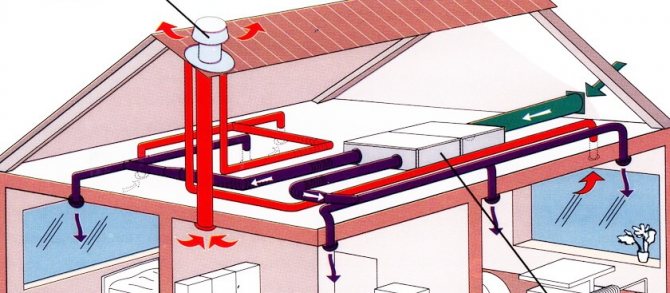

It is necessary to understand that, speaking about such a process as thermal insulation of air ducts, one must take into account the fact that these elements of the ventilation system are divided into household and industrial ones. The former are used in air extraction systems for residential and office buildings, the latter in industrial facilities or in buildings with an extensive ventilation network, where powerful fan units are used. For example, in the buildings of train stations, airports, shopping centers. Accordingly and the approach to thermal insulation in each case will be individual.

The benefits of insulating air ducts

To begin with, there are certain building codes according to which thermal insulation measures are carried out. They are determined SNiPom 2.04.14-88, in which it is clearly indicated where and how ventilation insulation should be carried out. This primarily applies to unheated premises and streets.

The thermal insulation of the ventilation system is carried out with one single purpose - not to reduce the service life of the air ducts.

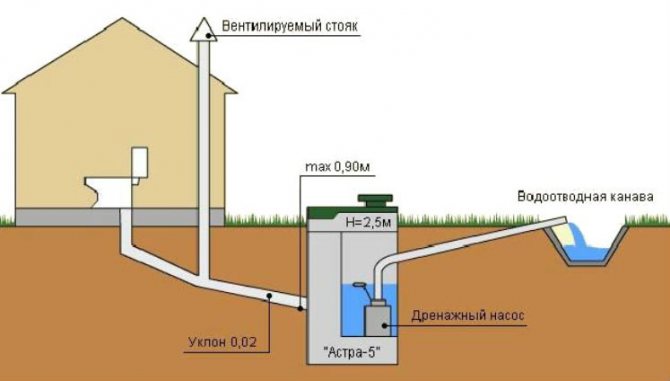

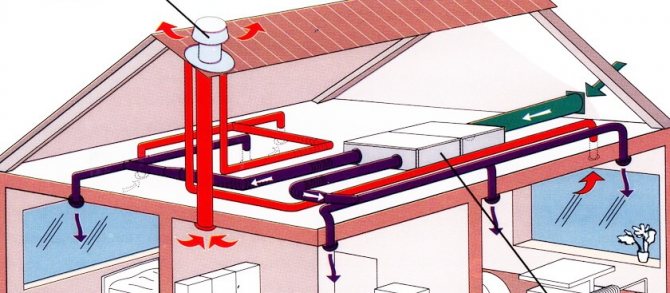

The thing is that the ventilation itself is the ventilation of the premises, in which the air inside the building moves at a speed of 1 m / s. And for this to happen, you need to install two holes (or more), into one of which fresh air from the street enters the inside of the structure, from the second the spent air is thrown out. So, the whole structural part of ventilation is a circuit for decoupling air ducts operating on an exhaust hood, that is, warm air from the building will move along them.

In unheated rooms or outdoors, warm air will begin to condense, forming moisture on the inner walls of sheet steel air ducts. Metal corrosion occurs, which leads to a rapid failure of the entire system. Insulated air ducts prevent the contact of warm air with a cold environment, which means there is no condensation.

SNiP rules clearly stipulate what kind of insulation and what thickness must be used in order to create all the conditions for high-quality and efficient operation of the ventilation system. And since the modern market offers a huge variety of thermal insulation materials, it is necessary to deal with them and determine the best insulation for ventilation pipes.

The main types of heaters for air ducts

The most common materials used as insulation for air ducts are:

• mineral wool; • aluminium foil; • expanded polystyrene; • foamed polyethylene.

All of the above and other materials used to provide thermal insulation and acoustic protection of air ducts fully meet all the requirements and standards, while absorbing vibration and noise well.

Mineral wool. With proper operation, it can serve as a heater for thirty years, if, of course, the waterproofing is done according to all the rules. Most often, for thermal insulation of air ducts, molded products are used, which are pipe sections - or semi-rigid. In addition, for the same purposes, you can use mineral wool insulation, which is supplied in the form of panels or rolls.

