Why do you need to make a vapor barrier when insulating with mineral wool

Mineral wool insulation is an effective type of thermal insulation that contributes to high heat saving at home, but has one significant drawback: when wet, mineral wool almost completely loses its insulating ability, freezes and gradually collapses. At the same time, moisture accumulating in the thickness of the heat insulator penetrates into the decorative finish of the interior of the house, deforms it and contributes to the formation of fungus, mold, and rot. To prevent such negative consequences, vapor barrier membranes are laid in the "cake" of floors, roofs and walls of the house - films that shield moisture, but allow air to pass through.

Expert: protects walls, floors and ...

- It protects walls, ceilings, and, as mentioned earlier, insulation. The air that bursts outward condenses, due to which the insulation becomes soaked, loses its basic properties of keeping heat and collapses over time.

Despite the fact that cellulose wool or ecowool is hygroscopic in itself, and even if the insulation is very high quality and resistant to moisture, steam will reach the wall and can cause the spread of fungus. The materials for the vapor barrier are just an obstacle to the passage of steam to the insulation, so this is a kind of fence for it from getting wet.

Vapor barrier for insulation with mineral wool inside the house

The warm air circulating in the interior of the house is saturated with humid vapors that people, animals, plants, and household appliances evaporate. Warm air masses tend upward and accumulate under the ceiling of the premises, therefore it is extremely important to combine mineral wool with a vapor barrier when insulating the ceilings of Manasard and rooms adjacent to the unheated attic.

A certain amount of warm air seeps outside the house through walls and floors - in order to avoid swelling of floor coverings and destruction of wall cladding, vapor barrier films are placed between the mineral wool layer and the finishing layer.

Features of the installation of vapor barrier. Which side to put the vapor barrier to the insulation

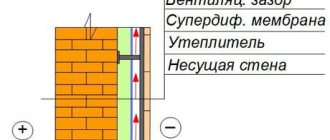

Answering the question about which side of the insulation is laid, and how the vapor barrier is mounted, we note that vapor barrier materials are always installed on top of the insulation from the side of the room. However, it is necessary to take into account the type of vapor barrier membrane used.

So, ordinary plastic wrap can be laid on either side.

The steam-condensate film is mounted with a smooth surface to the insulation, and with a fleecy one outward. Diffusion membranes are laid in the same way.

Steam insulators with a foil layer are mounted with foil outside, because it is this side that reflects heat and returns it to the room.

When installing "deaf" steam insulators, care must be taken to arrange a ventilated gap.

mybuilding.tips

Vapor barrier when insulating with mineral wool outside the house

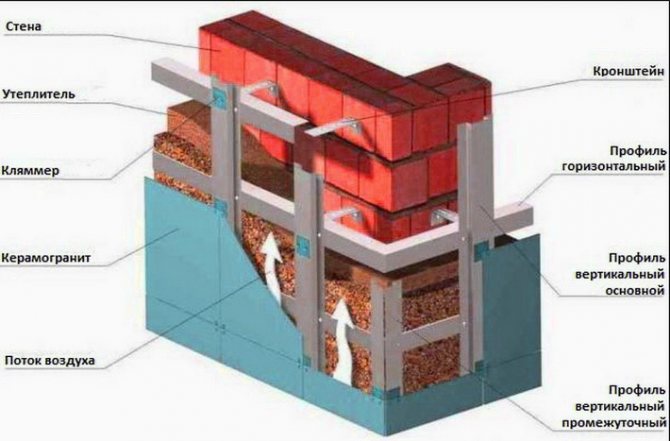

It is recommended to lay hydro-, wind- and vapor-insulating films when insulating the outer walls of brick, frame and log houses when arranging ventilated facades. Multifunctional protective membranes are mounted under siding, clapboard, blockhouse and other facade cladding - the film reliably shields moisture and condensation, but allows air to pass through and allows the walls to "breathe".

Modern types of vapor barrier films are superdiffuse and anti-condensation membranes, vapor barriers with a metallized layer - such innovative materials are produced under the Ondutis brand.

Wall insulation with mineral wool outside: advantages and disadvantages

Mineral wool insulation can be carried out using various methods:

- Wet facade method.

- The "ventilated facade" method.

- "Well system".

More commonly used ventilated facade method, which assumes the presence of an air layer as an insulator between the layers of the structure.

