- lower thermal conductivity;

- durability.

At the same time, expanded polystyrene is somewhat inferior to polystyrene, since it is definitely heavier and, although not much, is more expensive.

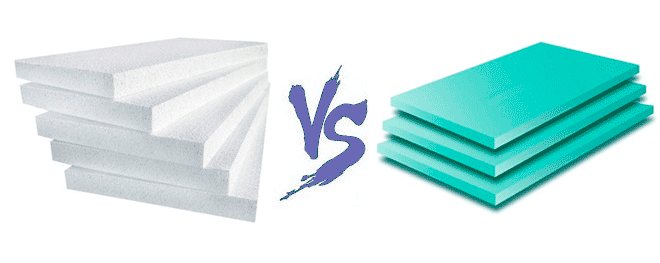

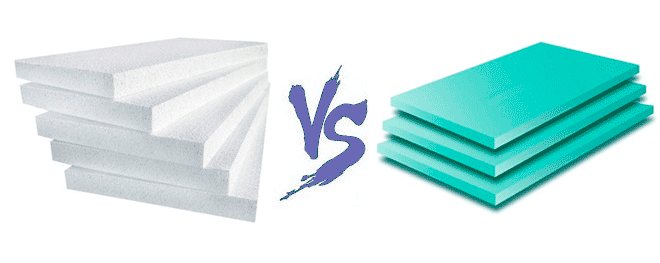

Styrofoam and expanded polystyrene

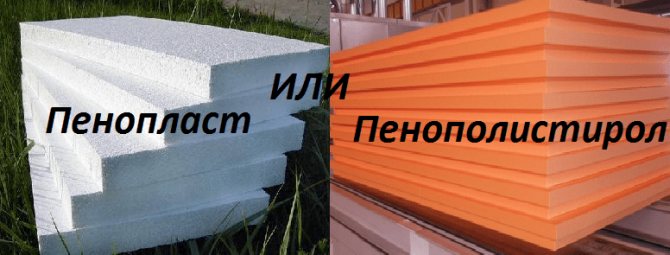

Are you sure Styrofoam and Styrofoam are the same material? Indeed, it is not easy for an outwardly simple man in the street to distinguish them. Nevertheless, the differences between these materials are huge and begin at the very stage of manufacturing, despite the fact that both materials include polystyrene granules.

Manufacturing differences

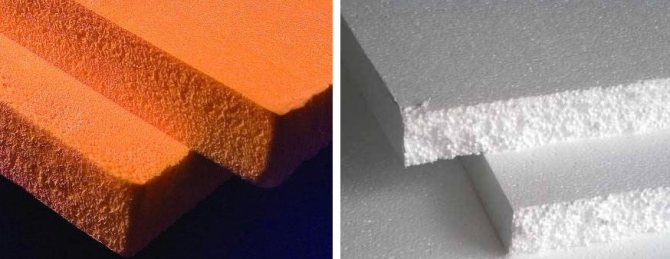

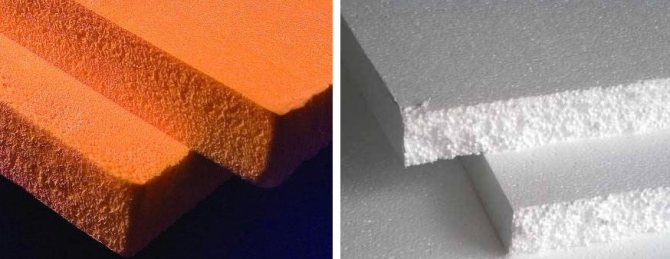

Styrofoam: The expanded polystyrene granules are immersed in a specialized container and treated with hot steam. As a result, the granules greatly expand in volume and sinter together. In the process of increasing polystyrene, a large number of micropores are formed, filled with air. This explains the brittleness and rapid wear of the foam during operation.

Expanded polystyrene: the technology is similar to the production of polystyrene, the main difference is the pretreatment of polystyrene granules with a high temperature. The granules melt, forming a viscous homogeneous mass, only after that the steam treatment is carried out. The resulting material is less grainy, without a lot of air in the pores. This pre-treatment results in lower thermal conductivity and greater strength of the material.

