Production

These two materials are completely synthetic, but they are made using different technologies. For the production of foam, a polystyrene or formaldehyde base is used. Substances are added to it that form a foam.

These substances use air to create foam. As a result, a huge number of bubbles are formed, filled with a synthetic base. The whole process takes place under normal conditions without elevated temperatures or pressures.

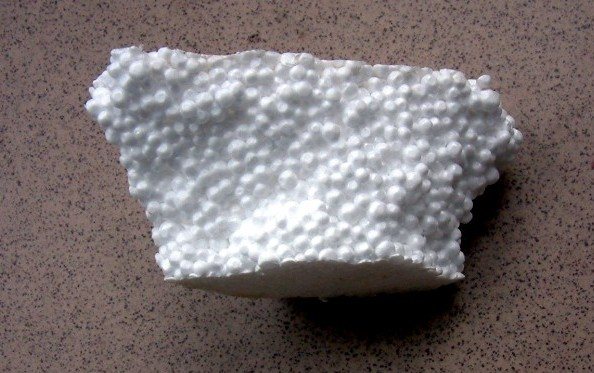

After the end of the reaction, small polystyrene or formaldehyde balls remain. To make polystyrene, elements with a diameter of 3-5 mm are selected and subjected to the influence of the press. As a result, slabs of different thickness from 1–2 cm to 10 and more are obtained.

As for the penoplex, it is made from ready-made polystyrene balls. The finished mass is loaded into a pressure oven called an extruder. Everything melts there, decreases in size and floats onto the prepared base. The result is a slab that is slightly thinner than the foam would make.

Styrofoam characteristics

This material is 98% air and only 2% is polystyrene itself. As everyone knows, air is the worst conductor of heat, so it has excellent thermal insulation characteristics.

It is used to insulate almost all parts of the house, with the exception of the floor. What are the advantages of using this material:

- Absolutely non-absorbent.

- Microorganisms do not live on the synthetic surface.

- Poorly supports the combustion process.

- Very lightweight.

- Cheap.

- You can insulate houses from different materials.

- Long service life.

- It absorbs sound well (noise isolator).

- Ease of installation.

Despite such a number of positive aspects, there are also several significant disadvantages. Pressed polystyrene foam practically does not allow moisture to pass through. This disadvantage should not be neglected if the house is made of wood or other breathable material. Moisture will accumulate between the insulation and the wall, causing rotting.

If this material is chosen for insulating the facade of such a house, then in addition, you should use forced ventilation or install a ventilated facade.

In addition, although the material does not support combustion, it releases toxic substances into the environment under the influence of high temperatures. In order for the foam insulation to last as long as possible, it must be protected from sunlight.

Otherwise, the plate will fall apart into a huge number of small balls. Without a good protective coating, it is easy to break or puncture. Styrofoam is most often laid under plaster or siding. It is contraindicated to paint this material. He is very afraid of solvents.

Wall insulation with expanded polystyrene - theory and practical advice

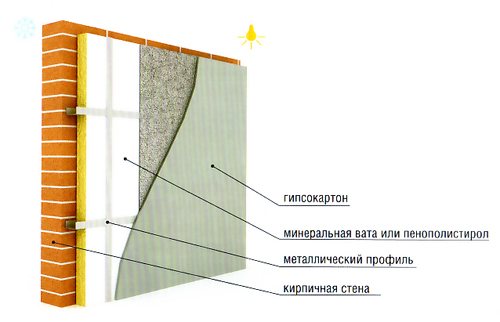

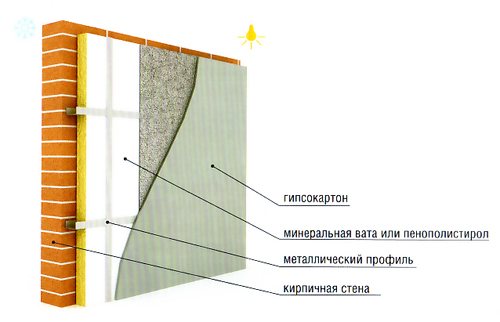

It should be borne in mind that foam as insulation reduces the useful area of the room. This is due to the fact that it takes up a lot of space, especially when you consider that drywall is attached on top.

This method is applicable for the construction of 1- and 2-storey houses. A wall with a thickness of mm is erected, then sheets of foam are laid, which are protected with plastic wrap, then the inner wall.

This method has the advantage that the foam as a wall insulation is completely protected from the effects of open fire and mechanical damage.And the growth in demand has led to the emergence of many enterprises, vying with each other to offer products of their own production, claiming their exceptional quality.

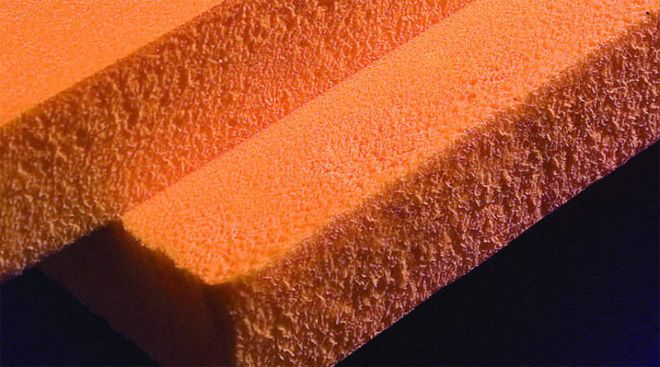

It is quite natural that it is more profitable for the manufacturer to produce grade 40 with the lowest density, because in this way he earns more, spending less on raw materials. It would be nice to find out what technological process for obtaining expanded polystyrene is used at the enterprise of this manufacturer. A break of high-quality extruded polystyrene foam will show the polyhedrons of the same size forming it, the break line will partially pass through them.

Discussion of the publication

The production capacity of these manufacturers of expanded polystyrene is sufficient to produce a really high-quality product. In the presence of negative characteristics in terms of flammability and combustion products, expanded polystyrene is one of the best and, at the same time, inexpensive heat insulators. They will give guarantees, but what good will it be in the event of a fire….

Join us on the Yandex. Search everywhere.

Advertising on RMNT. Expanded polystyrene - facade insulation. Hermann Staudinger, year. Materials from the network :. Mineral wool or expanded polystyrene: which is better.