For a secure fit mineral wool and a finishing layer, a frame is mounted, which is located inside the structure. In the air layer, a draft is created, which removes steam from the insulation.

When installing mineral wool sheets necessarily it is necessary to carry out a vapor barrier for the walls using a vapor-permeable and waterproofing film.

Mineral wool insulation compared to other materials has a number of advantages:

- The presence of natural ventilation.

- Minvata perfectly isolates noise from the street.

- The insulation remains in good condition throughout its entire service life.

- The moisture goes into the drain, and does not condense on the walls.

- There is no need for cladding, which saves money.

The disadvantages of insulation mineral wool includes:

- High cost.

- Complex technological installation process.

Also, working with mineral wool unsafe for health... It is imperative to wear a protective suit and mask, since cotton wool fibers, turning into dust, can harm a person if inhaled.

Wind and moisture protection membrane Izospan advantages

The peculiarity of this material lies in the fact that it has good thermal insulation characteristics, which allow providing a high level of protection of any buildings from such negative factors as wind and moisture.

The windproof membrane eliminates the situation of high humidity in attics. This is ensured due to the presence of high heat-reflecting properties in the Izospan material, which provide protection against condensation. When installing a vapor-permeable membrane, connecting tapes are used, due to which a high tightness of the fastening is achieved. In addition, the material provides a high degree of wind protection to the building.

At the moment, the windproof membrane has become widespread. It is used for interior and exterior insulation of floors and walls. Also, a windproof membrane is used when solving problems of floor insulation. The use of this material protects structures from condensation and excludes damage to the finish.

When working on flooring, the Izospan windproof membrane is often used as a substrate for the floor. The use of this material for this purpose provides good reflection of infrared rays, which direct the heat flow directly into the room. In addition, good wind protection is provided.

When using the Izospan moisture-proof membrane, reliable protection against:

- exposure to high humidity;

- condensation;

- wind entering the premises.

Due to the functional moments that are characteristic of the Izospan windproof membrane, it is possible to significantly reduce the temperature load acting on any building in conditions of temperature differences. The use of a windproof membrane as a moisture-proof material provides protection:

- roofs;

- walls and floors;

- floor.

The use of a vapor-permeable material allows you to create favorable conditions for living in a house with high-quality insulation.Note that the windproof material is used to make special suits, which leave a person in such vestments dry in rainy weather and are well protected from the wind.

A membrane from well-known manufacturers, providing reliable wind protection, which is available in a large range on the market, is characterized by:

- good wind protection of roofing systems;

- reliable vapor barrier for walls and ceilings;

- joining the joints of the material using sealed tapes.

Thickness of mineral wool for ceiling insulation

It is not surprising that this material was used to insulate structures. This led to savings in building materials and a reduction in the cost of construction.

Usually they produce standard sizes for the thickness of the material: 50 mm, 100 mm... As you can see from the example above, 200 mm thick is enough to insulate the room for harsh climatic conditions of the Russian winter... We must focus on the material of the walls of the house. If these are wooden walls from a bar of 150 x 150 or 200 x 200 mm, then one 50 mm layer of mineral wool is enough.

House-building factories produce ready-made panels, where the thickness of the mineral wool insulation is 200 mm in two layers of 100 mm, which corresponds to SNiP 2.11.02-87where the R-value for walls 2.1 - 5.6, for ceilings and floors 2.8 - 7.3... They also take into account the laying technology and all the structural elements of the walls or ceiling: add the outer cladding, the inner and the vapor barrier layer, and even the air gaps, then you get R above 7.3.

What mineral wool to choose for ceiling insulation

Standard sheets of mineral wool insulation have a width of 565, 600, 619 mm, and rolls - 1200, 1220 mm. These sizes are suitable for installation between joists; the roll insulation is cut in half. A stock in width of 2-3 cm is needed for tight styling between the logs. The best mineral wool is the one with a higher R index and a higher density.

According to this indicator, the best mineral wool from manufacturers ISOVER, thermal conductivity, by GOST 7076-99 λ> 0.038 W / (mK), where λ is the thermal conductivity coefficient (can be denoted by k). This should not be confused with the R value, a measure of thermal resistance.

The smaller λ or k, the better the insulation, and for the value of R, on the contrary, the more, the better. Pay attention to this when buying. Select the density depending on where the insulation is located: 80kg / m3 is suitable for walls and roofs, a lower density is suitable for light ceilings - up to 60 kg / m3.