The main stages of work in the process of thermal insulation with mineral wool:

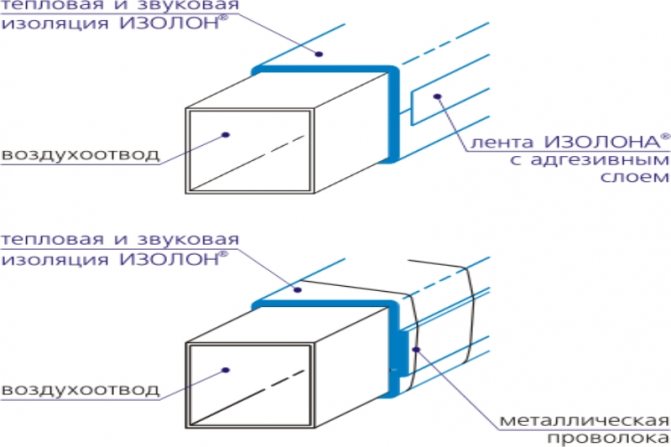

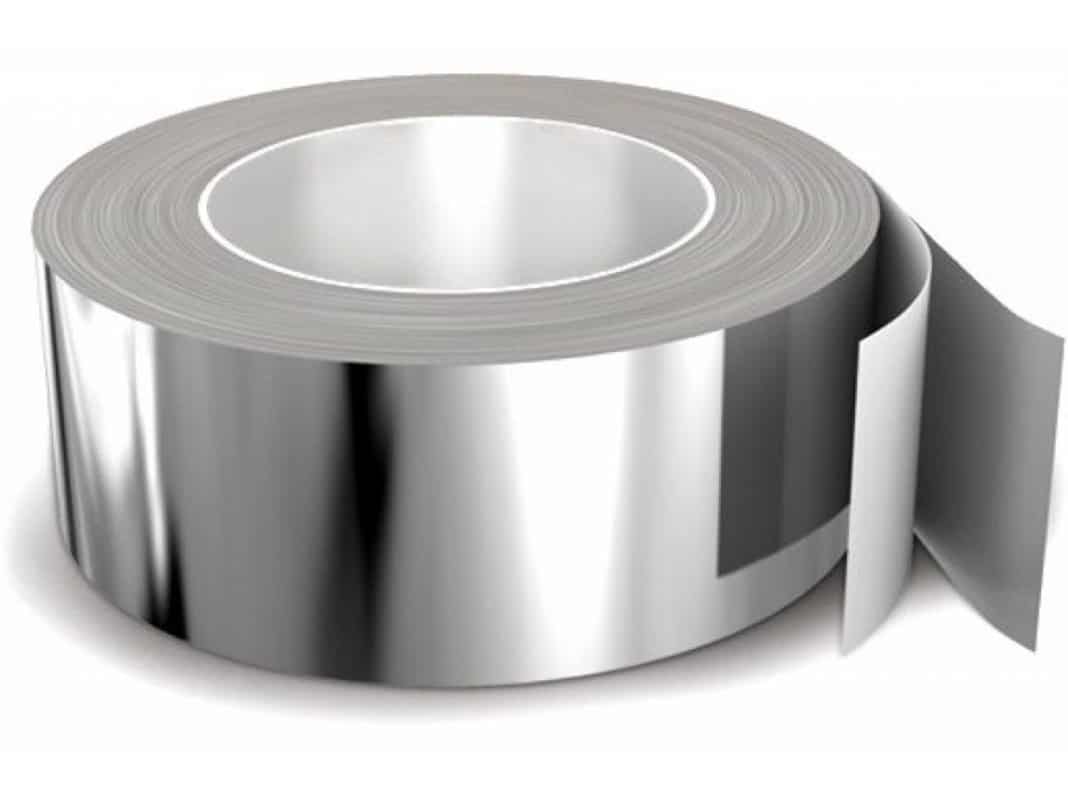

1. Cleaning the surface of the air duct from dirt, mold and rust. 2. Wrapping the air duct with waterproofing material. 3.Winding each element of the air duct with mineral wool, the joints of which are additionally fixed with adhesive tape or special plastic clamps equipped with metal fasteners. 4. Application of an additional layer of aluminum foil to the surface of the mineral wool, which can, if necessary, be replaced with a galvanized casing. 5. Connection by means of plastic or metal fasteners. 6. If necessary, fix the casing with galvanized wire. Using these simple tips for mineral wool insulation will make galvanized steel air ducts much quieter and will provide a longer service life.

