The first mention of expanded clay dates back to the 19th century. Even then, the question arose as to what the material was named after. It is clear that the Greek keramos, as we understand, is associated with clay and the ceramics produced from it. What does zit mean, there are discussions.

In the photo, expanded clay building material

A similar word was found only in the Czech language. There the concept is translated as "live". The relationship with clay is unclear. Therefore, probably, Americans and Europeans call the hero of the article haidit, from the surname of the scientist who patented the technology for the production of expanded clay. He claimed his rights in the 1920s.

What is expanded clay

Externally, expanded clay is brownish granules of different sizes, round in shape. Particle contours are irregular, asymmetric. The surface of the granules is porous and rough. The material is warm and firm to the touch.

Expanded clay is produced from low-melting clay grades. The content of quartz in these is less than 30%. The material acquires porosity in the course of reaction with diesel fuel, fuel oil or iron oxide. They are the ones who expand the baking clay. Without baking, expanded clay would not be hard.

In terms of application, expanded clay - a versatile material. He, for example, is poured into the bottom of flower pots. There, the hero of the article performs a drainage function. The porosity of the material allows it to absorb excess water, preventing root rot. When the soil is dried up, expanded clay, on the contrary, gives off moisture, allowing the plant to "get drunk".

Description of expanded clay

Expanded clay is a porous lightweight material that has a low weight and can also be produced by firing clay shale. Expanded clay gravel has an oval shape. As for expanded clay crushed stone, it has one difference, which is that the grains have a cubic shape with sharp corners and edges.

Expanded clay is a material that is also made in the form of sand. Depending on the technology used to process shale or clay, it is possible to obtain the final material with a certain bulk density, which is also called bulk density and varies from 350 to 600 kg / m³. However, this value can be higher.

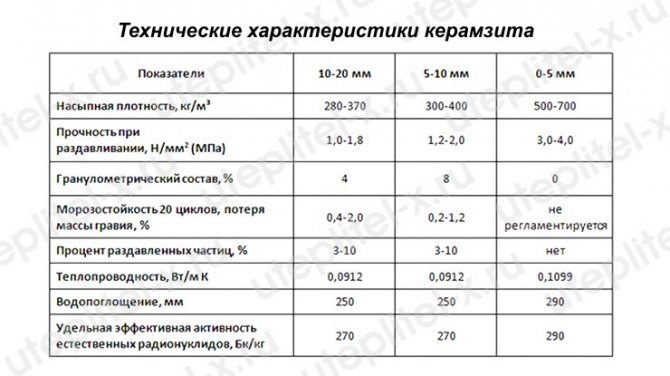

Properties and characteristics of expanded clay

As drainage fractions of expanded clay used for filling roads. It is important to "plant" them on a clay mound when the soil is saturated with groundwater. Expanded clay becomes an obstacle on their way to the road, the destruction of its canvas.

Foamed and baked clay granules are also called expanded clay gravel. The pores in it are easily filled not only with water, but also with air. The latter does not conduct heat and cold well. Therefore, dry granules serve as insulation in floors.

Expanded clay screed

In a dry screed, only expanded clay is used. It is evenly poured under wooden logs, on which sheets of plywood or boards are laid. Here, the hero of the article not only retains heat, but also eliminates the creaking of the floor. Screed with expanded clay limits the possibility of movement of boards prone to drying out and change in shape, and the support for plywood sheets turns out to be solid.

Floor with expanded clay in a dry screed it is as warm as possible, because the air is locked "not only in the pores of the clay, but also between the granules from it. If a wet screed is made with expanded clay, the gravel is inside a concrete slab instead of rubble.

The latter will not give heat, it will only strengthen the layer like reinforcement and reduce the cost of filling. According to the price tag, quarry is comparable to expanded clay, only the latter gives the floors the necessary warmth and soundlessness.

A building block is made from expanded clay

The air, as well as the temperature, is reluctant to transmit noises. Therefore, the expanded clay screed protects households from outside sounds, and neighbors from the details of the life of the apartment owners. In a private house, you can exclude audibility between the basement and first floors, between the first and attic.