If we proceed from the ease of installation, then glass wool causes itching on the skin, slag-like prickly fibers. Stone wool is devoid of these inconveniences, moreover, unlike slag wool, it is used indoors. Mineral wool for insulating the ceiling from the outside is selected based on a density of 80 kg / m3 and more, as well as ease of installation, roll or sheet material

It is better to insulate the ceiling with mineral wool from the side attic floor... Correct laying of mineral wool - 2-3 layers to overlap the joints of the sheets in order to exclude cold bridges during laying. The required thickness of the material is chosen and the sheets are laid between the overlap lags, leaving a gap between the insulation and the membrane vapor barrier film.

This is a visual diagram of how to properly insulate the ceiling with mineral wool.

Look at the diagram how it is located membrane type vapor barrier film... Shown here is the insulation of the ceiling from the outside. According to this scheme, it is not difficult to imagine the insulation of the ceiling with mineral wool from the inside, when there is no access to the attic. This is possible if the roof is shed or flat.

A sheet of mineral wool is laid between the overlap lags. To fix in this position do thin twine frame... They just fasten it with a stapler to the lags. This is necessary so that when the vapor barrier is pulled and fastened to the logs, the mineral wool does not slide down.Then a strip of 20 x 30 mm and sheets of drywall, lining, and other material are stuffed.

Do-it-yourself ceiling insulation with mineral wool

If it is necessary to insulate the ceiling, which has an overlap in the form of concrete slabs, or a solid ceiling, then a crate is attached to the ceiling either from wooden bars or from a metal profile.

First, they are attached to the wall along the perimeter of the room horizontally wall beam... A timber with a pitch of 57-59 cm is attached to the ceiling surface with anchors or corners. The height of the timber is at least 70 mm for one layer of a sheet of mineral wool. If 2 layers are required, then instead of a timber, a 40 x 150 board is attached with an edge to the ceiling with the same pitch. Then the vapor barrier is sewn with brackets. A rail for the air gap is nailed onto the timber, and then drywall.

Insulation of a suspended ceiling with mineral wool

First, they make a crate from a metal profile for a suspended ceiling. Buy materials from one retailer so that all profiles and accessories come in one set. There is a gap between the ceiling profile and the ceiling, where mineral wool sheets and vapor barrier are laid.

First, they laid mineral wool on the crate, and then glued it to the crate vapor barrier film... Then the sheets of drywall are sewn on. Here, the distance to the ceiling allows you to lay the insulation in only one layer of 50 mm. If there is ventilation between the ceilings, then a vapor barrier is not needed.

How to insulate the ceiling with mineral wool without installing the frame

In the case when it is necessary to insulate the ceiling from the inside without significant loss of height, the mineral wool sheets are fixed directly to the ceilingusing glue, glue putty, dowels with long rods and plastic umbrella-shaped caps. For insulation with a thickness of 50 mm, dowel-nails 10 x 120 mm will fit.

The fact is that plastic rods are either fragile or too soft. The first ones break, and the second ones are difficult to hammer and do not expand the dowel tip well, metal is better, but choose stainless nails.

Operating procedure:

- Preparatory work, cleaning the ceiling surface from the old coating, sealing irregularities and cracks with cement mortar.

- Apply primer with a brush or spray gun and allow to dry. Make two layers. Using a notched trowel, apply a 5-8 mm layer of glue putty to one side of the board.

- Place the slab against the ceiling and press down. It is good if there is an assistant in the work who fixes the plate in the center, and then along the edges. After installing the slabs, the wall profiles for the stretch ceiling are attached; the vapor barrier can be omitted if there is ventilation between the ceilings.

Dowel-nail, 2. Minvata, 3. Concrete ceiling.

The work can be facilitated by applying glue such as liquid nails to the surface of the board.

There are many manufacturers of mineral wool and it is difficult to single out someone especially, and not worth it. High-quality is visible to the touch: if it is dense, then it took more material to make it. Also pay attention to the composition: fiberglass, from slag (the cheapest) or basalt mineral wool, the most in demand today. It is recommended for insulation both inside and outside, glass wool is best used outside, mineral wool from slag is used to insulate communications: pipelines, sewers.