Basalt fiber. This material is represented by non-combustible mats, the density of which ranges from 20 to 90 kg / m2. Basalt fiber can be laminated with fiberglass or foil, due to which its service life, if properly used, increases to fifty years.

Glass wool - a material with a high level of thermal conductivity, capable of providing approximately 25 years of flawless operation.

Foamed polyethylene - high-density material, for which the manufacturer provides an eighty-year warranty.

Polyurethane, Expanded polystyrene, supplied in the form of tube sections, the split structure of which, in combination with special grooves, makes its use as simple and convenient as possible.

Liquid insulation. This material is a polymer that resembles a foam that hardens quickly during use and forms a durable insulation layer. Such a material is distinguished by increased adhesion in relation to almost all surfaces, while it does not allow steam to pass through and is completely unaffected by moisture. The only drawback of liquid thermal insulation is its excessive softness, due to which the structure of the material can easily be disturbed by even a slight mechanical effect. That is why, in addition to liquid insulation, additional protection is usually used.

Synthetic foam rubber. This material is supplied in sheet form and is flexible and resilient. It retains its shape well and has served for 25 years. With excellent sound insulation properties, it is not prone to fire and does not rot when in contact with a humid environment.

Aluminium foil. By itself, such a material cannot act as a heater, however, in this direction, its reflective properties are usually used. If foil is used for thermal insulation of air ducts, for example, in addition to foamed rubber, then it can become an ideal thermal insulator capable of retaining air channels, preventing heat loss and condensation.

The use of mineral wool as a heater for air ducts allows for ideal thermal insulation, provided that high-quality protection against moisture is provided, for which it is necessary to equip the outside waterproofing layer made of a material that repels moisture, thanks to which steam from the mineral wool can escape unhindered. This parameter is very important, since regardless of the insulation of the insulation, a small amount of moisture will still get into the heat-insulating layer, which means that it should be possible to ensure its exit to the outside.

Using foam as an insulating layer is only possible if it is supplied in the form of shells that can be put on the duct. However, in cases where the pipes have a very large diameter, this material cannot be used - it is usually replaced with liquid thermal insulation.

There is an opinion that the best insulation for air ducts is the one equipped with a foil layer. In fact, the modern market presents a lot of heat-insulating materials without foil, which in many respects are superior to previously used counterparts. These include, among other things, foamed rubber, which, in fact, is an excellent insulation, the difficulty of using which lies only in the nuances of bonding - for this purpose, construction or aluminum tape is usually used.

Many modern materials used for thermal insulation of air ducts initially have an adhesive surface, due to which the process of their installation is greatly simplified. Such insulation is in great demand, despite the higher cost, since its use can significantly reduce labor costs and completely abandon the use of auxiliary materials such as self-adhesive pins and wire ties. The adhesive composition, which is applied to the surface of such heat-insulating materials, is highly resistant to moisture, and therefore can guarantee that such a coating will serve for a long time.

Not everyone knows that some modern methods do not imply the use of thermal insulation for air ducts at all. For this purpose, special air insulated valves KVU, which are a grate equipped with a heating element and several rotating blades, which allows you to regulate the supply of warm air. The principle of operation of such a valve is that in the process of drawing in the cooled air, it is heated outside, which eliminates the cold-heat boundary.

The modern market for materials for insulating air ducts is represented by a huge selection of special tools that provide high-quality heat and sound insulation. The only subtlety is that it is necessary to calculate thermal insulation as accurately as possible, for which the current standards and SNIPs are used.

How to insulate

To answer this question, it is necessary, as mentioned above, to divide ventilation systems into two categories. The first includes engineering networks in private homes, shops, restaurants and other consumer service points. That is, where the ventilation system itself is a small and not too branched pipe distribution. It works either according to the natural method of air removal, or forcibly with the help of fans. The second category is industrial ventilation networks. They only apply to the forced system.

What is the danger of condensation

The appearance of moisture, regardless of whether it is formed inside the pipe or outside, causes a number of unpleasant consequences that shorten the service life of the air duct, and adversely affect the health of people who are forced to breathe air that enters the room through the ventilation duct.

Pipes where water vapor settles on the walls, if they are made of galvanized metal, gradually destroy the protective layer, and this sooner or later becomes the cause of corrosion, moisture is absorbed into the ceilings, gradually destroying them, stains appear on the ceiling, which spoil the appearance of the room.

Humidity also contributes to freezing of pipes, and, as a result, interferes with permeability.

The appearance of mold and fungal formations pollute the air that circulates in the pipes, the spores of protozoa are easily carried with the air stream, adversely affecting people who are constantly in the room. Headache, allergies - these are just some of the consequences of polluted air that spreads in the room from the air ducts with high humidity.