Heat-conducting networks, foundations, walls are insulated with expanded clay. In the "battle" with competitors, the hero of the article wins due to environmental friendliness and antiseptic properties. The bacteria prefer to stay away from the clay granules.

The fire also keeps away. Clay belongs to rocks, composed of particles of quartz, aluminum oxide, sometimes, particles of carbonate rocks. All these are stones, and all are non-flammable. Where synthetic insulation like expanded polypropylene flares up, expanded clay will remain unapproachable, moreover, it will not release harmful substances when heated.

Expanded clay is used in the construction of houses for insulation

Time thermal insulation with expanded clay perhaps due to the filling of gravel with air, which means that the material is light. The exact weight depends on the species. Granules are of different sizes, but they differ slightly within the same brand.

There is, for example, expanded clay sand, fraction from 5 to 10 millimeters in diameter, from 10 to 20. In total, there are 11 species. There are 0.2 grams per cubic centimeter of the 250th. Expanded clay weight brand "M-300" is equal to 0.3 grams for the same area. 0.05 grams is added to the "M-350". Respectively, expanded clay cube weighs about 300 pounds.

Considering the lightness of the hero of the article and its heat-saving properties, granules are added to concrete building blocks. The result is strong and warm slabs that reduce the load on the foundation.

Plus, lightweight blocks are easier to work with. Like aerated concrete, blocks with expanded clay can be folded into a one-story house by a couple of people. One stands on the wall and fixes the "bricks", and the second feeds them from below.

Types of expanded clay

Depending on the grain size and shape, it is subdivided into the following types:

- Expanded clay gravel - semicircular pellets, color - from red to brown.

- Crushed stone - large fragments of expanded clay after crushing. The shape is angular, with pointed edges.

- Sand is a production screening, in fact, a by-product, cheap material obtained in the production process.

Expanded clay gravel, in turn, is divided into fractions:

- 5 - 10 mm - the most demanded in a variety of areas. It is used as a filler in concrete solutions, participates in the manufacture of warm, lightweight expanded clay blocks, is used in facade and foundation insulation works. It has the highest bulk density and is therefore often added to the larger fraction to fill voids. The coarse fraction has a low bulk density, often voids form in the solution, which negatively affects the strength of the final structure.

This type is often used in various industrial filtration systems for water purification.

It is widely used in the decoration of park areas, lawns, flower beds, fountains, monuments .... In the personal plot, they are poured with paths, framed by flower beds.

- 10 - 20 mm also has a wide range of applications. It is often used as a drainage system for plants. They are introduced into the soil, thereby loosening the dense soil at the roots of plants, increasing the permeability of the soil with moisture and oxygen. In agriculture, it is brought into the beds in the places where vegetables and strawberries are planted in order to drain the packed soil. The chemical properties of expanded clay allow it to be used as drainage, because it does not decompose in the soil, which means it is environmentally safe - the plants will not absorb anything harmful from it. The conclusion is unambiguous - expanded clay for drainage is an ideal solution.

Also, this fraction is used as insulation for roofs, attics, partitions. It is successfully used in works for pouring floors.This option is very profitable - the floors will be warm, they are not afraid of fungus, mold, moisture.

When laying long overpasses, pipes, the trench is also necessarily insulated with expanded clay, this reduces heat loss in the cold season and protects pipes from corrosion.

- 20 - 40 mm is the largest fraction, it also has a fairly wide application. First of all, this is the production of lightweight concrete, in large quantities. The coarse grain size makes it suitable for use in places where a thick layer of insulation is required. These can be roofs of houses, light own weight will not give a high load on walls and partitions. They also insulate the attics of buildings, the foundations of houses.

Expanded clay sand - screening, granules of 0 - 5 mm are industrial waste obtained in the production process. As a material, it is not of particular value, its main use is as a replacement for ordinary sand in solutions. Its cost is zero, therefore, it is profitable for them to replace ordinary construction sand, the price of which significantly increases the cost of concrete masses.

