The American one first presented the material in 1957.Since then, the technology of its manufacture has remained practically unchanged. The versatility of expanded polystyrene foam allows it to be used in a wide variety of areas.

Currently, both the most famous brands and private entrepreneurs are engaged in the production of this type of thermal insulation. The technological capabilities of these manufacturers are very different, as well as the quality of the finished product.

What is Extruded Polystyrene Foam

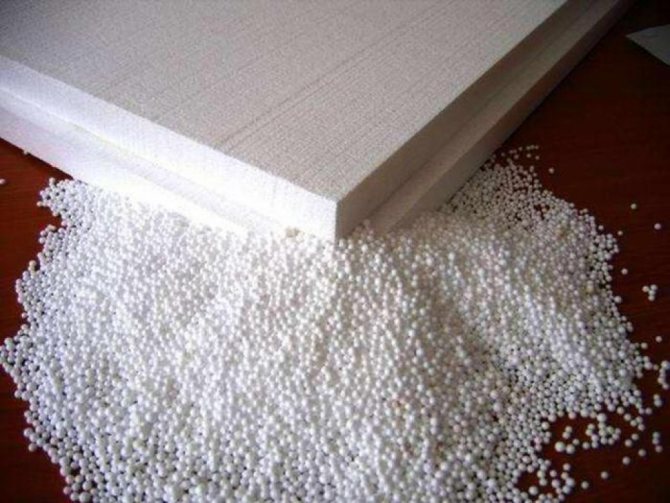

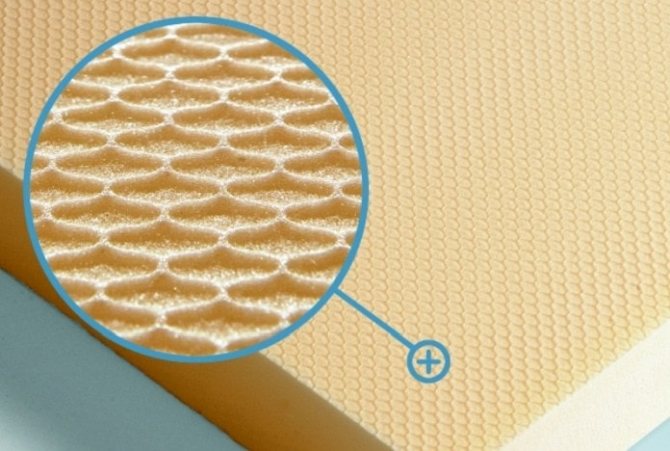

Extruded polystyrene foam is a universal high-quality heat-insulating insulation made of granular polystyrene using a special technology. At the first stage of production, the granules are mixed with special ingredients that enhance mechanical strength and fire safety. After that, the resulting mixture is melted until a homogeneous mass is obtained, and a foaming agent (most often carbon dioxide) is added.

At the next stage, the raw material is pressed under high pressure through the rectangular slot of the extruder. After the end of the calibration, the foaming agent expands, thereby providing the required porosity of the material. The leveled strip is cut, packed and sent to the warehouse.

Thus, extruded polystyrene foam is a mixture of polystyrene granules with special additives that has undergone extrusion processing.

Application of Penoplex Comfort

The use of this type of insulation is possible in almost any climatic zone. It can be used not only for thermal insulation of floors, but also for insulation of swimming pools, saunas, baths and other rooms with high levels of humidity. Installation work on laying sheet material is not difficult, it has clear geometric shapes, for the convenience of joining the edges are made in the form of the letter G. Penoplex "Comfort" is successfully used for insulation:

- balconies and floors;

- basement floor;

- building roofs;

- wall structures;

- foundations of the foundation.

Variants of application of "Comfort" foam for roof insulation

In thickness, this type of expanded polystyrene can reach 15 centimeters, this determines the mechanical strength of the coating and significantly increases the operational life of the building structure. In direct contact with moisture or soil, Penoplex "Comfort", due to its anti-fungal properties, does not undergo rotting and decomposition processes.

