Heated rooms are characterized by a partial vapor pressure, the values of which exceed atmospheric pressure. According to the laws of physics, steam seeks to escape through the holes. Wall structures and ceilings become steam escape routes. This process stops when the thermal insulation layer is installed. Any thermal insulation will contribute to the formation of condensation. But in the cold period of the year, a “dew point” is formed in the steam outlet zone - a place where condensation and settling of drops in the form of moisture occurs. This phenomenon becomes the reason for the moisturizing of the structure itself and the insulation during the entire autumn-winter period. To protect all the building envelopes, including the upper floor, a competent device of effective vapor barrier is required.

House ceiling vapor barrier: is it necessary?

For such premises as a bathroom, a bathhouse, a sauna, the problem of the correct vapor barrier device is one of the main tasks of forming the correct microclimate. You can read more about the rules for the vapor barrier of the bath ceiling here.

Partial pressure is the pressure that the gas would have in the absence of other components of the mixture.

The vapor barrier of the ceiling of a wooden house helps to solve several important problems:

- increase the service life of roofing materials;

- protect the structural elements of the house from the formation of mold and mildew;

- prevent heat leakage through cracks;

- do not sustain combustion.

A properly installed vapor barrier made of modern membrane materials does not require additional maintenance during the entire service life.

Delta-Duo Tape Vapor Control Tape

When installing vapor barrier films on the ceiling, all joints and gaps must be glued. Reinforced polyacryl tape Delta-Duo Tape allows hermetically to connect the overlaps of vapor barrier films. Delta-Duo Tape also serves to securely bond waterproofing films and membranes. The tape has a high adhesive force, has a longitudinal-transverse reinforcement and a width of 38mm.

The area of application of this tape is the connection of various roofing membranes: vapor barrier, waterproofing and wind protection. It can be glued to smooth wood, OSB or metal surfaces at temperatures above 5 ° C.

How to put a vapor barrier on the ceiling

The presence of a vapor barrier layer in a wooden house is an indispensable condition for the long-term preservation of floors. With an ideal assembly of a log house without gaps, condensation accumulates much faster than in a panel house. The vapor barrier layer can be installed both during the construction phase of the building and during the renovation period.

Preparatory work for the vapor barrier device:

- cleaning the surface from debris and dust;

- putty of existing gaps using special compounds;

- primer;

- drying.

Vapor barrier installation steps:

- The vapor barrier material is laid on the ceiling surface with an overlap with a wall vapor barrier (the overlap is 200 mm) and fixed to the ceiling with a stapler.

Ideally, thin slats are laid at the joints of the canvases.

- To obtain strong connections, a special waterproof tape is used.

It is important that the vapor barrier material covers the ceiling in a continuous layer without gaps.

- The layers on the ceiling are joined with an overlap of 100 mm. The material should lie freely, without tension. Experts advise to do even some sag so that the vapor barrier does not break through with sudden temperature changes.

- When laying insulation on the ceiling, it must be remembered that it is not allowed to pierce the vapor barrier with nails. Therefore, a frame system for laying heat-insulating material is used, which makes it possible to avoid damage to the vapor barrier.

And also you can watch an informative video about the vapor barrier of the ceiling:

Summing up

So, the topic was sorted out, how to properly carry out the vapor barrier of the ceiling in a private house (wooden or stone), what materials are best used for this purpose. In addition, the installation of the film was considered, where the nuances were indicated. Namely, which side to put and fix the film, how to properly lay it. They did not pass by the side and waterproofing, as one of the main stages in the protection of insulation. By the way, the waterproofing of the ceiling in the apartment is done in the same way as in the house.

Like?

Check out related articles:

Ceiling vapor barrier materials

The modern building materials market offers high-quality, environmentally friendly samples of vapor barriers with high fire resistance rates.

- The cheapest, but also the most primitive option is polyethylene and glassine, which create an uncomfortable indoor climate due to the lack of air circulation. In addition, these materials are subject to rapid wear.

- One of the most common methods for constructing a vapor barrier is to use a paint vapor barrier. For this purpose, cold asphalt, bitumen-kukersolny, bitumen-lingo-sulfonate mastics, hot bitumen mastics, rubber and polyvinyl chloride varnishes are used.

When the treated layer is adjacent to the vertical surface, it is also coated with mastic by 100-200 mm.

- Membrane films with limited vapor permeability are designed for controlled removal of excess moisture from the room. The moisture removal limit is set by the membrane itself.

- Membrane film with variable vapor permeability for dry and humid air. With increasing humidity, the throughput of this material increases.

- Membrane films fitted with aluminum foil. These materials have a reflective function and enhanced vapor barrier properties. In addition, this film also performs an additional function - it reflects and returns part of the thermal radiation to the room. Such membrane vapor barrier is widely used in baths, swimming pools, saunas, bathrooms.

Are you building a bathhouse? The vapor barrier of the ceiling in the bath is an important process that you can carry out yourself. In our article, we have collected all the information necessary for this.

The vapor barrier of walls is a complex process, the implementation of which must be carried out according to certain rules. Read here instructions on vapor barrier walls and which materials are preferable.

Choosing a vapor barrier material

When choosing a vapor barrier, in addition to functionality and application features, the price of the selected material, as well as the cost of its installation, plays an important role. The vapor barrier used to insulate the ceiling cannot be attributed to particularly expensive building materials, the production of high-tech films, including films of diffuse membranes, is also available in Russia, which prevented an increase in prices for this group of materials caused by fluctuations in the exchange rate.

Let's dwell on the main types of vapor barrier materials, with an assessment of their positive and negative qualities:

- Glassine.