Has a current application in the installation of floor screeds. The use of expanded clay in the screed allows you to get an even warm surface, which is not susceptible to dampness and fungi. In addition, the room will be warmer with such a floor. The thermal conductivity of expanded clay is much lower than that of similar materials.

When arranging hydroponic systems, expanded clay sand is also in demand as a filler.

Sand, fraction 0 - 3 mm, has its unique application in warm mortars when laying bricks. Everyone is familiar with the term - cold bridges, these are cement, cold joints between bricks in masonry. Indicators of thermal conductivity are on average 1.15 W / m3 С, but when replacing ordinary sand with expanded clay, thermal conductivity is significantly reduced, in figures it is 0.34 W / m3 С.

Production and use of expanded clay

Initially, expanded clay was obtained by burning a mixture of clay with dust or sawdust. A kind of cakes were formed in the furnace, which were broken after firing. Such expanded clay in bags sold in the 19th century.

Modern production of expanded clay begins with crushing the rock with rollers. They are also suitable for the production of shungizite, which many confuse with the hero of the article. However, shungizite is made from shale chips, not clay.

The material is more resistant to aggressive environments and less moisture-consuming. However, in terms of thermal conductivity, shungizite is inferior to expanded clay and externally differs from it. Quartz granules are darker.

The clay crushed on the rollers is sent to the kiln drum. Its diameter reaches 5 meters. The unit can be as long as 70. The high temperature inside the drum is maintained by the nozzle. The heat dries up the clay.

If you need the most warm and almost non-water-absorbing material, the rock is melted. The dense crust protects the granules from water. At the same time, cavities with air are formed inside the expanded clay. The process is spurred on by additives such as iron oxide that are sent to the drum.

The drum for drying expanded clay is located at an angle to the ground. The formed granules are poured into the receptacle by gravity. Further, the products are packed in polypropylene bags or sold in bulk.

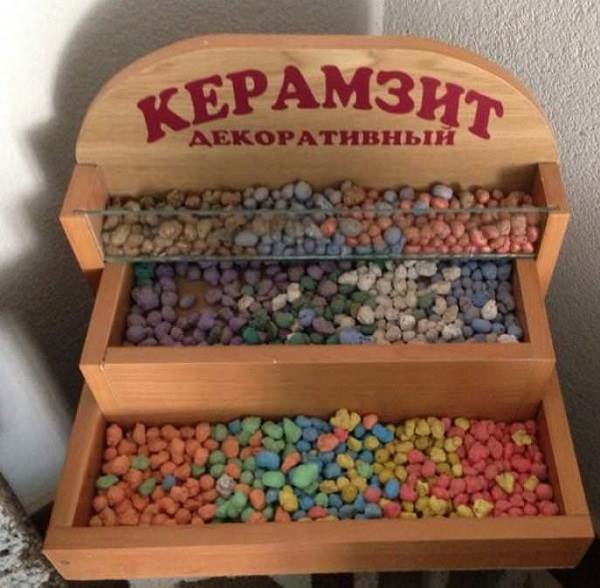

Decorative expanded clay

They hone the nuances of producing the hero of the article and come up with new approaches at the Keramzit Research Institute. This is the only research institute in Russia where clay granules are being specifically studied and experimented with.

The research institute is located in Samara. Rare black clay is also mined there. The rock is extracted from a 7-meter depth. Expanded clay turns out to be dark, like shungizite, and has something in common with its properties. Black clay is less porous and more durable than red and white varieties.

In the use of expanded clay, its strength is important. A screening test is done. The granules are poured onto the asphalt and pressed with your foot. If the "beads" are crumbled, but expanded clay price per 1 m3 high, requests are unreasonable.

Expanded clay is produced in various fractions

It is worth overpaying for the granules that remain intact. However, in some areas, the strength of the hero of the article is secondary. In the floor screed, for example, the granules will strengthen the concrete, and the dry backfill will cover and protect the final coating. The main thing here is the heat capacity of expanded clay.