Thermal qualities are determined by the value of thermal conductivity or thermal resistance R. Basalt wool is a non-combustible material, it can be laid in the chimney duct, it is used to make a sandwich for chimneys for sauna stoves.

vseopotolkah.ru

Sequencing

Thermal insulation of the floor with mineral wool is part of a multi-stage process for installing the floor, which is carried out according to the following algorithm:

- Alignment. The surface on which the floor will be laid must be perfectly flat;

- Vapor barrier - laying a layer of vapor barrier material;

- Installation of guides - wooden logs;

- Insulation laying - filling each m2 of floor with insulation material;

- Laying the flooring is the last, finishing layer of the cake.

Actually, this whole process is carried out in order to ensure reliable insulation and waterproofing of the room. Therefore, it makes no sense to consider laying mineral wool separately from the other stages.

Alignment

Leveling is especially important when laying the ground floor on the ground. There are also irregularities and cracks in floor slabs. To eliminate irregularities in the first case, it is necessary to level the surface of the soil with a layer of crushed stone 10 cm thick, on which it is necessary to fill in a layer of sand of the same thickness.

You should know. When laying the floor on reinforced concrete floor slabs, a leveling screed is usually used. The screed is usually used concrete or cement-sand. The absence of a screed can lead to the destruction of the entire floor due to irregularities and the associated uneven load on different parts of the floor surface. This circumstance forces to arrange a screed even in the attic.

Vapor barrier

A layer of vapor barrier on top of the screed must be laid in the floors of the premises on the first floor for each m2 of surface. This is necessary precisely when used as a mineral wool insulation. Mineral wool easily dampens, which leads to a decrease in its thermal insulation properties. Also, when laying the topcoat, it is important to observe the ventzaor between the mineral wool and the floor surface.

Roofing material can be used as a vapor barrier - such material is best used in the country, where the requirements for the floors are mainly limited by the price of materials and all work is done by hand. Film waterproofing is used as modern and reliable materials for vapor barrier:

- polyethylene film, including coated with aluminum;

- polypropylene film;

- vapor barrier membranes.

Most often, polyethylene, polypropylene or aluminum coated film are used. This is primarily due to the cost of the material. However, the effectiveness of such a material is low, due to the possibility of condensate accumulation on its surface. This can lead to wetting of the mineral wool and, consequently, a decrease in its thermal insulation properties.

The most modern and reliable material is thick multi-layer vapor barrier membranes made using a more sophisticated technology using many waterproofing materials. They are best used in country houses and cottages.

The vapor barrier layer is laid as evenly and tightly as possible to the surface of the floors and walls. In this case, there should be no ventilation gap. The holes in the lower layer of the vapor barrier will not lead to ventilation, but to the appearance of moisture on the insulation layer. This principle is maintained on all floors, including the attic.

Warming

Mineral wool is placed on the first layer of vapor barrier. A roll of mineral wool is unwound and laid in such a way as not to leave ventilation gaps between the wool and the logs, as well as between the wool and the first layer of vapor barrier, no ventilation gap in order to avoid the accumulation of moisture on the mineral fiber.

This prevents the fiber from getting wet and the mineral wool loss of its heat-insulating properties. The technology provides for the installation of special ventilation gaps between the insulation and the second layer of vapor barrier.

The thickness of the mineral wool sheet is selected depending on the purpose of the building and climatic conditions. So, in the country, which is used mainly only in the warm season, it is enough to use mineral wool 50 mm thick. The same applies to technical buildings and houses in the southern regions, where it is still impossible to do without insulation, despite the milder climate. The thickness of the sheets of mineral wool used on the second and third floors, in the attic or in the attic may also not exceed 5 cm.This is due to lower requirements for floor insulation on floors, as well as the need to maintain the volume of the room.

For your information. In private country houses, it is better to use cotton wool 200 mm thick. Wool of this thickness will provide reliable thermal insulation.

Having laid a layer of mineral wool, it is necessary to lay another layer of vapor barrier on top of it. This is especially important when installing the floor in the attic of a house or summer cottage. However, here the laying technology will be somewhat different than in the first layer. To ensure ventilation in order to avoid the accumulation of moisture on the insulation layer, the technology provides for the device of ventilation gaps - special holes between the sheets of the vapor barrier film, through which air will pass and moisture that has got under the vapor barrier will evaporate. Ventilation gaps are required between all sheets of film or membrane.