Differences in characteristics

Dry heat conductivity

Expanded polystyrene: 0.028 W / (m.K)

Styrofoam: 0.036-0.050 W / (m.K)

The lower the thermal conductivity, the less heat will pass through the walls of the room, and it will be easier to maintain the required temperature regime.

Water absorption

Expanded polystyrene — 0,4%

Styrofoam — 4,0%

This means that if a sheet of foam plastic is immersed in a hundred liters of liquid, then it will absorb 40 ml of moisture per day, and expanded polystyrene only 4 ml. This difference is explained by the presence of air between the granules and in the pores of the foam. A low water absorption rate indicates that the material will keep the walls from decay and destruction longer.

Static bending strength

Expanded polystyrene - 0.4-1.0; kgf / m2MPa

Styrofoam - 0.07-0.2. kgf / m2 MPa

If you put a sheet of expanded polystyrene and expanded polystyrene of the same thickness and area on two supports, and place a load in the center, then expanded polystyrene will withstand a greater load than polystyrene.

Life time

Expanded polystyrene - over 50 years

Styrofoam - 10-25 years old.

With the destruction and oxidation of any of these materials, substances harmful to the body are released. The longer the service life, the safer the use in residential premises.

Smoke production rate:

Expanded polystyrene - 1048 sq.m / kg

Styrofoam - 1219 sq.m / kg

In any case, when smoke is generated, harmful substances will be released enough for a person's death. For comparison: the smoke generation coefficient for wood (on average) is only 479 m2 / kg.

Application area

The field of application of polystyrene and expanded polystyrene has expanded significantly over the past decades.

Foam application:

- wall insulation of residential and industrial premises,

- shipbuilding,

- packaging,

- furniture manufacture,

- outdoor advertising,

- sewing clothes (as a heater).

Application of expanded polystyrene:

- construction of buildings (used as insulation for basements, basements and roofs),

- production of disposable tableware,

- in the production of household refrigerators,

- when laying roads,

- children's toys, designer furniture and interior items.

A significant drawback of both foam and polystyrene foam is their high fire hazard. To reduce the risk of ignition, in the process of making expanded polystyrene, experts add a fire retardant substance, and the resulting material is called self-extinguishing and is marked with an additional letter "C" at the end.

It is reasonable to assume that both polystyrene and expanded polystyrene can and should be used in a wide variety of construction industries. If we correctly take into account their properties and scope, then both materials will fully justify themselves.

Historical reference

The discovery of expanded polystyrene took place about 50 years ago in Germany, where it almost immediately began to be used in construction. During the time that has passed since this discovery, studies of its qualities, properties and merits have not stopped. In particular, the Germans tested polystyrene foam, which was removed from houses built 40 years ago.

The studies carried out made it possible to determine that expanded polystyrene retained its properties by almost 90%, and this once again confirms the durability of this material.

Comparison of foam and extruded polystyrene foam

Extruded polystyrene foam and polystyrene foam are among the most popular thermal insulation materials on the market. These heaters, it would seem, at different prices, have similar technical characteristics, and it is sometimes very difficult to choose a suitable option for use.

Foam plates PSB-S25

In this article we will figure out which is better - polystyrene or expanded polystyrene, and what is the significant difference between these materials.A comparison of their technical characteristics and operational properties will be made.