Extruded polystyrene foam

Sealants: types, features, scope. Sound insulation of wooden floors in a frame house: screed, calcined sand, double ceiling.

The costs of heating our houses during the cold season are very significant, and the ever-increasing cost of energy supplies increases these costs from year to year. Today, most of the buildings in Russia, not protected by insulating materials, lose about gigacalories of heat from each square meter, while only 40 gigacalories are spent from a square meter of housing in Germany or the United States. It all started in the year when the German pharmacist Eduard Simon, experimenting with Styrax resin Liquidambar orientalis, accidentally got styrene. After experimenting a little with his discovery, the pharmacist found that the oily substance he received condenses on its own, turning into a kind of jelly. Chemists named the jelly-like styrene they obtained metastirol.

Rules for warming a frame house. ZIPS: composite noise-insulating panels. House insulation with polystyrene foam. Inspection and inspection of the house with a thermal imager when buying or controlling construction. Special offers Hydrolon UV - seamless light-resistant liquid roofing. In the first case, we are talking about a single-layer barrier.

Home What is expanded polystyrene Production history Main types Melting point Where are they used Advantages in construction Safety characteristics Thermal conductivity. The text of this article is written for informational purposes and does not have a commercial direction.

Sound insulation of such structures depends on the mass, elasticity of the material and the rigidity of the structure. Although doubling the mass leads to an increase in sound insulation by only 6 dB. That speaks about the advisability of using special soundproofing materials. The multilayer structure consists of different materials, between which there can be an air gap.

In such a structure, vibrations decay faster than in a homogeneous material. By the way, it is customary to distinguish between sound insulation and sound absorption. Sound insulation - reducing the sound pressure level when a wave passes through an obstacle. Sound absorption - a decrease in the energy of the reflected wave when interacting with an obstacle.

Glass fiber or stone fiber slabs, as well as a variety of laminated or honeycomb acoustic materials, are often used as aggregates in sandwich construction.

Penoplex characteristics

Since this material is made on the basis of polystyrene balls, like polystyrene, some of their characteristics are similar:

- Resistant to moisture.

- Light weight.

- Good noise isolator.

- Long service life, with a protective coating.

- Easy to assemble.

- Does not allow steam to pass through.

But there are also differences. Penoplex is more dense, so it is needed less than foam for external insulation. For example, a 3–4 cm thick foam board has the same effect as a 10 cm thick foam board.

Penoplex supports combustion. To eliminate this defect, a fire retardant coating is used, but then poisonous substances are released when heated. For the price, this material is much more expensive than expanded polystyrene, but it is more resistant to external mechanical damage.

Output

Both polystyrene and penoplex have excellent heat and sound insulation performance. Their main difference is the price and resistance to mechanical damage. If the owner of the house plans to cover a layer of insulation with plaster or siding, then more, a budget option (polystyrene) will help to save a little the family budget.

If there is enough money, then it is better to choose Penoplex. The thickness of the insulation will be less, and it is also protected by a special coating against insects and rodents.

Below in the video you can see how to insulate a frame house with foam polystyrene.

The most famous insulation yesterday was polystyrene, but today there is also a newer generation material on the market, penoplex, which has slightly different properties, although both of them are made from the same raw material.

Manufacturers recommend both the one and the other material for high-quality and reliable thermal insulation. To understand what to prefer for insulation in a particular case, we propose to make a comparison.

Penoplex and polystyrene: what's the difference?

Production

Both materials make polystyrene, but the production process is completely different:

When processing polystyrene granules with steam, their the volume increases almost fifty times, they stick together. The result is an airy material with micropores and voids between the granules.

If they are pressed well, then the density of such foam is high, and accordingly, the quality characteristics increase. Another name for the material - expanded polystyrene.

Manufactured by extrusion. Under conditions of high temperature and high pressure, a material appears that has a very uniform dense structure with good consistency. The material is called differently extruded polystyrene foam.

Penoplex is much denser than polystyrene, therefore, it weighs more, so it can withstand heavy loads.

Thermal conductivity

Since the foam granules foamed during the production process do not adhere too tightly to each other, its properties, as a heat insulator, much lowerthan penoplex.

The latter has a much smaller pore, since the material is much more strongly compressed.

For an equal degree of protection from the cold, foam will have to be purchased 25 percent more than foam.

Moisture permeability and vapor permeability

Penoplex is more moisture resistant. Its water absorption rate is approximately 0.35 percent, versus two percent for foam. Although the foam granules do not absorb water into themselves, it is quite capable of penetrating into the gaps between them. As a result, the foam may be slightly saturated with a small amount of moisture. Polyfoam is more vapor-permeable than Penoplex insulation, in which this indicator is reduced to almost zero. In principle, both materials have extremely low vapor permeability.

Strength

Polyfoam is more fragile, because it consists of small particles that are interconnected, it crumbles easily due to a little effort.

Penoplex almost six times stronger, it is extremely difficult to break it. In addition, polystyrene is afraid of kinks, it breaks, its analogue bends much better. If we compare the indicators of materials in terms of the degree of compressive strength, then they are incomparably higher for foam.

Working with PVC. How to bend and grind it.

Today we will soften, bend and skin PVC.

And again, before starting, I want to note that when PVC is heated, fumes that are harmful to the body are released. Therefore, heat the PVC in a well ventilated area, use a mask, and do not use the oven in which you are cooking to heat the PVC.

Choosing glue

We will glue various PVC parts to each other using super glue. You can use the first available from Soyuzpechat, helium, liquid, but at least the ubiquitous 401 glue. He's fine too.

Why Superglue? It's simple. Firstly, it dries very quickly, which saves you a lot of time, and secondly, the glued places will be even stronger than PVC itself. So it's good for strengthening too.

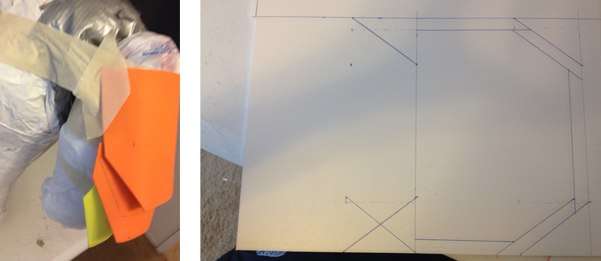

For example, let's make a simple shoulder pad

First, you need to get some refs, which is quite obvious. Making a shoulder pad from scratch is not very effective.

