Articles

All photos from the article

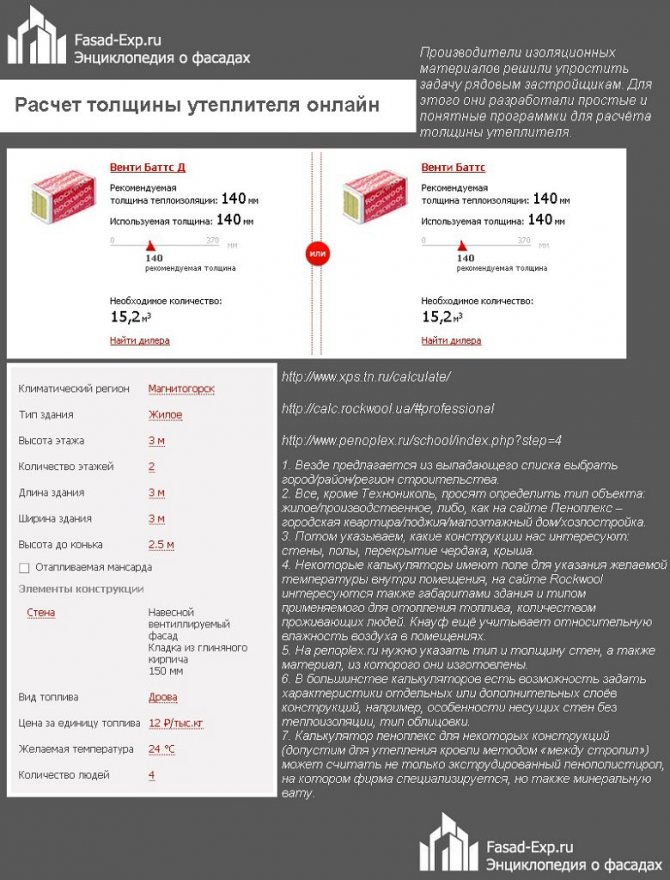

Mineral wool is one of the most common heat insulators due to its affordability and high consumer qualities. The only thing, as is the case with any other materials, it is necessary to observe the technology of its installation. Therefore, in this article we will look at how to make the most effective insulation with mineral wool under the siding of the outer walls.

External insulation of the house with mineral wool

The main varieties of mineral wool

Stone wool is highly resistant to fire and does not deform for a long time

Depending on the constituent parts of the mineral wool, it can be divided into 3 main groups:

- The stone variety includes rocks with analogs of gabbro-basalt groups, due to which the material has low water absorption and, conversely, high resistance to fire. Consequently, stone wool is able to withstand the highest temperatures without deforming for a sufficiently long time. Available in rolls.

- The slag type of mineral wool is produced using waste after melting non-ferrous or ferrous metals. It has good quality indicators, but they are slightly weaker than the previous type.

- Glass, limestone and other materials are used in the production of glass wool, and therefore this type can withstand high temperatures. Perhaps the only drawback is the fragility of the material, in which small particles can get directly onto the skin.

Material advantages

It is best to insulate the outside siding of a house with mineral wool, because installation is quite simple, and the quality of thermal insulation is high. Thanks to this, you can save a lot on heating appliances and heating in general. So, the main advantages of this insulation:

Mineral wool is an environmentally friendly material that resists fungus and pests

- applies to any surface and plane;

- fire resistance and fire safety;

- environmental friendliness;

- resistance to fungus and pests;

- low shrinkage after mounting;

- high operational life;

- high thermal insulation performance;

- resistance to moisture;

- the ability to install directly on the wall or using the lathing.

Materials and tools used

Mineral wool is fixed with mushroom dowels

It's no secret that insulating a wooden house with your own hands under siding also implies the presence of some tools and materials:

- drawn up schematic drawing;

- mineral wool;

- construction brackets;

- straight suspension (universal);

- screws and dowels;

- building level;

- special glue;

- screwdriver and hammer drill;

- butyl tape;

- bars or metal profiles.

It is worth noting that the insulation of a wooden house for siding can be done using a metal profile or wooden slats. But the principle of mounting is practically the same. Therefore, the tools and fixing materials are selected in accordance with the crate used. Butyl tape is glued between the joints of the membrane, which is installed on the mineral wool.