Polyfoam or expanded polystyrene, their differences and which one is better

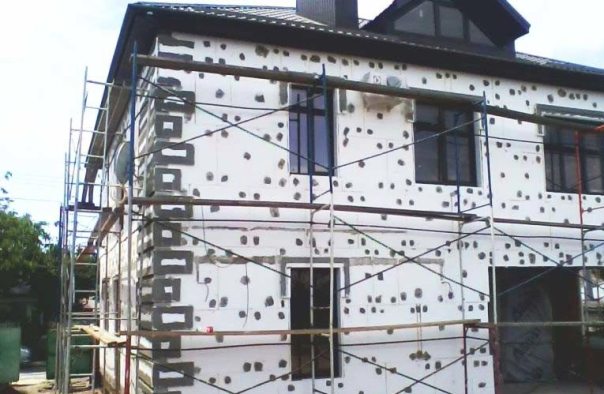

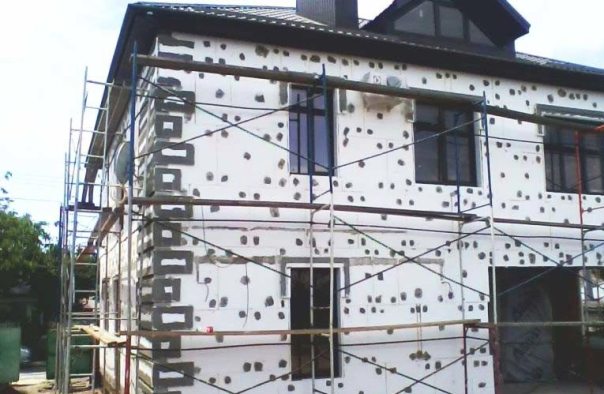

Wall insulation has become very important for most people, in the winter it is to protect the house from the cold, and in the summer - from the heat. The quality of insulation will depend on the heat-insulating material, the more effective it is, the better it will be able to retain heat in the room.

Currently, there is a large selection of materials for insulating the walls of the house from the outside, more and more of them appear on the construction market every year. Experts advise to insulate the walls of the house with certain materials, such as polystyrene and expanded polystyrene. It is difficult for ordinary consumers to understand what is the difference between these two names and which one is better, because at first glance they are very similar.

We choose insulation - polystyrene or expanded polystyrene, which is better and what is the difference?

It is believed that polystyrene and expanded polystyrene are exactly the same material. On certain sites on the Internet, there is information that this is generally all the same. Perhaps this is due to the fact that these materials have a lot in common, and the first thing is their "parent", polystyrene. And the main area of use is the same - thermal insulation and sound insulation of surfaces of various nature. But if you think carefully more carefully, then there is a difference, and quite noticeable.

The difference between foam and polystyrene foam

The very first, there is a big difference in the production technology of these materials. Polyfoam is made by dry steam finishing of granules of the initial material, polystyrene. As a result of the heat increase, they simply "stick" together. And this helps the appearance of certain empty spaces - micropores. Expanded polystyrene is made in a way that is known under the term "extrusion". If the manufacturing process is designated in general, then the polystyrene granules are melted. Therefore, bonds appear at the molecular level, a single structure appears. Second, there are differences in physical properties and technical specifications. This difference is reasonably derived from the properties of the production technology of these materials. We can confidently say that expanded polystyrene in many respects exceeds its own "younger brother" - polystyrene. Let's try to figure out what.

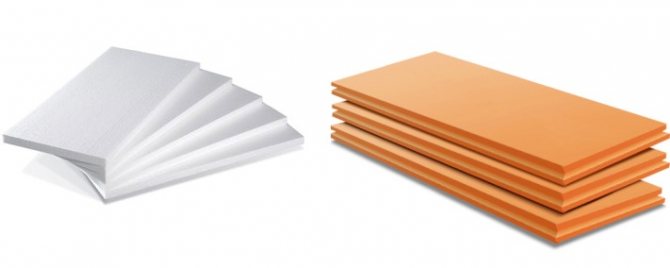

Styrofoam

Expanded polystyrene

Pros of expanded polystyrene

- Fortress. As already indicated, polystyrene foam is a unit mass of a substance, while polystyrene is simply a "coupling" of some particles. When the specific requirements of the environment change, the foam can break, but the expanded polystyrene never. Also, when bending, the foam breaks quite easily, and therefore it can be used only where the surface is not exposed to the effects of mechanics. Judging by its properties, expanded polystyrene is 5 - 6 times stronger in bending;

- Permeability. Due to the fact that there are many empty spaces in the foam, in specific situations they can very easily fill up, for example, with moisture. If we take such a characteristic as moisture absorption, then its indicator for expanded polystyrene is an order of magnitude less than that of polystyrene. The same applies to sound permeability;

- Density. This indicator for expanded polystyrene is 3 - 5 times higher. Therefore, it is somewhat heavier. But here it must be borne in mind that, as a rule, we are talking about small masses of matter. True, both materials are quite lightweight, but polystyrene foam is able to hold a certain load.