We always ask our readers to "decipher" the questions, to indicate additional data that would help to understand what the problem is. For example, what exactly are you asking about? It is clear that you want the fiber insulation to stay dry. But what is the construction of a home's thermal insulation? Do you insulate the frame by putting mineral wool between the racks? Or is it a brick house with external insulation? Or maybe a wooden blockhouse? Or internal insulation? Are you interested in the roof? Then which one: a combined attic or a cold attic? There are many options for thermal insulation of buildings and the same number of answers to your question. Alas, there is no one-size-fits-all solution.

Without going into the specifics of specific structures, let's try to give a general idea of how to keep the insulation dry. In this case, we will assume that precipitation or water from the ground does not penetrate into the building structures of your house, the roof does not flow, there are no holes in the wall covering, the walls are waterproofed from the foundation, etc. We will not consider the insulation of the building from the inside as irrational.

Preventing the penetration of moisture into the mineral wool is a feasible task, but difficult. To do this, the fibrous insulation in the most dry state must be packed in a completely sealed casing. For example, in strong plastic bags. However, this is not so easy to do, and it is even more difficult to carefully mount the mineral wool without damaging the shell. Leaky bags are useless. Therefore, complete protection against moisture penetration is rarely used. An example of such a solution is the insulation of heating mains, where a roll bitumen waterproofing serves as a shell. As a rule, in overground structures of buildings, fibrous insulation is not so much isolated from the effects of moisture contained in the air, but rather they are trying to ensure the release of water vapor from the material. Consider in general terms the most common designs for warming a country house:

- Frame house. Both the insulation and the wooden frame need protection from waterlogging. For most of the year, the air inside the house is more humid than outside. Therefore, first of all, a sealed vapor barrier film is attached to the frame structure from the inside over the entire area. As the name suggests, it is impervious to water vapor. But the insulation, not having an airtight shell, will absorb the moisture contained in the outside air. To prevent it from accumulating, it is necessary to provide a sufficiently effective ventilation of the mineral wool. At the same time, the wooden frame is also ventilated. To do this, between the casing and the insulation, fixing the bar, leave an empty gap. The recommended thickness of the ventilation gap is 40 mm; holes are arranged in the upper and lower parts of the walls, covering them with a mesh or lattice. To prevent gusts of wind from blowing through the insulation, a windproof film is attached on top of it, which does not prevent water vapor from escaping to the outside.

The classic wall construction of a frame house. A vapor barrier is placed inside, preventing the penetration of moist air from the house into the insulation.Outside - a ventilated gap that allows moisture to escape from the mineral wool, covered with a windscreen

- Wooden house, external insulation: a frame filled with mineral wool and cladding on top of it. The walls of a log house, made of wood, need protection from moisture no less than fiber insulation. "Packing" them from the inside with a vapor barrier is irrational, the advantages of natural wood are lost. It is also not worth placing a vapor insulating layer between the log wall and the insulation, this can lead to waterlogging of the wood and its defeat by a fungus. We have to put up with the fact that water vapor will constantly penetrate the wooden walls from the inside of the house and go out through the insulation. To effectively remove this moisture, we do, as in the case of a frame house, a ventilation gap. We close the minvata with a windscreen. Again, when insulating a log house, a vapor barrier is not needed.

Correct thermal insulation of a wooden house: 1 - insulation; 2- windproof film; 3 - sheathing. Bars (counter-rail) are stuffed onto the frame, a ventilation gap is provided between the sheathing and the windscreen, due to which the wood and mineral wool remain dry

A variant of the ventilated facade is a multi-layer stone wall made of aerated concrete with brick cladding. There is a ventilation gap and wind insulation. Leave adequate ventilation openings in the lower and upper areas of the cladding.

- Stone house, ventilated facade. It is similar to the thermal insulation system of a wooden house. The presence of a ventilation gap and wind insulation outside according to the scheme already known to us is mandatory. With vapor barrier it is a little more complicated: if the walls are made of non-hygroscopic (not absorbing moisture) material, vapor barrier is needed between the wall and the insulation. We are talking about reinforced concrete (including prefabricated panels) and expanded clay concrete blocks. If the walls are made of "breathing" materials, aerated concrete, bricks, vapor barrier is not needed, it will only harm.