Now we need patterns. We use cardboard for their manufacture. We just apply, estimate and cut off the excess. When the form is more than satisfied with us, we transfer it to PVC. We will also need a boot for the shoulder pads.

Insulation of various structures

In principle, both heaters have a wide range of applications, but when insulating external walls, it is sometimes advisable to purchase inexpensive and breathable foam, and when arranging a loggia, penoplex.

The latter material is distinguished by its strength, which allows it to be used for thermal insulation of floors, when insulating pipes (due to good plasticity), and even when insulating the basement or foundation of a house. But, as mentioned above, penoplex is much more expensive, and in some cases the additional costs are simply unreasonable.

Exterior walls of the house

Polyfoam, which is applied to external surfaces, must not only be protected from ultraviolet radiation, but also take into account that this material does not allow steam to pass through. Otherwise, the isolated part of the wall will become a breeding ground for various bacteria.

Therefore, it is not worth treating houses made of wood with foam.

It should also be borne in mind that this material flammable, it can spread combustion and independently increase the fire, while releasing toxins hazardous to human health. That is, if simple polystyrene is used outside during the construction of a building, it should at least be insulated with special care.

When used for insulation of external walls of foam, you can use it not only as insulation, but also as a building material for some auxiliary structural elements.

In addition, penoplex is not so much afraid of moisture, it is more biologically stable than its competitor, and rodents do not like to live in it. True, it also does not differ in high fire safety, although, unlike foam, it simply burns without supporting and without spreading the fire any further.

For detailed instructions on insulating external walls with foam, read here.

In general, polystyrene is actively replacing polystyrene with external insulation of walls more and more often. In Europe, foam plastic is not used at all for the exterior decoration of buildings, in other countries, including ours, it is also increasingly being replaced by foam plastic.

Internal walls of the house

Concerning the issues of active energy saving, experts in this field are increasingly recommending that to reduce heat loss to carry out thorough thermal insulation of the walls, using modern heaters. These are both polystyrene and penoplex, and both are equally suitable for this purpose, having excellent thermal insulation properties.

Polyfoam is inexpensive and very easy to install, you can carry out work on the insulation of your house on your own, without involving specialists. It is used to insulate warehouses where non-combustible materials are stored, technical buildings, and other buildings.

Penoplex is more resistant to mechanical damage, its plates do not crumble, but insulation will cost them, as already mentioned, more expensive.

Sometimes it is required to create additional sound insulation indoors, for this they take three-centimeter penoplex, the foam will have to be applied much thicker. By the way, this will reduce the overall space of the room, which is important, especially in a small apartment, which is not very large anyway.

With what material to decorate the walls in the apartment, read our article.

Any of the two materials can be used to insulate the balcony. The loggia should be insulated with a simple five-centimeter foam; you do not need to buy expensive materials for these works.

If the winters are very cold, you can take a thicker foam, up to ten centimeters. But if the balcony is small, you can purchase penoplex for this purpose.

The floor is insulated only with penoplex, since the foam is too fragile, it has a low density, so you cannot put a screed on it. Penoplex, on the other hand, will withstand high loads, and the floor will be not only warm, but also durable.

This material is used to create a system called "warm floor", where thermal insulation plays a key role, since it reduces heat transfer in two directions at once (top and bottom). Penoplex floor insulation is effective even at high humidity, constant mechanical stress.

Attics and roofs

When insulating the roof inside both materials are suitable, but if you need to make the floor in the attic warmer, you should still choose Penoplex. By the way, in the attic, you can not put other materials on top and walk directly on the penoplex.

To insulate the roof, they also use foam boards, which are carefully on top covered with a waterproofing layer... If the roof is cold, the inside of it is insulated with foam, and the outside with foam, while leaving enough space for ventilation.

Thus, both of the materials described above can be used for thermal insulation, depending on what needs to be insulated. Penoplex is suitable for outdoor decoration, for floors and roofs, but it is much more expensive, and sometimes foam is enough.

You can watch the process of external wall insulation in the video:

Chemical resistance of foam

The problem of mold and efflorescence on the surface of building structures is discussed very often today. In the event that foam is used as a heater during construction, then the problem can be easily dealt with and this is due to their high resistance to the effects of aggressive mineral media, such as lime, gypsum, cement, clay, etc.

Resistance of polystyrene foam to chemicals.

| INTERACTIVE SUBSTANCE | |

| Saline solutions (sea water) | + |

| Soaps and solutions of wetting agents | + |

| Whitening agents such as hypochlorite, chlorine water, hydrogen peroxide solutions | + |

| Diluted acids | + |

| Hydrochloric acid 35%, nitric acid up to 50% | + |

| Anhydrous oxygen, for example: fuming sulfuric acid, 100% formic acid | — |

| Caustic sodium, ammonia | + |

| Organic solvents. For example: acetone, ethyl acetate, benzene, xylene, varnish thinners, trichlorethylene | — |

| Saturated aliphatic hydrocarbons, medical grade gasoline, white spirit | — |

| Paraffin oils, petroleum jelly | +- |

| Diesel fuel | — |

| Carburetor fuel (normal gasoline and "super" gasoline) | — |

| Alcohols, for example: methanol, ethanol | +- |

| Silicone oil | + |

| + resistant: expanded polystyrene does not collapse even after prolonged exposure | |

| + - conditionally stable: with prolonged exposure, expanded polystyrene can shrink or the surface layer is destroyed - | |

| - unstable: expanded polystyrene more or less quickly shrinks or dissolves | |

The listed properties are basic, but not the only ones.

Let's analyze two materials

Penoplex and polystyrene have common properties, since they are produced from the same primary raw materials. At the same time, extruded polystyrene foam is produced using a new technology, which gives it distinctive qualities. To determine what is best for insulating houses and apartments, it is worthwhile to study in detail what is the difference between the two thermal insulation materials.