We can draw the following conclusion - expanded polystyrene (for example, the Penoplex brand) for use as an insulating material and a material for insulation is in most cases better, but where an available material is required that does not experience high loads, it is advantageous to use foam.

Related videos:

How is styrofoam made

Foam insulation of the facade. How to choose Styrofoam. How to choose a foam mesh.

In this video, we tried to answer the question of facade insulation and the choice of materials for this.

How to glue styrofoam

After watching this video, you will learn how you can quickly and conveniently insulate your house, apartment, balcony with foam ...

How to quickly glue styrofoam on walls

Building, super essential lessons for life.

How it's done. Expanded polystyrene.

How it's done. Expanded polystyrene. Discussion on.

Expanded polystyrene pros and cons.

Extruded polystyrene foam has a wide range of applications: thermal insulation of foundations and plinths, layered ...

Polyfoam (expanded polystyrene, PPS, EPS). Advantages and disadvantages.

Consideration of the qualities of expanded polystyrene, which are indicated on the websites of manufacturers and distributors. ...

Polyfoam, its characteristics and advantages

This heat-insulating material is produced from polystyrene by foaming and in finished form in it. 98% air, it is a classic type of insulation. Polystyrene granules are treated with dry steam and at the moment of thermal expansion they adhere to each other, resulting in micropores in the finished material. For a long time, people began to use it for thermal insulation at home, use the material to insulate walls, floors, roofs. Such protection not only saves from the cold in winter, but also serves as a kind of protection for the walls of the building.

Due to the basic characteristics of foam, many believe that it is best suited as insulation. Its main qualities can be attribute the following properties.

- It is 98% air.

- Its thermal conductivity ranges from 0.038 to 0.050 W / m K, which is significantly lower than that of wood or brick. For example, wood in terms of thermal conductivity exceeds foam plastic by 3 times, and brick by 17 times.

- Only 2-3cm of foam can make a complete soundproofing of the building.

- They do not absorb moisture more than 3% of its mass and at the same time its thermal insulation properties remain unchanged.

- The light weight makes it easier to work with the material, it is easy to install, no special tools are required for cutting.

- It is non-toxic, odorless, does not generate dust during operation, therefore, protective equipment is not needed during operation.

- Polyfoam is resistant to cement, gypsum, alkalis, water-based paints, but is afraid of acetone and benzene.

- In contact with an open fire, it ignites, but quickly extinguishes.

- The material is environmentally friendly, safe to use and dispose of, it is also widely used in the food industry and as packaging for many goods, including for children.

Styrofoam also has disadvantages, it very fragile material, which in bad weather complicates the work with it, as well as the transportation of insulation.

Despite the fact that foam appeared a long time ago and now there are many new and modern materials, it has not lost its relevance. Its low price is also attractive to many, which makes it possible to use foam in many types of construction work.

Comparison

Despite the fact that in fact expanded polystyrene is one of the types of foam, the process of making materials is significantly different. Their chemical composition is related; polystyrene is mainly used as a raw material. At the same time, it is much more efficient to use expanded polystyrene in operation as a heat-insulating material, which is influenced by the production technology.

Polyfoam used in construction is obtained by processing raw materials placed in a block mold with water vapor. As a result, the volume of the molecules increases, and they are sintered together. Naturally, as the surface of the granule grows, the number of micropores becomes larger. Over time, under the influence of precipitation and other damage caused by the environment, the connection between them weakens, which leads to the destruction of the material.The weakness of the interaction of the granules also explains the lower strength of the foam.

Expanded polystyrene is produced by extrusion. Due to this, the transformation of the polymer occurs according to other mechanisms, which also affects the structure of the material. At the beginning, the granules melt, as a result of which the raw material becomes viscous-flowing. This leads to the fact that polystyrene foam has an integral microstructure of closed cells, which are filled with gas molecules. For traditional material, natural gas is used, which dissolves well in styrene. In the production of the fire-resistant version, the pellets are filled with carbon dioxide.