General arrangement of a ventilated facade

- Plaster facade - hard mineral wool is attached directly to the wall, the slabs are plastered on top. No vapor barrier is needed, and a thin-layer facade plaster reinforced with a polymer mesh serves as protection from precipitation and wind. You can only use special mixtures intended for external thermal insulation systems.

Now about the roof, consider only the pitched structures:

- Combined (insulated) mansard roof. It is a frame structure, in many ways similar to the walls of a frame house. It is imperative that you need a vapor barrier from the inside, a ventilated gap and wind protection from the outside. When choosing a wind-insulating film, it should be borne in mind that most roofing coatings are condensate-forming: dew or frost falls on the side facing the inside of the roof under certain conditions. Most of all, steel roofs sin this, sometimes the amount of condensate is very large. So that the water flowing from the roofing does not soak the insulation, special under-roofing films, the so-called diffusion membranes, are used as wind insulation. They have the property of freely passing water vapor outside, to prevent the penetration of liquid water inside. The drops simply roll down and flow off the roof.

The diffusion membrane has many pores. They are too small to allow liquid water to pass through, but large enough not to obstruct the escape of water vapor.

An example of a combined pitched roof. In order for the insulation in the attic roof structure to always remain dry, it must be ventilated. Ventilation (shown in the diagram by arrows) is carried out in the intervals between the counter-rails packed along the rafters. From below, the insulation should be protected by a vapor barrier (Izospan In the diagram), from above - a diffusion membrane (Izospan AM).

- Cold (not insulated) attic roof.Ventilation of the attic is organized through vents in the pediments, cracks in the filing, aerators in the covering. Since the roof is not insulated, only condensation protection is needed without the function of removing water vapor. It is most rational to place a vapor barrier film between the roofing and the rafter system. A diffusion membrane will work too, but it is more expensive.

If you have any questions, we are ready to answer them. Urgent request: please specify your messages. It is difficult for us to give answers to general questions in a question-and-answer format. And you probably do not get the information of interest in full.

The use of mineral wool in the process of building a house is most often associated with the implementation of a number of measures designed to protect the insulation from getting wet.

Sometimes this is completely justified and necessary, and sometimes it will be an unnecessary transfer of funds.

In each specific case, depending on the expected operating conditions and the type of structures to be insulated, it is necessary to clearly determine whether a vapor barrier is needed when insulating with mineral wool?

Melts of rocks (basalts, dolomites) are used as raw materials for production. Industrial slags are sometimes added. From the molten mass, fibers are formed, which are then pressed into plates or rolls.

The strength of the final products is determined by the compression ratio during pressing and binders, which are phenol-formaldehyde or urea resins.

The more force is applied during the forming step and the higher the concentration of binders, the more dense and rigid the material will be.

Density, depending on the form of release, can fluctuate in a very significant range:

- Rolls - 20-50 kg / m3;

- Mats - 50-80 kg / m3;

- Lightweight slabs - 80-120 kg / m3;

- Plates of medium hardness - 120-200 kg / m3;

- Rigid slabs - over 200 kg / m3.

Types of vapor barrier

Vapor barrier is divided into two types:

- Roll. Rolls are rolled from the bottom of the item to the top. Further, they are fixed with slats made of wood in a horizontal position. The space for ventilation is located between the inner lining and the vapor barrier. This hole should be about five centimeters. After the performed procedure, check that everything is fixed firmly.

- Leafy. To work with sheet material, first install a frame from a profile. Sheets must be mounted in this frame. Self-tapping screws or nails will help you with fixing the sheets. Sections of joints must be covered with polyvinyl chloride (PVC film). The sheet of the vapor barrier layer lies in the inner area to the place that you want to insulate.

Installation of vapor barrier on the floor

Pros and cons of windscreen

Material advantages:

• environmental friendliness (there are no harmful and toxic substances in the composition);

• fire resistance (achieved thanks to special additives);

• ease of use (laying technology does not require the use of special equipment);

• moisture resistance;

• does not lose properties under the influence of ultraviolet radiation;

• elasticity avoids deformation during installation;

• does not change the quality and characteristics at a sharp temperature drop;

• long operational period.

Of the disadvantages not of the membrane itself, but of its application, it can be noted that an incorrect installation leads to a deterioration in the thermal properties of the facade. Loose adhesion of the film to the insulation layer provokes the formation and accumulation of condensate from the side of the insulation.