Within the walls of the laboratories, you can also check the radioactivity of the hero of the article. This was done, for example, in Chuvashia. The expanded clay concrete produced here was sent to the center of hygiene and epidemiology.

They checked it according to the method certified at the Mendeleev Research Institute. The radioactivity of the blocks is several times lower than the norm permissible for building materials. Since radioactive nuclides are contained in the earth's crust, they also end up in human-made products.

Expanded clay is used in landscape design

It is important that the radiation from it is not overly active. As for expanded clay, the background in some samples is completely absent. So, the material can be easily used by people with a phobia of radioactivity and all those who wish to protect themselves and their families as much as possible.

There are no phenol, formaldehydes and other non-radioactive, but harmful and volatile components in clay granules either. However, this is a moot point. Working with low-quality clay, its properties are improved with the help of synthetic additives. They can be identified, again, only by an examination in the "Center for Standardization", "Rospotrebnadzor".

The use of expanded clay in agriculture

According to most farmers, the material is the best drainage and substrate for crops grown in hydroponics.

Expanded clay absorbs moisture when watering and gives it back when the soil dries. Quite often, crushed stone and sand are added to optimize air exchange between the plant and the air in heavy clay soils.

Drainage, based on expanded clay, does not allow the soils to acidify and silt. At the same time, the material does not weigh down the soil and prevents the formation of molds, the appearance of mosses and fungi.

The material showed itself remarkably when arranging beds. A layer of 2 - 3 cm, poured into its base, provides excellent drainage. The gravel scattered between the plants retains moisture, performing a mulching role.

Expanded clay has a hard outer shell and a porous core, which makes it a unique organic substrate for hydroponics, a full-fledged soil substitute.

Pros and cons of expanded clay

Let's start with the flaws. Purchase for construction works expanded clay m3... There is a lot of dust in cubic meters of material. No matter how strong the granules are, the clay microparticles still detach from them. Therefore, it is better to work with expanded clay in a mask. The process is dusty in the truest sense of the word.

If expanded clay is used as a heater, the granules must be waterproofed. Though slowly, the hero of the article absorbs moisture. By filling the pores in the clay, it squeezes out the air. Expanded clay loses its ability to retain not only heat, but also noise.

Insulation of the ceiling with expanded clay

Liquid mixtures based on bitumen or roll materials are used as waterproofing. The latter include, for example, hydroisol. However, plain polyethylene is also suitable for floor stitching. It is often taken as a vapor barrier underlay.

High-quality thermal insulation with expanded clay is achieved only when the granules are backfilled with a thick layer. 40 centimeters is the minimum. Not every building has the ability to "throw out" so much usable area. It is acceptable in a private house on the ground floor, but rarely in an apartment. It is also problematic to insulate the roof with a 40-cm layer of expanded clay.

Moving on to the pluses of the hero of the article, here are the numbers. The service life of a wooden screed with expanded clay reaches 50 years versus 25-35. The hero of the article itself does not collapse even longer. Retaining properties for centuries. Expanded clay is not called gravel for nothing. We are dealing with a stone.It is formed artificially, but carries the "baggage" of the natural.

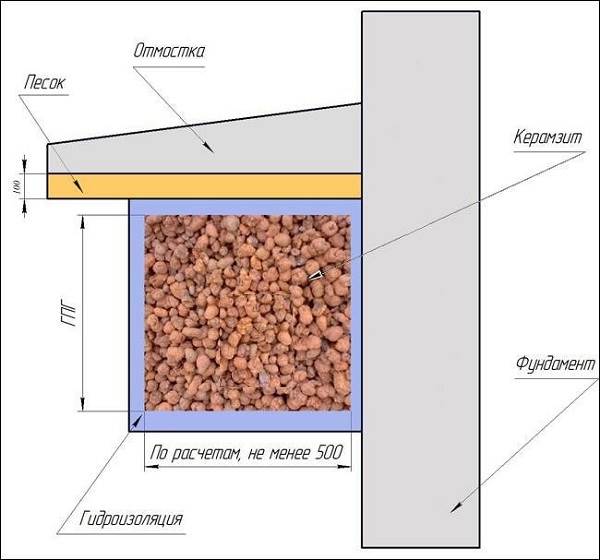

Warming the foundation with expanded clay

It takes no more than an hour to make the hero of the article. Usually, it is 45 minutes. The speed of the process indicates its simplicity. This means there are no extra costs. Hence the low price of granules "follows". This is another plus of the material. Let's talk about specific numbers.