Note! Insulation of pipes, in addition to helping to avoid these unpleasant consequences, is an excellent means of sound insulation. The sounds coming from the pipes are sometimes much more annoying than the loud music in the next apartment.

Self-adhesive insulation for room air ducts

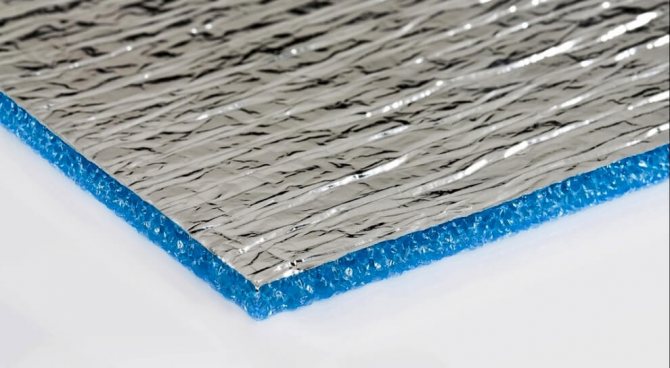

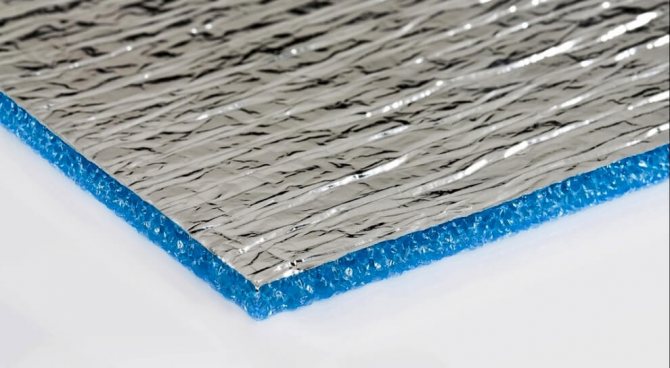

I would like to dwell separately on self-adhesive insulation for ventilation, as a very convenient option for doing work with your own hands. First of all, it is necessary to designate that this is "C" brand penofol. On the one hand, the foamed polyethylene is trimmed with foil, on the other, with a polyethylene film, on which an adhesive composition is applied. The latter is covered with another layer of film, which is removed before installation.

Self-adhesive heat-insulating material is simply cut to the required size, which must correspond to the perimeter of the duct, and then they close the pipe with it, pressing it with hands to its surface. The edges of the insulation are folded up to 5 cm and covered with foil tape.

How to insulate an air duct

Before proceeding with thermal insulation, you need to decide where the pipe needs to be insulated.

The most vulnerable place for the appearance of condensation is the place where the temperature drops, that is, where the pipe passes through the wall of the house, or where it passes through the roof and unheated attic.

- In the first case, the wall opening of the pipe passage is insulated with a heat-insulating material, as well as the pipe itself up to the reflector.

- In the second case, the place of passage through the ceiling is insulated, and the pipe is wrapped with insulation to the point of exit to the roof.

We recommend that you familiarize yourself with: How and at whose expense is the replacement of the sewer riser in an apartment building

Thus, insulation begins from the so-called dew point - the place where condensation falls.

It is important! Determining the dew point is one of the first tasks when insulating a ventilation duct.

It is more difficult to determine the dew point in the supply ventilation system, where the amount of moisture falling into the condensate is determined by the length of the duct and its installation features. Often, such air ducts need not only heat insulation of the pipe, but also heat insulation of the valves, for example, using an electric drive system, which resembles blinds, limiting the air flow and heating valves using tubular heating elements.

The choice of insulation option depends on the length of the pipe, the required amount of insulation and the possible repair costs.

The feasibility of using one or another heat-insulating material depends on the economic feasibility.

The dew point can be determined using a table that takes into account the room temperature and humidity level.

Installation of thermal insulation

Consider several thermal insulation materials in terms of answering the question of how to insulate ventilation pipes in a private house. With penofol everything is clear, we will immediately make a reservation that this is the simplest option.

Mineral wool insulation

Insulation of a ventilation pipe with mineral wool requires the manufacturer to understand that this material is hygroscopic. Therefore, all work is carried out in the following order.

- All piping wrapped in a waterproofing membrane without gaps and gaps. Complete tightness of the coating.

- Mineral wool is wound overlapping with respect to the strips to be laid. The thickness of the paving is determined by the above designated SNiP.