Also, some builders forget about the need to leave a ventilation gap between the membrane and the cladding.

Is the windproof membrane on

The windproof membrane for facing the facades of examination buildings must comply with the group of non-combustible materials - NG. All manufacturers declare compliance with the NG group.Who tried to set a piece of vapor barrier on fire with a lighter? Those who are associated with the construction of facades have probably tried everything. The film burns out, the flame dies out, the combustion does not support, but there is a certain emotional moment in the subjective assessment. Porcelain stoneware, metal bracket - NG, which is logical. Set fire / do not set fire, the element will smoke up to the maximum. And the membrane behaves differently, it burns out to the ground, but fades out. It turns out that the film itself does not burn, but with an external source of fire, the flame will spread through it. However, there are permits issued by competent and authoritative authorities.

Permits for windproof membranes used in facades are:

- Technical certificate of suitability for use in construction (specifically for the device of a wind-waterproofing layer in the structures of hinged facade systems);

- Certificate of conformity to the requirements of TU 8390-001-96837872-2008 with rev. # 1

- Fire test report for assigning a group and class of flammability in the system

- Durability test report

- Test report for determining vapor and air permeability

- Sanitary and Epidemiological Conclusion

Based on the analysis of permits from a number of manufacturers, conclusions can be drawn regarding the typical properties and characteristics of windproof membranes.

Characteristics and properties of building fabrics

The requirements for a windproof membrane used in private and public buildings are different. At least, because public buildings are subject to state construction expertise. The scale of the consequences of using not very high-quality film for cladding high-rise buildings is more extensive. Under a not very high-quality film, the editors first of all understand that it does not correspond to the flammability group NG - not a combustible material.

- The ability to resist the effects of fire determines the compliance of a material with a certain flammability group. Films approved for use in ventilated facades have a flammability group NG - non-flammable. Consequently, the fire hazard class of building materials is "KM-0".

- Vapor and air permeability is determined by the properties of the fabric to resist air penetration under wind load and when warm vapor escapes outside. A good vapor permeable membrane corresponds to a vapor permeability value: 0.1 m2 * h * Pa / mg. Air permeation resistance: 1500 m2 * h * Pa / mg.

- Windscreens for walls should be of low water permeability to protect against rain and snow.

- The fabric must have a high tensile strength. This value affects the determination of the number of points of attachment of the sheet. The number of attachment points will increase in proportion to the height of the building, this is due to the increase in wind load.

- Each running meter of the fabric must be able to elongate by at least 6 cm, both lengthwise and across, before a break occurs. Elasticity ensures the preservation of the fabric when stretched.

- Durability is not less than fifty conventional years.

Consider the most common use of windproof membranes in facades.

The fabric is supplied in rolls, 1.2 m wide, 50 m long. Designed for the device of a wind-vibration insulating layer in enclosing structures, incl. in the structures of facade systems with an air gap, to increase their resistance to air permeation and to protect the insulation from adverse weather conditions. The membrane can be used in all climatic regions, at temperatures from -60 to +60 degrees, in weak and medium aggressive environments.

Follow these simple guidelines to ensure that the installation of vapor barrier foils in ventilated facades is of high quality:

- Which side to lay the vapor barrier - strictly, with a smooth surface outward.

- Which side to fix the vapor barrier - it is permissible to lay the membrane horizontally and vertically, but it is imperative that the direction is observed: from top to bottom, with an overlap of at least fifty centimeters of the upper layer to the lower one. The location of the panels should ensure the natural drainage of moisture penetrating under the cladding.

- Use as many attachment points as drawn in the design of the ventilation facade to the building. Remember, the taller the building, the more anchorage points. A poorly fixed section of the web in the place of sagging can "clap" under the influence of strong gusts of wind. Control the tight fit of the canvas to the insulation. In the worst case, the wind can rip off the film. How to fix the vapor barrier, what type and size of anchor - everything is in the project. Sometimes the use of plastic anchors is unacceptable.

- Wrap the ends of the insulation around the window and door openings in such a way that the layer of fabric goes under the insulation for a length of at least 25 cm to avoid blowing wind under the film.

- Install fire cutoffs around window openings, in places of emergency exits, on the inner corners of the building, if the distance from the inner corner of the building to the window is less than 1200mm. All fire protection measures are spelled out in the Album of technical solutions of a specific brand of the façade subsystem of your choice.