Our company offers in unlimited quantities high-quality, environmentally friendly expanded clay of the following fractions and grades in terms of bulk density and strength: Loading rate in railway p / c - 70 - 94.3 cubic meters. The loading rate in the railway p / v in the MKR is 70.2 cubic meters. (78 MKP) Norm of loading in a covered wagon (bags of 0.05 m3) - 80 cubic meters. (1600 bags); - 95 cubic meters (1900 bags)

About building material - expanded clay.

Expanded clay is an environmentally friendly, lightweight porous material obtained by accelerated firing of fusible clays. In appearance, expanded clay is a predominantly round or oval granules of various sizes. Low-melting clays, softening under conditions of accelerated heat treatment, swell due to the pressure from the inside of gaseous products released in the fired clay mass, and form a vitreous material with a cellular structure, consisting of glassy and crystalline phases. In contrast to dense, porous and hollow ceramic materials and products made from clays, the cellular material expanded during the firing of clay rocks is called expanded clay - this name emphasizes the relationship with ceramics and glass. It takes into account not variable characteristics (production method and field of application), but constantly acting factors (the nature of the feedstock, the physicochemical process of formation and the properties of the product). Despite the variety of production methods and equipment for swelling of clay rocks, the physicochemical nature of the formation of expanded clay remains as unchanged as, for example, the nature of the formation of cement or steel does not change with different methods of production. This made it possible to classify expanded clay to the class of materials with pronounced individual physicochemical and technical characteristics.

The production of expanded clay is evaluated according to the standard: GOST 9757-90 "Gravel, crushed stone and artificial porous sand".

It should be especially noted such an important property of expanded clay as the environmental friendliness of the material. After all, the composition of expanded clay is only clay and nothing more. Thus, expanded clay is an absolutely safe, natural material, akin to ceramics. Suffice it to recall the history of mankind and the clay vessels that have been used by people for thousands of years. A person kept food, water and wine in such vessels, in order to preserve the natural and natural taste of products for a long time, he used clay products as utensils for eating food. And even now, each of us has more than one household item that would contain clay in its composition. The only difference between expanded clay is that the clay swells up during rapid firing. The gravel obtained in this way does not burn, does not sink in water, does not cake, does not rot and has thermal and sound insulation properties. It, like any earthen vessel, is not affected by time. And at the same time, this material is safe for humans and nature.

Expanded clay is one of the most reliable and effective building materials, which is currently in great demand. The main properties of expanded clay are: grain size, bulk density and strength. According to the grain size, expanded clay is subdivided into fractions: 20-40 mm; 10-20 mm; 5-10 mm; sand (0-5 mm). By bulk density and strength - by grades. Expanded clay sand - aggregate with particle sizes from 0.14 to 5 mm, is obtained by firing in rotary kilns, due to the destruction of part of the granules during heat treatment, it is relatively heavy, since small particles of clay raw materials practically do not swell.

For a more complete assessment of the quality, frost resistance, losses during boiling, the content of sulfur and sulfuric acid compounds are determined. Determination of properties of expanded clay is carried out in accordance with GOST 9758-86 "Porous inorganic aggregates for concrete". Test methods.

The specific activity of natural radionuclides in expanded clay gravel is confirmed by the sanitary and epidemiological conclusion and meets the requirements of the Basic Sanitary Rules.