Wall insulation and cladding

Do-it-yourself home insulation for siding with mineral wool is carried out in the following several stages:

- preparation of walls for work;

- installation of the frame and installation of insulation;

- installation of siding.

Below we will consider all the stages of work.

Preparing the walls

If you are not insulating a new house, then, as a rule, there are plums on the walls, visors over the doors, antennas and other elements. Therefore, before proceeding with the insulation, it is necessary to dismantle all the attachments.

It is also important to eliminate all kinds of defects - cracks, crumbling areas, etc. To seal cracks, you can use a sealant or polyurethane foam.

Sealing the cracks of a wooden house

If a wooden house is insulated outside with mineral wool for siding, then the preparation of the walls must be approached even more responsibly.

The procedure in this case is as follows:

- as when working with ordinary houses, first of all, the dismantling of the hinged elements is carried out;

- then it is necessary to fill in the gaps between the crowns of tow;

- then it is necessary to treat the walls with an antiseptic compound to prevent the occurrence of mold or damage to the tree by other biological factors.

Advice! If brick walls are insulated outside with mineral wool for siding, it is also advisable to treat them with an antifungal composition to prevent mold.

Scheme - insulation of a brick house outside with mineral wool for siding

Wall cladding with mineral wool

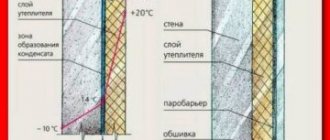

Installation of insulation under siding is a ventilated or hinged facade. The basis of this design is a frame made of wooden slats or profiles.

Therefore, wall insulation outside with mineral wool for siding is carried out as follows:

- first of all, the installation of racks is carried out. More often, for these purposes, adjustable brackets are used, which are familiar to many for installing drywall. The distance between the beams must correspond to the width of the heat insulator so that it fits snugly into the formed space.

In addition, it is necessary to ensure that the racks are in the same plane so that the walls are flat. Therefore, in the process of their installation, beacons and a building level should be used;

Ventilated facade frame

- then between the racks you need to lay insulation. For its additional fixation, you should use special dowels with wide caps, which are called "umbrellas" or "fungi". To install the dowels, you need to drill holes in the wall through the mineral wool;

An example of fastening mineral wool to the wall

- after laying the material, it is necessary to fix a vapor barrier film on the walls, which will allow the steam to escape outside, but at the same time will not allow moisture to penetrate into the insulation. You can fix the bar with paper clips.

Note! To ensure high-quality thermal insulation, the thickness of the mineral mats must be at least 10 cm.

Now that the walls are insulated, you can start attaching the siding.

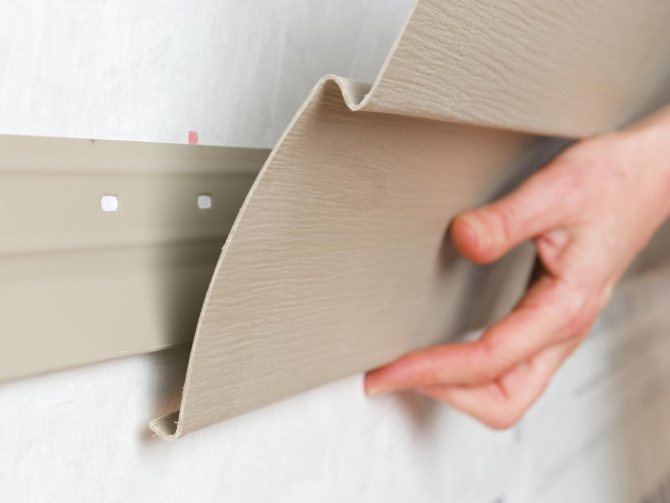

Attaching the vinyl panel to the starter bar

Fastening siding

The instructions for sheathing the frame with siding largely depend on the type of material. However, in general, the principle is about the same.

So, the work is done in the following sequence:

- vertical slats are attached on top of the frame so that the vapor barrier film is not damaged during the fastening of the siding;

- then along the perimeter of the house, a starting profile is attached below, which should be located strictly horizontally;

In the photo - an example of fixing the siding with a self-tapping screw

- then the first row of siding is attached, which is inserted from the bottom into the starting profile, and from above is fixed to the slats with self-tapping screws. In this case, the self-tapping screw should be in the middle of the mounting hole;

- the remaining rows of panels are installed in the same way;

- before attaching the last row, the finishing profile is pre-mounted;

- at the end of the work, the installation of additional elements is carried out - drains, slopes, etc.