Floor insulation on logs

Warming the floor on the logs begins with inspecting and replacing damaged areas and treating the boards with a special compound that prevents them from decay. Then all cavities are leveled with putty, the surface is dried and covered with primer. Insulation sheets pre-cut to the required dimensions are laid on dry boards with a minimum gap. The joints are glued with tape.

From above, with overlap, sheets of material are laid, intended for arranging a vapor barrier layer. Chipboards, plywood or other similar material are attached to the maximally leveled surface, parquet, laminate or linoleum are laid on top.It turns out several layers:

- beam floors;

- wooden lumber;

- foam sheets;

- vapor barrier layer;

- shield covering;

- material used as a floor.

Floor insulation with laying on the ground

Penoplex "Comfort" is laid on the ground to insulate the floor in building structures, which is supported by a strip or pile-type foundation. A layer of crushed stone or gravel is poured onto the leveled soil, on top of it is sifted sand, which is compacted tightly.

Insulation sheets are laid on the resulting surface with minimal gaps, the joints of which are carried out using spikes and grooves cut out in them. A film is placed on top of the insulation to form a waterproofing layer, a reinforcing mesh is laid, and the surface is covered with cement mortar. After it dries, the floor covering is laid. The following layers are obtained:

- soil surface;

- crushed stone backfill;

- sand pillow;

- insulation;

- film waterproofing;

- mesh reinforcement;

- a layer of cement mortar;

- material used as a floor.

Insulation of walls from the inside

Insulation of walls from the inside begins with their thorough cleaning and applying a layer of soil to their surface. Insulation sheets are reinforced with glue and plastic fasteners. The joints are filled with construction foam. If their width exceeds 100 mm, it is necessary to insert scraps of insulation boards into the cavity.

Insulation of walls, floor and ceiling of the loggia with penoplex

On the formed surface, a reinforcing mesh is strengthened, on top of which a layer of assembly plaster is applied. After it dries, finishing plaster is applied to the surface and the final wall covering with wallpaper or painting is performed. Thus, the following layers are formed:

- primed surface;

- adhesive layer;

- insulation sheets;

- fiberglass mesh;

- plaster layer;

- putty;

- finishing material of the walls.

Technical characteristics of extruded polystyrene foam

The performance and mechanical characteristics of this thermal insulation material require special consideration.

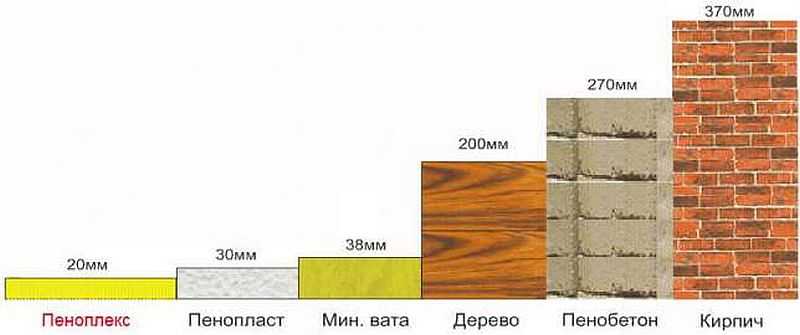

Thermal conductivity

, regardless of the brand, lies in the range from 0.03 to 0.04 W / (m · 0K). Such indicators allow the use of expanded polystyrene foam when insulating any building elements, as well as highways, runways, etc.

Density of slabs

, depending on the modification of the material, it can be from 20 to 50 kg / m3;

Moisture resistance

... Due to its closed porous structure and chemical composition, the material does not deteriorate under the influence of dampness, condensation and even direct ingress of water. The only weak point is the end surfaces, the waterproofing of which should be given special attention.