- Wrapped over another layer of waterproofing.

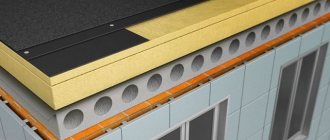

- If the air duct passes outside, then it is installed on top of the thermal insulation threshold boxbetter made of tin.

By the way, the installation of boxes is a prerequisite for assembling an outdoor area, which will provide not only protection of the system, but also effective air exchange inside the building.

If the ventilation pipe is not circular, but rectangular, then you can use mineral wool in mats to insulate it. They are cut to the required dimensions, they are placed over the pipe and pulled together with a clamp, tape or knitting wire. Waterproofing must be installed. Here it is important to tightly lay the pieces of cotton wool so that there are no gaps between them. The most inconvenient place is the outer corners of the ducts. After pulling together the main heat-insulating coating, they are filled with pieces of material cut from the mat to the required dimensions.

How to properly insulate?

Methods for insulating outdoor air ducts

1. If the flexible duct was previously insulated, the old layer of thermal insulation should be removed.

2. The surfaces are cleaned, glue residues and other protective materials are removed.

3. If the insulation is rolled or sheet material, they need to wrap a flexible duct. The number of layers depends on the requirements for thermal insulation. Self-adhesive insulation is the best option.

4. When using polyurethane thermal insulation, a reinforcing frame (metal or synthetic mesh) is required. It is pulled over a flexible air duct, fastened with bolts or clamps made of metal tape.

5. The most time-consuming method of insulation is laying insulation in the form of mats on a flexible air duct. Fastening is done with clamps, tape or knitting wire.

6. At the end of the work, the insulated air duct is closed with a layer of waterproofing and a mechanical protection casing (neoprene, sheet aluminum or galvanized sheet is used). For high-quality waterproofing, you should use durable and reliable materials with the longest possible service life. The protective cover must withstand the effects of wind, precipitation, solar radiation and temperature extremes.

How is the insulation of air ducts inside the premises

Despite the fact that air ducts are very often located indoors, they also need to be insulated. At the same time, the insulation technology practically does not differ from insulation performed on the street, the only difference is that it is not necessary to use a protective layer for it, except for cases when the air ducts are located in rooms where the humidity level is increased or there are any aggressive environment - then you can hardly do without protection. However, most often in apartments and private houses, insulation is used, similar to floor or wall insulation. For this, the air ducts are covered with a special membrane, which is used to provide waterproofing. Next, the insulation is laid, which is covered with another layer of membrane or aluminum foil, the latter option being preferable, since it acts as a kind of vapor barrier.

How to calculate the required thickness of insulation

When calculating the required thickness of the insulation, it is necessary to take into account such indicators of the material used as the coefficient of thermal conductivity and heat transfer of the surface. For example, the heat transfer of mineral wool and felt is 0.045, foam, expanded polystyrene and polyurethane foam sheets - from 0.040 to 0.37, and foamed rubber - 0.03. The lower the level of thermal conductivity, the thinner the insulation layer can be used in the process of finishing the duct.

Warming with expanded polystyrene

Polyfoam or expanded polystyrene is a slab material, so they insulate a rectangular hood. The technology of thermal insulation of ventilation pipes is exactly the same as in the case of mineral wool mats. The only thing that can be noted is the optional installation of waterproofing layers, that is, they can not always be used. It all depends on the density of the material used, which varies between 40-75 kg / m³.

The denser the material, the higher its ability not to absorb moisture.

For example, for PPS-40 it is better to lay waterproofing, for PPS-60 it can no longer be used. And one more point regarding the insulation of ventilation pipes in the attic, as in an unheated room. This is a tight joint of insulation boards with filling of cracks and gaps with polyurethane foam.

Characteristics of thermal insulation materials

The main characteristics of insulation materials include:

Thermal conductivity

The coefficient of thermal conductivity shows how well a material transfers (conducts) thermal energy. The lower the coefficient of thermal conductivity, the thinner the thermal insulation can be installed on the air duct. By the way, thermal conductivity and most of the characteristics of thermal insulation materials are collected in this article.

Temperature

The maximum and minimum temperatures at which the insulation will be in working order. Typically, temperature ranges from -30 to +100 ° C are required.

Vapor permeability

The insulation must be additionally insulated with a thin film (layer) of a material that does not allow moisture to penetrate into the insulation. When moisture penetrates inside the insulating material, its thermal conductivity rises tenfold, which leads to the uselessness of air duct insulation.