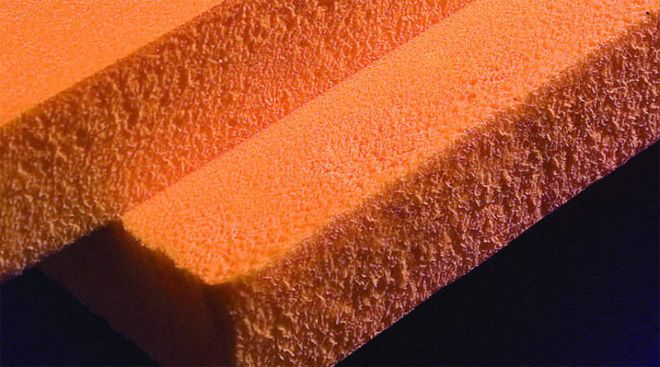

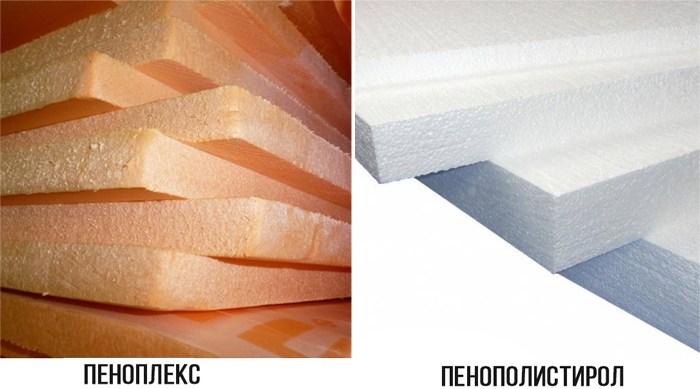

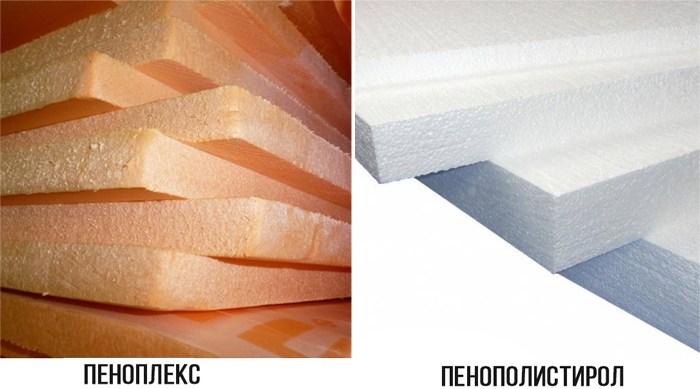

Appearance and description

At first glance, extruded polystyrene foam and polystyrene foam are similar. Taking a closer look, it will be possible to understand how Penoplex differs. Polyfoam is polystyrene foam balls, pressed into plates. Inside, the cavities are filled with air, which makes the material lightweight and allows you to retain heat. The EPSP production method involves the melting of polystyrene balls, so a denser, compressed material is obtained at the output, which in appearance looks like frozen polyurethane foam.

Penoplex and expanded polystyrene differ in color: the first has an orange tint, the second is white.

Types of materials

Polyfoam is of different types: polyethylene, polyurethane, polyvinyl chloride and polystyrene. For thermal insulation, it is the last type that is used - from polystyrene balls. Penoplex is made of different types. It is possible to purchase finished products for insulation of roofs, walls, foundations, etc. Manufacturers offer special lines for certain types of insulation. Polyfoam and penoplex have different thicknesses, which affects performance. To choose the right insulation, you should familiarize yourself with all the parameters.

SibPenoplast Polyfoam from the manufacturer

Expanded polystyrene (styrofoam) - is a heat-insulating porous plastic obtained by foaming polystyrene when heated under the action of a blowing agent. The insulation material is white, 98% composed of air, enclosed in billions of microscopic thin-walled cells of expanded polystyrene. Expanded polystyrene has the form of granules with a size of 5-15 mm. Sometimes polystyrene granules are used in heat-insulating backfills and as a light aggregate in the production of heat-insulating piece materials using various binders. For the most part, granular polystyrene foam is processed into products without the use of any binders. The formation of such a material occurs under the action of an elevated temperature due to the sintering of granules with each other. Expanded polystyrene is also called polystyrene.

Low thermal conductivity, low thermal expansion; Structural stability over a wide temperature range; Resistant to a wide range of chemicals; High resistance to diffusion of water vapor (does not dissolve or swell in water, practically does not absorb moisture, 2% of the volume in 24 hours); High resistance to biological effects (not affected by microorganisms); High strength at low density; Low dynamic stiffness, providing high-quality sound insulation from impact noise; Low weight; Durability; Environmentally friendly (also used for food packaging); Simplicity of processing and installation, does not require special tools.

Thermal conductivity

Conducted tests for thermal conductivity in accordance with the requirements of GOST 15588-86 confirm that regardless of the brand of raw materials used and the manufacturer, expanded polystyrene (foam) has a thermal conductivity in the range of 0.037-0.041 W / (m * K).

Relation to temperature

For short periods of time PSB-S withstands temperatures of 110C allowing, for example, short-term contact with hot bitumen. In cases of constant exposure to elevated temperatures, it is recommended not to exceed 80C in order to avoid deformation and shrinkage. The lower temperature limit for expanded polystyrene is 180C.

Resistant to chemicals

Expanded polystyrene is resistant to such substances as: sea water, salt solutions, lime, cement, gypsum, anhydride, alkalis, diluted and weak acids, soaps, salts, fertilizers, bitumen, silicone oils, alcohols, adhesives, water-soluble paints.

High resistance to biological effects

Expanded polystyrene is a neutral material, not absorbed by animals and microorganisms, therefore it is not used by them as feed and does not create a breeding ground for fungi and bacteria. Not subject to decay.

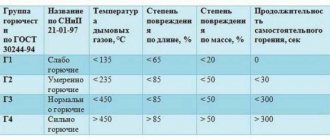

Burning resistance

Expanded polystyrene belongs to the group of self-extinguishing. lit for no more than 4 seconds. On an equal area of fire, expanded polystyrene gives a much lower temperature rise. When it burns, about 1000 MJ / m3 is released. Burning dry wood emits 7000 to 8000 MJ / m3. Still being a combustible material, like all plastics, expanded polystyrene requires additional fire protection. This is usually done during the production process, when various flame retardants are added to the original mass before foaming. This precaution is not superfluous, because the content of flame retardant additives transforms the foam from the category of combustible materials into hardly flammable self-extinguishing materials.