Health safety

allows you to use extruded polystyrene foam even in hospitals and children's institutions. The boards do not emit harmful vapors even at high temperatures. In addition, the heat-insulating layer is usually covered with a layer of finishing materials (plaster, putty, drywall, etc.).

High strength parameters

... The permissible stress, depending on the modification, ranges from 18 to 20 t / m2.

Other characteristics of extruded polystyrene foam include:

- Frost resistance.

The material retains its insulating properties even at -700C; - Low vapor permeability

, from 0.007 to 0.008 mg / (m · h · Pa); - Antiseptic properties

the material practically excludes the occurrence of fungal colonies; - Long service life

... Regardless of the operating conditions, expanded polystyrene foam is guaranteed to last at least 45 years.

Such indicators will undoubtedly arouse increased consumer interest.In addition, it is also important that the installation is quite possible to do it yourself, and the cost of the material is relatively low.

Fire resistance of expanded polystyrene

Expanded polystyrene has a very high fire resistance. The temperature at which spontaneous combustion of polystyrene foam boards occurs is +4910 degrees. This is 2.1 times higher than the ignition temperature of paper (it is calculated at +2300 degrees), and 1.8 times higher than that of wood (which spontaneously ignites at +2600 degrees). Regardless of the fact that polystyrene foam boards, like most other building materials, are still susceptible to combustion, however, they themselves do not support combustion, and if there is no direct contact with the flame, then the polystyrene foam extinguishes within 4 seconds. In other words, we can say that the combustion of expanded polystyrene plates can only be in the presence of an open flame, and after removing the foam from the fire, the combustion process immediately stops.

In addition, to date, polystyrene foam boards are produced, which are enriched with fire retardants, they are also called "self-extinguishing" boards.

Summing up, we can say that polystyrene foam, thanks to all of the above properties, is deservedly considered today one of the most demanded and popular materials, and although you can always choose analogues, you should always carefully compare all the advantages and disadvantages.

Scope of application of extruded polystyrene foam

Let's consider in more detail the possible areas of use of expanded polystyrene plates. Operational and mechanical characteristics make it possible to actively use expanded polystyrene for:

- Thermal insulation of private households and CBC facilities;

- Frost protection for road cushions, main pipelines, runways;

- Thermal insulation of foundations, retaining structures and roofs;

- Manufacture of household and industrial refrigeration units, refrigerators;

- Devices of various types of hydro-barriers;

- Production of packaging and disposable tableware;

- Making household items.

Despite the fact that the scope of use of extruded panels is quite extensive, there are some limitations.

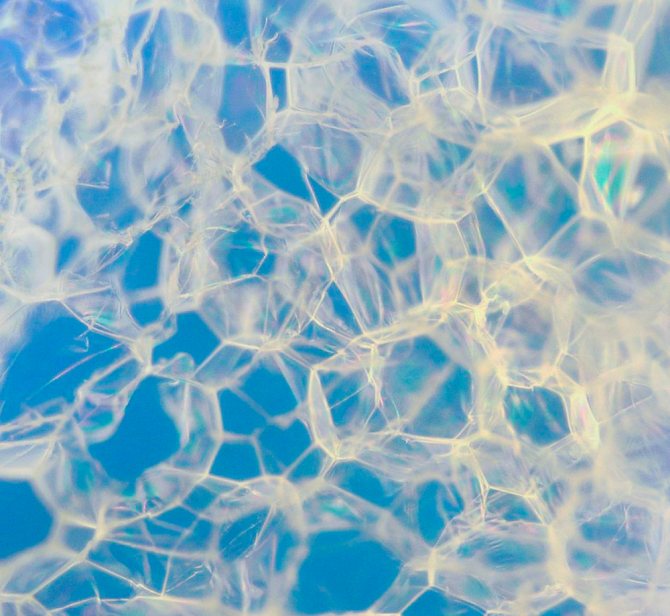

Acoustic properties of expanded polystyrene

The effect of sound insulation and noise absorption is determined by the ability of materials to convert sound energy into thermal energy. In this regard, the highest sound insulation qualities are possessed, first of all, by porous materials, which have low thermal conductivity and are able to pass air. Therefore, it is the cellular structure of polystyrene boards that ensured their maximum soundproofing and noise-absorbing characteristics.