Note! When attaching the siding to the wall with self-tapping screws, it is necessary to under-turn them by a few millimeters.This will allow the sheets to move freely under the influence of thermal expansion.

This completes the process of warming the house and finishing the facade.

The order of work

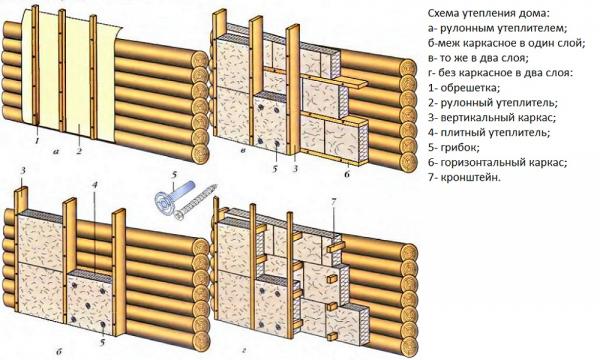

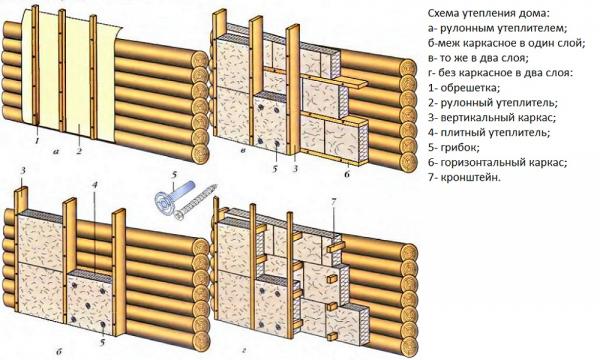

Most often, the insulation of the house from the outside, especially for siding, is carried out using a wooden structure. A double lathing is being erected to provide ventilation between the insulation, cladding and wood. First you need to draw up a diagram. Here are 4 options from which you can choose the right one.

Scheme of home insulation options

Next, you need to thoroughly clean the surface of a wooden house from dust and dirt. It is advisable to do this in dry weather. After that, it is imperative to prime the tree in order to avoid the formation of mold in the future. Now you need to mix the glue base and grease the surface of the mineral wool with it. Then the cotton wool is applied to the wall surface and glued. If you use rolled mineral wool for siding, then it is applied along the entire length. If the cotton wool is in the form of blocks, then gluing is done in a checkerboard pattern. It is imperative to strengthen the structure with dowels, since the glue is unable to withstand the mass of cotton wool.

It is advisable to use 2 layers of insulating material, between them a reinforcing mesh is installed for the strength of the structure. Glue is also applied to the mesh, after which it is, as it were, embedded in cotton wool.

Recommendations

- Decide correctly on the thickness of the insulation before you buy it. For example, if a house is made of silicate bricks and stands near a reservoir, products with a thickness of 15 cm will be required.In general, a thickness of 10 cm of mineral wool is recommended; for a wooden house, the layer can be taken thinner.

- Before strengthening the insulation, carry out preparatory work to free the wall from old paint, grease and plaster. To ensure good adhesion between the wall and the insulation, there will be no possibility of mold, rotting and the formation of fungi.

- A common mistake isthat the builders do not take into account the vertical deviations and unevenness of the walls. Experts advise to correct irregularities, then the result will be evident.

- It is considered a mistake to apply glue with cakes., as with other types of insulation. Here you need to apply the mixture over the entire surface. When dry, the glue will give rigidity to the underside of the insulation and will not wrap, roll, and the integrity of the mineral wool layers will also be preserved.

- Protective curtains should be hung on the scaffolding during work. Firstly, there will be no moisture ingress on fresh plaster, which, in turn, will lead to erosion and efflorescence. Secondly, it is an excellent protection of the facade and insulation from cracking, drying out, wind and dust.

- It is impossible to fill the joints with a solution between the sheets of insulation, as this leads to the formation of cold bridges. To do this, you must use a sealant.

- So that there are no cracks in the outer coatings, it is worth making a dressing of the reinforcing layer during gluing.