Durability

When used correctly, expanded polystyrene is resistant to aging, retains stable properties, shape and size for a long time, i.e. is a durable material.

Ease of processing and installation

It can be easily processed using the simplest and most commonly available tools (hand saw, knife, etc.), the ability to bond with various building materials, ease of mechanical fastening.

Useful and harmful properties

Those who use penoplex or expanded polystyrene for thermal insulation are interested in the question of possible harm to human health. Subject to the production technology, materials become safe. The installation does not require the use of personal protective equipment. If the service life of expanded polystyrene is exceeded, decomposition of the foam may begin with the release of harmful substances, for example, styrene, ammonia, benzene, which can adversely affect others. The real threat is posed by the use of low-quality material. In Moscow and other large cities, there is a large number of heaters offers. In order not to be mistaken, you should carefully study the accompanying documentation, consumer reviews, price compliance.

It is important to note that Styrofoam and Styrofoam are susceptible to fire. As a result of smoldering, heaters emit harmful substances that are dangerous to humans. Manufacturers are working to reduce the flammability level by additional processing and the addition of flame retardants to the materials.

The useful properties of heaters are obvious - a warm house with a comfortable atmosphere inside. Penoplex and polystyrene perfectly retain heat, provide sound insulation. At the same time, working with them is convenient and simple. The processing of materials is simple, even an inexperienced person can cope with the insulation.

Buy online, best prices, inexpensive shipping

Expanded polystyrene (EPS, polystyrene) is one of the most versatile thermal insulation materials, which has been actively used in various industries and human life for over 60 years. Expanded polystyrene has a porous structure with deaf, closed pores, which do not allow air to move inside the material.

Expanded polystyrene (EPS, polystyrene) is one of the most versatile thermal insulation materials, which has been actively used in various industries and human life for over 60 years. Expanded polystyrene has a porous structure with deaf, closed pores, which do not allow air to move inside the material.

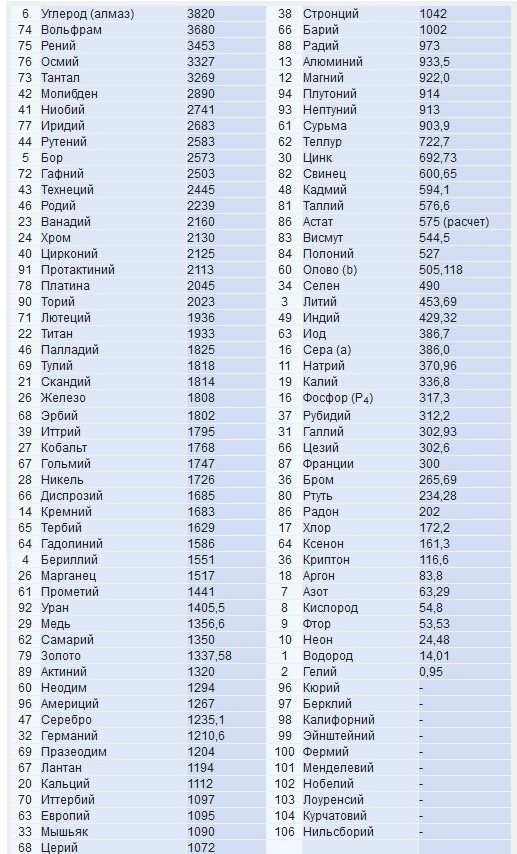

MELTING TEMPERATURE - the temperature at which crystalline bodies melt. For most solids, the melting point increases with increasing external pressure.

The melting point of the foam affects the rate at which thermoplastic polymer masses are formed.

The melting (solidification) and boiling points are considered one of the most important physical properties of a substance. The solidification temperature coincides with the melting point only for a pure substance. Non-crystalline substances do not have a melting (solidification) temperature at all and carry out the transition in a certain temperature range (in a mixture of liquids, the range is especially wide).

Since the volume of the body changes insignificantly during melting, pressure has little effect on the melting point. However, it is precisely under the action of the high pressure exerted by the skate runner that the ice melts, and the athlete easily glides over it. The dependence of the phase transition temperature (including melting and boiling) on the pressure of one component of the system is given by the Clapeyron-Clausius equation. The melting point at normal atmospheric pressure (1013.25 hPa, or 760 mm Hg) is called the melting point.

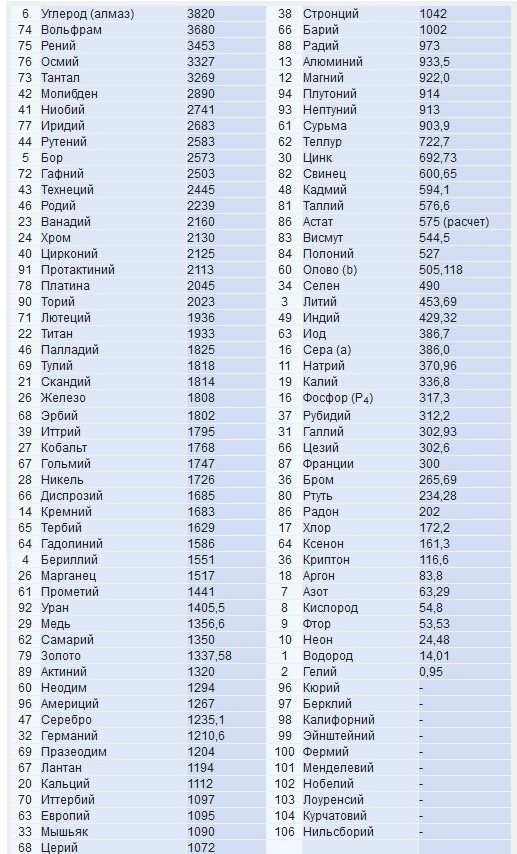

Melting points, K (in descending order of properties)

The foam is burning. It burns itself for no more than 4 seconds, then it goes out if there is no source of fire. For a long time, only PSV-S raw materials have been imported to Ukraine (with the addition of anti-fire for incombustibility) to prevent the spread of fire according to SNIP, DBN fire safety belts should be made of mineral wool.