So, for example, to ensure optimal sound insulation, it will be enough to use a polystyrene foam plate, the thickness of which is only 2-3 centimeters. Accordingly, the greater the thickness of the polystyrene foam layer, the better and more significant the sound-absorbing and sound-insulating properties will be.

What surfaces can not be insulated with polystyrene foam

First of all, you should not use extrusion plates for thermal insulation of surfaces, the temperature of which does not correspond to the modes declared by the manufacturers, from -50 to + 750C.

In addition, the extremely low vapor permeability of the material does not allow its use in saunas, swimming pools and other rooms with high humidity. In this case, the use of expanded polystyrene as a heat insulator will require additional measures to ensure ventilation, which will negatively affect the labor intensity and cost of work. Ignoring these measures can lead to the appearance of mold or mildew between the insulation and the enclosing structure.

GOST 32310-2012

Foreword

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions "n GOST 1.2-2009" Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for Development, Acceptance, Application, Update and Cancellation "

Information about the standard

1 PREPARED by the non-profit organization "Association for the Manufacturers of Extruded Polystyrene Foam" RAPEX "on the basis of an authentic translation into Russian of the European regional standard specified in clause 4

2 INTRODUCED by the Technical Committee for Standardization GK 465 "Construction"

3 ACCEPTED by the Interstate Scientific and Technical Commission for Standardization, Technical Regulation and Conformity Assessment in Construction (ISTC) (Minutes Xa 40 of June 4, 2012)

Voted for the adoption of the standard:

| Short name of the country according to MK (ISO 3166) 004-97 | Country code according to MK (IS03166) 004-97 | (.'Colored name of the national government building authority |

| Azerbaijan | AZ | State Committee for Urban Planning and Architecture |

| Armenia | AM | Ministry of Urban Development |

| Kyrgyzstan | KCi | 1 osstroy |

| Moldova | MD | Ministry of Construction and Regional Development |

| Russian Federation | RU | .Ministry of Regional Development |

| Tajikistan | and | Agency for Construction and Architecture under the Government |

| Uzbekistan | UZ | 1 osarchitsktstroy |

| Ukraine | UA | Ministry of Regional Development, Construction and Housing and Communal Services |

4 This standard is modified from the European regional standard EN 13164: 2008 Thermal insulation products for building - Factory made products of extruded polystyrene foam (XPS) -Specification Specifications) by making changes, details of which are set out in the introduction to this standard.

The name of this standard has been changed in relation to the name of the European regional standard to bring it in line with GOST 1.5-2001 (subsection 3.6).

Translation from English (cn).

When applying this standard, it is recommended to use, instead of the referenced European regional standards, the corresponding interstate standards, the details of which are given in the additional annex YES.

Compliance Degree - Modified (MOD)

5 By order of the Federal Agency for Technical Regulation and Metrology or December 17, 2013 Хг 2306-st the interstate standard GOST 32310-2012 (EN 13164: 2008) was put into effect as a national standard of the Russian Federation from July 1, 2014.

6 INTRODUCED FOR THE FIRST TIME

Information on the entry into force (revocation / of this standard and changes thereto is published in the index "National standards".

Information about changes to this standard is published in the index (catalog) "National standards". and the text of the changes can be found in the information signs “Nazis are Opals! standards ". In the event of a revision of the cancellation of this standard, the relevant information will be published in the information index "National Standards"

© Standartinform. 2014

In the Russian Federation, this ns standard may be fully or partially reproduced, replicated and distributed as an official publication of the beta permission of the Federal Agency for Technical Regulation and Metrology.