- Observe safety precautions when working with a product such as slag wool or glass wool. Its particles have a detrimental effect on the skin and mucous membranes, with subsequent irritation or worse, can cause an allergic reaction.

If we talk about the price of the issue of different manufacturers, then the difference among them is small. And with a thickness of 10 cm, the average price of facade wool is 200 rubles. for 1 square meter. The cost is influenced by the density of the slabs, the lower the density, the lower the cost of the goods.

Installation of lathing and siding

The question of how to install the crate should be given special attention, since the strength of the entire structure depends on it. It is preferable to install the slats in this order: if the siding is installed horizontally, then the slats are mounted vertically.In the case when it is necessary to install the siding vertically, the crate is laid horizontally. Please note that the pitch between the slats is determined by the distance between the holes for siding fasteners. Also, slats are mandatory installed in the corners, near openings, and so on.

Siding insulation scheme

It should be noted that the plane of the lathing must be checked all the time with the building level, because the evenness of laying the siding depends on this. Wooden slats are mounted into the walls using dowels or galvanized nails (weaving). Note that the lathing is also treated with a primer if it is made of wood.

Siding is installed directly on the elements of the sheathing using self-tapping screws or nails. In this case, it is necessary to make a ventilation opening of several centimeters between the insulation and the facing material. Thanks to this, the walls will breathe. The siding is laid directly from the bottom up.

Please note that this material is quite brittle, so a very sharp knife and saw should be used when cutting.

- How wall color stencils are created and used

- Installation and operation of moisture-resistant panels for bathtubs made of fiberboard, MDF and chipboard

- Advantage of Penetron waterproofing

Insulation technology

- Preparatory work (cleaning walls, treatment with an antifungal primer, stuffing rails or profiles).

- Installation of insulation (mineral wool) and siding.

We install profile guides on the prepared walls. The starter profile is fastened along the base. It will support the first row of cotton wool and protect against rodents. Vertical profiles should be fixed with dowels 0.6 meters from the ground. Since siding will be used, a moisture-proof film should be fixed.

Using wooden slats, first they should be treated with an anti-corrosion compound. Mats can be fastened with special glue or with dowels with "umbrellas". If glue is used, it should be applied to the entire surface of the sheet.

Required materials and tools

You should not use a different type of fastening. If the siding is on the profiles, so will cotton wool.

When choosing a material, quality and packaging are important. Since there is insulation in sheets and rolls, it is more convenient to work with sheets.

They fit well into grooves and fit perfectly. You will also need a profile for siding and insulation, a moisture-resistant film.

You will need tools such as:

- screwdriver;

- Screwdriver Set;

- drill;

- glue or dowels "umbrella";

- level;

- scissors for metal;

- roulette;

- saw on plastic;

- knife;

Detailed step by step guide:

Preparing the walls

We clean the surface from dirt and debris, grease stains, excess paint. Platbands from doors and windows must also be removed, since they will have to be changed, relative to the future wall thickness. We remove all existing communications. We carefully seal cracks and chips with a solution. We apply an anti-fungal coating on it, which should dry.

Installation of mineral wool and siding

We attach a vapor barrier film to the wall, moreover, the insulating membrane must be on the inside. This removes excess moisture from the insulation. For fastening, we can take liquid nails or thin slats. It mainly depends on the wall, depending on what material it is from.

The next step is to install a steel profile or wooden slats. Here you should pay attention to the step width and the thickness of the rail. We choose a distance less than the insulation sheet, so that it sits down thoroughly in the grooves. We take the thickness of the rails no more than the material itself.

We install mats from bottom to top, avoiding gaps. After installation, we fix the canvases with dowels, which have special "umbrellas" of large diameter. If glue is used, apply to the entire surface of the sheet. And we do a careful examination of the entire wall, if somewhere there is a pass of cotton wool, you should cut out the desired piece and fill the gap with insulation.We strengthen the small pieces with masking tape.

Let's say you needed a second layer of mineral wool, for this we fill the frame again. Reiki, unlike the first option, is stuffed horizontally. The work is carried out similar to the first, with the only difference that the mats will be inserted perpendicular to the first layer.

Now we mount the protective layer of the vapor barrier film. Install the siding mounting profile on top. There should be ventilation grilles at the bottom of the structure.