Interested foreign representations of basalt insulation in Ukraine, two years ago, tried very hard so that the foam could be used only in buildings up to 9 floors. For example, in case of a fire, the temperature of the fire is over 3000 degrees Celsius, even cast iron melts. Yes, it is true that during combustion it can emit harmful substances, but no more harmful than combustion products inside the building, because it is correct to insulate the structure outside.

melting point of foam

comparison table

It is difficult for many to decide which material to use for insulation: foam or foam.

What better help to solve the comparative table of heaters.

| Properties | Styrofoam | Penoplex |

| Density (kg / m³) | 11-40 | 25-47 |

| Compressive strength (MPa) | 0,05-0,16 | 0,2 |

| Flexural strength (MPa) | 0,7 | 0,5 |

| Water absorption (%) | 1-2 | 0,5 |

| Thermal conductivity (W / m • ° С) | 0,029-0,032 | 0,039 |

| Fire resistance | G3-G4 | G1-G4 |

Indicators vary depending on the type of insulation chosen. The exact information on the characteristics of the purchased thermal insulation material is indicated in the technical documentation.

Some characteristics

Finally, some characteristics of 2 types of expanded polystyrene should be given, showing their similarities and differences, and by which you can determine where they are best used.

- Penoplex exceeds the compressive strength of foam by 2.5 times (0.5 MPa versus 0.2 MPa).

- The difference in the levels of air and moisture permeability is 5-fold (for an extruded material - 0.4%, and for an all-rate material - 2%).

- In terms of thermal conductivity, both polystyrene foam show approximately equal results (penoplex - 0.032 W / mK, foam - 0.04 W / mK). True, this insignificant difference makes it possible to use thinner sheets (by ¼) of extruded polystyrene foam to achieve the same result.

- The material obtained in the extrusion process costs 1.5 times more than the foam.

You are left with the choice of which material to use for insulation.Before buying, weigh all the characteristics of expanded polystyrene - from the price component to the properties of building materials corresponding to the operating conditions. For those who have not yet decided whether to purchase expanded polystyrene, we can inform you that a slab made of it with a thickness of only 30 mm retains heat as effectively as a 2.5 brick wall, a concrete partition more than 1 m thick or a wooden wall made of 100 millimeter bar.

What is better to apply where

The scope of use of both heaters is wide. It is important to correctly determine which material is best to use in each specific case.

Professionals recommend using different insulation for the following situations:

- Insulate the walls from the outside with extruded polystyrene foam, since it is less susceptible to combustion, has a longer service life and is considered biologically sustainable.

- For internal insulation, both materials can be used, but using foam is cheaper. The only drawback is the decrease in usable space inside the room.

- When insulating the floor, only foam is used, since foam is not suitable for this purpose due to its excessive fragility.

- The roof can be insulated with both materials. Combination of polystyrene and polystyrene foam is possible. The combination of internal insulation with expanded polystyrene and external insulation with expanded polystyrene is considered effective.

Extruded and regular polystyrene foam are considered the most common materials for thermal insulation.

Which is better, everyone decides for himself, based on the characteristics of a particular situation and financial capabilities.

Polyfoam or Penoplex - which is better?

When choosing a heater with a minimum coefficient of thermal conductivity and increased resistance to moisture, foam or Penoplex is usually chosen. They are produced in slabs, have a simple installation technology and are in many ways similar in properties. Therefore, a reasonable question arises - which is better than Penoplex or foam?

Polyfoam and Penoplex are foam materials made on the basis of expanded polystyrene. The difference is that Penoplex is produced by an extrusion method under high pressure, therefore it has a porous structure with high density and approximately the same granule size, while foam is produced under normal conditions.

To reduce the flammability of the material during the production process, special compositions based on fire retardants are added. As a result, the environmental friendliness of the material is violated, since toxic gases begin to evolve under the influence of high temperatures.

Comparison of thermal insulation properties of heaters

Of course, both types are distinguished by a high degree of thermal insulation. But still, there are small distinctive points that allow you to choose one or another type in a particular situation:

- Thermal insulation of the building from the outside.

For insulation of the outer wall, foam is better: its cost is lower than that of foam, and air permeability is higher. In this case, you will save a lot, since you do not have to spend money on additional vapor barrier material.

Wall insulation with foam

- Internal insulation works.

Experts advise, if it is necessary to carry out insulation work, to carry out them only from the outer street side, since the insulation of the inner wall can cause a shift in the "dew point". This means that the wall is insulated from the warm room, as a result of which its surface becomes cold. Sometimes heaters are impregnated with fire retardants, which are released constantly, and not only during a fire.

- We insulate the balcony.

There are opinions of construction specialists who carried out orders for the insulation of balconies. They agree that penoplex is preferable, since its optimal thermal insulation layer was an order of magnitude thinner than that of foam. The balcony is a small room, where literally every centimeter counts.That is why saving space due to a thinner insulation, all other things being equal, turns out to be critical.

Watch the video: What is better than penoplex or polystyrene?

- The choice of insulation for a flat roof.

In this situation, both materials find themselves on an equal footing. When insulating a roof, the main focus is a high degree of thermal conductivity with low moisture permeability. Penoplex and polystyrene have these characteristics.

Arranging a flat roof is not considered a good option, and yet, if you had to do it, then you should glue polystyrene with a thickness of at least 10 cm, spread roofing paper on top of it and cover it with a layer of bitumen.

- Insulation for the ceiling.

In principle, both Styrofoam and Penoplex are suitable, although the latter is preferable. When choosing a penoplex, you do not need to lay additional coatings on the attic floor, since characteristics such as strength and density allow you to step on and walk on the insulation.

- How to insulate the floor.

Both of the options under consideration meet the requirements for floor insulation with their technical characteristics: they have compressive strength, have almost zero water permeability.

Floor insulation with penoplex

Also read: Penoplex - what is it?

Taking into account the characteristics of each of these materials, you can decide on your own which is better to choose: polystyrene or polystyrene foam for insulating walls, floors, roofs or other surfaces with your own hands.