In the production of expanded clay gravel, technical quality control is carried out, which means a set of operations to ensure the production of high quality products. Technical control is subdivided into input control - control of clay raw materials, additives; operational control - quality control of materials and technological parameters during production; acceptance control - control of product quality after completion of all technological operations for its manufacture. Technological control is carried out by the production laboratory. The adoption of new building codes for heat conservation does not allow the design and construction of housing without the use of insulation, therefore, the demand for expanded clay, which has a low thermal conductivity combined with lightness, strength and fire safety, is currently increasing.

The scope of application is diverse: The areas of application of expanded clay gravel are quite wide, which is easily explained by its excellent performance. Firstly, expanded clay is free-flowing and takes any form given to it. Secondly, they can fill any environment, since it has a number of advantages. Thirdly, subject to the technological requirements in production and proper use, expanded clay can reduce heat loss by 50-75%. Expanded clay gravel is inexpensive compared to other popular heaters.

The use of expanded clay gravel is very diverse: 1. Thermal insulation and sound insulation of floors, walls, ceilings, basements; 2. Thermal insulation and reduction of the depth of foundation laying; 3. Thermal insulation of lawns on terraces, soil; 4. Thermal insulation of a pitched roof; 5. Thermal insulation and sloping of flat roofs; 6. Production of lightweight expanded clay concrete blocks and ultra-lightweight concrete; 7. Drainage and thermal insulation in earth embankments of roads laid in water-saturated soils; 8. Hydroponics, creating an optimal microclimate for the root system of plants. Due to the presence of voids in expanded clay gravel, with an excess of moisture, it takes it to itself, and if there is a shortage, it gives it to the root system; 9. Expanded clay is used as a heater for water supply and heating networks. This is justified for two reasons at once: firstly, it helps to create and maintain the temperature and humidity in the bath at the required level; secondly, in the event of a network breakdown, expanded clay facilitates contact with the accident site, and after elimination of the accident consequences, the material can be reused.

The main consumers of expanded clay gravel are such large enterprises as reinforced concrete factories, construction organizations in cities: Yekaterinburg, Tyumen, Surgut, Kurgan, Nizhny Tagil, Moscow, Sochi, Chelyabinsk, Novy Urengoy, Perm, Novosibirsk, Blagoveshchensk, Khabarovsk, Vladivostok, Verkhnyaya Pyshma. Kachkanar, the Republic of Kazakhstan and many others.

Expanded clay is shipped by rail, road transport, expanded clay is loaded in bulk, or in bags of 0.05 cubic meters, bags of large-size blocks of 0.9 cubic meters.

We hope that our expanded clay will find a worthy application in solving your problems.

We are here for you! Contact us, we are glad to see you!

Expanded clay price

Expanded clay is packed in bags, as a rule, at 0.04 cubic meters. Together with the packaging, it costs 120-600 rubles. The exact price tag depends on the fraction, the type of clay used and the need for delivery of raw materials. In regions with deposits of rock, expanded clay, as a rule, is produced and immediately sold. In other areas, the goods are transported, which adds to the price.

In Russia, expanded clay has been in price since Soviet times. Then the hero of the article helped the country to step over to the stage of industrial construction. Socialist attitudes demanded that all citizens be provided with housing.

It was necessary to build quickly, from light and affordable materials. We developed standard projects of box houses and added expanded clay to concrete slabs for apartment blocks. It turned out faster and warmer than conventional blocks.

The citizens of the USSR also appreciated the silence in the apartments. Houses with them stand to this day. After the overhaul, Khrushchev's new buildings will last for decades. Keeping this in mind, expanded clay continues to be purchased for construction needs.

Layer thickness calculation

To effectively carry out insulation, the expanded clay layer must have a thickness of at least 40 cm for wood and 30 cm for expanded clay concrete flooring. Between floors in private houses there will be enough thickness of 20 cm when the floor is wooden, and 15 cm when it is made of concrete.

Important! In the process of calculating the thickness of the expanded clay layer, it is necessary to take into account the load that goes on the floor. The quality of energy saving will depend on the accuracy of measurements. Having established what thickness of the material is required, it is possible to determine how much insulation is required to be poured under the screed.