A layer of thick technical paper impregnated with bituminous materials. Supplied in sheets, mounted on regular wood nails. An obvious disadvantage is the high probability of the release of harmful substances when heated. In addition, glassine and its analogs are very short-lived, such a vapor barrier is good for secondary structures, or outbuildings in a country house or a personal plot.The only advantage is the cheapness of the material.

- Polyethylene film.

Supplied in various thicknesses in rolls up to 2m wide. The main advantage is cheapness and ease of installation. But the vapor barrier made with its help is completely sealed, natural air exchange is disrupted in the room, constant ventilation is required, otherwise there is a feeling of mustiness. A special perforated plastic film will correct the situation. Its installation requires special care, as the material can tear along the perforation lines.

- Foil materials.

Most effective where it is required to maintain a high temperature regime. The shiny layer reflects infrared heat rays back into the room. Indispensable for the vapor barrier of saunas, baths, swimming pools. In order to properly lay foil materials, the skills of a home craftsman are enough. The disadvantage of the material is the relative high cost.

- Sealing mastics and varnishes.

They provide a good quality vapor barrier, close to "breathing" film membranes. Disadvantage‒ the complexity of application, requiring professional skills and inconvenient packing in plastic buckets. When working on small areas, for example, the ceilings of insulated loggias and balconies, a lot of unused material remains. The disadvantage is that it takes time to dry and, in some cases, to apply a secondary coat. Most of all, the material is suitable for the device of vapor barrier of large areas during major repairs, when the drying time of the layer is not so critical, other work can be performed.

- Multilayer films - membranes, diffuse membranes.

An effective, easy-to-install material with a very long service life, allowing the entire ceiling insulation pie to "breathe". The effectiveness of such films lies in their multifunctional action. The two-layer structure fully protects the insulation: the fleecy side absorbs and evaporates condensate, the water-vapor-impermeable layer serves as a reliable barrier to its penetration. During installation, you should carefully monitor which side to put the vapor barrier. The fleecy side must be facing outward.

Having chosen the necessary material that is optimal in terms of properties and price, it is necessary to ensure correct styling.

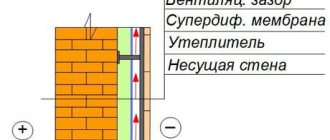

Steam and thermal insulation of a cold attic

For a roof with a cold attic space, it is most important to minimize heat loss through the attic floor as much as possible.

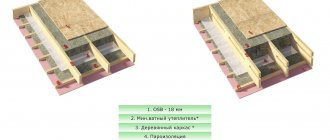

... For both wooden and reinforced concrete floors, a vapor barrier is mandatory. It fits on the floor itself and protects the insulation from vapors that can condense in the heat insulator, passing through the ceiling of the living room. Plate and bulk materials can be used as insulation. The ceiling cake consists of a vapor barrier, floor beams and insulation.

The following types of heat insulators are often used in the ceiling ceiling

:

- expanded polystyrene and foam boards;

- mineral wool boards or mats;

- expanded clay granules;

- fuel or granular slag;

- sawdust with lime or clay;

- pumice.

The thickness of the required insulation layer is selected depending on the estimated winter temperature using the table below.

Winter temperature is calculated according to SNiP 2.01.01-82 (construction climatology and geophysics) or selected by regions of the Russian Federation from the corresponding climatic maps.

Insulation is laid between the lags or beams of the ceiling, and a boardwalk for attic passages is made on top. The logs are usually 50 mm thick, and the floorboards are 25-35 mm thick.

For ventilated attic spaces, soft or semi-solid heat-insulating materials are considered the most optimal.

Attic waterproofing device

Waterproofing roofs with a cold attic, according to many experts, is a controversial issue.Some say that waterproofing must be present under the roofing material, and someone strongly recommends abandoning it. Much depends on the type of roofing material and the angle of inclination of the roof slopes.

Metal roofs are most susceptible to corrosion due to possible small leaks or condensation

.

Therefore, we once again draw your attention to the fact that ventilation plays one of the main roles in the fight against the formed condensate.

.

For shallow metal roofs, experts recommend installing superdiffusion membranes. It will prevent moisture from entering the outside of the roof when blowing snow or rain. No matter how well the roof is laid, there is always the possibility of minimal leaks. That is why, by overpaying a little, you will receive additional protection against moisture ingress on the insulation in the ceiling of the cold attic.

Possible leaks or condensation when entering hydrophobic heaters significantly reduce their thermal insulation properties.

If, for example, slate is used as a roofing material, then waterproofing can be abandoned. There is also a corrugated board with an anti-condensation coating on the market, which can hold up to 1 liter of water per 1 m2. For our part, we recommend that you always use waterproofing membranes, because this is the cheapest and easiest additional way to protect your roof from possible leaks.

.

When installing waterproofing membranes, a counter lattice is used. It performs the function of a fixing rail and, due to its height, provides the necessary clearance for ventilation of the under-roof space. The device for the lathing of the cold attic is no different from the insulated roofs. The dimensions of the lathing and its pitch determine the type of roofing to be installed.

Temperature range of the cold attic

To prevent ice and icicles from forming on the roof, it is necessary to maintain the correct temperature and humidity regime in the attic. If the thickness of the insulating material is insufficient, significant heat losses occur through the floor. Warm air, heating the roofing, causes snow melting and ice formation. By choosing the right layer of insulation, this can be avoided.

You can evaluate the effectiveness of a heat insulator using the temperature measurement of the top layer of the insulation. An electronic thermometer is immersed in insulation by 10-20 mm. The temperature readings should correspond to the values in the table below.

As you can see, the arrangement of the cold attic pie is not particularly complex. The main task is to provide the required ventilation intensity and the thickness of the thermal insulation layer in the ceiling slab.

We will carry out the installation of a copper roof quickly and efficiently