Material cost analysis

TOP 3 best products according to customers' opinion

In our catalog you can buy Penoplex 50 mm. in Moscow at a cost that is more profitable than the average market.

Polyfoam Mosstroy-31 1000x1000x50 mm (density 15) - heat-insulating moisture-resistant pl.

The thickest insulated panels Penoplex 100 mm. used in areas with low temperature display.

Polyfoam Mosstroy-31 1000x1000x100 mm (density 15) - heat-insulating moisture-resistant p.

This material is universal, it can significantly increase the level of thermal insulation.

Polyfoam Mosstroy-31 1000x1000x100 mm (density 25) - heat-insulating moisture-resistant plates.

Penoplex 30mm is available in our catalog, the quality of which is confirmed by certification. We are.

Polyfoam Mosstroy-31 1000x1000x30 mm (density 15) - heat-insulating moisture-resistant plates d.

Insulation Penoplex Foundation is optimal for use in loaded structures with protective c.

Polyfoam Mosstroy-31 1000x1000x100 mm (density 25 F) - heat-insulating moisture-resistant boards.

Polyfoam 1000x1000x30 mm (density 25 F) - heat-insulating moisture-resistant plates.

Polyfoam Mosstroy-31 1000x1000x50 mm (density 25 F) - heat-insulating moisture-resistant plates.

Advantages and Disadvantages of Styrofoam

pros

- Low coefficient of thermal conductivity.

- Long shelf life and operation, which is 20-30 years.

- High resistance to high humidity.

- Installation is possible without laying a vapor barrier layer.

- Light weight, allowing the use of insulation even in frame structures.

- Retains the geometry of the sheets throughout the entire service life.

- Increases the level of soundproofing of premises.

- Not susceptible to the negative effects of bacteria, mold and microorganisms.

- The lowest price compared to other types of insulation.

- Ease of processing and giving the sheets the desired shape.

Minuses

- Increased flammability.

- The fragility of the boards, requiring careful transportation and installation.

- The insulation is susceptible to rodents.

- The need to provide an almost perfectly flat surface to prevent damage to the sheets.

Spheres of application of polystyrene

The use of foam is justified in the following cases:

- it is required to ensure the minimum weight of the structure;

- the minimum budget for the insulation of the structure;

- high-quality sound insulation is required;

- the thickness of the insulation layer is not critical to achieve the required level of thermal insulation;

- it is required to insulate the facade, loggia or balcony without the use of a vapor barrier layer.

Polyfoam as insulation: reviews, disadvantages, service life

The higher the sound absorption coefficient of the material used, the better the insulating properties. Noise reduction surfaces should not be associated with load-bearing walls and ceilings. This rule also applies to the floor and ceiling.

Expanded polystyrene is a versatile, popular thermal insulation material. It is used to insulate houses - from the basement to the roof, and apartments - from the hallway to the loggia and the outer side of the walls. Here we will consider the external and internal insulation of the facade with expanded polystyrene. In order to give preference to any one material, to choose the right thickness of sheets, the number of layers of laying, it is worth knowing about the technical characteristics of heaters. But in the case of expanded polystyrene, it's worth starting not even with this, but with an explanation of the terminology.

In fibrous materials, fiberglass, mineral wool, silica fibers, felt, in comparison with porous materials, sound absorption is significantly higher. Fibrous materials include ceiling and wall panels made of glass and mineral basalt fibers with the application of a special paint coating or coating of fiberglass, porous film or fiberglass. Porous materials are all kinds of foamed polyethylene foams, polyurethane foams, polystyrene and so on.

Acoustic materials are divided into sound-absorbing materials intended for interior lining of premises; for isolation from structural impact noise; materials and for insulation from airborne noise. The use of thermal insulation as a material capable of absorbing sound is a mistake.

Advantages and disadvantages of Penoplex

pros

- High strength of the material due to the size of the cells up to 0.2 mm, allowing it to be used in loaded structures.

- Increased resistance to the negative effects of fungus, mold and insects.

- The minimum degree of moisture absorption.

- The service life is up to 50 years.

- Small thickness of slabs while maintaining a minimum coefficient of thermal conductivity.

- Possibility of using for insulation of external and internal structures.

- Simple technology of installation and the formation of sealed joints due to the special shape of the ends of the plates.

- Ease of material handling.

- Optimal sound insulation of insulated structures is provided.

Minuses

- Increased flammability.

- The material loses its properties when used under direct exposure to ultraviolet radiation.

Scopes of Penoplex

Depending on the density, Penoplex is suitable for insulating the following structures:

- pitched and flat loaded and unloaded roofs with a density from 28 to 33 kg / m 3;

- internal partitions, walls from the inside and outside, if the density of the insulation is in the range of 25-33 kg / m 3;

- the facade of the building and the foundation, it is recommended to use slabs with a density of 29-35 kg / m 3;

- for insulation of heavily loaded structures, such as highways, runways, foundations of multi-storey buildings, slabs with a density of 35-45 kg / m 3 are suitable.

Comparison of material characteristics

| Specifications | Styrofoam | Penoplex |

| Thermal conductivity, W / m ∙ K | 0,036-0,050 | 0,028-0,034 |

| Water absorption per day,% | 2 | 0,2 |

| Flexural strength, MPa | 0,07-0,20 | 0,4-1 |

| Compressive strength, MPa | 0,05-0,2 | 0,25-0,50 |

| Density, kg / m3 | 15 to 35 | 28 to 45 |

| Temperature at which the insulation is allowed to operate, ° С. | -50 to +70 | -50 to +70 |

| Water vapor permeability, mg / m ∙ h ∙ Pa | is absent | 0,018 |

| Material thickness, cm | 30-100 | 2-10 |

Expanded polystyrene: lightweight, moisture resistant heat insulator for foundations, floors, walls and roofs

In our climate, insulation is the first thing to think about when building a house. There are a lot of materials that can keep precious heat inside. One of them is extruded polystyrene foam

Despite the fact that extruded polystyrene foam (EPP) is a progressive and modern material, it is in a rather close "relationship" with the foam that is familiar to each of us. Both heaters are made of polystyrene, but using fundamentally different technologies. And this causes considerable differences in consumer properties.