Expanded polystyrene consists of closed cells. In this way, maximum impermeability of substances from the environment to the material is achieved. Polyfoam as a heat insulator has such a feature as the passage of water vapor that comes from the room. Then they condense and increase the moisture content of the material. This leads to the fact that the thermal insulation properties of the foam are reduced, and over time it collapses.

Due to the improved technical characteristics, including the density of the material, expanded polystyrene has a higher price than other types of foam on the construction market.

Expanded polystyrene (penoplex)

Extruded polystyrene foam is produced by extrusion, the method forces the polymer to first melt, after which a viscous mass is formed. From the solid state granules turn into viscous-viscous, as a result of which a single liquid-phase substance with a solid and durable microstructure is obtained.

Extruded polystyrene foam looks like a mass of closed cells, inside which there is gas, it is much stronger than foam. Polystyrene foam cells are impermeable, they do not have micropores, like foam plastic, so water or gas cannot penetrate into the cells. The cells of expanded polystyrene look like a solid mass, air or water can penetrate only from the cut side of the side surfaces. In its general state, the material cannot absorb moisture, steam, and much more from the outside.

We often call expanded polystyrene foam polystyrene, since the domestic brand of extruded polystyrene foam is produced with this name, in fact, they are the same thermal insulation material... The polispen brand is also widespread, it is used in various industries: agriculture, in the construction of runways, when laying oil and gas pipelines, with it they make a heat-insulating layer in civil and industrial building structures.

Since the moment of mass production, penoplex has become widely used in construction as a high-strength heat-insulating material. It is always used for work outside, since it is not suitable for internal insulation, polystyrene foam at high temperatures can release styrene. Main characteristics material are:

- Increased compressive and fold strength.

- High density foam.

- Does not crumble, unlike styrofoam.

- Thermal conductivity 0.028 W / m K.

- It absorbs moisture no more than 3% of its mass, this indicator does not affect its thermal insulation, strength and structure.

- Has excellent sound insulation.

- Penoplex is not afraid of insects and rodents.

- Does not rot and burns poorly.

Types and methods of producing expanded polystyrene.

The general scheme of the technological process for the manufacture of expanded polystyrene consists of the stages of dissolving the foaming components in the polymer, heat treatment with water vapor of the reaction mixture and subsequent molding. The polymer base is polystyrene or polychlorostyrenes, as well as styrene copolymers (butadiene, acrylonitrile and others).

Foaming components can be pentane, dichloromethane, as well as petroleum ether, related to low-boiling hydrocarbons, or porophores that decompose at high temperatures with the release of a large volume of gases.During heat treatment with steam, hydrocarbons boil or decomposition of chemical reagents occurs, as a result, the volume of the reaction mass increases many times, the granules completely fill the mold and are interconnected. The formulation of expanded polystyrene may include plasticizing components, pigments, fire retardants, stabilizers, modifiers and other fillers.

Depending on the molding method, types of expanded polystyrene are produced:

- non-pressed type (EPS brands. PPS, PSB-S);

- press type (designation PS-1, imported brands);

- extrusion type (penoplex, technoplex, techno-nicol, XPS, URSA);

- autoclave and autoclave-extrusion type.

Styrofoam or expanded polystyrene, which is better

Comparing both heaters, we can say that they very similar to each other... Having carefully studied their main characteristics, we can say for sure that foams have a higher degree of strength, moisture resistance and air permeability. Due to its density, the insulation has the best thermal insulation qualities, but without special processing it is more flammable than foam.

Compared to penoplex, foam loses in density, insulates less from noise. Polyfoam retains heat better due to its looseness, but this property protects it from moisture worse. Styrofoam always needs to be covered with other materials in order for it to serve for a long time.

If you compare the price of one and the other insulation, then penoplex will cost more than polystyrene, which means that more money will have to be spent on all construction work. When choosing polystyrene, you need to know which brand you need to purchase, they have differences in their characteristics.

Before buying, you need to compare all the basic properties of the two materials, know in advance where they will be used for insulation and make your choice correctly.

What is Styrofoam

In fact, the two concepts of foam and polystyrene foam represent the same material, but produced using different technologies. As a result, both of them acquire differences in technical characteristics. The starting material for both polystyrene and expanded polystyrene are polymers based on:

- polyvinyl chloride;

- polyurethane;

- phenol formaldehyde;

- polystyrene;

- combinations of urea and formaldehyde.