Sanitary standards

Each heat-insulating material must comply with sanitary and hygienic rules, according to which it is not permissible to release any toxic substances from the insulation that threaten human health.

Fire resistance

This parameter is already an additional option that a heater can perform: thermal insulation and fire protection. Read more about materials for fire protection of air ducts.

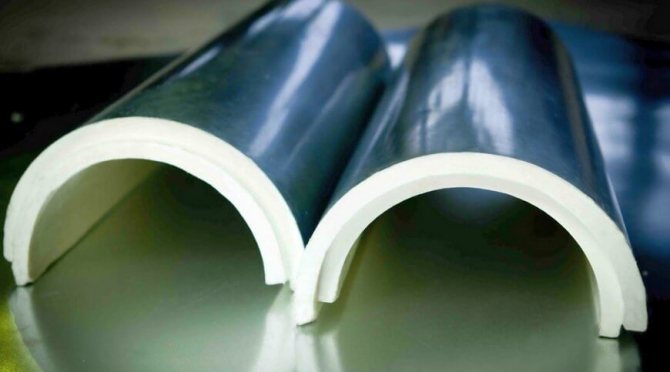

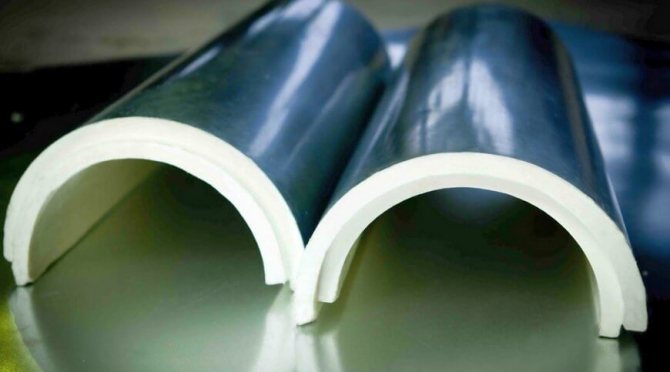

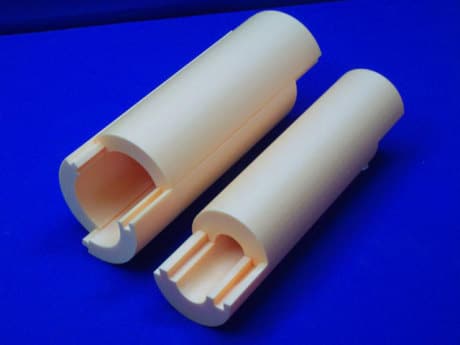

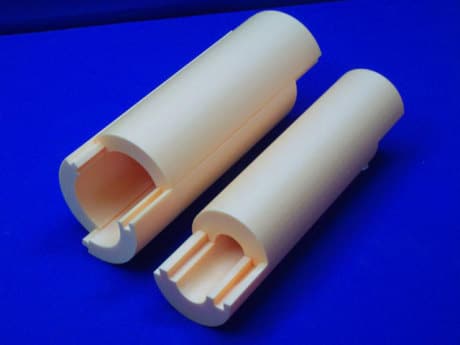

Heat insulating cylinders

Insulation of ventilation pipes can be carried out using special cylinders (shells), which are made of mineral wool, expanded polystyrene, polyurethane foam and polyethylene foam. They are used only for round pipes. They are selected by diameter and are of several varieties:

- One-piece with a longitudinal section;

- Consisting of two parts;

- Three;

- Four.

The type of cylinder is selected taking into account the diameter of the duct. The larger it is, the more parts the shell has. For example, a plastic pipe with a diameter of 110 mm, which is often used in the ventilation system of private houses, is closed with a cylinder in the first position. It is simply opened at the gap and put on the pipe, fastened with tape.

Insulated pipes for ventilation using this technology are a guarantee of their effective protection, plus ease of work. It should be added that the exit of the duct to the street, as well as the street area, can be insulated with cylinders. The only requirement is the installation of a protective box.

As for the price component of the insulating material, it should be noted that the cheapest shells here are made of mineral wool, polyethylene and polystyrene. The most expensive polyurethane foam. Manufacturers now offer this type of foam rubber material. Insulated ventilation pipes for them are the best, but very expensive option.

Ventilation thermal insulation

Insulation of ventilation and ventilation ducts can be carried out from the inside and from the outside. The method of insulation from the inside of the duct is currently of little relevance, since it has a number of disadvantages over the external method.