Where Penoplex 45 is justified

First of all, the use of this material is justified for the thermal insulation of bases that are regularly subjected to dynamic loads. Here penoplex slabs are assigned the role of stabilizers and vibration dampers, which are capable of withstanding up to 50 tons of excess weight per 1 sq. M. and distribute gravity evenly.

Penoplex type 45 also serves as an auxiliary supporting structure - for example, in the construction of agricultural hangars and private low-rise buildings.

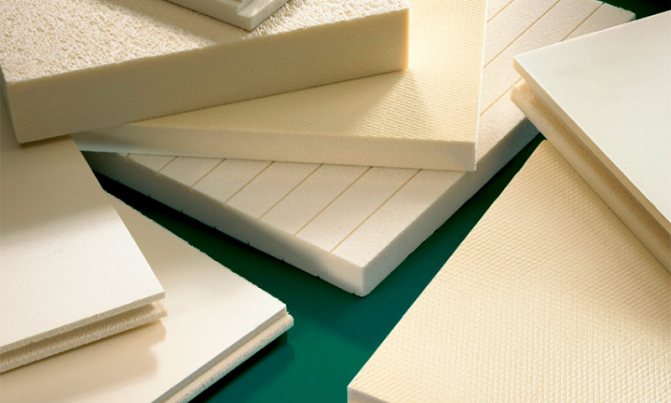

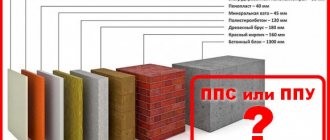

Different types of Penoplex have their own characteristics, they can be divided into several main groups.

The main properties of the material include a fairly low coefficient of thermal conductivity. Another important advantage of this material is sound insulation.

Penoplex allows you to create noise absorption in the room, this is especially important in the use of private housing construction. The service life is also important, the sheets of Penoplex will effectively serve for more than a dozen years, and the waterproofing properties of the penoplex are manifested in low moisture absorption

The safety characteristics of penoplex are expressed in environmental friendliness and moderate fire resistance (Fire resistance category: G3 or G4).

The durability of Penoplex is due to the low compression rates of the material. Penoplex also will not decompose under the action of some solvents and soil salts.

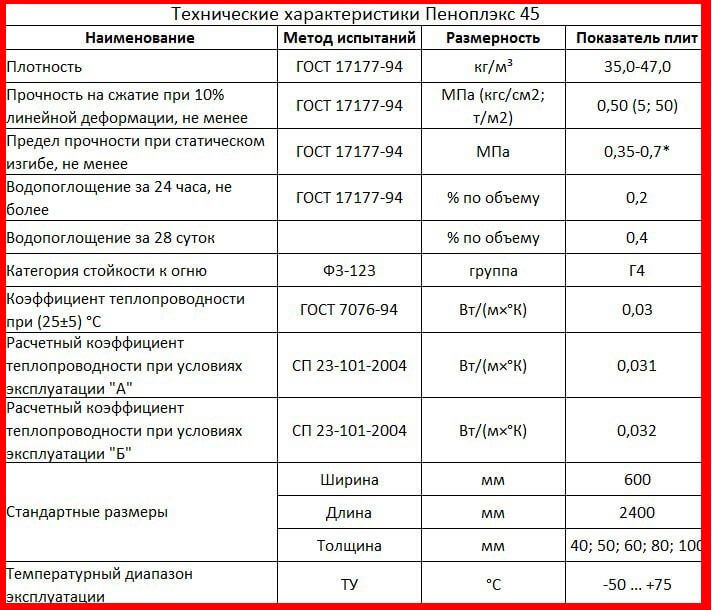

All the main characteristics of Penoplex are shown in the table:

Thermal insulation of external and internal enclosing structures

Not for use in stressed structures!