In everyday life, the most common type of foam, called polystyrene, is produced without such a technological stage as pressing. This material was first obtained at the BASF factories in the middle of the last century, where it was first named "styrofoam" or PSB-1 foam.

Manufacturing technology

Granular styrofoam is produced using pentane, a substance that promotes the formation of tiny pores filled with gas.

Raw material for the production of foam

At the same time, styrene itself in the total mass of the material contains no more than 2%, the rest is gas. During production, the foam is pure white in color, it is extremely light due to the fact that it consists practically of air. And it is precisely this circumstance that became the reason for the use of foam as an insulating material, since there is no better insulation in nature better than air.

The entire production process for obtaining foam includes several operations:

- Primary foaming of granular styrene under the influence of hot steam.

Foaming polystyrene

- Placement of foam in a drying chamber.

- Extract of chilled foamed granules.

- Secondary foaming.

- Cooling the resulting mass.

- Cutting products according to the specified parameters.

Foaming of granules can be performed several times, depending on the required density of the finished product.

How epps is made - extruded polystyrene foam

The technological process for the production of raw materials for foam and extruded polystyrene is the same.Differences begin at the foaming stage, where special additives are introduced into the raw material.

The process takes place under the influence of high temperature steam in a special device called an extruder, where the mass under the influence of steam acquires a homogeneous and smooth consistency that can take any shape.

Production of extruded polystyrene foam (foam)

Through a special hole in the extruder under high pressure, the liquid mass is squeezed out into prepared forms. Finished products, after cooling, have the necessary density, rigidity and, at the same time, plasticity. On sale you can find insulation called penoplex, which is nothing more than extruded polystyrene foam.

The difference between concepts such as foam and extruded polystyrene foam lies in the production technology, as a result of which the materials acquire different technical properties and characteristics.

Polyfoam vs Extruded polystyrene foam

Various Internet sources may contain quite contradictory information regarding the issue of penoplex or polystyrene, which is better. These materials have a certain similarity, since they are made from the same component - polystyrene. Even so, there are many similarities between foam and extruded polystyrene.

- Polyfoam is not durable.

- Manufacturing technology.

Expanded polystyrene consists of polystyrene, which has a granular structure, melts under the influence of high temperature. As a result, a single structure is formed, which is used for insulation and sound insulation.

To obtain foam, the material is treated with dry steam. As a result, a whole mass is not formed from the granules, but they simply adhere to each other.

- Extruded polystyrene foam is produced by extrusion, due to which it has a lower moisture absorption value compared to foam. As for the penoplex, water, although slowly, can seep through its cells. Water access is possible only in the cells that are located on the side surfaces. that is, the entire slab of material does not absorb steam and moisture from the outside.

- With noise insulation, the situation is similar.

- Extruded polystyrene foam has a density that is 4 times that of foam. Expanded polystyrene is slightly heavier than foam, which means it is able to withstand a heavy load.

The gradual replacement of obsolete foam with newer extruded polystyrene foam has already become a global trend. For example, in the USA it is already forbidden to use it, now extrusive polystyrene foam is massively produced there.

Scope of foam and expanded polystyrene

Considering that the foam is the same expanded polystyrene, but of a higher density, the area of its use in construction is mainly reduced to the insulation of structural elements of buildings and structures. For example, non-extruded polymer material is quite often used for thermal insulation of facades, given its high heat-insulating properties, ability to adhesion.

Roof insulation with polystyrene

But with penoplex it is good to insulate basements, foundation and basement elements of buildings, loggias and balconies. At a thinner thickness, it retains all the thermal insulation properties inherent in thicker foam.

At the same time, it is not recommended to insulate with these materials indoors, especially in residential premises, due to the fact that during production the insulation is treated with anti-combustion compounds that can be released into the environment throughout the entire period of operation. In some countries of Europe and America, the use of foam as a heat-insulating material is not allowed. The reason is the release of toxic substances during a fire.

Basement insulation

Extruded styrene foam is used in the production of decorative interior products.