- the ability to transmit fire through the air duct in case of fire;

- influence on the parameters of the air moved inside the ventilation duct;

- the difficulty of monitoring the deterioration and replacement of thermal insulation materials;

- influence on the aerodynamic characteristics of the ventilation pipe;

- the need to use a larger air duct.

Simply put, the only significant advantage of using this method is the highly efficient noise absorption from the ventilation system.

Nowadays, almost always, they use the method of external insulation, and the insufficient ability to absorb noise is compensated for with the help of mufflers, which are installed near the fans.

findings

So, when choosing insulation for ventilation pipes, it is necessary to take into account the shape and size of the latter. Do not forget about the simplicity of the work carried out, if they are done by hand.

It is better to give preference to penofol than to tinker with polystyrene foam plates, trimming and adjusting them to the size of the air ducts.

Of course, the price of thermal insulation for ventilation will also play an important role. Therefore, it is recommended to choose the best option for the ratio of price and thermal conductivity. Let's go back to the thermal insulation of air ducts with penofol. For example, the thermal conductivity of mineral wool-penofol: 0.045-0.049 W / m K, that is, almost the same. The price of mineral wool-penofol for 1 m²: 1200-100 rubles. So much for the difference.

Insulation thickness

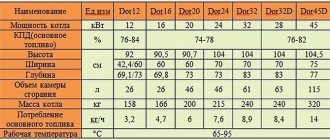

| The minimum thickness of the thermal insulation of the air duct, depending on the thermal conductivity (at an average temperature of 40 ° C) of the material used | |||||||||||

| Thermal conductivity coefficient of heat-insulating material, W / m • ° С | 0,03 | 0,032 | 0,034 | 0,036 | 0,038 | 0,04 | 0,042 | 0,044 | 0,046 | 0,048 | 0,05 |

| Insulation layer thickness, mm | 19 | 21 | 23 | 25 | 28 | 30 | 32 | 35 | 38 | 41 | 44 |

Ventilation insulation materials

Installation of technical communications refers to construction activities that require a thorough approach and the use of quality products, the service life of which is at least 15 years. The reason lies in the practical approach: replacing the "wrapper" of the pipeline or repairing one of the structural fragments is quite difficult, especially if the breakdown happened in the area covered by overlaps. Consider the characteristics of products that have good recommendations and are suitable for self-arrangement of insulated air ducts.

Thermal insulation with foil material

Mineral wool, glass wool, basalt wool

The prototype of mineral wool is glass wool, an inexpensive fireproof product based on fiberglass. It is still actively used for reliable protection of pipelines. Sample product - IsotecMat-Al, flexible roll products made from melted glass. Due to the low coefficient of thermal conductivity and water-repellent properties, thin foil mats maintain the integrity of the air ducts and prevent getting wet.

Minwata Rockwool with metallized coating

Technical characteristics of IsotecMat-Al meet the requirements of GOST:

- composition - fiberglass + metal;

- thickness - 50 mm;

- flammability - G1 (slightly flammable);

- density - 22 kg / m³;

- thermal conductivity coefficient - 0.036 W / (m * K);

- type of use - internal;

- types of work - for ventilation.

Thanks to a special production technology, the fiberglass gets a vertical orientation and allows bending the mats without the formation of creases. Unlike old analogs, modern mineral wool has a minimum thickness that is retained when folded. If you follow the installation technique, you can create a durable, tight-fitting "cover" that prevents condensation and absorbs noise.

Soft rolls are great for protecting rounded and curved surfaces. If you have purchased an inexpensive budget option that is not reinforced with foil, you will have to additionally use waterproofing - the same foil or at least roofing material. To fix the rolled fragments, a reliable bandage made of synthetic or metallized tape is used, in its absence, a simple winding with steel wire.

For equipment of rectangular shapes, mineral wool mats are sometimes used, which have a higher density. They are divided into convenient parts with a construction knife, glued to liquid nails, covered with foil and fixed with tape.

Styrofoam, polyurethane, expanded polystyrene

Three synthetic modifications are not afraid of moisture, have suitable thermal conductivity parameters and have a service life of up to 50 years. The main disadvantage is inconsistency with fire safety requirements, therefore PPU products are not recommended for use in residential buildings (class G3). When ignited, structural parts begin to melt and release compounds harmful to health.