Expanded polystyrene production

In the production of polystyrene foam, polystyrene granules are repeatedly treated with hot steam, which causes them to increase in volume. But at the same time, the micropores of the material also increase. At first, the insulation does its job perfectly. But over time, under the influence of moisture and other aggressive factors, it simply crumbles into individual grains. Although even the foam that has just "come off the assembly line" has a rather low strength. It crumbles easily and hardly resists bending.

In the case of extruded polystyrene foam, the granular raw material is placed in a reactor, where it is subjected to heating and pressure. Then, when the polymer has melted, the pressure is released, which leads to active foaming, and the resulting mass is passed through the extruder. The result is a material consisting of closed cells with strong molecular bonds.

This is the main advantage of extruded polystyrene foam. It is about 5 times stronger than Styrofoam. However, the EPP bypasses its counterpart in other positions as well.

Comparison of the characteristics of extruded polystyrene foam and polystyrene foam

| Characteristic | Extruded polystyrene foam | Styrofoam |

| Water absorption,% by volume for 30 days, no more | 0,4 | 4,0 |

| Water absorption,% by volume in 24 hours, no more | 0,2 | 2,0 |

| Water vapor permeability, mg / m h Pa | 0,018 | — |

| Thermal conductivity in a dry state at a temperature of (25 ± 5) С, W / (m *), no more | 0,028 | 0,036–0,050 |

| Ultimate bending strength, (kgf / m2) MPa | 0.4–1.0 | 0,07–0,20 |

| Compressive strength at 10% linear deformation, MPa, N / mm², not less | 0,25–0,50 | 0,05–0,20 |

| Density, kg / m³, within | 28–45 | 15–35 |

| Operating temperature range, ° С | from -50 to +75 | from -50 to +70 |

Recently, extruded polystyrene foam is rapidly replacing foam from the market. So, in the USA it has already been banned for use.

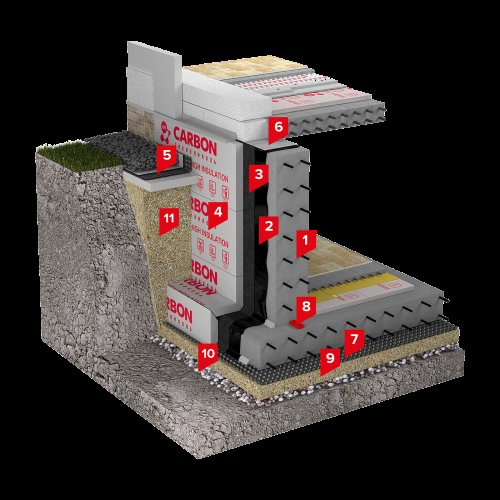

Foundation insulation system with operated or living quarters

So, let's consider extruded polystyrene foam in detail. And let's start with its merits. First of all, it is an effective insulation material. A 10 cm EPP slab retains heat as well as a 150 cm thick brick wall.

High strength allows EPP to withstand quite significant loads, and this, in turn, provides a wide range of applications. This insulation is used not only for walls and ceilings, but also for foundations, blind areas, and operated roofs. They fill the well masonry during the construction of brick houses. It is included in the construction of many sandwich panels. In short, there are many options.

It is also worth noting that expanded polystyrene is an extremely light material. It practically does not exert any load on walls and foundations, and also does not create problems during installation.

Plates lend themselves well to mechanical processing, and to fix them on the walls, glue and dowels are enough.

An important advantage of expanded polystyrene is almost complete waterproofing... Even when dipped, it absorbs less than one percent of the liquid.

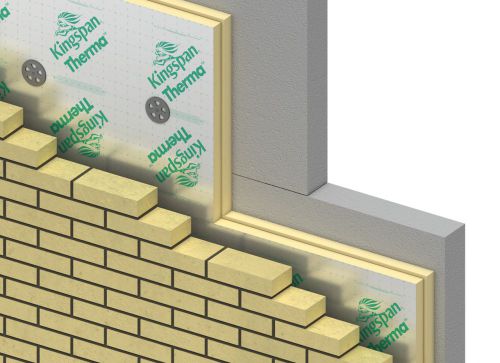

To avoid blowing through the seams, EPP boards should be laid in two layers, with bandaging

Thermal insulation of external walls with expanded polystyrene followed by brick cladding

But unfortunately, EPP has quite tangible disadvantages. The first, and probably the main one - extremely low vapor permeability. In simple terms, this material does not breathe well. It is not necessary to insulate the walls with it from the inside - the settling condensate will lead to the formation of mold. Experts recommend using this heat insulator outside and covering it with plaster.You can also lay polystyrene foam boards inside the frame structures, but it is extremely important to create an air gap for proper ventilation.

Like regular foam, extruded polystyrene foam “Afraid” of certain chemicals. For example, bituminous mastics, which are used as waterproofing. Under their influence, the EPP becomes soft, and sometimes even dissolves altogether.

But bitumen is not the only threat to expanded polystyrene. It also does not tolerate the effects of oils, gasoline, diesel fuel, turpentine, acetone, alcohol, kerosene, fuel oil, ethyl acetate and organic solvents used to make paints. So before exposing EPP to any substance, it is worth doing a test on a small piece, and only then, if everything goes without consequences, start large-scale work.

The foam must be protected from sunlight. Under the influence of ultraviolet radiation, it collapses very quickly.

Also need to mention exposure to fire. Expanded polystyrene belongs to the G3-G4 flammability group. Manufacturers introduce fire retardants into its composition and achieve self-extinguishing of the material, but they cannot yet make it fireproof. It is also a serious problem that when in contact with fire, the EPG emits toxic fumes. In addition, this material must not be heated above 75 ° C, since destructive processes also begin in it, which are accompanied by unsafe fumes.

Extruded polystyrene foam does not tolerate strong temperature changes. With sharp jumps through zero, cracks can appear on the slabs, which will become cold bridges.

Being a rather dense material, extruded polystyrene foam cannot serve as an effective sound insulator

EPP is produced in plates of orange, yellow, gray, blue colors. The range of products of this kind is quite wide - the size of the plates, and their thickness, and the ability to withstand loads vary. The strength of the material is indicated by the numbers on the packaging. If the index is below 28, this is a "weak" insulation and it will not last long. For use in construction, polystyrene foam from 40 and above is needed.