Polystyrene tiles as a finishing material in the interior of premises

In the medical industry, polystyrene foam, just like foam, is used as a material for the manufacture of packaging.

These materials serve as insulation in household appliances, industrial refrigerators, buoys, floats, life jackets are made from them, they fill the compartments of ships, which ensures their ability to stay on the water.

In the food industry, packaging for products and fragile items is made from extruded styrene foam.

Styrofoam in the production of food packaging

Polymer materials obtained without pressing or by extrusion are used in different fields, and when the question arises what to choose, you need to know what is the difference and the properties of these materials.

What is the difference between polystyrene foam and polystyrene foam

Both materials have a lot in common. Considering that the foam is essentially the same expanded polystyrene, however, they have significant differences due to the technology of their production. Consider first the positive and negative properties of foam. The positive characteristics of this material include:

- Low cost of finished products, which is one and a half times lower than the price of extrusion material.

- Long service life provided that installation and operating conditions are observed.

- High degree of thermal insulation with proper installation and further operation. Light weight for easy transportation and installation.

- The structure of the material, if used in dry conditions, does not develop fungi, mold and other microorganisms.

- It is easily processed (cut, sawn, broken) with any available tools and even hands. It does not require providing the worker with protective equipment, since it is an environmentally safe material - it does not emit harmful odors and dust, does not prick. This is confirmed by the production of disposable tableware and toys for children from polystyrene.

Foam application

- It can also be used as sound insulation, when a three-centimeter slab of polymer material is able to completely drown out sounds.

- Temperature range of polystyrene use, without loss of thermal insulation properties and mechanical strength, from -60 ° Ϲ to + 95 ° C. Practically does not absorb moisture.

- Does not support combustion. Extinguishes within 4-5 seconds after contact with an open flame.

The negative properties of foam include its non-contact with solvents and relative fragility. In the event of a fire in a room where Styrofoam has been used, the toxic smoke can cause death. Domestic rodents often settle in the porous material.

Polyfoam is not a hindrance to mice

Comparison of foam and extruded polystyrene material

Quite often, when choosing a heater, consumers ask themselves what is better than polystyrene or expanded polystyrene, what is the difference between these heaters, which is warmer, easier to install and more economical. To understand, you need to consider the technical characteristics of both materials:

- The thermal conductivity of foam is 0.04 W / mK, for foam -0.032 W / mK.

- The mechanical strength of the foam is inferior to the extrusion material.

- The density of foam is 20-30 kg / cm3, foam is 30-45kg / cm3.

- Vapor permeability 0.022 and 0.005 mg / mchPa, respectively, for foam and foam.

- Due to the higher density, which is achieved by better molecular bonding, the mechanical compressive and flexural strength of the extruded polystyrene insulation is higher, as well as the ability to withstand a wider range of temperature differences.

- Polyfoam can absorb no more than 3% of water from its mass, penoplex - no more than 0.4%. If you choose a material for warming a bath, it is better to dwell on the second option.

- The shrinkage of the foam is much greater than that of polystyrene. The first is afraid of sunlight and heavy mechanical stress. The second is more resistant to both UV radiation and stress. Therefore, polystyrene foam products can be used to insulate facades with subsequent plastering, when installing a warm floor, which cannot be said about ordinary foam.

In terms of flammability, both materials are equally susceptible to fire, but when flame retardants are added to the styrene formulation at the manufacturing stage, neither the foam nor the extruded polystyrene sustain open combustion. Both have the property of self-extinguishing if they are not in the center of the fire.

If there is a choice of insulation, and you do not know which is better - to buy extruded polystyrene foam or to stay like a cheaper foam, take into account all the characteristics of the materials.

Technical characteristics of expanded polystyrene.

The main advantages of expanded polystyrene are low density (on average from 10 to 50 kg / m³) and good sound and heat insulation properties. All types of polystyrene foam have low thermal conductivity coefficients, are breathable, hydrophobic (practically do not absorb water), do not interact with acids, alkalis, alcohols, but are destroyed by organic solvents.

Expanded polystyrene convenient for mechanical processing - it is easy to cut, drill, such material environmentally friendly, no toxic binders are used in its composition, as well as biologically inactive, not susceptible to mold and decay.