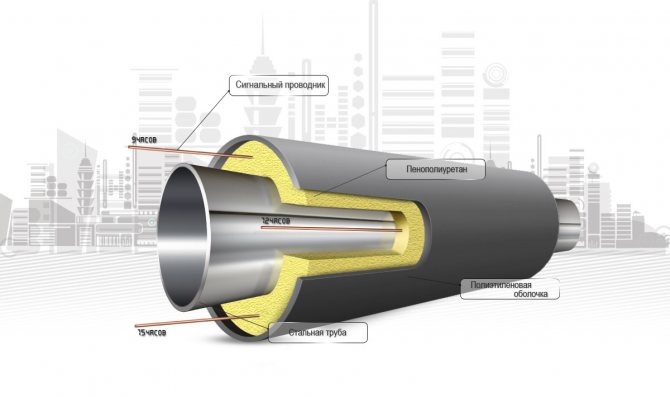

Unlike mineral wool, expanded polystyrene has a rigid structure, therefore it is not realized in the form of slabs (as for walls or floors), but in the form of a shell - 2 or 4-segment tubes, fixed from the outside and forming a solid cocoon. The prefabricated parts are connected according to the “thorn-groove” principle and glued or wrapped with a bandage of tapes. There are reinforced foil types that are more effective.

Styrofoam shell for pipes

Polyfoam is cheaper than expanded polystyrene, has a looser structure, but this property is useful for warming curved structures. Styrofoam is preferred by economical owners who do not see the difference between almost the same materials used in an inaccessible or hidden place (for example, in the attic).

An example of a hard shell is PPU K 1 (design No. 1) of the Far Eastern manufacturer Avangard. Specifications:

- composition - polyurethane foam;

- density - 60 kg / m³;

- flammability - GZ (normally combustible);

- thermal conductivity coefficient - 0.029 W / (m * K);

- water absorption - 2.0%;

- max operating temperature - 130 ºС.

Due to its synthetic composition, PU foam has a high biochemical resistance, that is, even in the presence of dampness, it is not covered with mold or fungus.

Foamed polyethylene

Soft elastic material, inexpensive and suitable for DIY installation, became popular immediately after its introduction on the market. It looks like foam rubber, but it has a more elastic structure and does not allow moisture to pass through. The most famous representative is Penofol, the name of which has already become a household name. A thin layer of foamed polyethylene is covered with foil on one or both sides.

Pipe insulation with Penofol

Despite the external lightness and minimal thickness, Penofol has all the qualities of good insulation:

- perfectly retains heat;

- reduces noise level;

- does not allow moisture to pass through.

Suitable for equipping ventilation structures with complex configurations, adheres well to curved areas and joints.

If you want to improve communications on your own, pay attention to the self-adhesive insulation for ventilation pipes. The manufacturer Penofol also has a category convenient for installation - Penofol C. Roll products made of a thin layer of foamed polyethylene are covered with metal foil on one side, and with an adhesive layer on the other.

Technical characteristics of Penofol C:

- composition - foamed polyethylene;

- thickness - from 3 mm to 10 mm;

- water absorption - 0.35%;

- thermal conductivity coefficient - 0.038-0.051 W / (m * K);

- type of use - internal;

- types of work - for ventilation.

There are several ways to install Penofol. If it is necessary to insulate large straight pipes, they are simply wrapped in roll material without cutting it into fragments. Conversely, short curved sections and joints are insulated with small, easy-to-attach pieces. It is enough to cut off a fragment of the required width, remove the protective film and stick it on the surface. To create a thick layer, Penofol is wrapped several times.

Self-adhesive rolls for pipe insulation

SNIP and GOST for thermal insulation of air ducts

Thermal insulation of outdoor ventilation ducts must be safe for people and the environment, as well as comply with other requirements specified in the documentation.Insulation of ventilation ducts according to SNiP allows you to avoid various problems with the operation of the ventilation system, therefore, it is necessary to monitor compliance with these standards. It is important that the material used can withstand the operational loads and also comply with fire safety requirements. All this contributes to the observance of the norms established for living quarters and ensuring optimal living conditions.

Thermal insulation

Insulation of ventilation with mineral wool shell

Proper insulation includes several basic requirements:

- All insulating materials must fit snugly against the pipes. The best option is to insulate ventilation ducts in the form of shells for pipes that correspond to the diameter. Each layer must be securely and tightly fixed so that there is no sagging in any place.

- Inside the house, it is necessary to insulate the supply ventilation duct, which is also called negative temperature and fan pipes. A vapor barrier layer is also required. Fastening is done on clamps, wire, aluminum tape, special glue.

- Pipes in the attic and in the basement are sure to be insulated.

- For outdoor insulation, a layer of thermal insulation with UV protection is required.

Hood insulation is made from the same materials as ventilation insulation. Due to the low temperature, there is practically no risk of fire, therefore there are no special requirements for combustibility.