Select sheet thickness:

| 20 mm | 30 mm | 40 mm | 50 mm | 60 mm | 80 mm | 100 mm | 120 mm |

Description

PENOPLEX OSNOVA is a high-performance thermal insulation material of the latest generation, produced by extrusion from general-purpose polystyrene. Zero water absorption, high strength, low thermal conductivity and environmental friendliness are the main advantages of PENOPLEX insulation in comparison with other materials.

Application of PENOPLEX BASIS

Designed for use in industrial and civil construction, it is a universal material for use in any structures (walls, roofs) where there are no special requirements for structural loads.

Characteristics of PENOPLEX BASIS

- consistently low thermal conductivity;

- zero water absorption (homogeneous structure of sealed cells);

- high compressive and flexural strength;

- absolute biostability;

- durability;

- environmental friendliness.

Technical data

Name

Test Method

Dimension

Index of slabs

Compressive strength at 10% linear deformation, MPa (kgf / cm2; t / m2) 50 mm

GOST EN 826-2011

Water absorption in 24 hours, no more

Water absorption in 28 days, no more

Fire resistance category

Calculated coefficient of thermal conductivity under operating conditions "B"

Partition sound insulation (GKL-PENOPLEKS 50 mm-GKL), Rw

Structure-borne sound insulation improvement index in floor construction

Advantages of Styrofoam

In a number of situations foam has no alternativesdue to its unique properties.

- Little weight... The technology for the production of expanded polystyrene provides for the subsequent cooling of polystyrene, which accounts for only 2% in the structure of the finished product, and the rest is occupied by air bubbles. This feature makes the polystyrene boards so light: their weight is so small that a child can hold them in their hands. It is a well-known fact that the weight of the foam is more than comparable to that of water. For this reason, if thrown into water, it will not drown. This feature ensured its distribution as buoys, giving a clue about the places where the depth reaches its maximum marks.

- Of the other advantages of expanded polystyrene, it should be noted no processing problems and installation. But at the same time, it is necessary to get an idea of the technology for gluing the plates to a certain surface and exactly follow the requirements of the instructions.

- A significant advantage of polystyrene is its high resistance to external factors. This material is neutral to the effects of sunlight, sharp temperature fluctuations, frost resistance, and also resistant to high atmospheric pressure. It was these qualities that ensured its distribution as a building material used in the construction of residential buildings and finishing work.

- Also, mention should be made of such a parameter as heat capacity. It is no coincidence that the opinion is widespread that it is expanded polystyrene that is able to provide the best level of thermal protection. Also, this material has a low coefficient of thermal expansion: foam plates remain stable at operating temperatures ranging from - 180 to + 80 degrees. When working with large-format blocks, they are most often laid on the walls of buildings, which significantly increases the heat-saving characteristics of the house.

- Ability effectively resist outside noise impact character and create structures of complex configuration, which is practically realized through the use of solutions based on cement, gypsum and mastic.

- Foam boards are safe to use in construction in terms of fire safety. Therefore, for buildings where such a threat is especially high, this material seems to be the best choice. Although it cannot extinguish fire, it will still prevent it from spreading and even be able to reduce it.

- Plates of this material have a significant service life.

- In addition, they demonstrate neutrality to many chemicals. This material is absolutely environmentally friendly, does not generate dust and does not have an unpleasant odor. The material is absolutely safe for health, since the main components used for its production are gases and substances that do not harm the environment and humans. The plates do not contain freon compounds that can have a destructive effect on the ozone shell.

Disadvantages of Styrofoam

For all its advantages, polystyrene cannot be considered an ideal material due to the presence of and certain cons:

- First of all, mention should be made of its mechanical strength, which has a certain margin. For this reason, after laying the slabs, it becomes necessary to create additional protection against mechanical damage.

- Plates of this material do not have the ability to "breathe", which negatively affects air exchange.

- Various paints and varnishes or nitro paints have a negative effect on this material. For this reason, before laying the foam, you should select a suitable composition for gluing it.